Thanks,

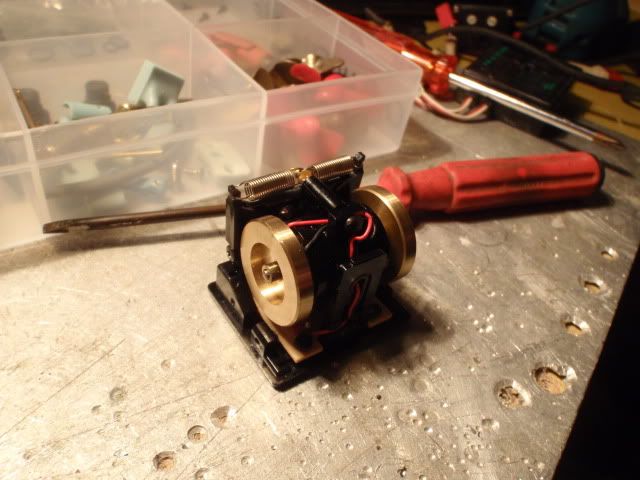

It's always a surprice if things work like i had inside my head, this build will be the result of all gained experience all those years, to give you guys some more, i've started to work on the servo's, placed the servo's in such way that they all can do their work without troubles, pictures.

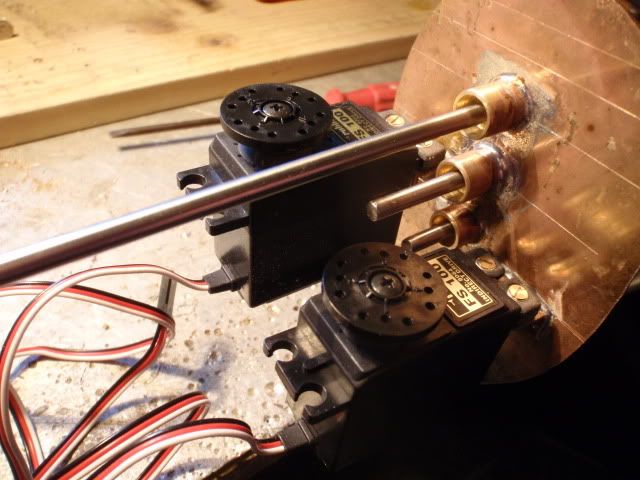

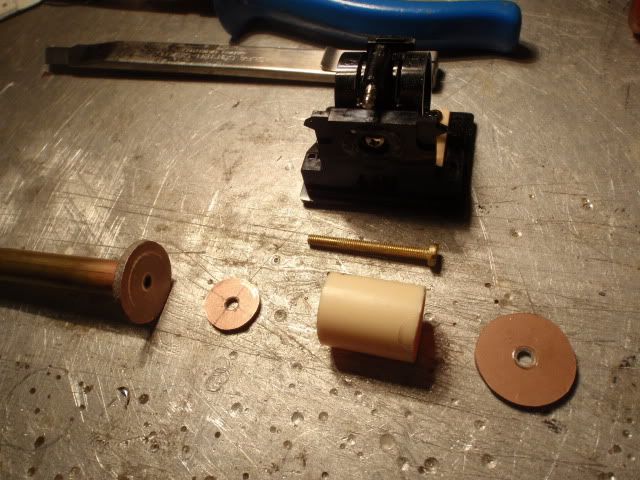

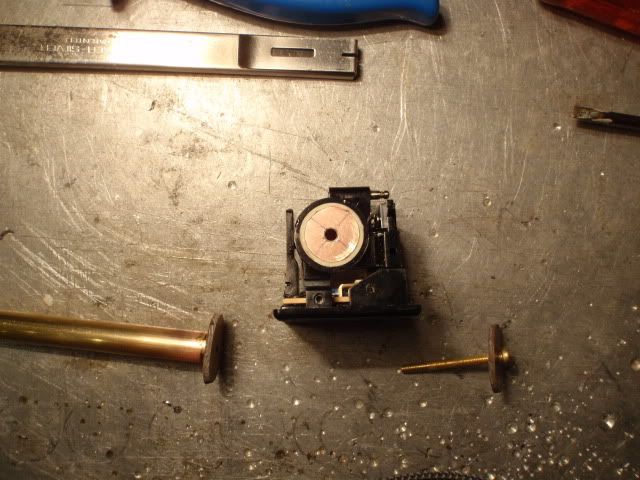

The rear bulkhead with both the rudder and diveplane servo, have to make the couplers for the steeringrods.

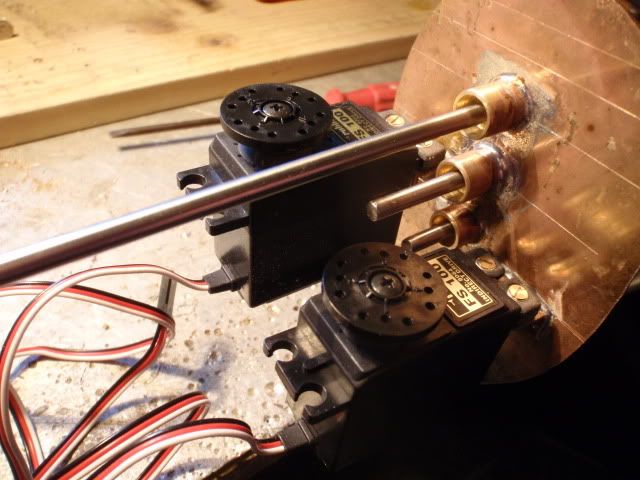

The front bulkhead is a bit different, i need two servo's for the launchtubes and a third one for steering the strange stabilising wing, this arrangement seems to be the best.

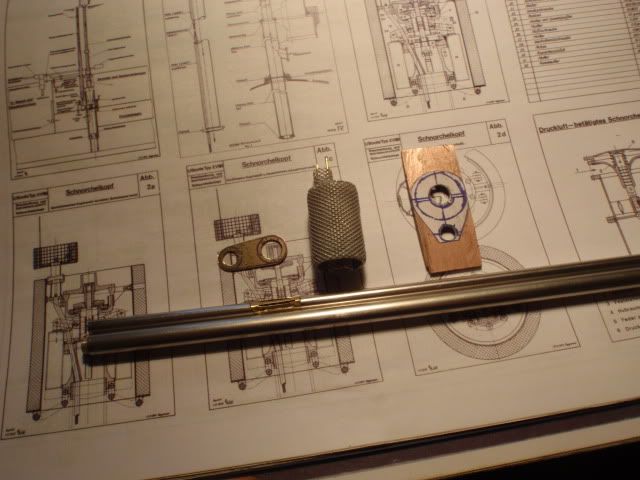

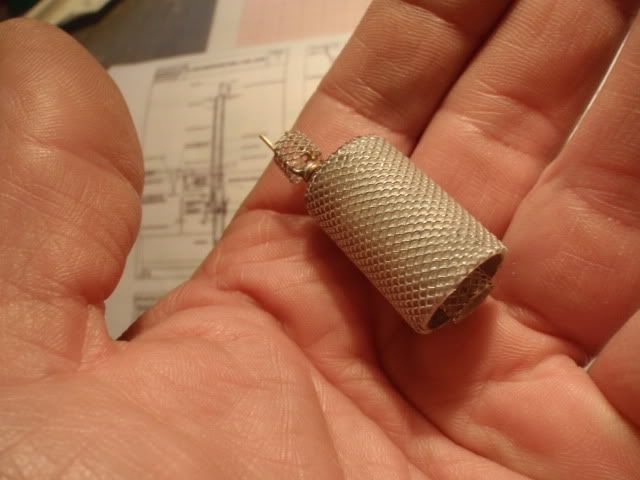

Dryfitting both bulkheads inside the hull, next stage will be, making the connections to the rods, since you have movement around both axes i have to make a bit different connection, i'll copy the one from the V80, which is working fine.

Manfred.

It's always a surprice if things work like i had inside my head, this build will be the result of all gained experience all those years, to give you guys some more, i've started to work on the servo's, placed the servo's in such way that they all can do their work without troubles, pictures.

The rear bulkhead with both the rudder and diveplane servo, have to make the couplers for the steeringrods.

The front bulkhead is a bit different, i need two servo's for the launchtubes and a third one for steering the strange stabilising wing, this arrangement seems to be the best.

Dryfitting both bulkheads inside the hull, next stage will be, making the connections to the rods, since you have movement around both axes i have to make a bit different connection, i'll copy the one from the V80, which is working fine.

Manfred.

Comment