Next mold dilema.

Collapse

X

-

-

I'll be counterpoint and say 688. How are you going to get a Yankee to turn? I have tried a clear rudder extension and an all flying lower rudder on the Delta. Next summer it will have both to see if it will turn in something smaller than the Carmel pond. At least make the rudders larger than scale.Comment

-

Comment

-

Those two widely spaced screws gives us the opportunity to mix rudder with two ESC's to use differential propeller thrust to assist in yawing the boat.I'll be counterpoint and say 688. How are you going to get a Yankee to turn? I have tried a clear rudder extension and an all flying lower rudder on the Delta. Next summer it will have both to see if it will turn in something smaller than the Carmel pond. At least make the rudders larger than scale.

DavidWho is John Galt?Comment

-

Plans show nice size dual rudders. Don't see much of a problem. Like Dave said I have a dual motor speed controller where depending on how it is set up during a turn one screw will rotate backwards for a tighter turn. I will get some pics today of the hull and sail plugs and the plans.Comment

-

Looking good, Tim. I'll have drawings in hand this afternoon. Might even start in on the master blanks tonight. PLAY TIME! Hey, it's how I spend my holiday!

I found only one good shot of the YANKEE stern in dry-dock. You got any pictures that will help me out with the stabilizers, control surfaces, and propellers, Tim?

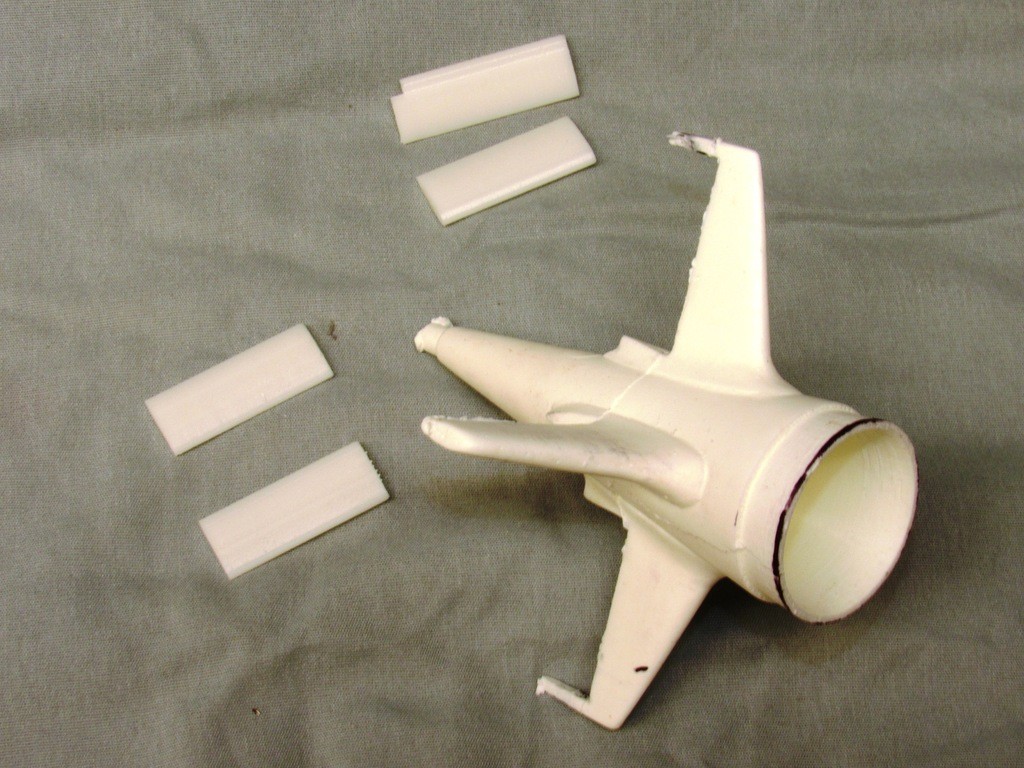

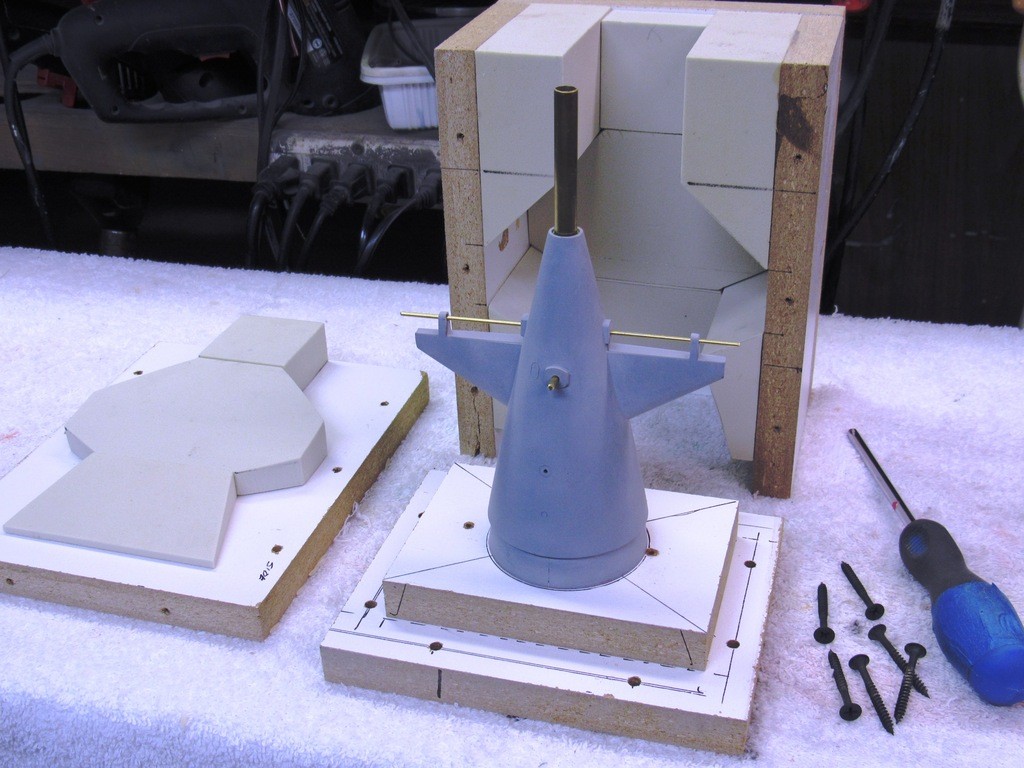

Here's an idea: you slice off the ass-end of your foam master and send it to me so I can consolidate the vertical and horizontal stabilizer masters to that cone. That way I produce a master and tool that represents the ass-end of the YANKEE as a homogeneous unit -- the eventual casting is hollow and has the stabilizers attached. Like so:

If we present the stern in such a manner to the customer, it will be much easier for him to integrate it with the hull as he assembles his YANKEE kit. We become rich and world famous!

David

Adjusting Medications CarelesslyWho is John Galt?Comment

-

My Delta II uses two esc's and a futaba f-14 with navy twin stick so i can use the screws to assist turning.the turn radius is quite large indeed. Plus i found the forward sail-mounted diveplanes to be very effective.I'll be counterpoint and say 688. How are you going to get a Yankee to turn? I have tried a clear rudder extension and an all flying lower rudder on the Delta. Next summer it will have both to see if it will turn in something smaller than the Carmel pond. At least make the rudders larger than scale.

Regards JörgComment

Comment