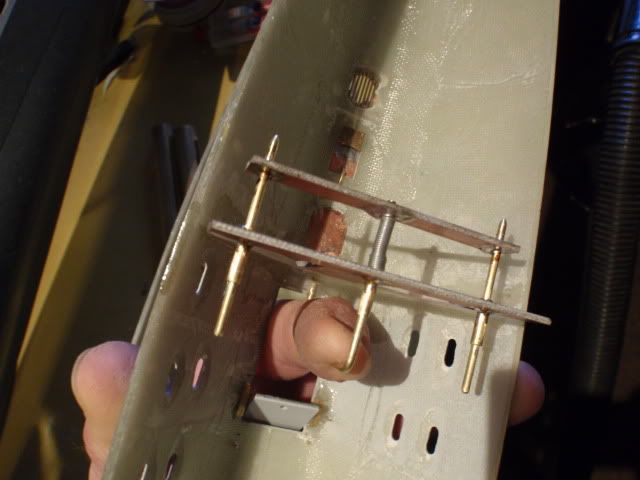

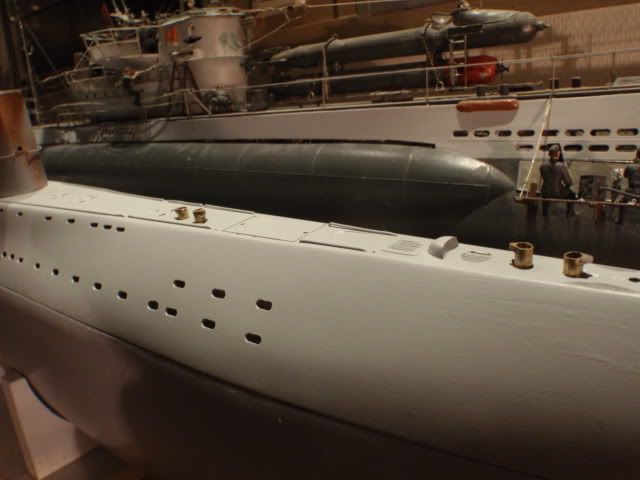

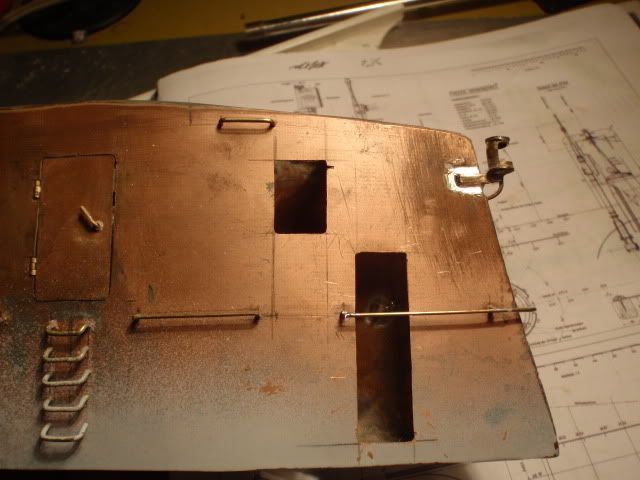

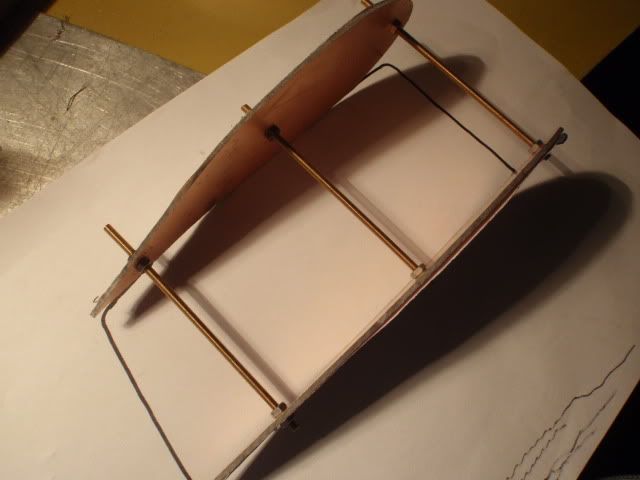

Made a start with the lockingmechanism for the upper deck, used some pins at the rear and the front to secure it into it's right position.

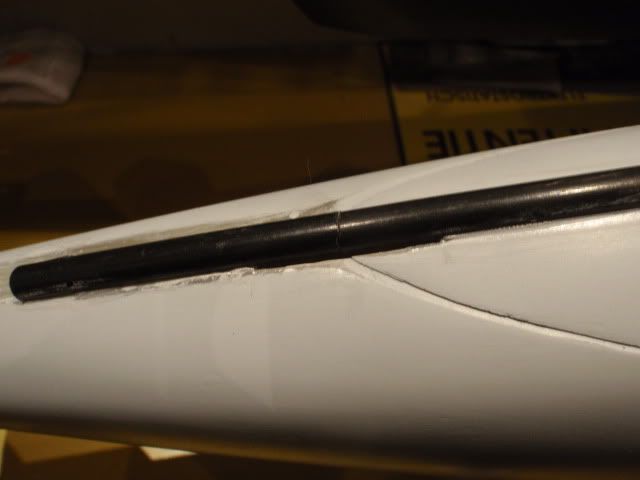

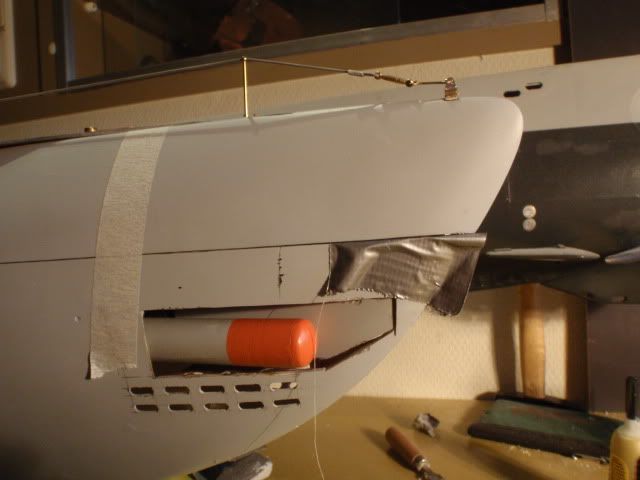

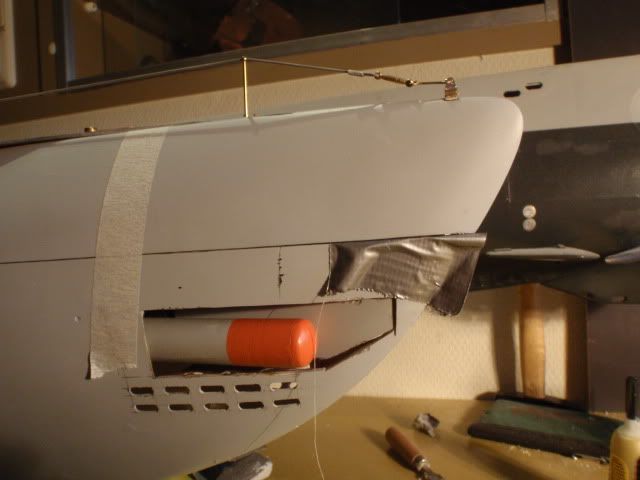

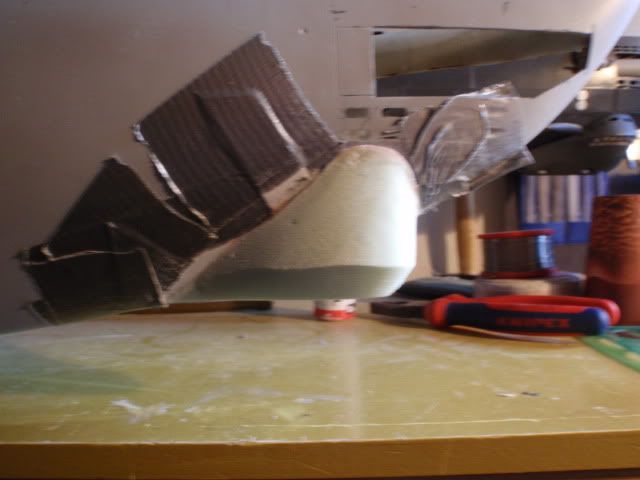

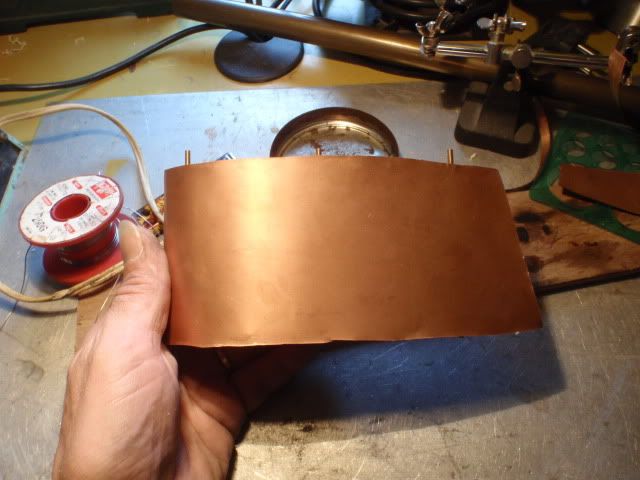

Since the type XVIIb has a exhaust i wanted to use that for hiding the rear pin, used the tube from this cat toy because it had the right size.

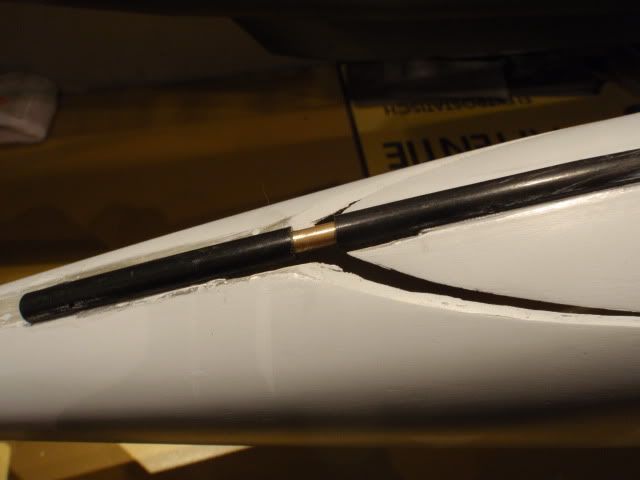

Cutted it to the needed size and left some ends intact, cutted the slits into the deck and the hull and glued it together.

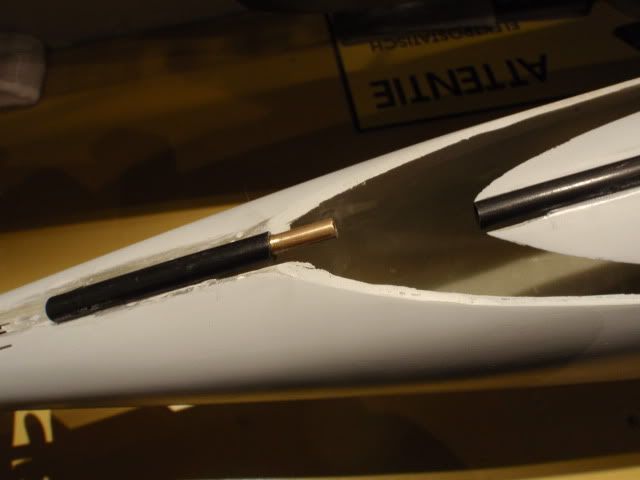

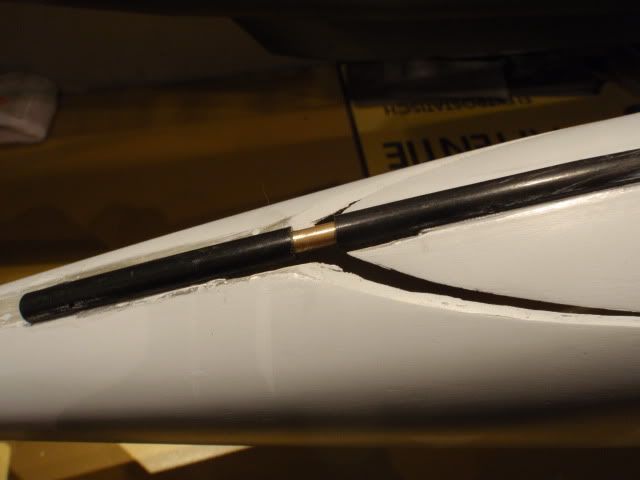

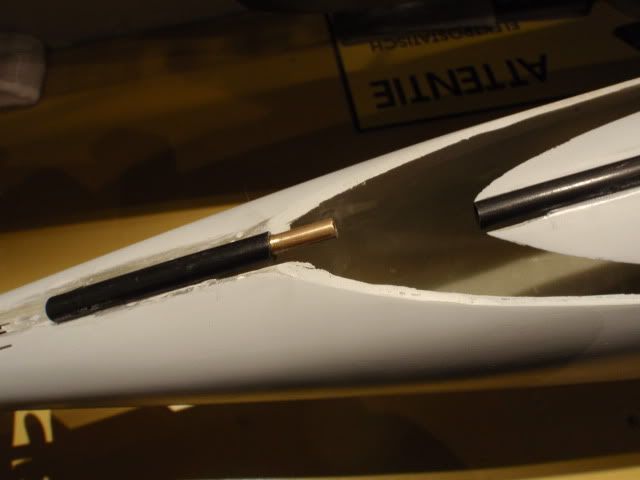

Once dry it's possible to slide the upperdeck on or off the copper tube placed inside the plastick tube.

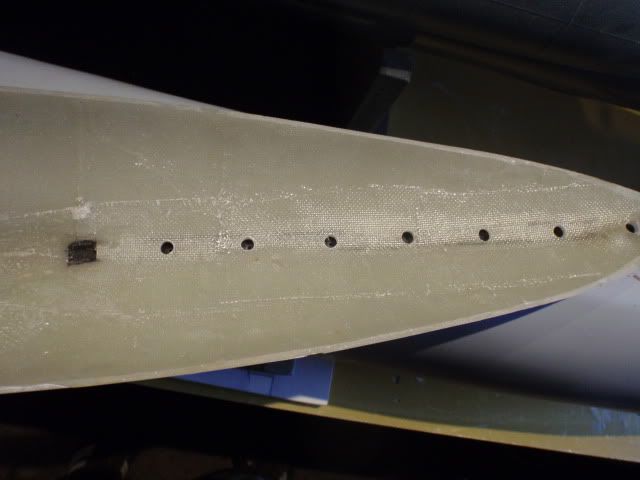

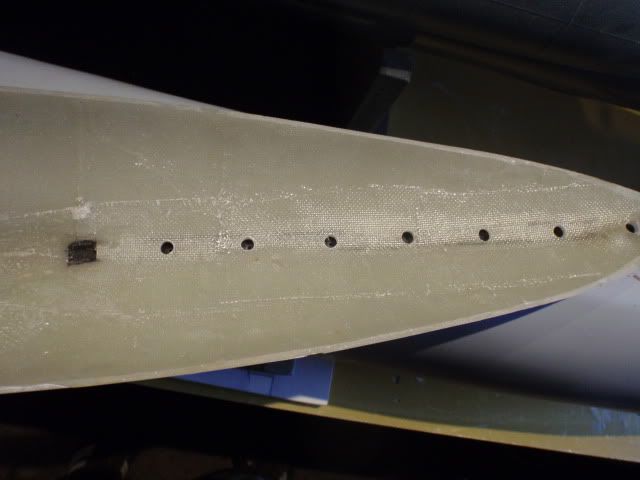

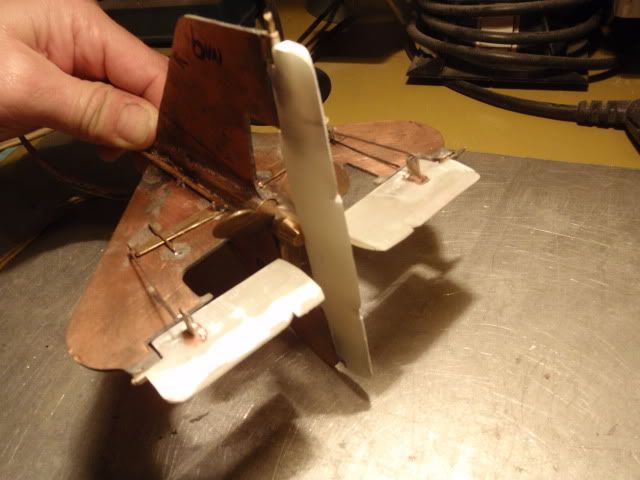

To prefent getting airbubbles trapped inside the hollow exhausttube i drilled it open underneath the upperdeck and drilled some extra holes inside the tube itself and some bigger one's at the underside of the deck.

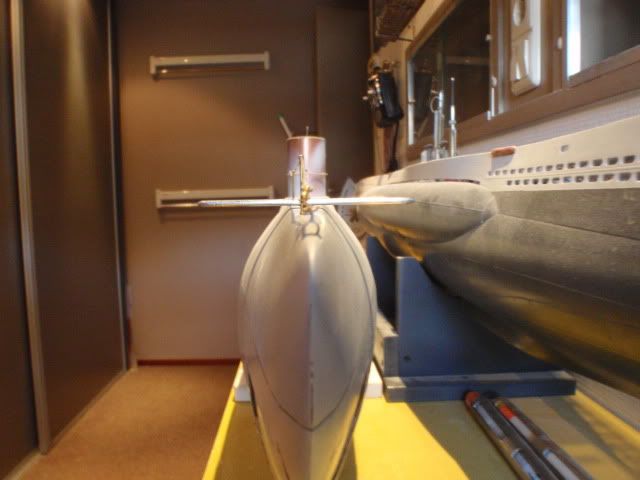

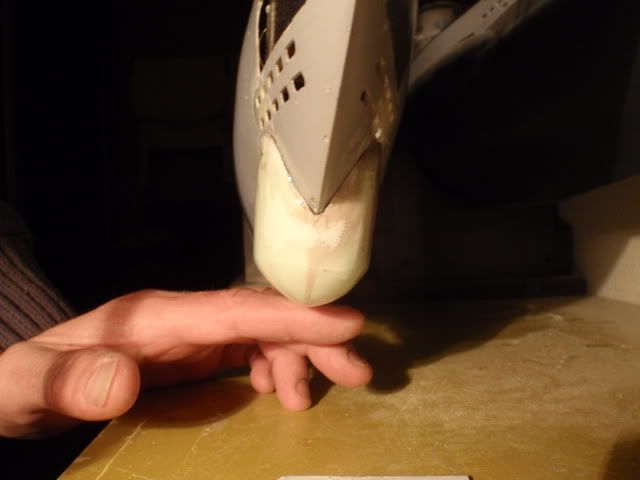

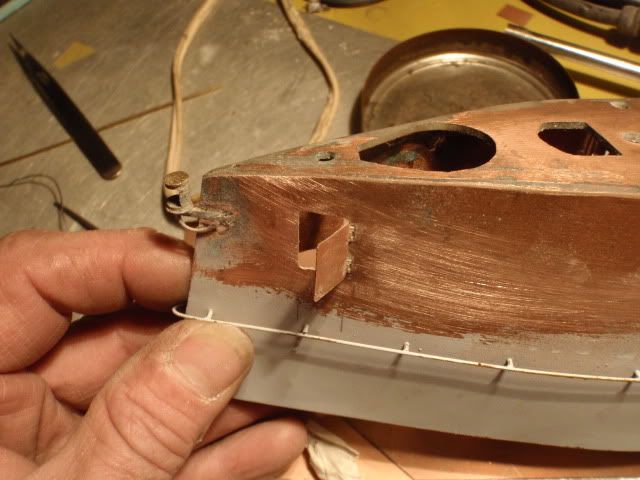

Glued in the front pin and lined up the toppart with tape for letting it dry.

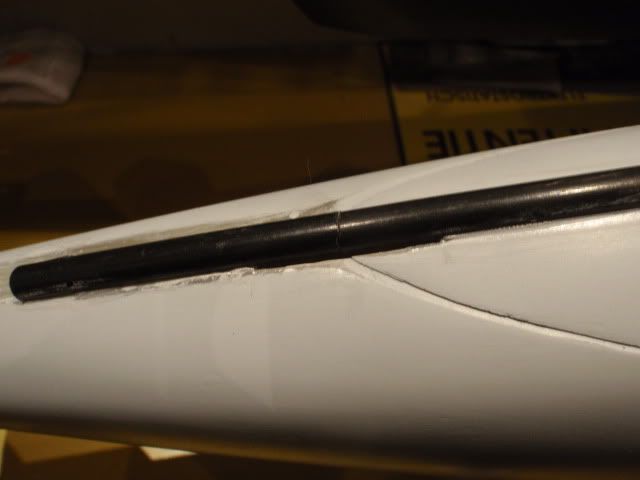

Once dry i have me a pin and a tube glued at the bowpart.

The aim was to get me a centeringpin, so each time you put the upperdeck on the hull part it will be in the same position, adding the lockingmechanism will secure it to the hull.

The lockingmechanism itself is the next part i have to build, it will be located at the biggest front hatch.

Since the type XVIIb has a exhaust i wanted to use that for hiding the rear pin, used the tube from this cat toy because it had the right size.

Cutted it to the needed size and left some ends intact, cutted the slits into the deck and the hull and glued it together.

Once dry it's possible to slide the upperdeck on or off the copper tube placed inside the plastick tube.

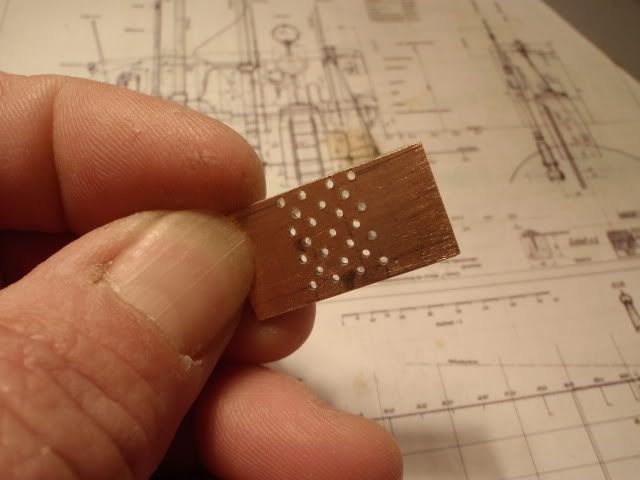

To prefent getting airbubbles trapped inside the hollow exhausttube i drilled it open underneath the upperdeck and drilled some extra holes inside the tube itself and some bigger one's at the underside of the deck.

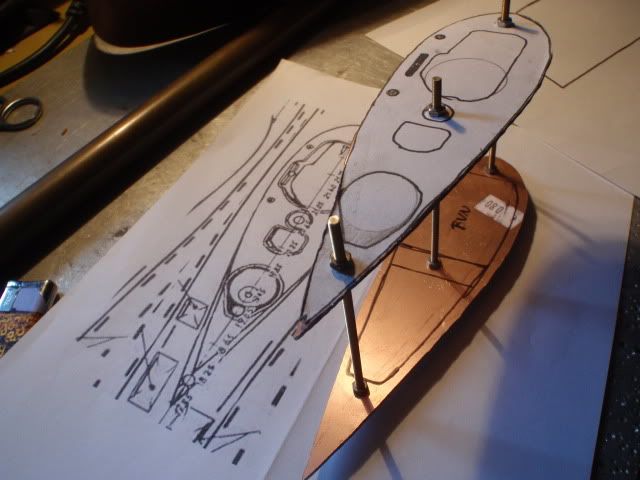

Glued in the front pin and lined up the toppart with tape for letting it dry.

Once dry i have me a pin and a tube glued at the bowpart.

The aim was to get me a centeringpin, so each time you put the upperdeck on the hull part it will be in the same position, adding the lockingmechanism will secure it to the hull.

The lockingmechanism itself is the next part i have to build, it will be located at the biggest front hatch.

Comment