Building the french suffren sna

Collapse

X

-

-

Good News. AnyCubic is sending me a free new replacement LCD screen.

[/QUOTE]

Still awaiting Any Cubic LCD screen from China. It is in customs in Los Angeles. Grrrrr. Been so damn frustrating with this printer the last 5 months. When it does print, the results have been amazing. I am going to print this sub if it kills me...Once the new LCD screen is installed any cubic (who has been standing by their product and this customer having sent new parts to me free), and my community help thinks it should all work as designed finally. I think the printer was damaged receiving from Amazon.

In meantime, someone photographed and posted a series of photos at Toulon of an operation of what appears to be an attachment or detachment of Duguay-Trouin

(second Suffern class boat) towed array. Cable boat and divers zodiac on portside correlates with the subs towed array location also.

The images posted did not describe what may have been a happening in the photos, this has been my interpretation.

Last edited by Albacore 569; 08-17-2025, 03:19 AM.Comment

-

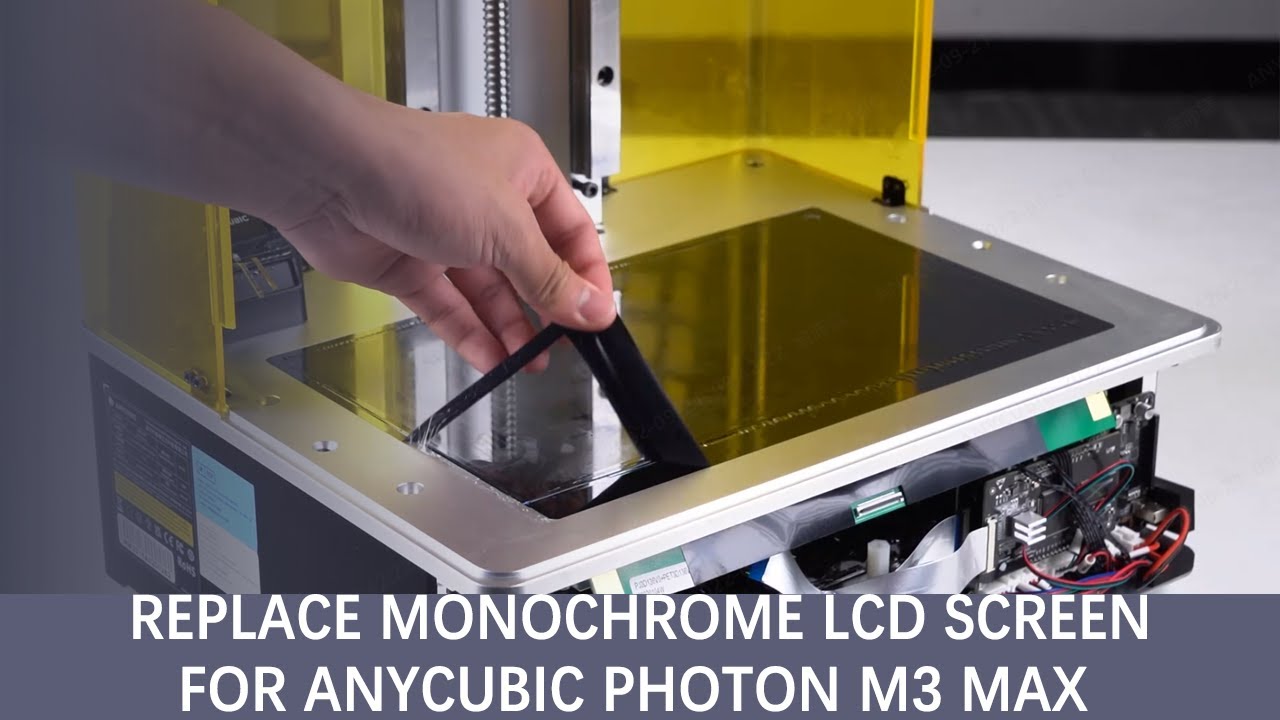

My replacement LCD part from Hong Kong for my Any Cubic printer after a month waiting finally arrived today after several attempts. Any cubic sent replacement free. Several packages sent by them seemed to get lost damaged or stolen? Now after my shop been at a standstill, I will take my time replacing the screen tomorrow and hopefully all my printing issues will be solved.

I need to get this Sub built!

I think my original LCD screen was damaged originally & never worked right to begin with. Any cubic covered for it. Trumpp tax Tariffs didn't affect it since it was $220.00 normally, and under the $800.00 tariff threshold but that all changes this Friday. Are we having fun yet?

Last edited by Albacore 569; 08-28-2025, 03:47 PM.Comment

-

Installed carefully LCD screen yesterday, hours after arrival. A second free LCD screen was just delivered from China too. Aire and spare. lol Leveled plate and will test screen and record for records. Hope to commence printing asap. Hopefully success.Comment

-

Installed new LCD screen. Exposure tests successful. Will commence printing parts again hopefully now. Too hot to print now in garage but will do a small part with a shorter print time in the morning when its cooler (96F today) and see what happens. Photo below shows a sheet of blank white paper illuminated from below with UV light.

Last edited by Albacore 569; 08-31-2025, 10:05 PM.Comment

-

Success after many starts and stops over 5 months. This stern section came out perfect today. I guess this is how it's supposed to work. lol Immediately starting next part now.

Comment

-

Today's part is the Suffren sail in 1/64.

I am not using the Auto resin feed for now. Buildng my trust back with this machine and my general nervous attitude about anything digital. I love digital, but digital doesn't like me.

But when it works...Behold! The Printers larger size is now paying off. Suffern's sail (fin) in one single unit.

Still wet from Isopropyl Alcohol and water soap gentle wash. When the sun comes up this morning, then it's time for its UV sun bath.

I think I will do the pump Jet shroud next

Thank you Randy Sanders, your drafting skills is really shining now well deserved.Last edited by Albacore 569; 09-03-2025, 06:53 AM.😀 1Comment

-

Bow section. Largest part on project. Fail but is salvageable (a Battleship West Virginia Pearl Harbor salvage hull patch made of baking soda, CA super glue and bondo sanding would work). But since the problem is identified, best to print all new part so the hull materials are all uniform in the hulls future lifetime expansion contraction rates).

Fail due to too high ambient temperature in printing area (too damn hot in garage..lol). Will print smaller parts and wait for cooler temps. Confident it will work then. I could wait and print in middle of the night, but since the bow print takes 28 hours 1 minute, I don't think so.. Even the flawed part is rather beautiful. Sharing so you learn from my mistakes. Learning with you.

Where is that Star Trek TNG food replicator? "Earl gray hot". or Klingon Bregit Lung in Grapok sauce...lol.

Qapla! (Klingon for good luck (success) but sounds like Ker plop! lol

Last edited by Albacore 569; 09-04-2025, 02:00 PM.Comment

-

Parts finally begins to accumulate.

Left to right, the stern for stern planes and pump jet. Suffren sail sanded primed, and masts made months ago added for trial fit. All set. Row of small parts. 4 stern planes, two new bow planes, and two pairs of bow plane covers. Pump jet propulsor painted a Rustolrum satin finish 'Champagne' color. The print was sanded lightly, balanced (if any) rattle can painted with a gloss black and several days later the champagne coat.

Rattle cans colors have a wider variety if they are available locally. These paints are more durable for a operating model.

Not sure if the French propulsor is a bronze material color or the RL propulsor might actually use carbon composite blades (gloss black?)

I might lower that prominent satellite link antenna aft a bit. Attempting second Bow hull part print today. Temperature expected t be a bit milder a will open garage an turn on fans to moderate temps.

The French seem to reverse the cord on their masts. Using the same aluminum foil shaped tubing, but the trailing edge on these boats points forward. Interesting. I guess at model regattas I'll be destined to spend time explaining to knit pickers it's not a mistake. lol.Last edited by Albacore 569; 09-05-2025, 11:02 AM.Comment

-

Printer working nonstop. I might have all parts printed next week. Exciting recent part printed is the pump jet shroud. The exterior of shroud is as scale as we can deduce, but I am digressing from scale only in one new non scale (best we know..lol) feature making the pump jet thrust vectoring.

The design in physical form works perfectly. The propulsor blades slips inside easily and slides into place with perfect tight clearances for rotation.

I expect the French use a pre swirl pump jet like every other Navys using fixed stators forward. But in order to make a swiveling thrust vectoring pump jet here. I must compromise scale by making the pump jet a post swirl (stators aft of propulsor. It also acts as a passive rudder too. I expect it will transform the boat into a highly maneuverable model.

It even affords me the option of making the x stern planes operate in up and down force only, but it will have a mixer so rudder will be tied to the shroud in this experiment.

Port turn

Starboard turn

Credit goes to Randy Sanders. I came up with the idea, and drew up sketches, but Randy interpreted my sketches and made it work mechanically along with the rest of the model. A robust smooth system. It should work.Last edited by Albacore 569; 09-11-2025, 12:00 AM.Comment

-

You can see the four holes that will accept epoxy rod stringers to align the future hull sections now printing. These rods will stiffen the hull longitudinally and were planned when the hull sections were drafted.

Printing now is the section hull ring that will be mated to the aft section seen below with the x stern fins. This part labeled 'after fore section'. It will have the ballast tank drain holes and the reactor cooling intake scoops and discharges.

I requested this hull area be in two sections for very easy access to install the X stern rods and clevises prop shaft flexible coupling.

I decided to do this after the crowded X stern internal spaces on the previous Israeli Dolphin 2 model

Realizing my printer across the garage has become my Quonset Point RI facility making the hull sections for assembly at my Electric boat Groton (my old beaten-up work bench)..lol. Proceeding to printing the parts now that go in-between.

Last edited by Albacore 569; 09-07-2025, 11:46 PM.Comment

-

Parts starting to pile up finally after months frustration learning the printer curve. Giving the printer a rest over night to cool down. Proceeding with further parts. Resin likes ideally 20 to 25 C temps.

First two hull sections in sun being cured in UV light after cleaning. Abut 45 minutes to an hour. Top is a front top hull section, Lower is bottom aft hull section. opening at top part for sail part. Holes for bolting the sail in place align perfectly. Forward hatch DSRV mating surface, Safety tracks and scribing all in. After sun bath It is lightly sanded with 320 or 400 sandpaper and blown with air to clear away dust to preserve scribe lines and primer painted.

My liittle 1/32 scale CB pig boat hogging picture as 1/64 scale Suffren parts accumulate. Yes that is a prather thrust bearing for the pumpet on left Merriman sent me 20 years ago, ready for use on the Suffren pump jet. Nothing lost, nothing wasted. Prather parts have been gone for many years. Bless them.

The printer establishes a sort of rhythm in the workshop. As I am retired my submarine hobby gives me a sense of purpose in life as a hobbyist & artist tengineer that I am discovering keeps me going. The printer gives me a robot partner to pace against to keep at it each day & night.Last edited by Albacore 569; 09-10-2025, 01:07 PM.Comment

Comment