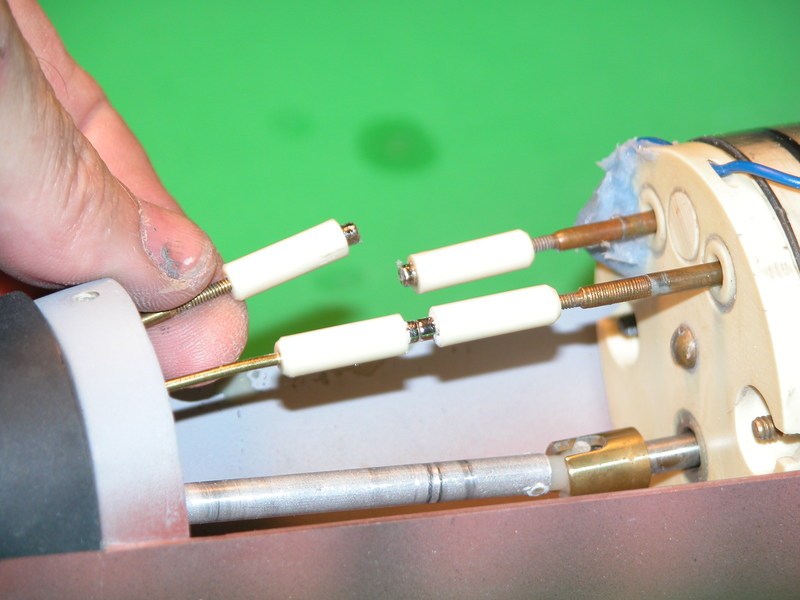

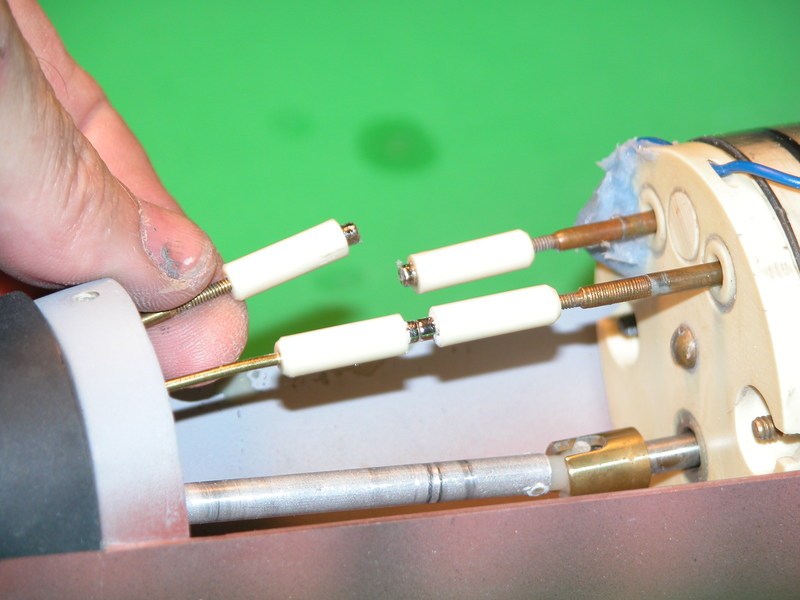

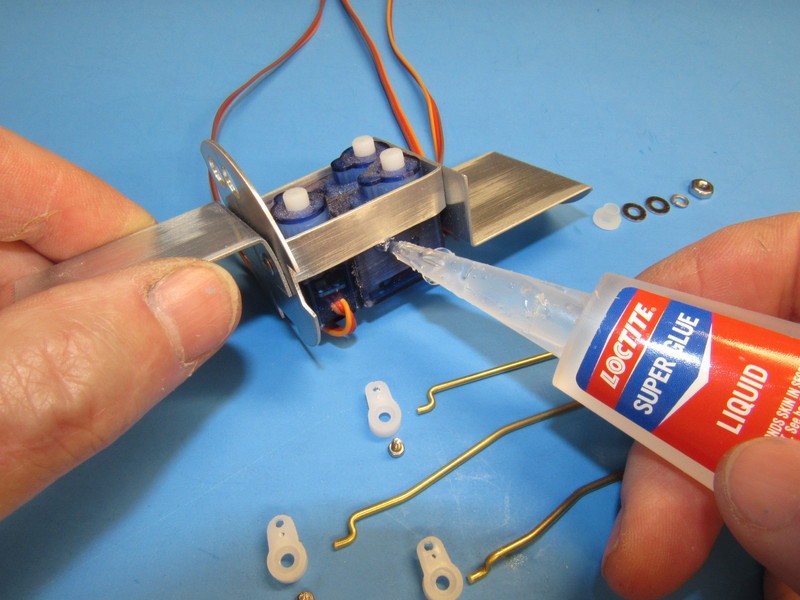

You're not alone there. It's happened to me. Either owing to some mechanical binding within the linkage or hydrodynamic forces from the control surface itself. The solution, as some have done is to go with bigger magnets that are less prone to de-coupling under tension. What I do is slip on a bent 'U'-shaped retainer clip that keeps the two magnets in close proximity, no mater how much tension is exerted to break union between magnet faces.

David

David

Comment