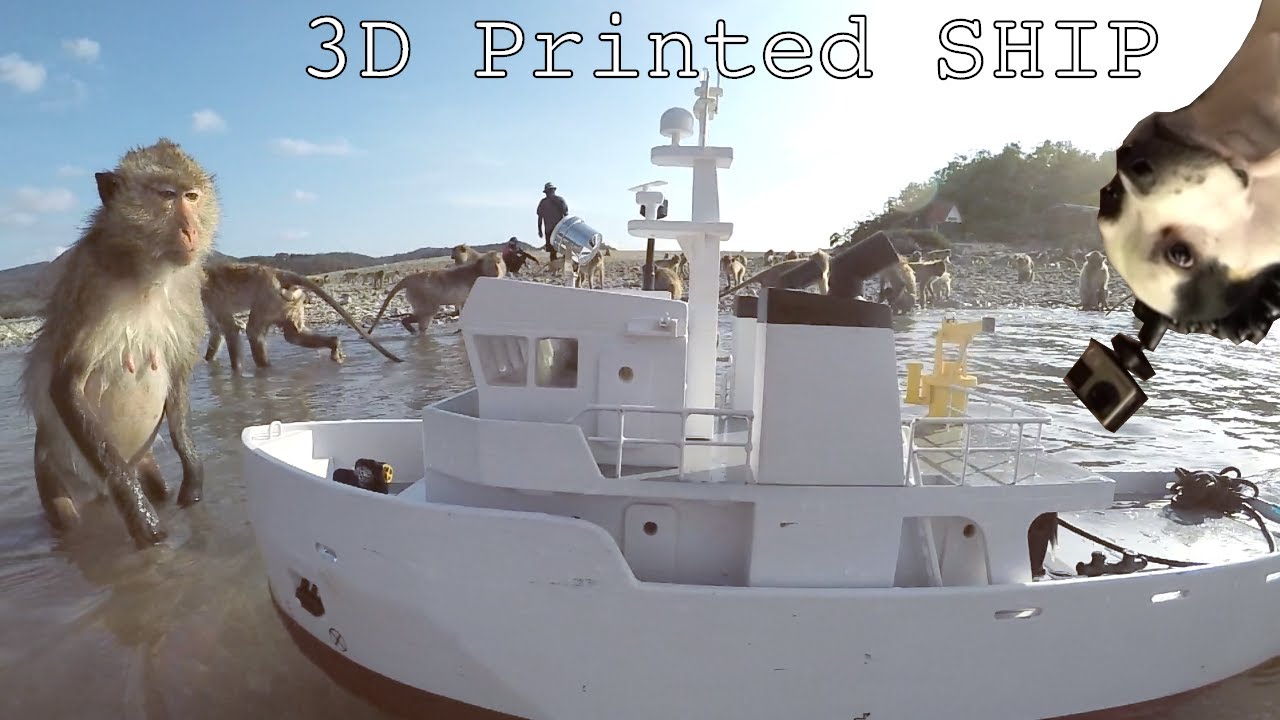

3D Printed Utility Boat

Collapse

X

-

This boat when complete, will be a total 21.5" long with a beam of 5.25".

I will be printing this boat using a Dremel DigiLAB 3D40. I will be using Dremel PLA White filament, and printed at 100% infill. The photo shows the bow section of the boat (5 total hull sections) and it will take a total of 24.5 hours to complete the bow!

Rob

"Firemen can stand the heat" -

Comment

-

-

Comment

-

-

Thanks Nick,

It is turning out to be a very strong hull building at 100% infill, but that will give me a good base to really get a smooth surface for applying my final finishing. I will apply glass and resin to all the interior joints, and then apply a coat of resin to the entire surface interior for keeping out any possible water penetration.

Rob

"Firemen can stand the heat"Comment

-

Make it simple, make strong, make it work!Comment

-

Very similar, but not the same size. Mine is a smaller version.

Rob

"Firemen can stand the heat"Comment

-

Comment

-

Rob can take a picture of the hull with you holding it so I can get a reference to it's size.Make it simple, make strong, make it work!Comment

Comment