Dsrv-1

Collapse

X

-

I had the honor of meeting Admiral O'Kane at a book signing at Bangor. Great guy. Spent many years working aboard hte Georgia fish and Captain Raaz was quite the character, always walking around with an unlit cigar dangling from his mouth. The ship had just cast off lines and gotten underway for patrol when we received a message that sonar was down. I jumped on a tug and boarded in the Hood Canal. I met the sonar chief, (George Lindell who died early a few years later) and he explained how the system wouldn't communicate with the Central Computer Complex downstairs while they were doing routine PMS. (Planned Maintenance) to ensure the system was running optimally.

The Q-6 sonar system had a number of quirks, (technically referred to as System Anomalies) that IBM could never find the root cause for and we, (TRF Sonar shop) had them memorized. A system communications I/O error could be initiated by leaving any of the three console's CRT test switch in the On position after finishing a console diagnostic. I checked each display console and sure enough, someone had forgotten to switch one of them out of test mode. It was probably covered the first day of console maintenance training.

This would have been unthinkable for the Sonar Chief to tell the CO, so I dismantled one of the lower electronics chassis and pretended to inspect it. Capt Raaz was in and out of sonar every five minutes. "How long is this gonna take?" he asked. My reply was simple and direct - something he was fond of: "If I can't fix it, it ain't broke, but it's going to take longer if you keep interupting me."

A few minutes later, I buttoned everything up and the system came back to life. I explained to him there was a pinched wire that his guys wouldn't have known to look for but I'd seen it once before on another boat. The sonar gang was in stiches when he left the shack and George was very relieved he didn't get relieved.

Capt Raaz made it a point to send the TRF CO a nice letter of commendation for me and I received a welcome cash award for the emergent repair. We laughed about that for years whenever their crew was in refit.

Leave a comment:

-

Love that movie. If the story was real life WTF is that old fart (the character not the RL actor) and his bleep bag Dog doing even on board. He fail promotion review three times and not been moved up or out.? Denzel Washington, his smarts and sense of command floods into the scenes, F****he's the officer that if he ordered us to the bottom to save the world, then to bottom we are going...

Gene Hackman as an actor is one of my favorites too. He is my sister's favorite actor too I learned recently.

I always wondered if the spark for his character in 'Crimson Tide' was based on the Captain Raaz of the USS Georga in the great Documentary 'Submarines: Sharks of Steel' on the Discovery channel (1993).

I remember at a talk at the officer's club at Mare Island, where the Sub Committee was invited to display their submarine models for the sub veterans there. Rear Admiral Richard 'Okane with Alzheimer's disease. & Rear Admiral Jon Barr 1993-1996 SUBCOMPAC were present. He talked about being in Charlie Lockwood's old job & at the presentation. Rear Admiral Barr mentioned Raaz from the documentary and how he made some uncomfortable. That was interesting to hear. Barr didn't elaborate of course. But what a sense of history.

Last edited by Albacore 569; 02-03-2024, 08:40 PM.Leave a comment:

-

Leave a comment:

-

Anyone leaving their dog's ****/**** on my deck plates, action would have been taken. One possibility: Wait for the quarterly PMS cycling of the forward signal ejector -- though only having a three-inch bore, a suitably cut up fido could be made to fit. Filthy animals!

David

Leave a comment:

-

-

-

-

I tell a lie, Carsten Heintze has printed one of these models and looks to have it operational, or well on its way to being so anyway.Leave a comment:

-

Reg. CC Post 14

Thanks for your reply and I understand your reasoning. I did not want to bother you, just thought I would ask. Thanks for sharing your work here.

Leave a comment:

-

There are easier 3D base UUVs models for search and rescue work available, but they would need mechanical/electrical mods to be effective. And a dedicated aircraft (or overnight-cable crate) for worldwide deployment. (I've got a Schilling Titan manip with working onboard cameras in a file I animated for demos someplace.)

Boy I feel like an ass hxxx.... Excuse me David. I thought you did parts and Greg Jein and his gang in California put it together. Wouldn't joining a Studio Union offer you better pay? I can understand why you wouldn't. You love your independence and artistic freedoms too. So would I.

Would a DSRV model scaled up to like 1/12 scale make a good search nd rescue underwater drone at all? With a mechanical arm / lights / camera?

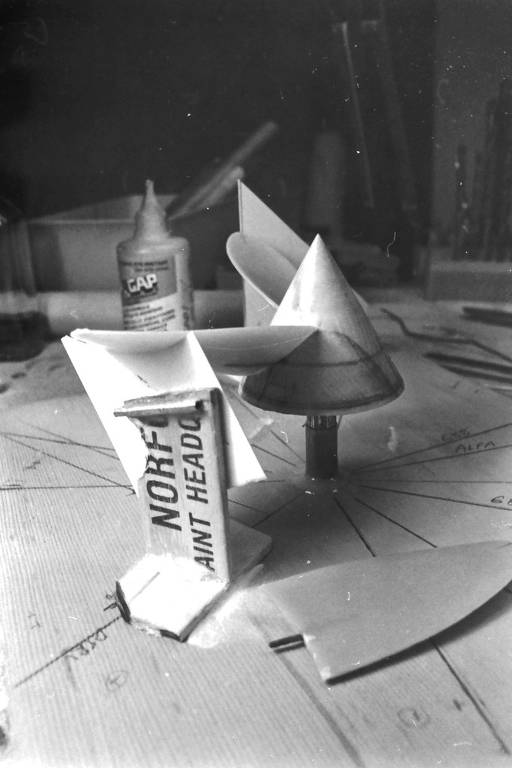

But for the heavy lifting, this model I made (with a few touch-ups needed) years ago ought to be sufficient if 3D printed and a lot of bucks thrown at it for thrusters:

Leave a comment:

-

No. The DSRV is too specialized. Off-shore UUV's are the right robot for such jobs.

Boy I feel like an ass hxxx.... Excuse me David. I thought you did parts and Greg Jein and his gang in California put it together. Wouldn't joining a Studio Union offer you better pay? I can understand why you wouldn't. You love your independence and artistic freedoms too. So would I.

Would a DSRV model scaled up to like 1/12 scale make a good search nd rescue underwater drone at all? With a mechanical arm / lights / camera?

Your assumption, Steve, is basically correct. As to our involvement with TV and movie production, Ellie and I built masters and sub-assemblies for the effects miniature makers -- we were always independent, third-party contractors engaged by guys like Greg Jein, who were employed by a studio/Producer to work a particular production. With the exception of one job, we never left Virginia Beach.

Red October was that rare exception where I was lead on specific vehicle design AND specific sub-assembly fabrication. I provided drawings to the Art Director of the ALFA, LA, and DSRV vehicles. Shortly after that work was submitted Ellie and I were commissioned by Greg (miniatures Lead till things were turned over to ILM -- that's another story!) to do all the propellers, and LA appendages, to varying scales, for Greg's team. Most of our work was retained by the ILM guys after Boss (who employed Greg) got the boot half-way through production.

Here is some of the work we did for The Hunt for Red October:

This is the LA miniature they assembled using castings pulled from tools they made from my appendage masters. The Navy continuity/security guy put the stink-eye on the seven-blade screw I provided. That bump-in the road put Ellie and me into crazy-mode to produce a more 'acceptable' five-bladed wheel to keep the post-production work on schedule. ****!

Ellie and I, even before we hooked up, were anti-Union. I grew up in Michigan and saw what collective bargaining produces; and Ellie suffered attack from picketers when she pushed through their line while working at EB.

We were our own people.

Why seek the level of the most useless guy in the room? That's what Unions and the Guilds breed.

Professionally, it mattered little to us. We got the jobs; we were good enough to secure work from the effects houses whenever the miniature work was overly complex, or the shop personnel were over-extended.

However, CGI changed all that.

David

D&E Miniatures

Leave a comment:

-

Boy I feel like an ass hxxx.... Excuse me David. I thought you did parts and Greg Jein and his gang in California put it together. Wouldn't joining a Studio Union offer you better pay? I can understand why you wouldn't. You love your independence and artistic freedoms too. So would I.

Would a DSRV model scaled up to like 1/12 scale make a good search nd rescue underwater drone at all? With a mechanical arm / lights / camera?Last edited by Albacore 569; 01-29-2024, 06:55 PM.Leave a comment:

-

Hi George,

With respect to your first question, I think you know the answer.

As for the second, it is too cost-prohibitive to make ones-ies and two-sies of parts - especially screws which require expensive engineering resin (up to $90 a bottle) to do it right, --in lieu of metal versions which present challenges of their own in regards to the time and cost to manufacture by hand, Add the time to set the 3D files for idiot-proof slicing, (I've printed four sails with multiple revisions @ 18 hours a shot alone this week, just to optimize them for printing without noticeable banding and minimal polishing --except the flat upper and lower flat ends which need to be planed before adding a customized sail cap) machine time, and . . . you get the idea.

If you can't find someone to make one for you, there are a number of sites that offer 3D printed, 3-bladed aircraft propellers that might work with some sanding to get the desired shape. Shapeways is one example. (I buy 1/72 naval figures from them to save time.) TurboSquid is another recommended site and often offers scaling.

Time is the one commodity none of us will ever have a surplus of. Labor is the most time-consuming facet of any submarine build and I am swamped with work. I'm truly sorry.

I'm not a hobbyist and now that I'm finally retired, design submarines full-time while (resin) printing nearly 24/7 to remove any bugs discovered during the R&D phase. Anything printed that meets my strict requirements, (one of my skill sets involves years of high-reliability, aerospace-level QA, so being a stickler for detail comes naturally) is the result of many, many failures on my part. Prototyping can be a log process and the interior of the hulls which nobody sees are a big part of achieveing dimensional accuracy without warping. I shoot for hull sections with < .1mm tolerances to minimize bonding and sanding their respective joints. Yeah, I'm anal-retentive - which is better than anal-receptive. Perfection is the goal, but reality that meets the requirments is the tradeoff. (Just like the ribs I smoke and cook all day on my BBQ. My first forays would gag a maggot.)

More transparency: While any hull I design can be adapted for RC use, that has never been my intended market for multiple reasons - chiefly: There is no need for more RC-related vendors - those that have survived have it rough enough as it is. My target market consists of demanding, well-heeled, private collectors within the submarine community. No fish - no boat. These folks know when a detail is off and will pay for accuracy. (They'll also crucify you in a heartbeat if something is wrong.) Making big money is also not my goal, but my time and experience are worth something.

I only build in 1/72 scale to be able to display that level of detail, (ie: bolt holes around covers, line locker hinges, and rotated cleats with securing bolts.)

Any potential competition are companies who create display hulls out of kiln-dried mahogany, with minimal detail, and sometimes 3D-printed masts and antennas. For $90+ an inch, they'll add a couple of DSRV landing stripes, some circular scribing for hatches and a recessed line for a safety track. (Not all safety tracks are recessed.) The appendages are usually thicker for strength and don't operate. For for a "realistic" base, some offer rows of "railroad ties", --some of which don't contact the hull. (I create keel blocks and try to get the most accurate placement from drydocking plans.)

Before I close my long-winded post, I would be remiss if I did not extend my gratitude to those on this site who take the time to teach the fundamentals, (especially weathering) that never fail to leave me in awe. Most of the sites I learn and take inspiration from are plastic model or 3D printing-related, but there are gems here that really stand out.

It's called work for a reason. After seventeen years of modeling, I'm still learning new tricks. Failures are the yardsticks of growth when they impart lessons learned.

Out of the formal classes I've taught at a basic level, maybe 5% stick with it afterwards, and that's being very generous. In the school, (DAVE School, Universal Orlando) where I first learned professional modeling, the attrition rate was 50% after two-weeks, and half of the rest by the 30-day point - and these were students paying $30 grand for the chance to learn from industry professionals. (My job paid for it so I made sure they got their money's worth). Most of the students were too young to know how lucky they were and those that dropped were put off by how much efffort was required. There is no Staples EASY button to instantly confer proficiency to generate paying cutomers through one's work, but it sure is satisfying when one gets to that level of interest. Those who can relate, know.

CCLeave a comment:

Leave a comment: