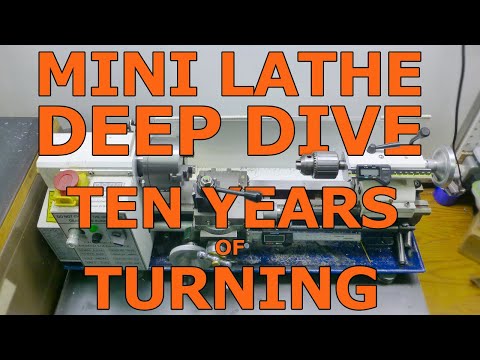

This video came across my Youtube feed. I thought it was interesting. It was well done and had some good ideas. Although if you are really into customization of your lathe, the lathe can be a full project just like building a model.

Lathes

Collapse

X

-

David,

And thanks, Rob, for helping to keep these Black Arts alive -- few of which solely rely on electrical energy to be accomplished -- in this age of all thing's electron dependent (the 'grid', our most vulnerable infrastructure!).

Read, One Second After.

David

You are welcome David. I for one really enjoy watching the process of mold making that these guys use, and then to see how it relates to exactly what you are doing for sure.

For those that watched the entire video, I did notice one thing about the lathe operation. When they were turning the hub, it seemed to me (based on my woodworking experience) the hub was turning on the chuck in the wrong direction to the cutting tool!? There might have been a reason for it, but it seems to me it needed to be turning the other direction, but again because of the cutting tool holder design you have the option of either direction with that metal lathe!?

Rob

"Firemen can stand the heat."Last edited by rwtdiver; 12-07-2023, 02:22 AM.Leave a comment:

-

And thanks, Rob, for helping to keep these Black Arts alive -- few of which solely rely on electrical energy to be accomplished -- in this age of all thing's electron dependent (the 'grid', our most vulnerable infrastructure!).

Read, One Second After.

David

Leave a comment:

-

David,

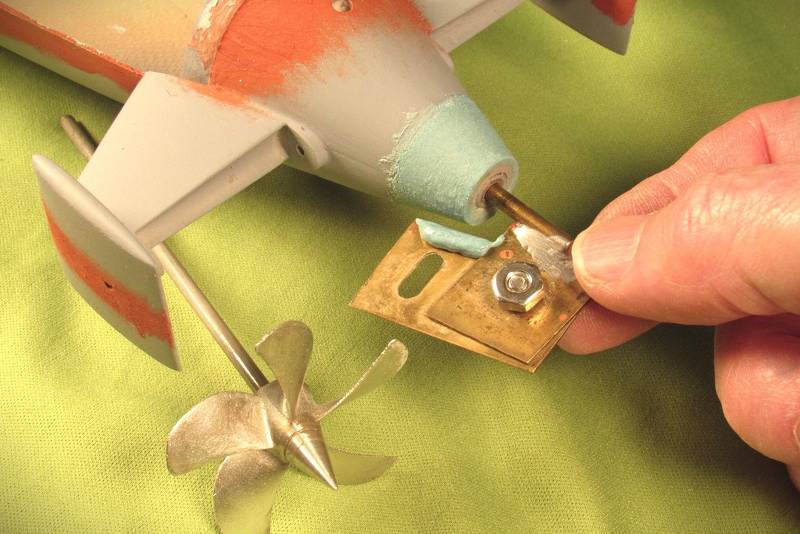

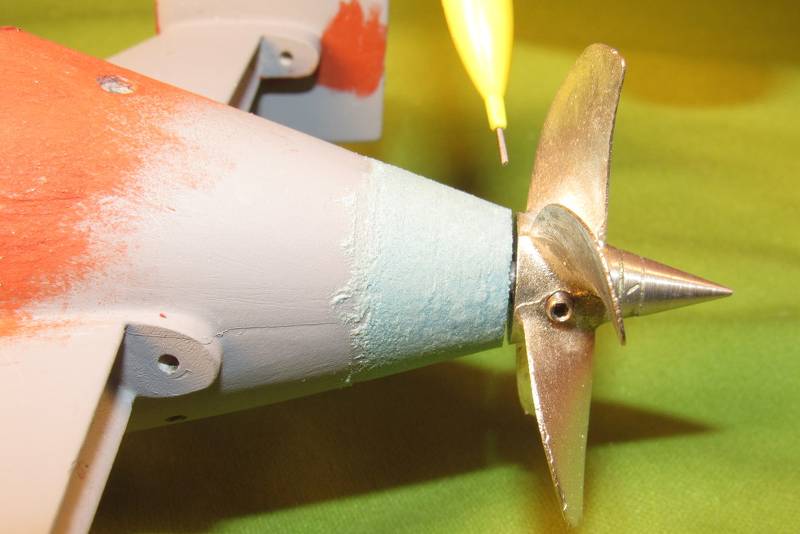

The similarity is sure obvious, only difference is the size of the project. The metal work you do using molds. The old school methods are alive and well.

Thank you for the photos!

Rob

"Firemen can stand the heat."Leave a comment:

-

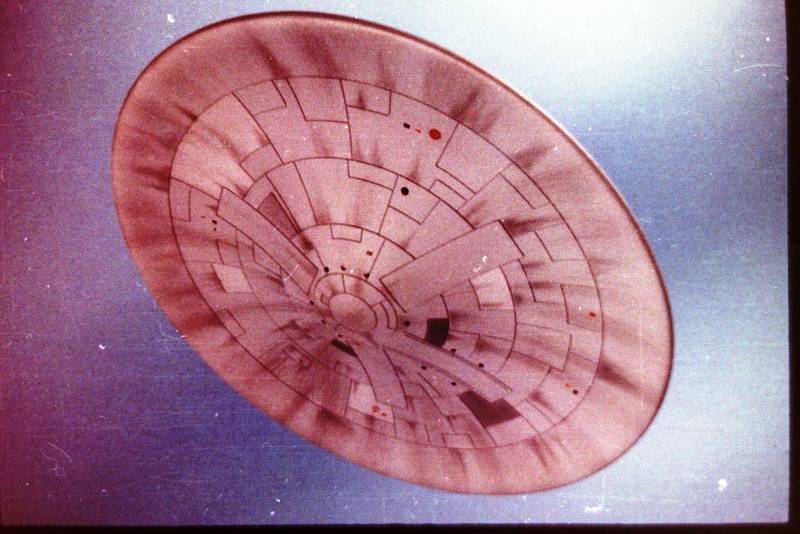

I can almost smell the oil-rich greensand!Interesting lathe work!

Biggest Gear of Manufacturing The Largest Industrial Gear for Rolling Mill Plant HugeGear Production - YouTube

Rob

"Firemen can stand the heat."

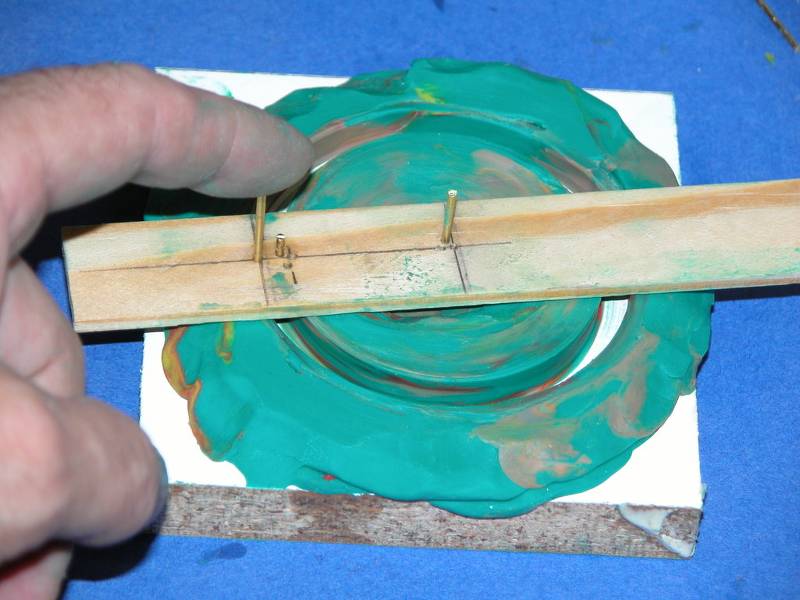

And no better example of radial screeding have I seen on YouTube!

Here are some of our efforts employing that fabrication technique:

Leave a comment:

-

Interesting lathe work!

Biggest Gear of Manufacturing The Largest Industrial Gear for Rolling Mill Plant HugeGear Production - YouTube

Rob

"Firemen can stand the heat."Leave a comment:

-

-

Leave a comment:

-

Vis-a-vis the reclining drill press approach, surely you have a chart listing the correct SLA amp-hour rating of battery/tool rest to be used with all common drill press sizes? Also, the whimsical use of French is just to get your blood pumping this morning.

Leave a comment:

-

I admit my statement over simplified the entire process involved with 3D printing and it is not easy, especially for those just getting into it. Everything you mentioned, absolutely true about the entire process from learning it to printing the part. And I am not bashing 3D printing, never intend to. YES, it is another tool in our toolbox. I love adding tools to the toolbox! I've taken things David has showed us in his 'today' thread and run with it. Things I have never done before, and now it is in my toolbox, and improving it. He also got me doing scribing with my Marlin even before I joined this forum. Another tool process learned, yeah! Added tooling for my lathe which I am learning to use. Some of these processes take time. You see me building a party boat in the 'Target' section. That boat was designed with paper and pencil from pictures. A lot of things I make are made from my mind, not put on paper. The next party boat I will be using a 2D CAD program (and paper & pencil), which I am learning now, to design the frames. CAD, added to the toolbox. At the same time I installed Fusion 360 so that I can familiarize myself with the program as, I know myself, it will take me a while to be proficient with this program. Sometime in the future, I will be asking on the forum suggestions for a 3D printer. Any printing that I do will be for small size parts, no plans to print an entire boat from stl files. Start small and work your way up to bigger things? I can foresee parts for my party boats that can be 3D printed. I'd say I am rather good at scratch building, something that I am very comfortable with. The 3D printing world not so at this time, but more so in the future. I like technology and advancement. I'll get there, slowly, and eventually.Leave a comment:

-

-

Disagreed...I like the idea of your method better! Casting. And using the tools I have. My preferred method being old school. Doing it with my hands. I'm with you!

Not so much leaving it to a computer, sending it to a printer, walking away and it's done. Yes there might be some talent that way but less satisfaction. Better building it with your own two hands.

Put your money where your mouth is.

You all think it's just that. Try 3D Modeling it first. If you can get past that you have more skills than just your hands. Modeling the subject on 3D software is no easy feat, or y'all would be doing it and not whining. I would say it's on par with you wood whittlers out there.

That's JUST the start there bucko......

NOW choose a printer.

Choose the right material.

Now work out the tolerancing.

Did the supports work out? Is it orientated properly?

Let's discuss infill, shell, layer thickness etc.

Now spend hours to get the first print to stick right.

Now get it to complete.

Now finish the striations...

Yeah, 3D printing is so F#¢%ing easy. We should just give up and go play with stone hammers to prove our craftsmanship.

Just because you both don't understand it, or choose not to, doesn't make it any less valuable or easier.

It's a friggen tool in an arsenal. Like a hammer. like the lathe, like the exacto. Each with it's own merit.

I do one off's and rapid prototyping, plugs and molds are meaningless to me. But I got it easy, right?

No dude, it's not easy, and it IS just as satisfying if not more so, because I OUTSMARTED HARDWARE and even a few millennials at their own game.

I bet these were the same arguments Dave heard when he went from stone knives to the exacto knife.

It's a personal choice YOU are making, NOT an indication of skill level or satisfaction.

LET IT GO.Last edited by QuarterMaster; 12-04-2023, 06:26 PM.Leave a comment:

-

OK now, back to the topic at hand................... Lathes.

I'd say stop showing neat things we can add to our toolbox, but that is a good thing to see!!!Leave a comment:

-

Get a long piece of extruded aluminum L channel and dress up that edge -- now you can use that T-square. You PITA! Groton. Can't wait.

DavidLeave a comment:

Leave a comment: