It's becoming even more slick when you get the hang of it, after making the vid i seperated the boat a few times more for practice, once you get more experience in doing this you can take this baby apart in a few seconds.

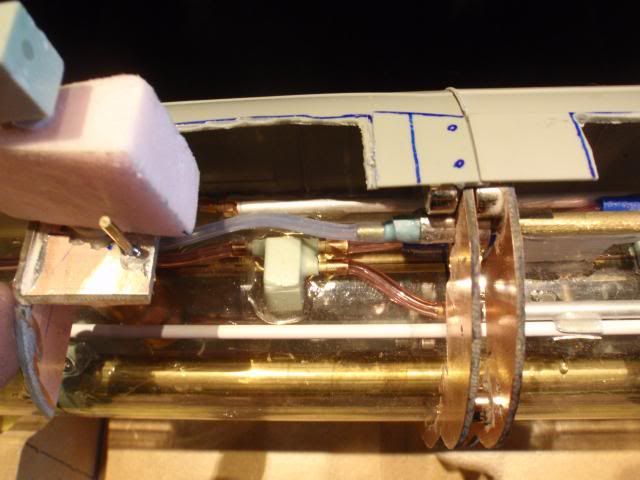

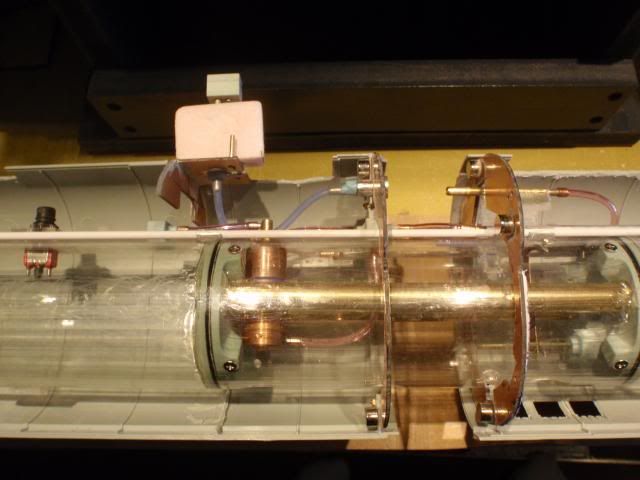

Making the connection between the SD and the proplsion shaft was tricky, at first i wanted to use a magnet, but i went for the mechanical way, i'll try to explain.

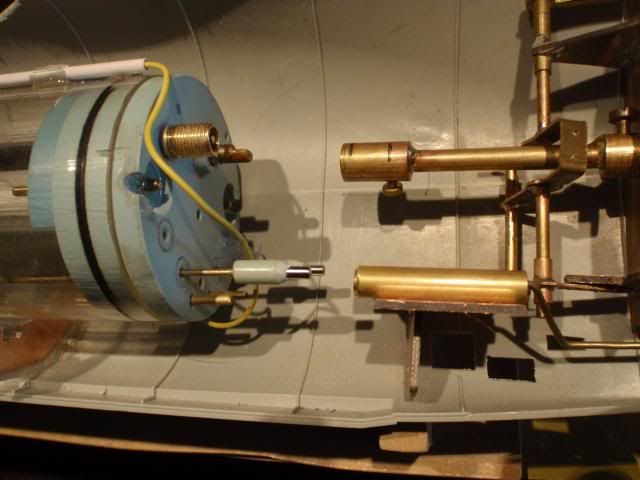

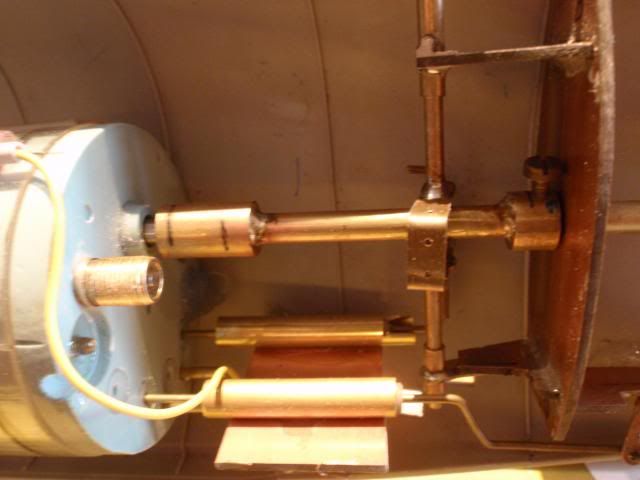

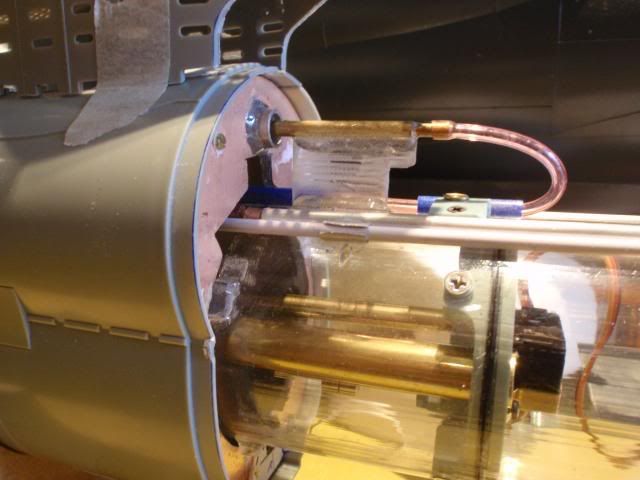

If you look at the shaft on the SD you can see there is a piece grinded away, giving you a step.

At this picture the connection is made between the SD and the shaft with the propellor, the brass connector has on the SD side a opposite grinded step inside as well, actually the same shape as on the SD shaft, placed at this position it will interlock with the shaft from the SD, both halves will unite as one when placed together.

The brass connector itself is locked onto the propellorshaft with two grubscrews, one near the SD and another one near the brass bearing, it's securing the connector from both sides on the propellor shaft, once you pull out the SD, the connector will stay at it's place complete with the propellor shaft.

Making this special connector took some time to measure up, and it took some more time on the lathe to turn it to my specs.

Manfred.

Leave a comment: