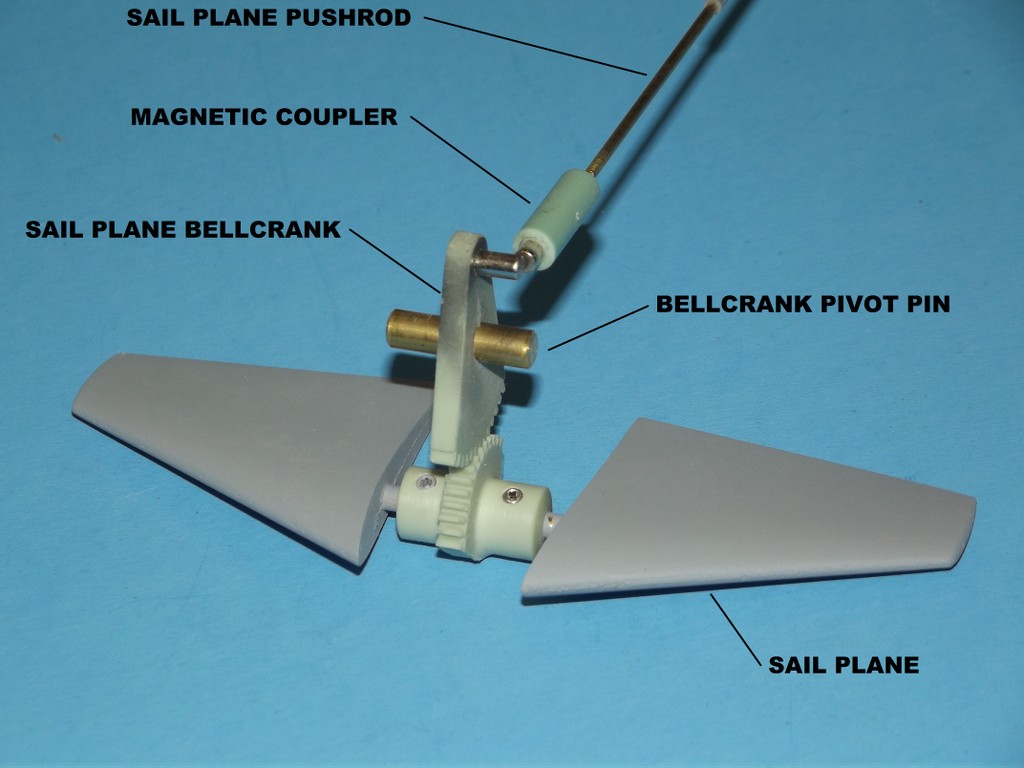

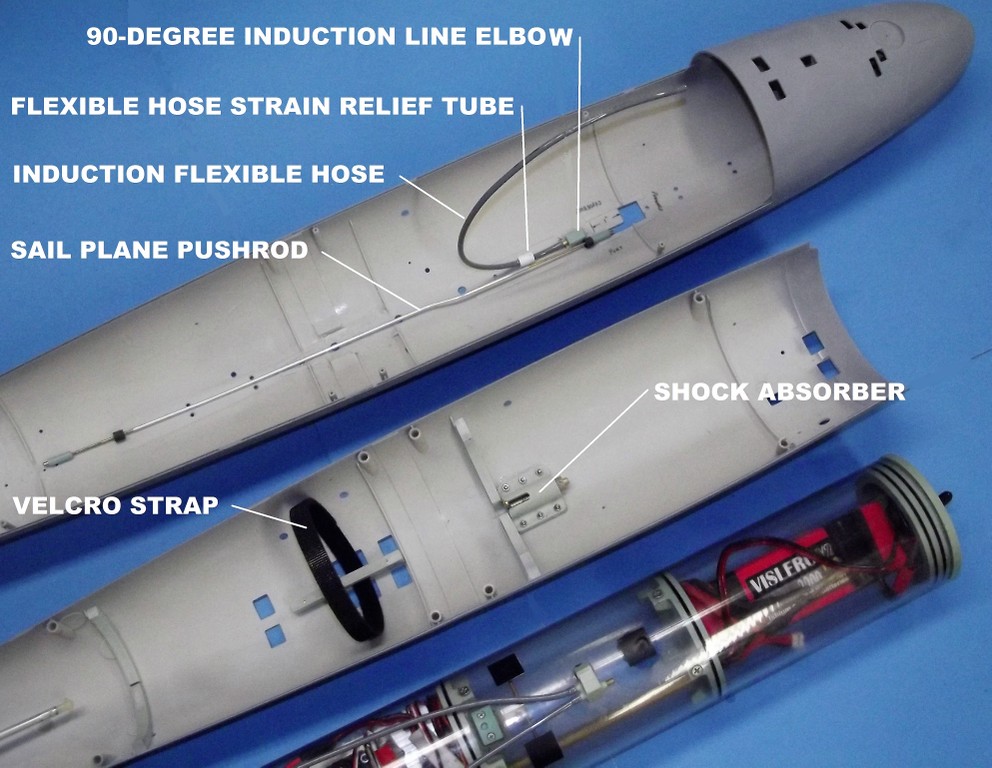

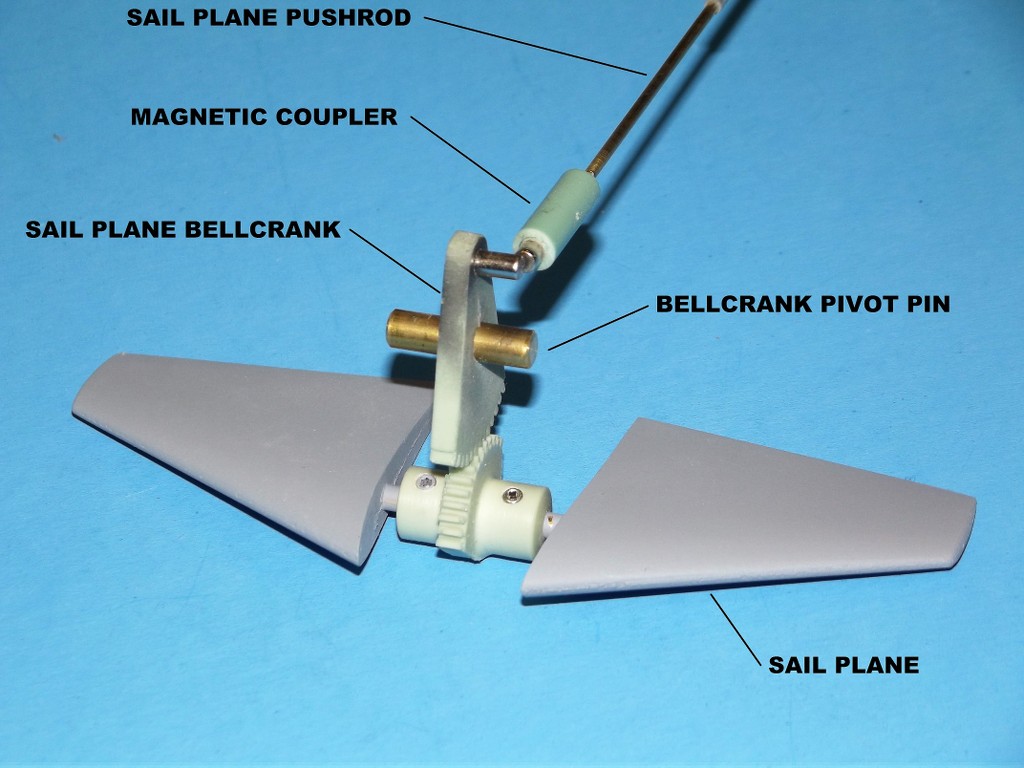

I am having a heck of a time getting the subject pushrod to play nice between the magnets ends, both in the run and automatically hooking up. Could you masters of this beast please post some pictures and some verbage of successful set-ups to help us klutzes get on the same playing field?? At present I'm trying to do this with a Lazer rod and David's Klick-ons.

TIA,

Bill

TIA,

Bill

Comment