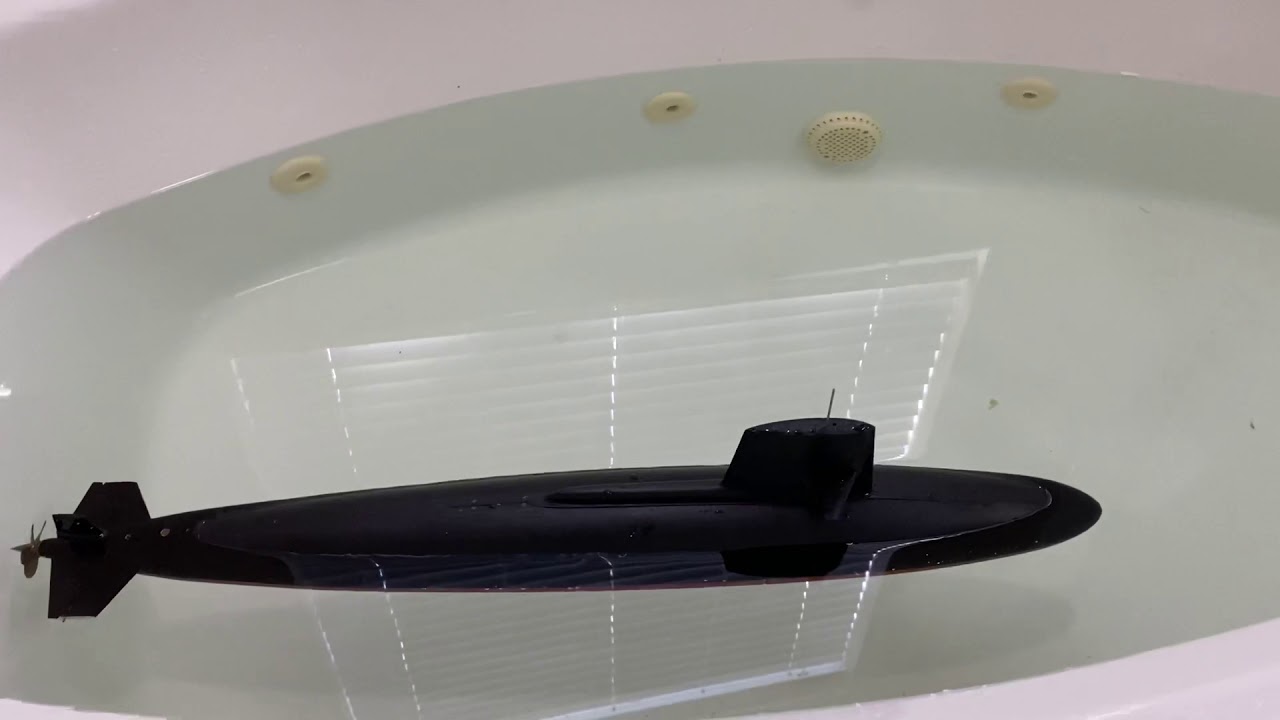

In my rebuilding of my D&E Skipjack I am trying to rework the trim. I removed all the open cell foam I had used back in ‘96 that I feel was holding som water. I had the entire nose of the sub in front of the WTC filled with foam. Now with the inner hull empty I started attaching foam blocks outside the hull to set the trim. From the attached pics I am not sure I can fit all that foam I side the nose of the boat. Could I use the Spray on expand O foam to fill the nose or will that stuff melt the hull? Does the Almighty remember if the entire nose needed to be full of foam for this sub? There were 2 semi circular strips of lead that are glued to the hull for Dynamic stability. Should I remove some of that lead that was glued just up toward the front of the WTC so I don’t need so much nose foam? As can be seen from the submerged pic the boat is nose high when under water. So now I am scratching my head on how to proceed.

Suggestions?

Suggestions?

Comment