I thought some folks might find this a useful tool! The price is right too! https://www.wdivorce66.com/products/...EB8Ky2vC0w7LYU

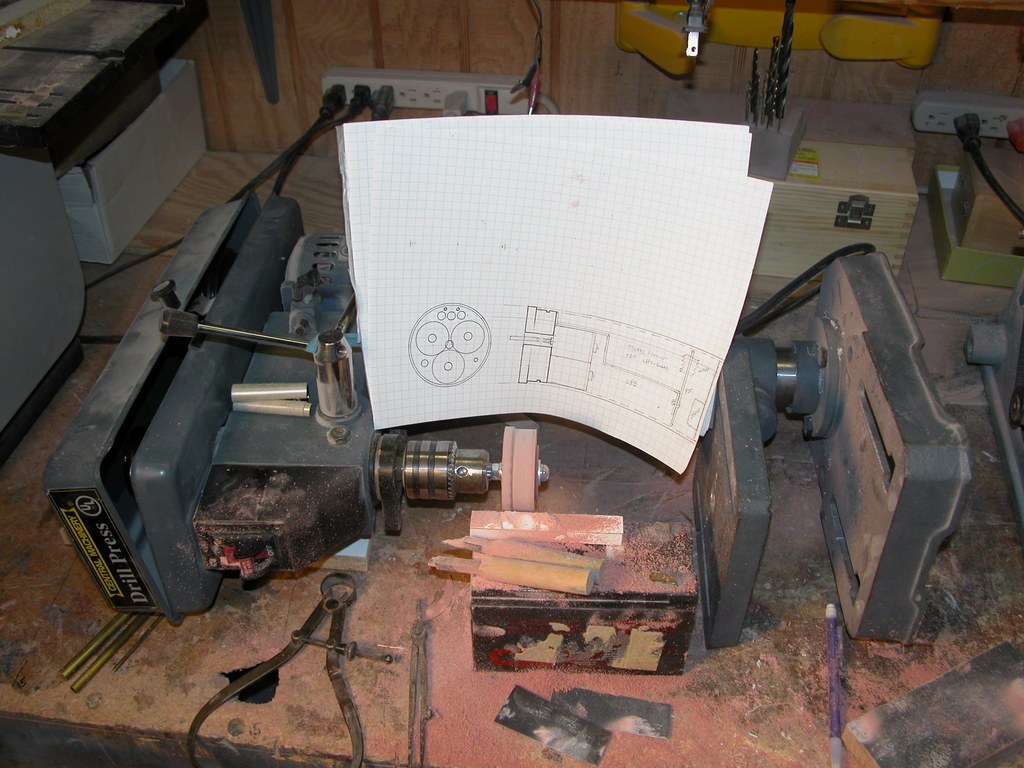

A mini lathe

Collapse

X

-

Thanks, Mike. Very good steer. Just ordered mine.I thought some folks might find this a useful tool! The price is right too! https://www.wdivorce66.com/products/...EB8Ky2vC0w7LYU

DavidWho is John Galt?Comment

-

Comment

-

Slow speed, very soft metal (white-metal, machine brass, etc.), sharp tool, tool rest right up against the work. Band-aids at the ready! When work is completed, inventory fingers. OSHA can kiss my fat, pimple-encrusted, diabetic ass!

DavidWho is John Galt?👍 1Comment

-

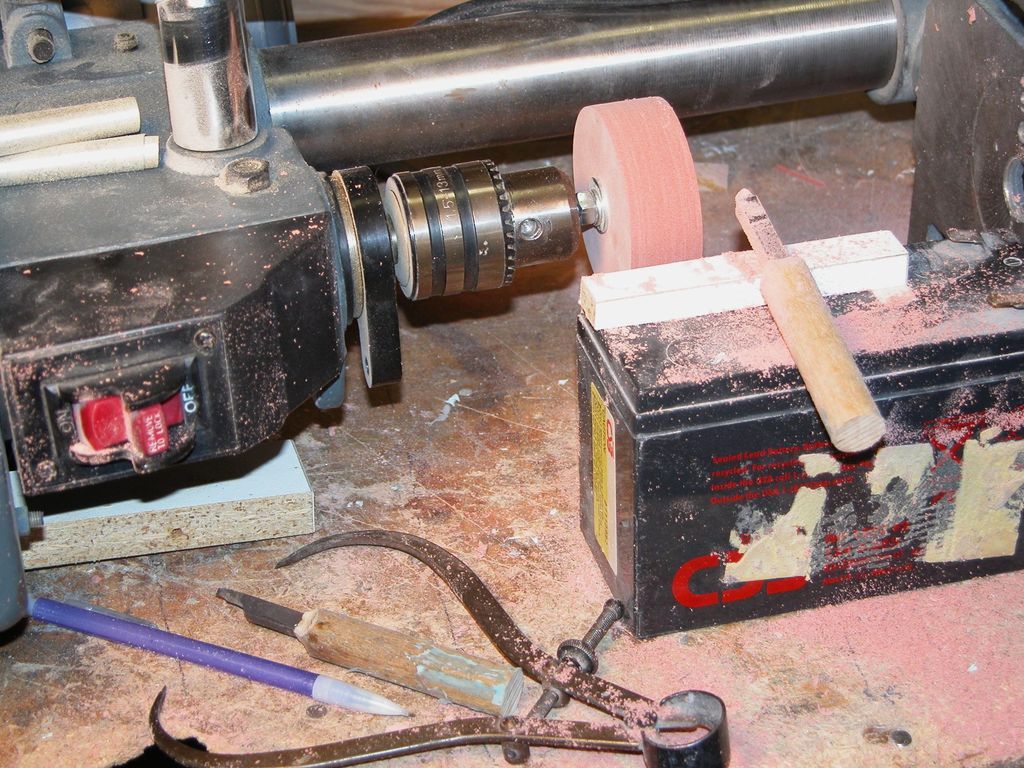

3/8" chuck. Tapered shank. Make sure the bearing is tight.

Dremel AC speed controller. A generic version is also sold by Harbor Freight. And buy the foot-switch -- makes life easier.

DavidWho is John Galt?Comment

-

The spindle the chuck is attached to; or, if you will, the shaft that leads from the motor/belt pulley down to the chuck. The spindle/shaft Is usually supported by one or two roller/ball bearings (or a big Oilite in cheaper units). If, over time, and/or hard use, ware increases the non-interference fit between bearing and spindle/shaft, it will cause the work to vibrate laterally to the tool pressed against the work. Setting up -- under the right conditions of load, feed-speed, tool pressure and angle, and RPM -- a resonate vibration that will evidence on the work as 'wavy' lines. Chattering. Change any one of the variables and you alter the amount of vibration. Tight bearings mitigate all this happy horse-****.

Loose bearings breed vibrations. Duh!

Don't make me come over there!

DavidLast edited by He Who Shall Not Be Named; 12-03-2019, 05:28 AM.Who is John Galt?Comment

-

-

Comment

-

Only the cross feed screw had any appreciable wear, as the machine was primarily used for facing operations. A machine like this will last for generations in a home workshop.Comment

Comment