This is more for the operator than the builder (who never/rarely operates their boat)

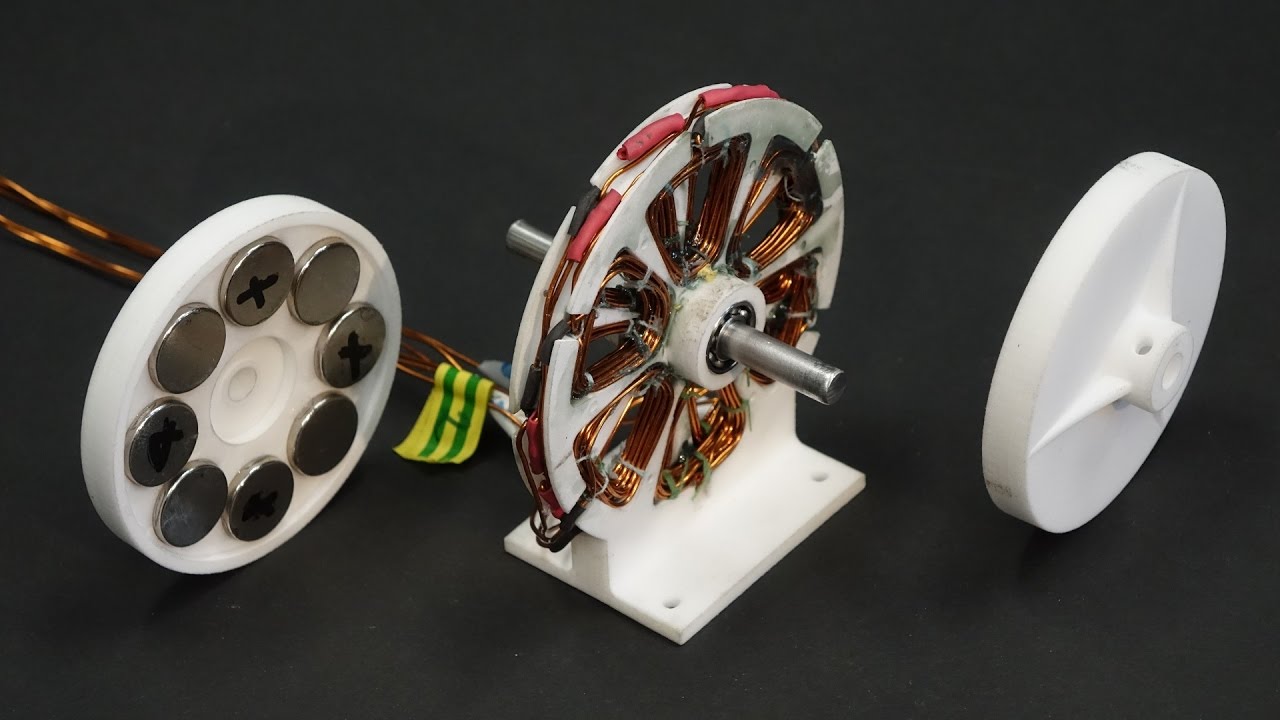

I'm not a fan of (any) exposed electrical devices in the water. These items containing such items as exposed solder joins, ball/roller bearings made of ferrous metals, any metal subject to long term electrolytic/galvanic corrosion.

Galvanic corrosion, also known as bimetallic corrosion, is an electrochemical process whereby one metal (Aluminum housing) corrodes in preference to another metal (Steel bearings/shaft etc) that it is in contact with through an electrolyte (our case: water that is not 100% H2o). Galvanic corrosion occurs when two dissimilar metals are immersed in a conductive solution and are electrically connected. Electrolytic corrosion is very similar to galvanic corrosion. The oxidation process is the same. The major difference is that an electric current has been introduced into the conducive electrolyte solution. When the electric current is added into water, it speeds up the oxidation rate as the electric current is passing from the anode metal to the cathode metal (one of which is your exposed solder joints in this "waterproof" motor. Don't believe me? Tear one down). Why do you thing all your exposed + contacts turn green? (Cu oxidation in the brass)

Those metal bearings, the shaft, are the stainless steal? What about the magnets themselves? Have you ever seen magnets corrode after exposure to water?

This photo is what occurred over 1 boating season to an OB motor on a boat at the dock by an owner who left it down. The stary electrical currents from other boats and the shotty dock wiring attacked the Al housing.

Now you tell we all hear vendors of of these motors on Amazon and what not, claim they're designed for water. Hey, you hear that all over the internet, it must be true! They are not, if so don't you think they'd cost a lot more? You can also say , they sell it, so it must be true!. If you believe that, I have a certain faction of a red American Political Party you can join. Do you really think these Manufacturers (China, home brewed 3D printed) really give a $#*! about what happens to their product as long as they made $$ off you?? Caveat Emptor

Many say, they're so darn cheap, I'll just replace it. Funny coming from a group that often complains about the cost of this hobby. My real issue is with introducing failure. Murphy's law is a "Real and present danger." in most everything I do. Ed's law? "Your RC Sub will fail, at PD, 50 meters out, in cold water, and you ran alone that day." (Been there done that.)

I need to get off the soapbox, yet my valid concern is FOR the newbie purchasing these only to have it fail on his $1500 model and walk away from the hobby as it's tough enough without asking for trouble.

However, there is a valid requirement to do this, so how do we do it and see the motor doesn't fail at the most inopportune moment (like after a 12hr drive to a big sub meet), or to provide every penny of value with respect to MTBF? (Mean Time Between Failure, aka life rating). I run my boats quite often, and hate replacing things

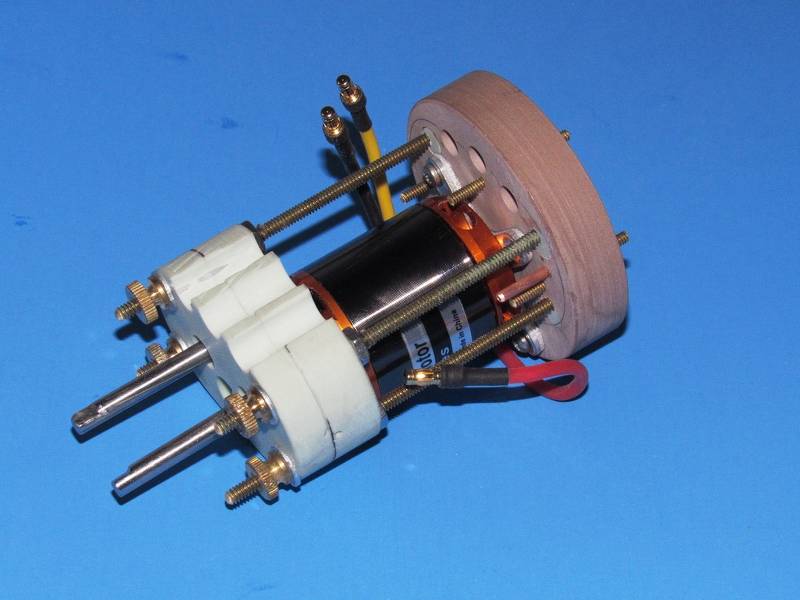

I now have such a requirement, and plan to expose a $60 USD Brushless Motor to the "wet". While I don't count my pennies, I do respect them as they're hard earned. Hence the need to waste my time and write this.

So after all this hooplah (Bob loves my mental meanderings ) though he'll never admit it:

Brushless Motors - The Truth About Waterproof

My plan is to have the motor as easily removable as the common WTC. I plan to give a WD 40 before I submerge for the 1st time, and going forward bathe after each run. Bathing will consist of a WD40 spray down to remove particulates, followed by a bath (1/2 hr) in a container filled with WD40, air blast dry.

Maybe 10 minutes of post Patrol process to eliminate potential failure? I don't mind post Patrol maintenance, it's like the same joy I have of cleaning the firearm I used at the range earlier that day. Some tuneskies, a good stogie, beverage of choice.....(meandering again).

Look, if it's just a toy to you, fuhgeddaboudit and move on.

Thoughts? (fire away)

I'm not a fan of (any) exposed electrical devices in the water. These items containing such items as exposed solder joins, ball/roller bearings made of ferrous metals, any metal subject to long term electrolytic/galvanic corrosion.

Galvanic corrosion, also known as bimetallic corrosion, is an electrochemical process whereby one metal (Aluminum housing) corrodes in preference to another metal (Steel bearings/shaft etc) that it is in contact with through an electrolyte (our case: water that is not 100% H2o). Galvanic corrosion occurs when two dissimilar metals are immersed in a conductive solution and are electrically connected. Electrolytic corrosion is very similar to galvanic corrosion. The oxidation process is the same. The major difference is that an electric current has been introduced into the conducive electrolyte solution. When the electric current is added into water, it speeds up the oxidation rate as the electric current is passing from the anode metal to the cathode metal (one of which is your exposed solder joints in this "waterproof" motor. Don't believe me? Tear one down). Why do you thing all your exposed + contacts turn green? (Cu oxidation in the brass)

Those metal bearings, the shaft, are the stainless steal? What about the magnets themselves? Have you ever seen magnets corrode after exposure to water?

This photo is what occurred over 1 boating season to an OB motor on a boat at the dock by an owner who left it down. The stary electrical currents from other boats and the shotty dock wiring attacked the Al housing.

Now you tell we all hear vendors of of these motors on Amazon and what not, claim they're designed for water. Hey, you hear that all over the internet, it must be true! They are not, if so don't you think they'd cost a lot more? You can also say , they sell it, so it must be true!. If you believe that, I have a certain faction of a red American Political Party you can join. Do you really think these Manufacturers (China, home brewed 3D printed) really give a $#*! about what happens to their product as long as they made $$ off you?? Caveat Emptor

Many say, they're so darn cheap, I'll just replace it. Funny coming from a group that often complains about the cost of this hobby. My real issue is with introducing failure. Murphy's law is a "Real and present danger." in most everything I do. Ed's law? "Your RC Sub will fail, at PD, 50 meters out, in cold water, and you ran alone that day." (Been there done that.)

I need to get off the soapbox, yet my valid concern is FOR the newbie purchasing these only to have it fail on his $1500 model and walk away from the hobby as it's tough enough without asking for trouble.

However, there is a valid requirement to do this, so how do we do it and see the motor doesn't fail at the most inopportune moment (like after a 12hr drive to a big sub meet), or to provide every penny of value with respect to MTBF? (Mean Time Between Failure, aka life rating). I run my boats quite often, and hate replacing things

I now have such a requirement, and plan to expose a $60 USD Brushless Motor to the "wet". While I don't count my pennies, I do respect them as they're hard earned. Hence the need to waste my time and write this.

So after all this hooplah (Bob loves my mental meanderings ) though he'll never admit it:

Brushless Motors - The Truth About Waterproof

My plan is to have the motor as easily removable as the common WTC. I plan to give a WD 40 before I submerge for the 1st time, and going forward bathe after each run. Bathing will consist of a WD40 spray down to remove particulates, followed by a bath (1/2 hr) in a container filled with WD40, air blast dry.

Maybe 10 minutes of post Patrol process to eliminate potential failure? I don't mind post Patrol maintenance, it's like the same joy I have of cleaning the firearm I used at the range earlier that day. Some tuneskies, a good stogie, beverage of choice.....(meandering again).

Look, if it's just a toy to you, fuhgeddaboudit and move on.

Thoughts? (fire away)

Comment