Next mold dilema.

Collapse

X

-

-

Comment

-

Comment

-

Comment

-

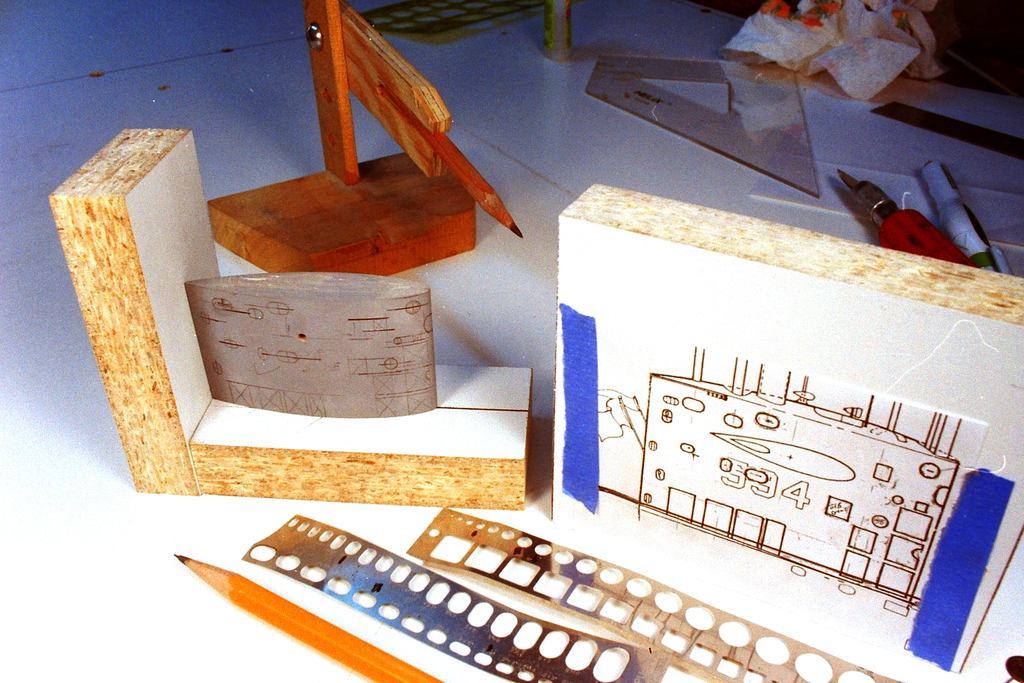

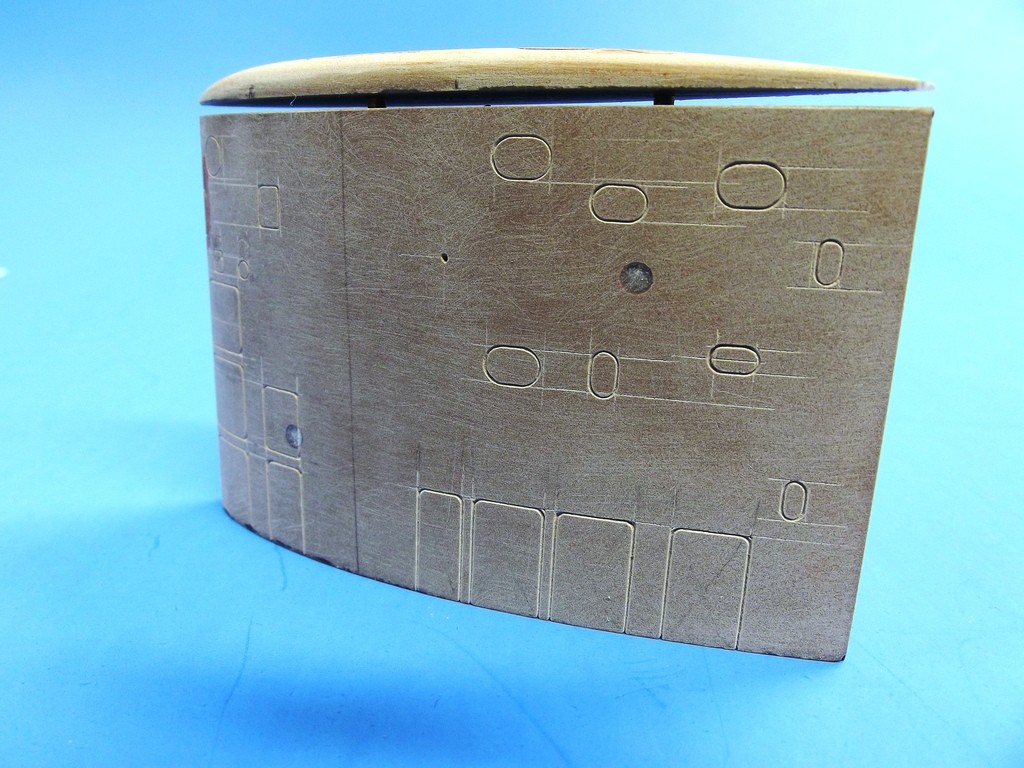

Getting down to the wire. Sail is primered and ready for my least favorite thing scribe work. Just have to start laying coats of epoxy,sand and primer and that's ready for scribe. Used 3 layers of 4oz boating cloth on hull and sail. Hull is heavy from using 21/2lb styrofoam.1 PhotoComment

-

A thought, Tim: give that sail master two thin coats of gel-coat (I make mine from either micro-balloons or colloidal silica fiber), and sand smooth. That type substrate makes the scribing chore much easier. And while you're at it, dope that gel-coat with gray pigment -- makes the work very easy to see as you go along. I hate scribing into glass fibers! Hard work, and dulls the scratch-awl/scribing tool quickly.Getting down to the wire. Sail is primered and ready for my least favorite thing scribe work. Just have to start laying coats of epoxy,sand and primer and that's ready for scribe. Used 3 layers of 4oz boating cloth on hull and sail. Hull is heavy from using 21/2lb styrofoam.

DavidLast edited by He Who Shall Not Be Named; 12-04-2019, 10:53 AM.Who is John Galt?Comment

-

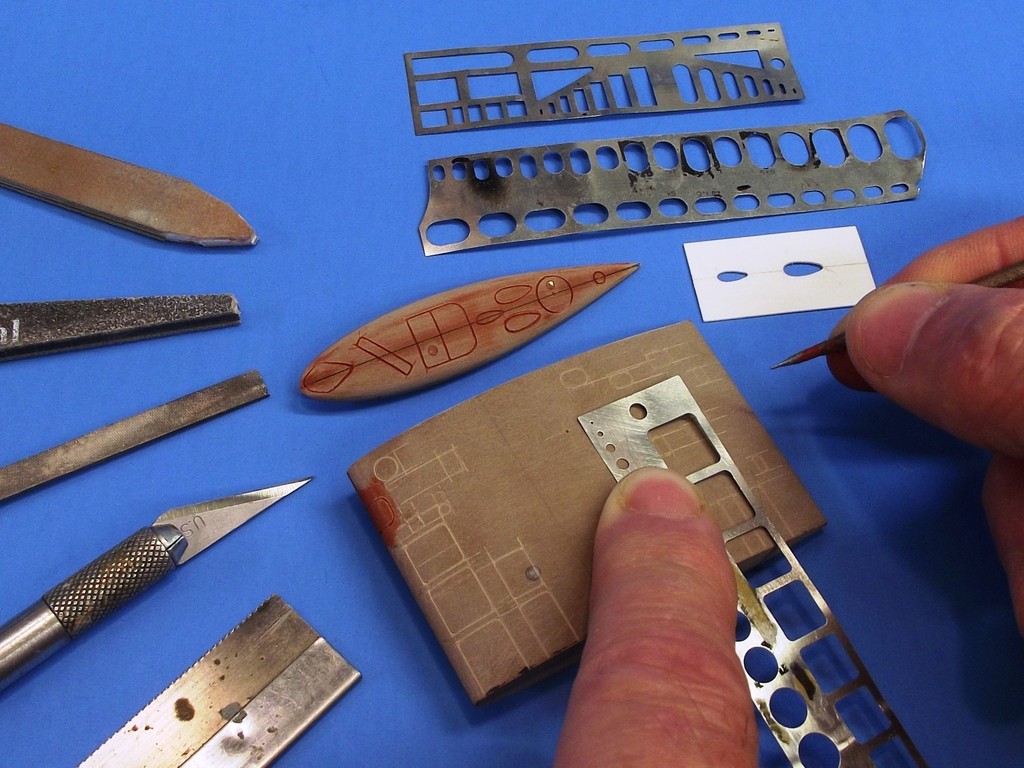

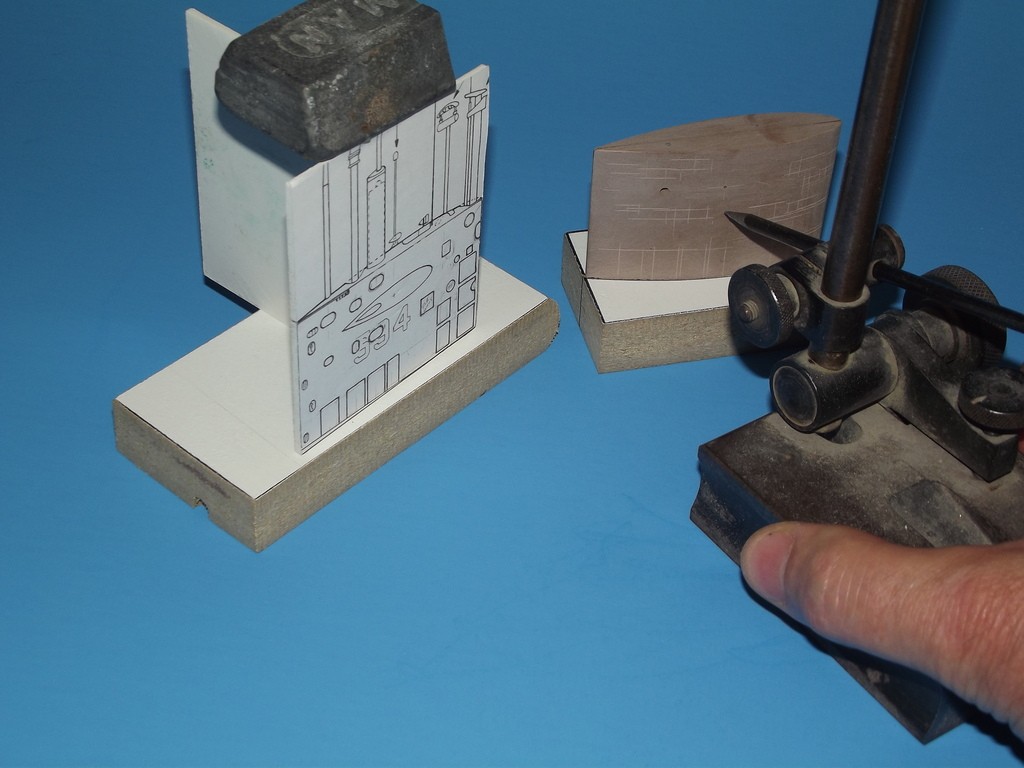

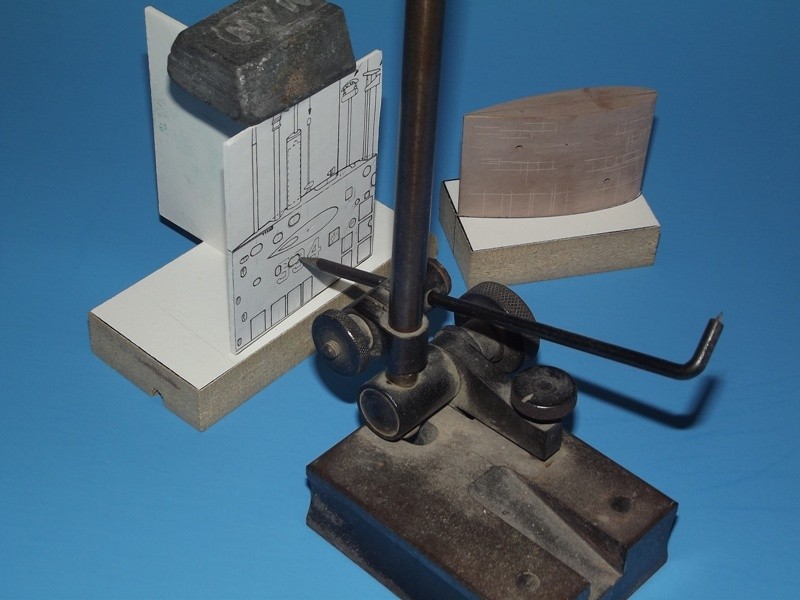

The way I made a surface coat when I was laying up hulls I mixed up epoxy resin and fiberglass powder. Mixed it until it was like syrup. Brushed a coat of that in the molds to pick up all the detail. Then I started laying down 4oz cloth. I will do that on the final coat of resin on the hull. I use needle/jewelers files ground to shape and thickness I need. I use a carbide chop wheel for a dremel and shape them. Those files will stay sharp for a lot of scribe work. Then I use a small wet stone to sharpen them.1 PhotoComment

-

Just to be clear, Tim. I was describing a SURFACE coat to the master, to produce a substrate to make your scribing job easier. But, we all have our favorite modes of operation.The way I made a surface coat when I was laying up hulls I mixed up epoxy resin and fiberglass powder. Mixed it until it was like syrup. Brushed a coat of that in the molds to pick up all the detail. Then I started laying down 4oz cloth. I will do that on the final coat of resin on the hull. I use needle/jewelers files ground to shape and thickness I need. I use a carbide chop wheel for a dremel and shape them. Those files will stay sharp for a lot of scribe work. Then I use a small wet stone to sharpen them.

DavidWho is John Galt?Comment

-

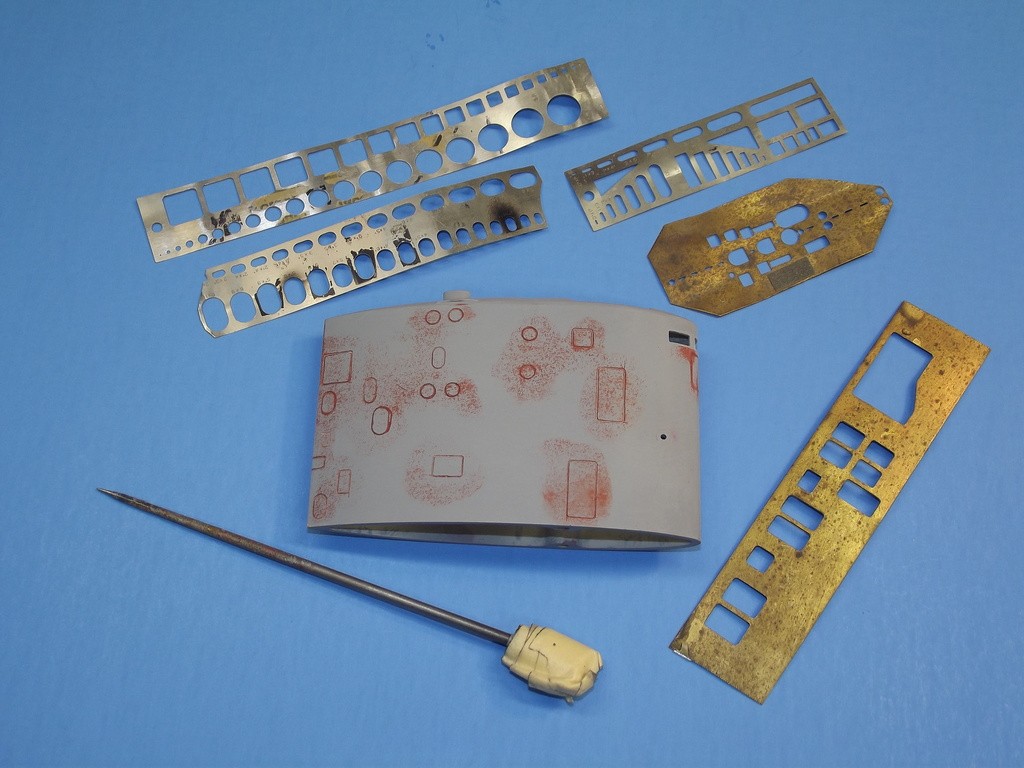

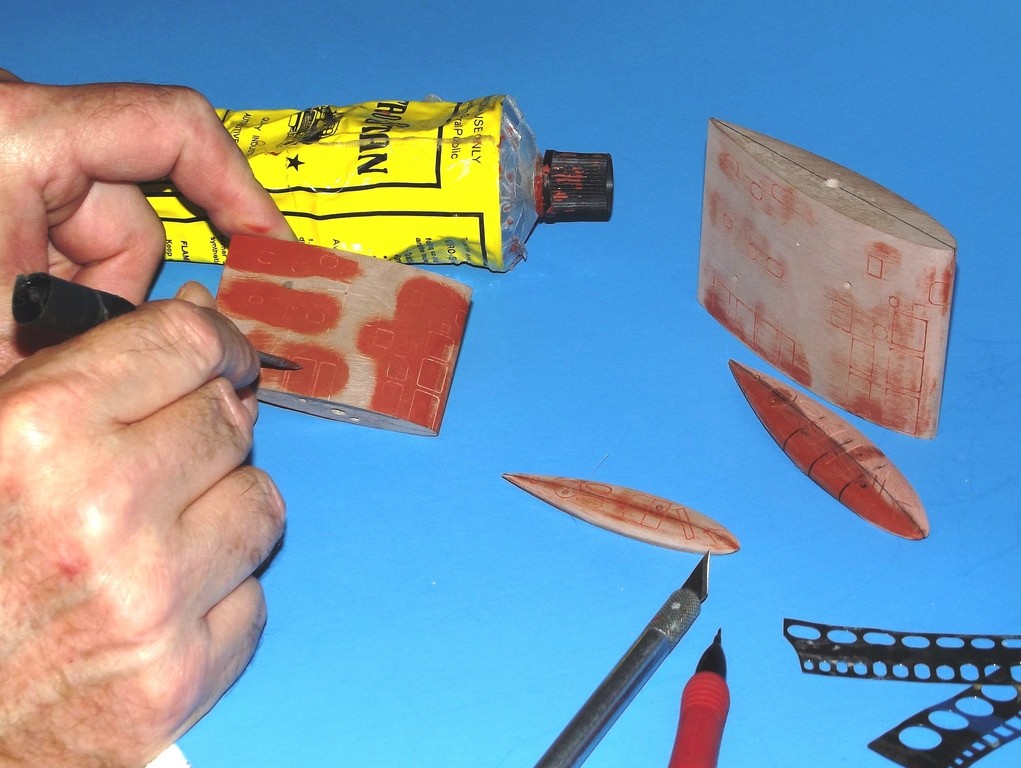

I am going to use the epoxy resin/fiberglass powder mix and put a coat of that on the hull plug as final coat so I can scribe easier. Want to know if you have any PE mesh for the vents on the Yankee sail. If you have the Yankee plans I sent you you can see what size rectangle mesh. Looks like 1mm x 2mm. I have dug through all my stuff and looked on the net but can't find. Would be better to glue PE mesh to sail instead of trying to scribe.1 PhotoComment

-

No, Sorry. I don't have anything like that. How about this source: Gold Metal ModelsI am going to use the epoxy resin/fiberglass powder mix and put a coat of that on the hull plug as final coat so I can scribe easier. Want to know if you have any PE mesh for the vents on the Yankee sail. If you have the Yankee plans I sent you you can see what size rectangle mesh. Looks like 1mm x 2mm. I have dug through all my stuff and looked on the net but can't find. Would be better to glue PE mesh to sail instead of trying to scribe.

DavidWho is John Galt?Comment

Comment