Inserts in place, motor attached.

Servo link bushing glued in place shaft seal fitted.

Servo rack attached to endcap (3 servo's)

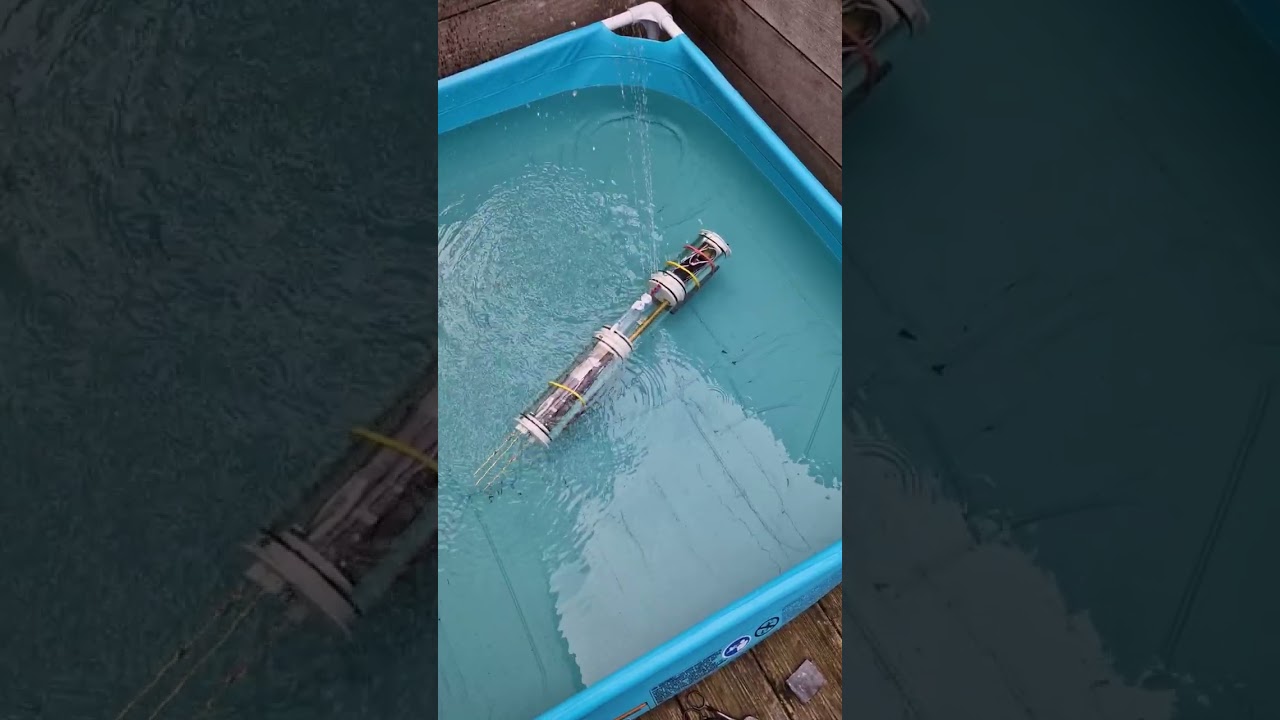

test fitting ballast tank and aft compartment

ESC for propulsion and pump will also live in the aft compartment, space is available.

Ballast tank layout.

Grtz,

Bart

Servo link bushing glued in place shaft seal fitted.

Servo rack attached to endcap (3 servo's)

test fitting ballast tank and aft compartment

ESC for propulsion and pump will also live in the aft compartment, space is available.

Ballast tank layout.

Grtz,

Bart

Comment