David I have a couple of questions for you regarding my tooling for the upcoming project 667. I am on the cusp of producing some silicon moulds for the 667. The rear appendages and some of the reactor coolant scoops. However I will soon also be creating the moulds for the stern horizontal planes. As you know the 667's stern planes featured fences, (plates at either end of the movable surface.) I am concerned about how to best arrange them on my moulding board arrangement and designing the mould to eliminate the possibility of trapped air bubbles in the outer edges of these really thin sections. I have never moulded parts with such thin plate sections before and I am concerned that because of their thin-ness they may be susceptible to bubbles if the air venting is not well designed and I think this could be greatly helped by their orientation.

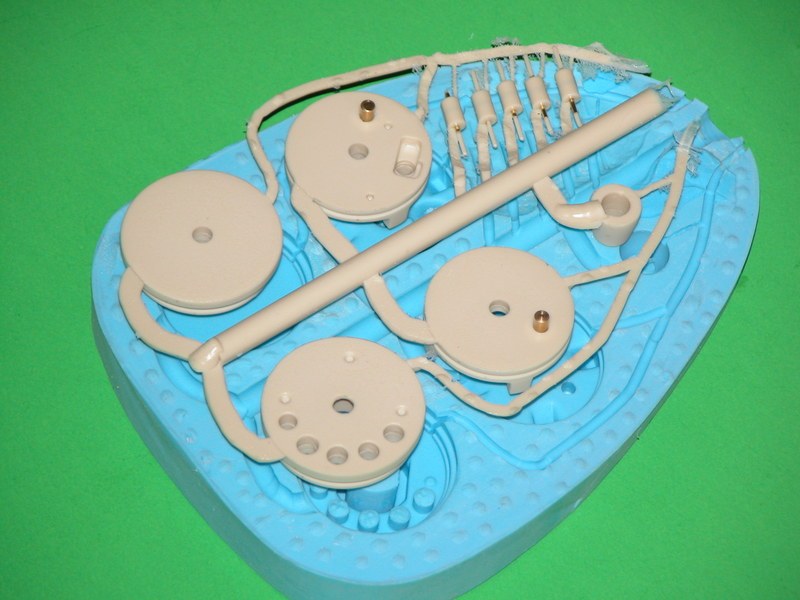

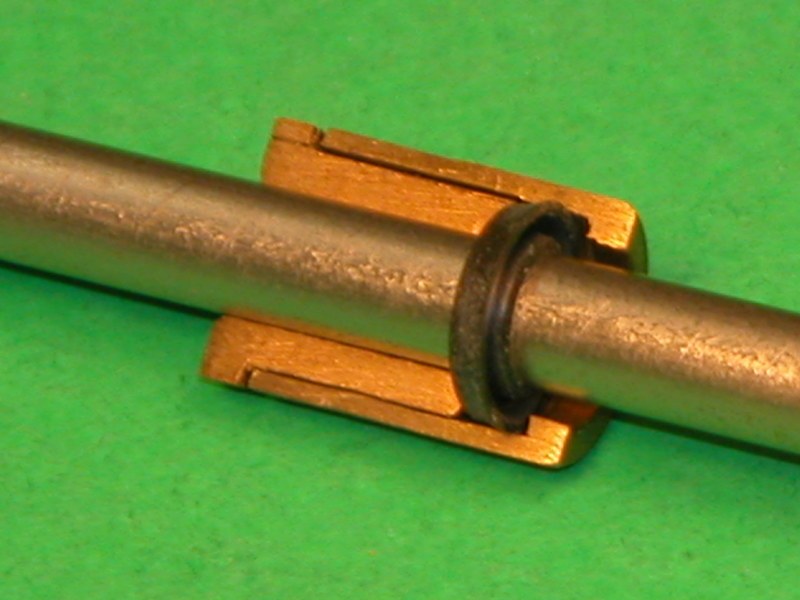

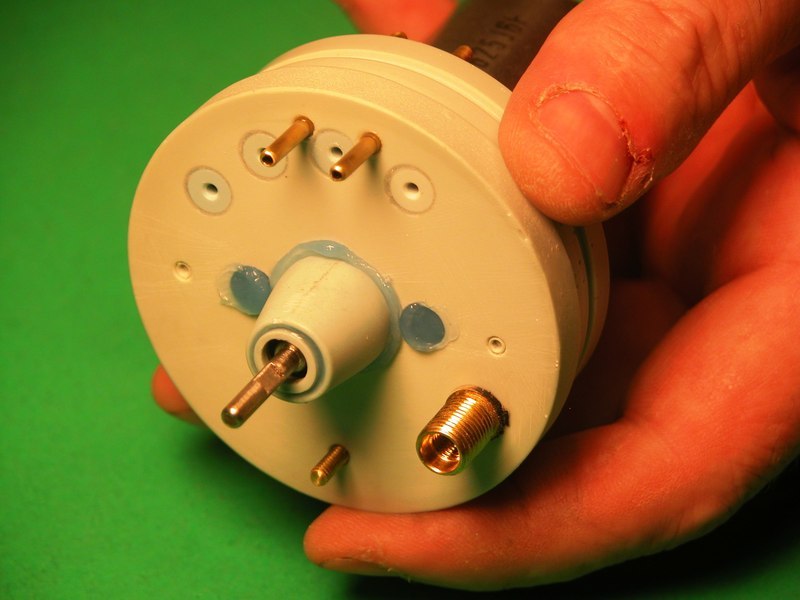

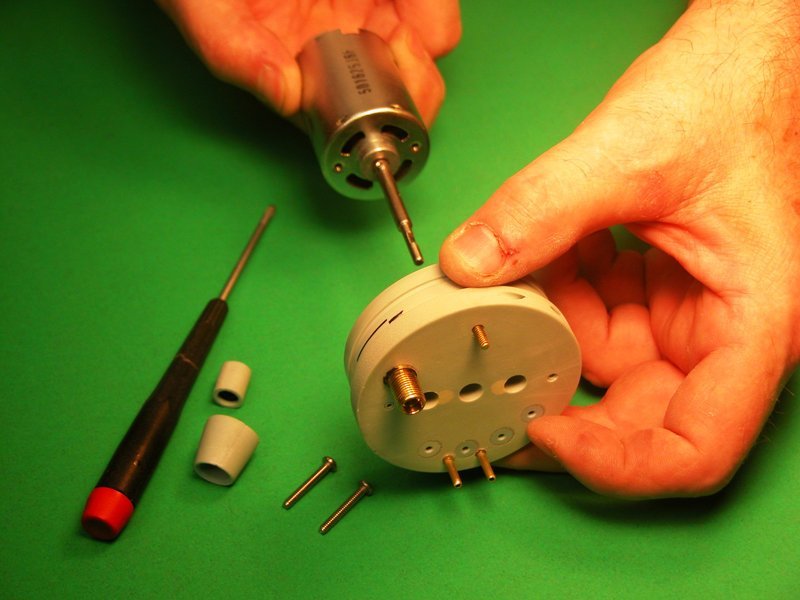

This first picture shows my typical mould board set up with the movable surface with the leading edge upwards. The sprue (dark shaded in section) attaching to the leading edge where the foil is thickest. The thinking being that the plates are pointed upwards therefore allowing one vent placed at the top tip of the plate to allow air to move out as the resin fills up. The downside is that the resin will be pouring into the mould immediately over the brass rod insert, thus hampering a clear open space to pour into. What do you think of this?

Second photo shows the movable surface in the more conventional position that I would usually have it with the plates in a horizontal position, My concern being that the air will not be able to escape out the sides of the mould as my vent lines only really run up the split surface. Should I be concerned about extra venting lines or is it really in your experience, not an issue? This is how I would prefer to mount the piece as it allows the brass insert to be away from the pouring sprue. It also means I can have the air vents on a easily sandable flat surface rather than on the curved thick end of the foil.

Or is this all not really an issue?

Second point.

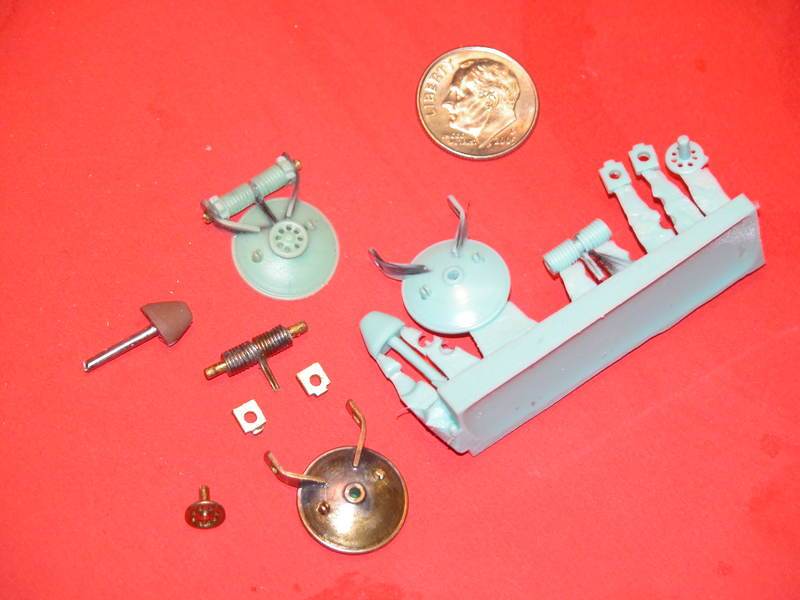

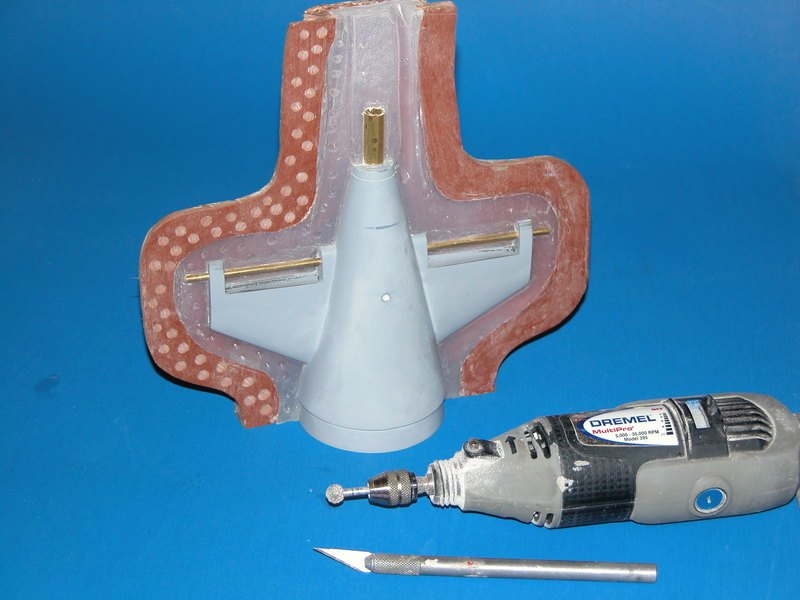

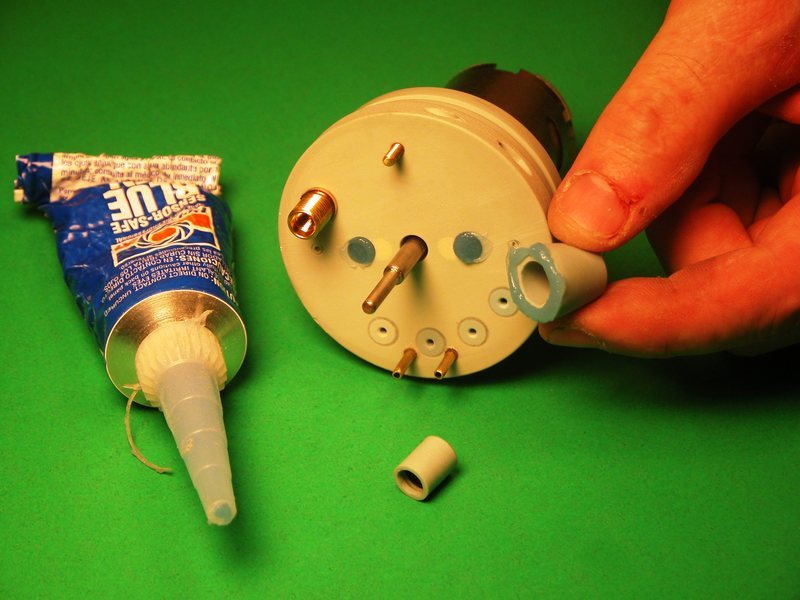

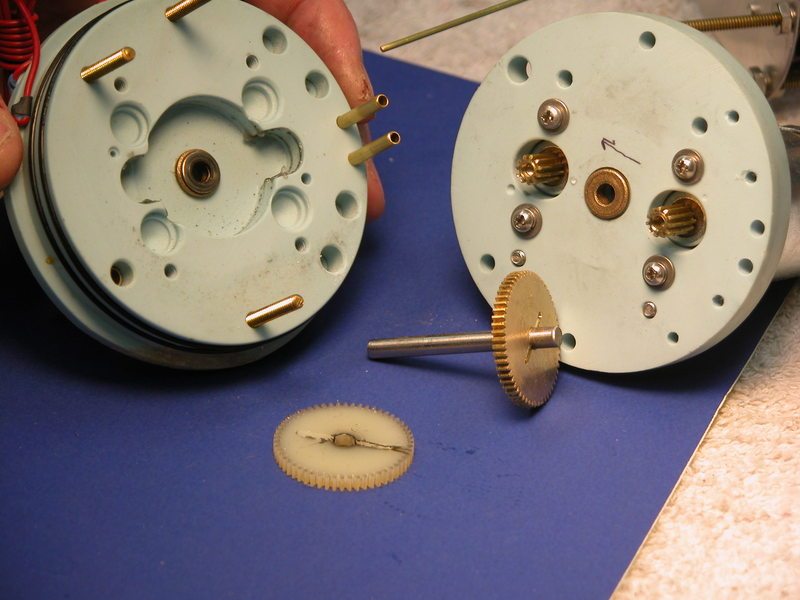

This has to do with you Fin build on the November class that Scott is developing. I really wanted to see what happened with the rest of the Sail/ Fin fabrication. The reason why I am so interested in this is that I am considering a one piece mould for the 667's fin. However I am thinking of creating a moulded part but out of Glass rather than moulding it out of Polyurethane.. You got up to splitting the mould in two with a knife and then were about to lay up cloth and then that's where I was left hanging....

I am thinking of producing my 667 fin mould as a one piece exactly like above however instead of cutting it in two, just brushing in gel coat and then layers of cloth. I am going to have to make a added section on the rear of the sail to create void where the missile deck would be and to make sure that the piece could be pulled out. I hope this makes sense. Do you see any problems with this?

Regards,

David H

Leave a comment: