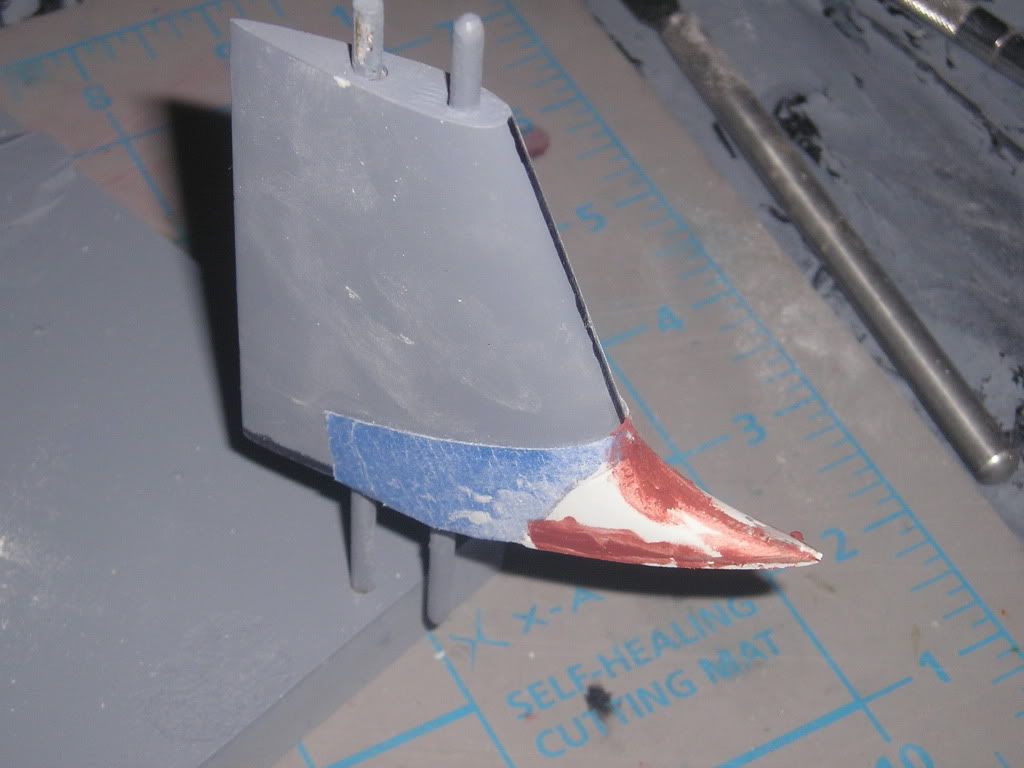

Anhedrals and their functions aside, the Seawolf in 1:1 or any other scale is no Formula One machine.

In my 1/96 version, I found that ballast weight placement and determining the exact COG were crucial. Boat was very sensitive to changes both in pitch and yaw planes.

I do not think that the presence of anhedrals are a huge obstacle to a nice handling model. Pete Piekarski's Virginia behaved very well at the Carmel SubRegatta, as good as any 1/96 LA ( pre-I ) I have seen. Anhedrals or no, still doubtful any LA, Seawolf and Virginia will approach the sports car performance of earlier SSN hullforms.

Make any sense?

In my 1/96 version, I found that ballast weight placement and determining the exact COG were crucial. Boat was very sensitive to changes both in pitch and yaw planes.

I do not think that the presence of anhedrals are a huge obstacle to a nice handling model. Pete Piekarski's Virginia behaved very well at the Carmel SubRegatta, as good as any 1/96 LA ( pre-I ) I have seen. Anhedrals or no, still doubtful any LA, Seawolf and Virginia will approach the sports car performance of earlier SSN hullforms.

Make any sense?

Comment