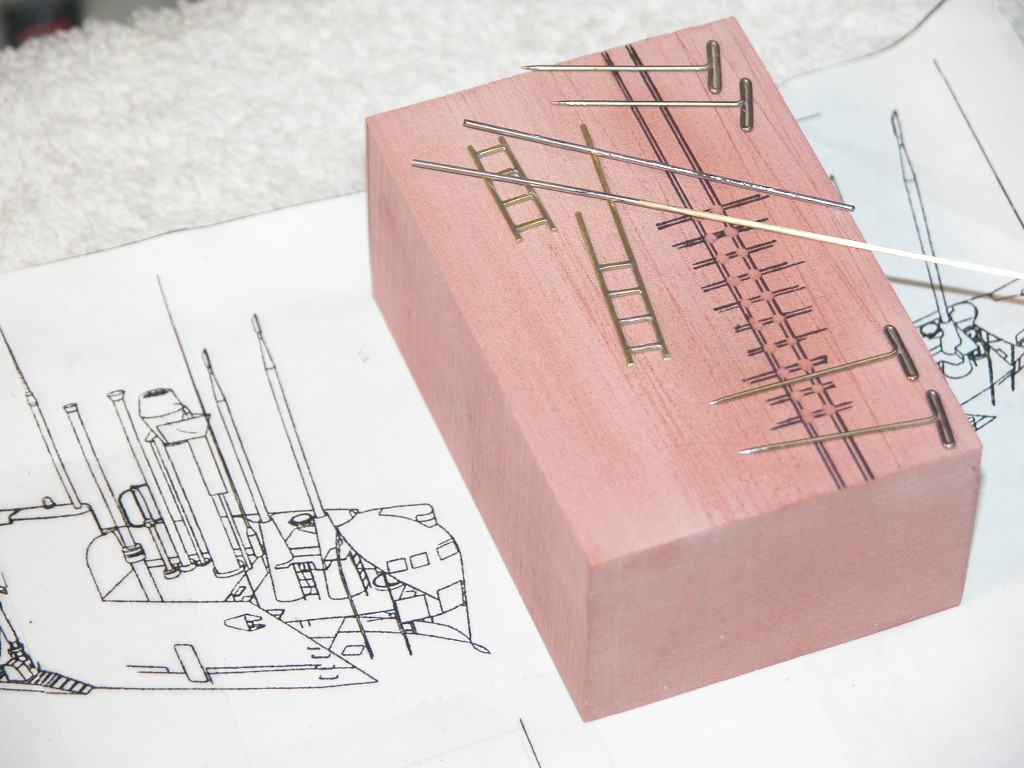

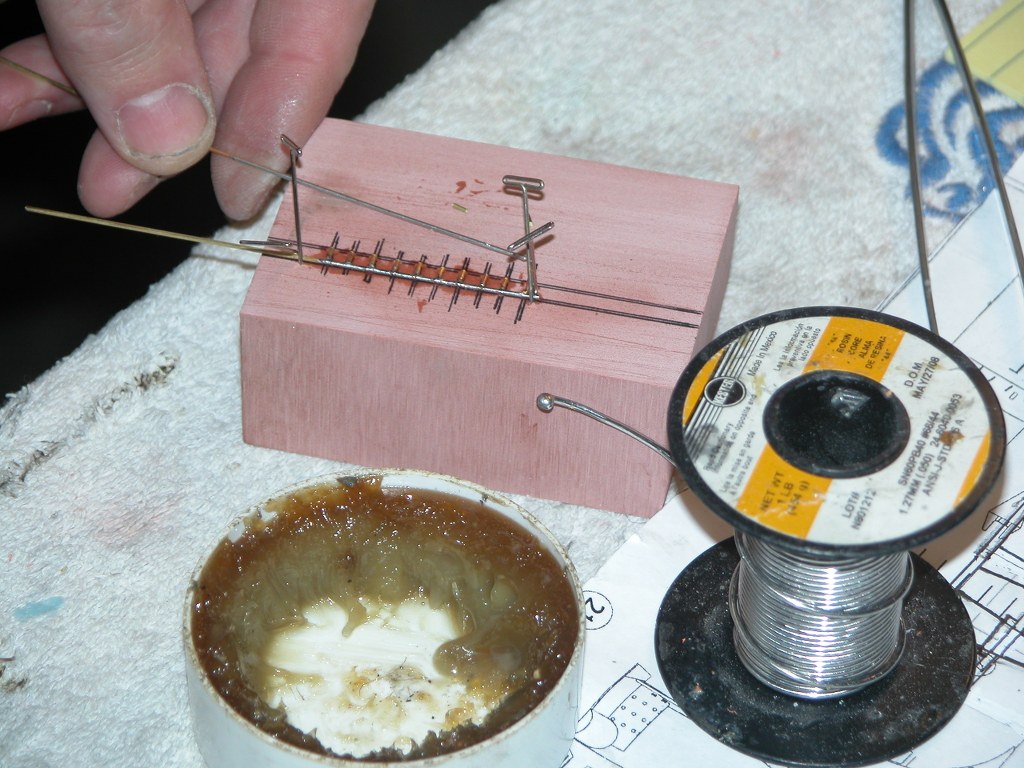

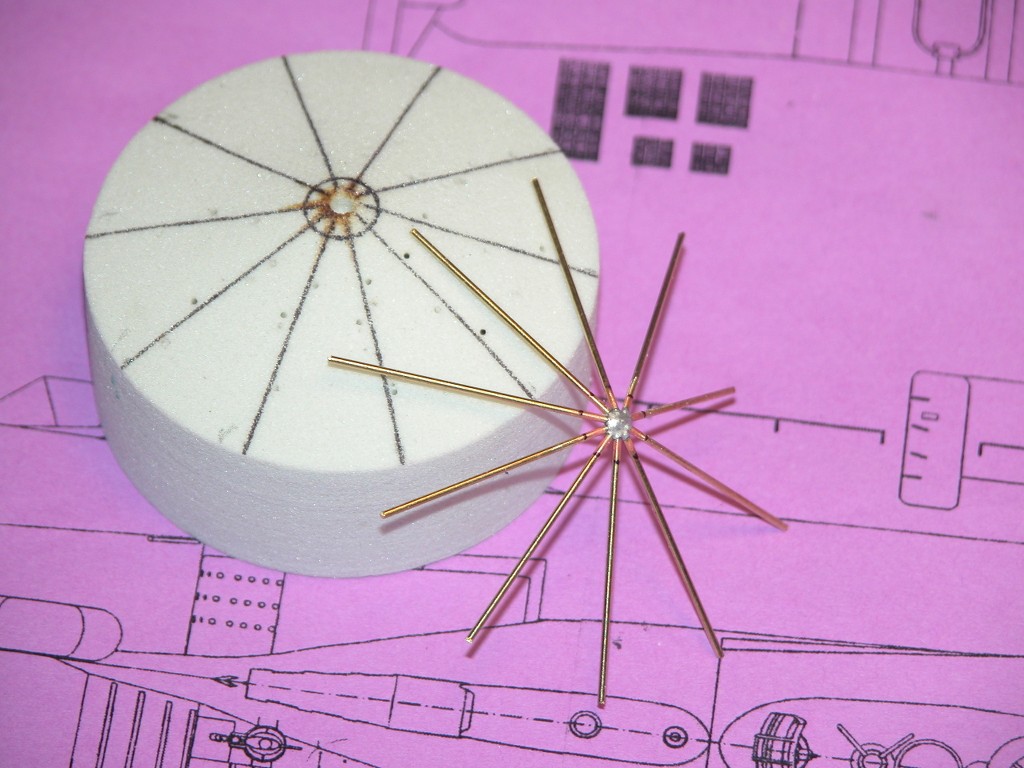

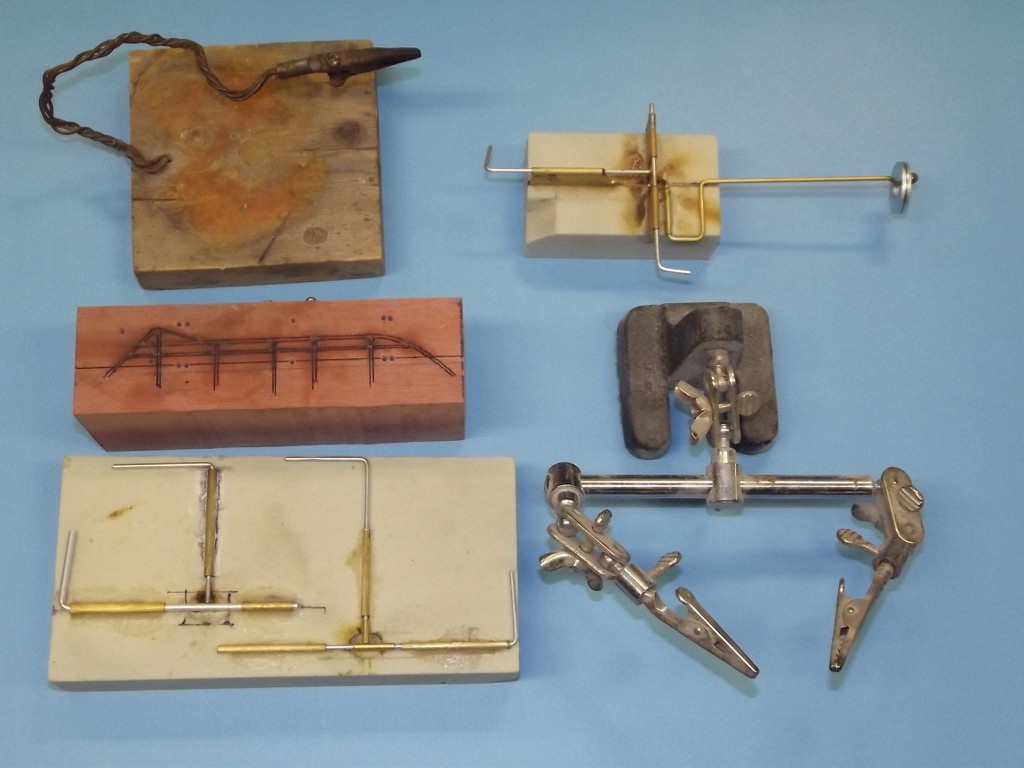

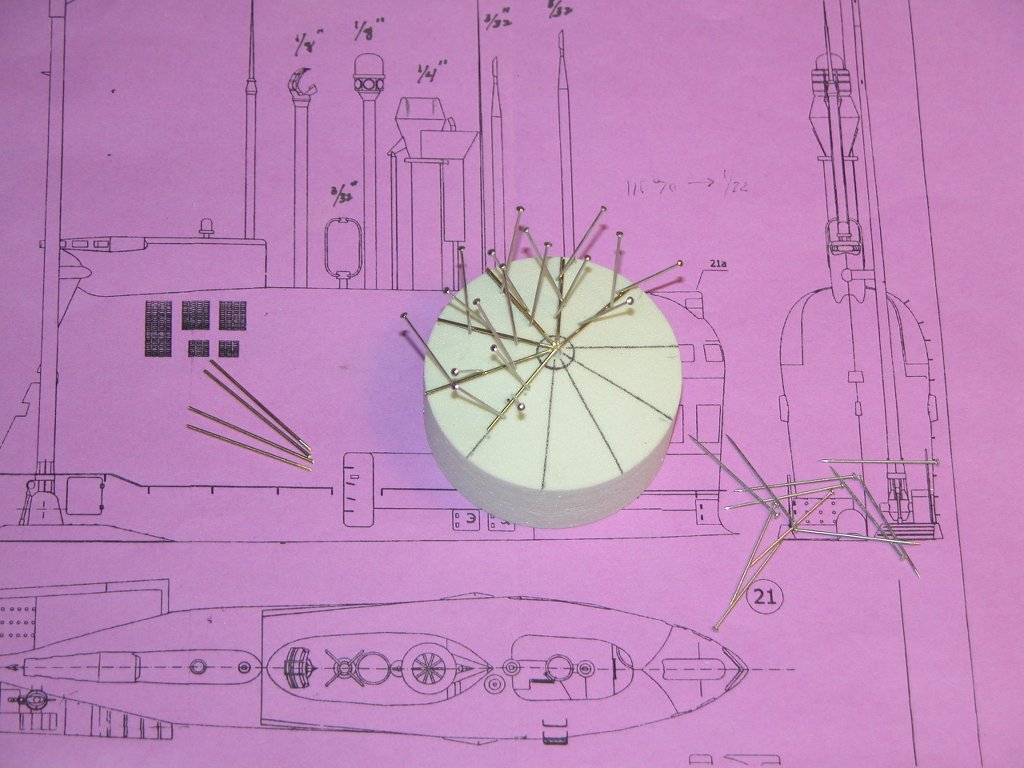

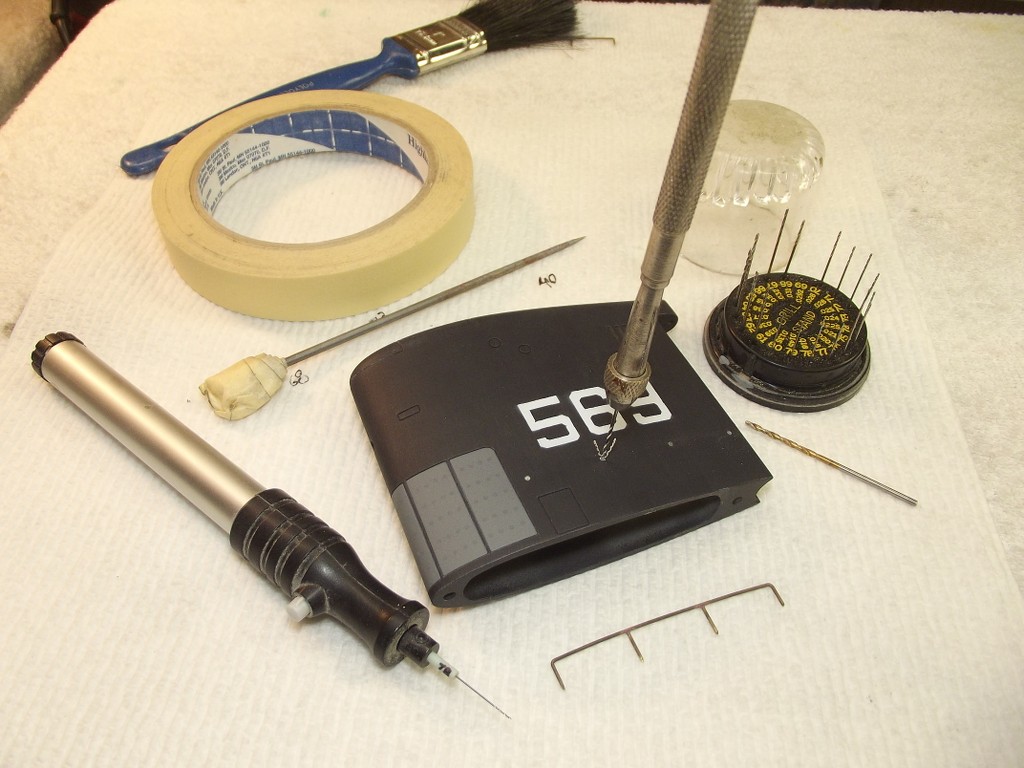

Now that I have the U-2540 built I can start on the brass work!

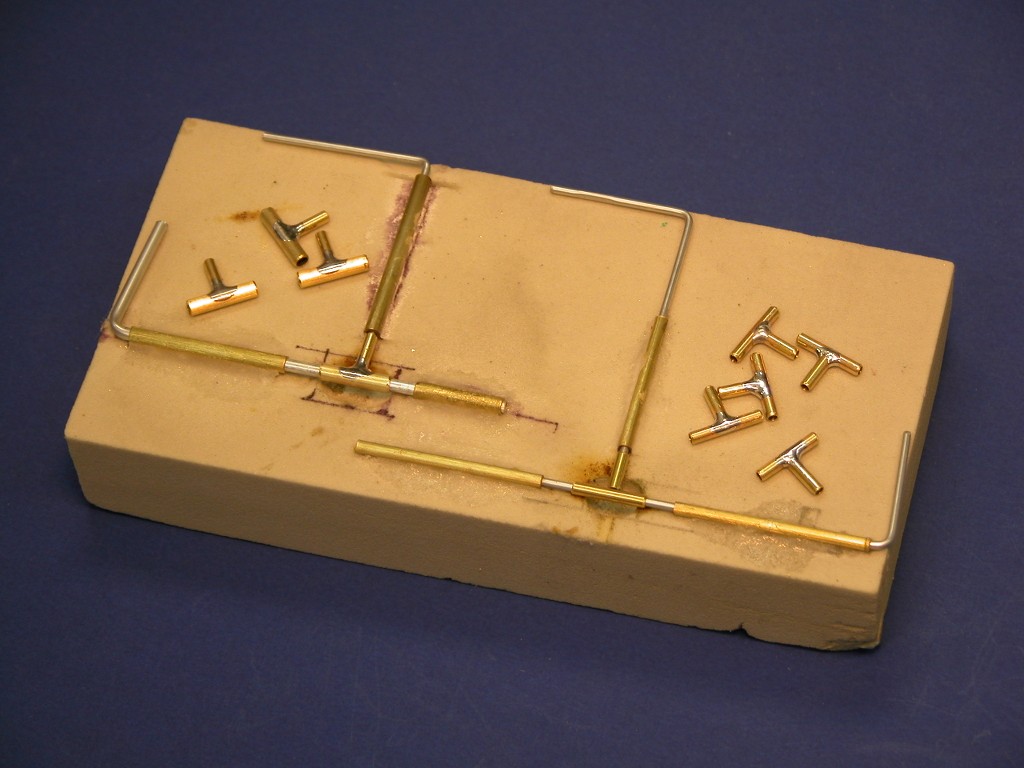

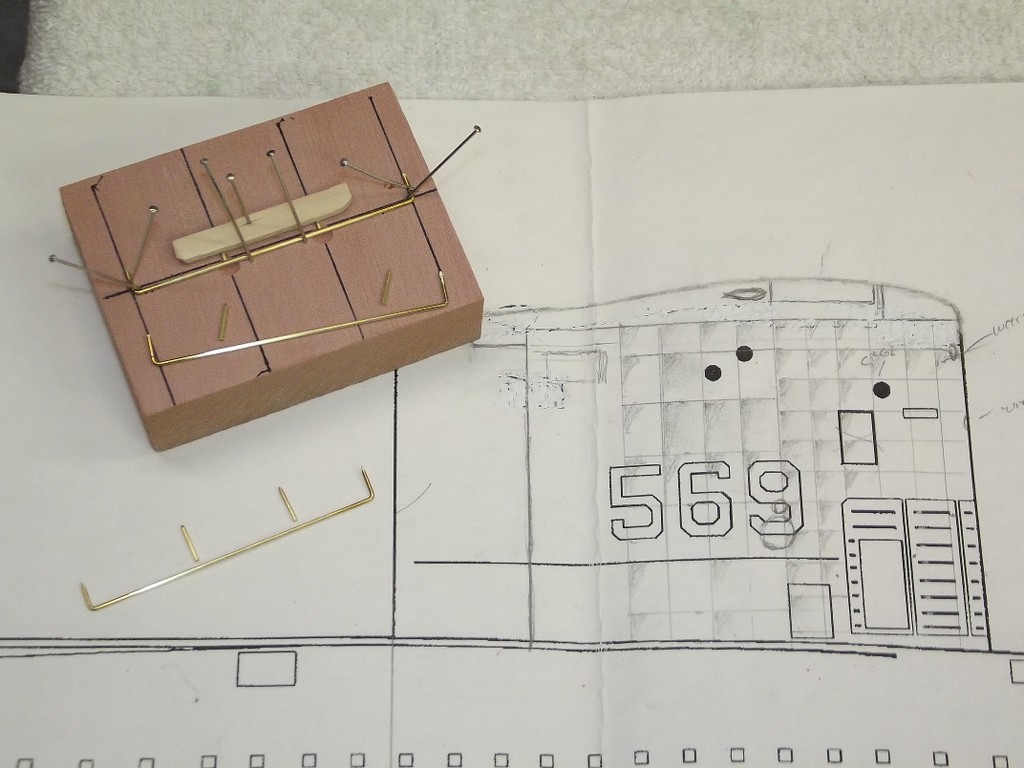

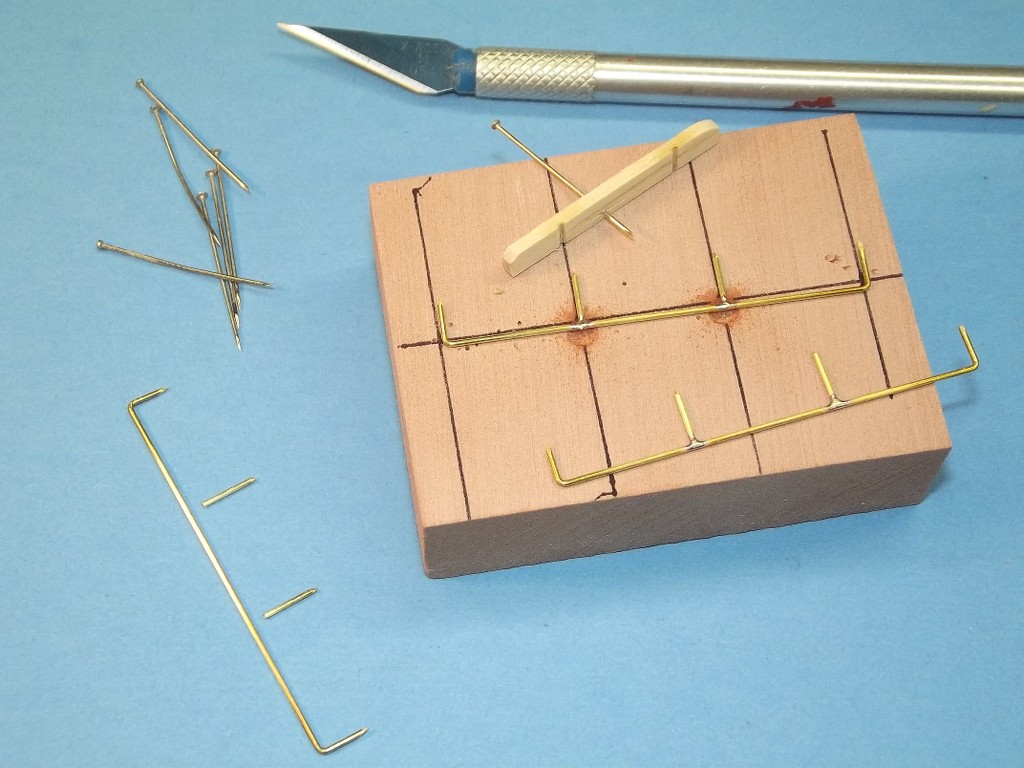

There are individual plan details as to where each piece of brass is to be placed on this model! The detailed sheet has every piece of brass numbered and each number corresponds to the two plains (Sail & Hull)

In my opinion! As a 3D printed boat, (quality print files) and how well it is laid out, it will build into a really nice static boat if one where to put in the time and effort! I am really looking forward to this model build!

Rob

"Firemen can stand the heat"

There are individual plan details as to where each piece of brass is to be placed on this model! The detailed sheet has every piece of brass numbered and each number corresponds to the two plains (Sail & Hull)

In my opinion! As a 3D printed boat, (quality print files) and how well it is laid out, it will build into a really nice static boat if one where to put in the time and effort! I am really looking forward to this model build!

Rob

"Firemen can stand the heat"

Comment