I received some brass sheeting of 0.15mm (0.006Ē) thick. It is more suitable for stencil making especially for the scribing stencils of the sail then the 0.35 I used before (more flex).

The brass stencils are a copy of the styrene test stencils I made previous.

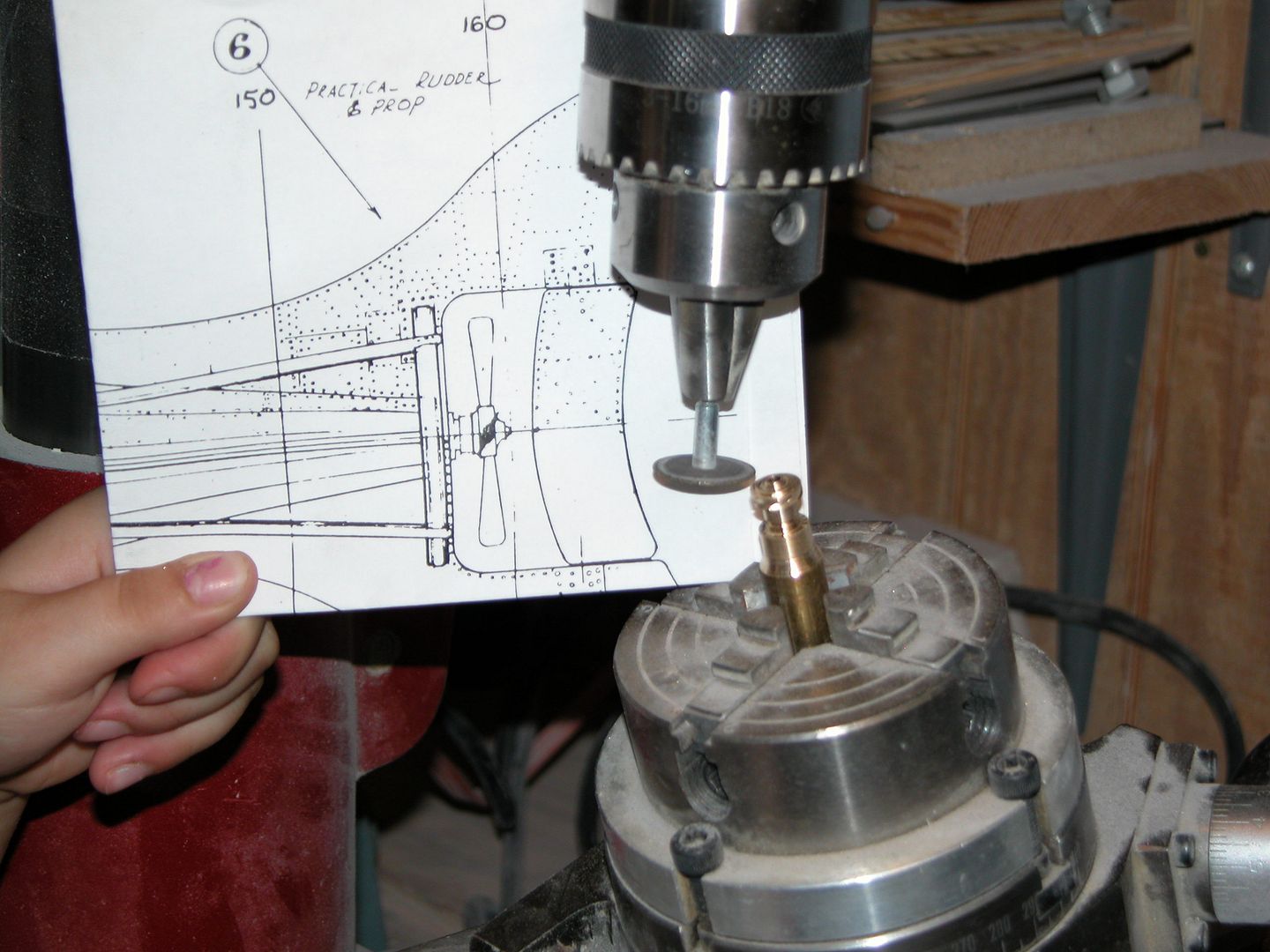

Next up were the different air vents gratings. Round ones (2 pc) will be used on the towed array pod, the rectangular ones (15 pc) will be used on the upper hull. I donít have equipment to etch so I used a 0,4 mm drill to fabricate them. I used the 0.15mm brass as material.

I made 20 rectangular and 4 round ones, I will use the best out the pack to apply on the model, Yes Iím insane.

I cut out all vent holes in the upper hull, to take the gratings. They were scribed but never the less I used two of the out casted gratings for dimensioning testing. Squeezed two of them in tweezers one for controlling the width and one for the height.

Rudder and planes. I think I got caught by resin shrinkage. I did put a lot of effort to get the gap between, the control surface and the rudder and plane structure as narrow as possible. After the casting however I noticed that the cap was bigger than the masters. I couldnít leave it like this (yes I tried to ignore it but I failed) so I rectified it with some EUREKA putty.

That's it for now, Grtz, Bart

Leave a comment: