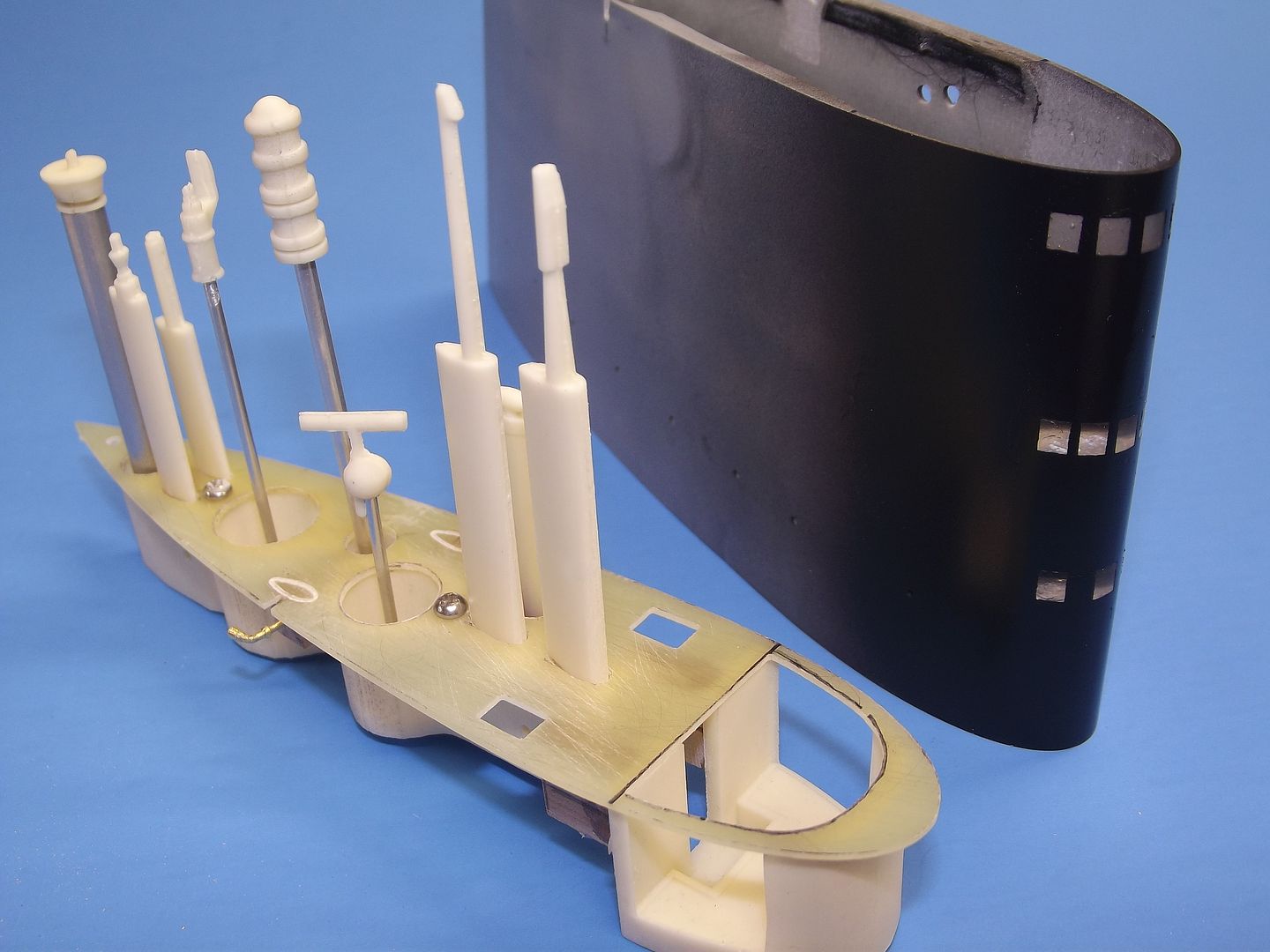

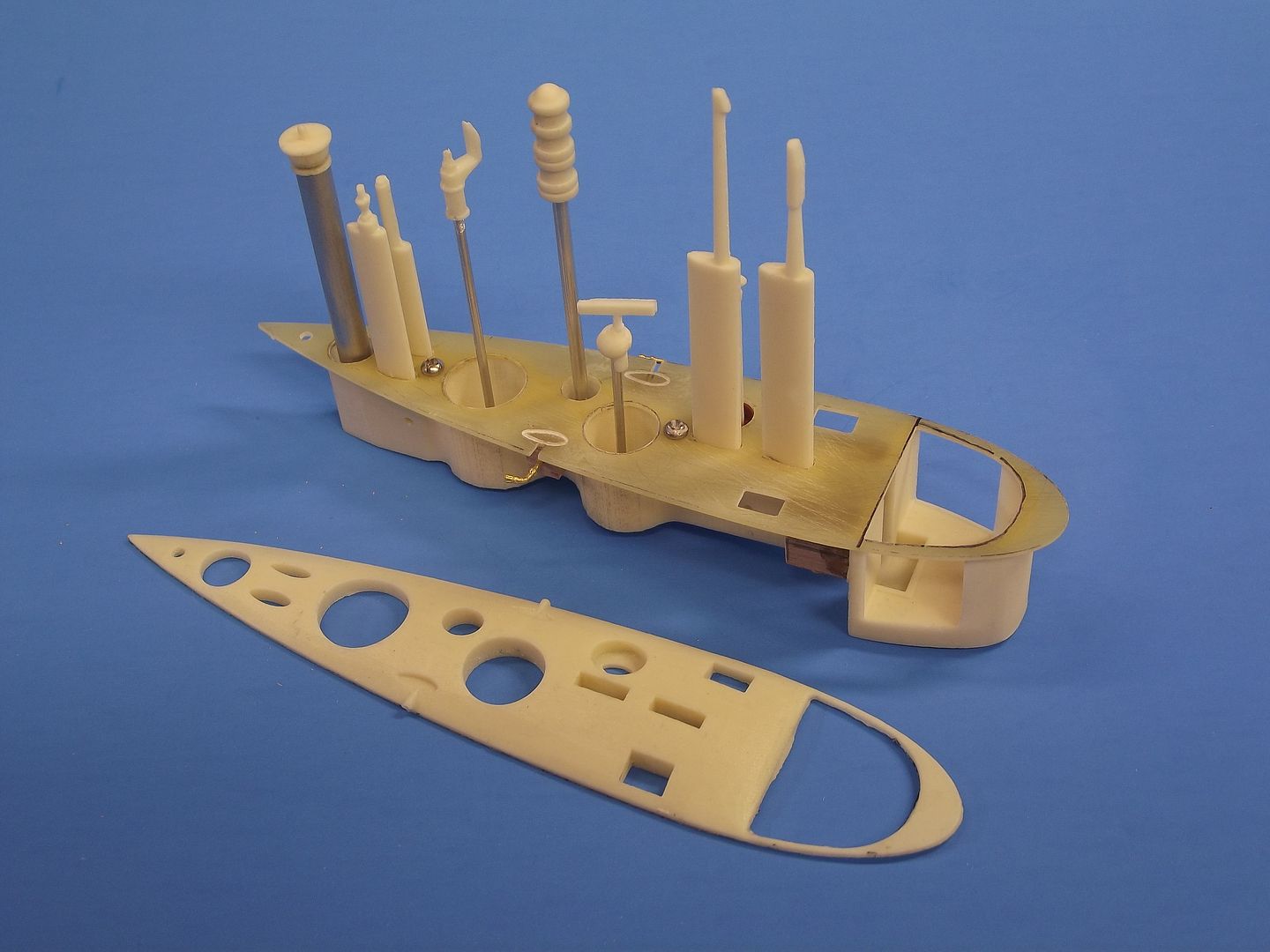

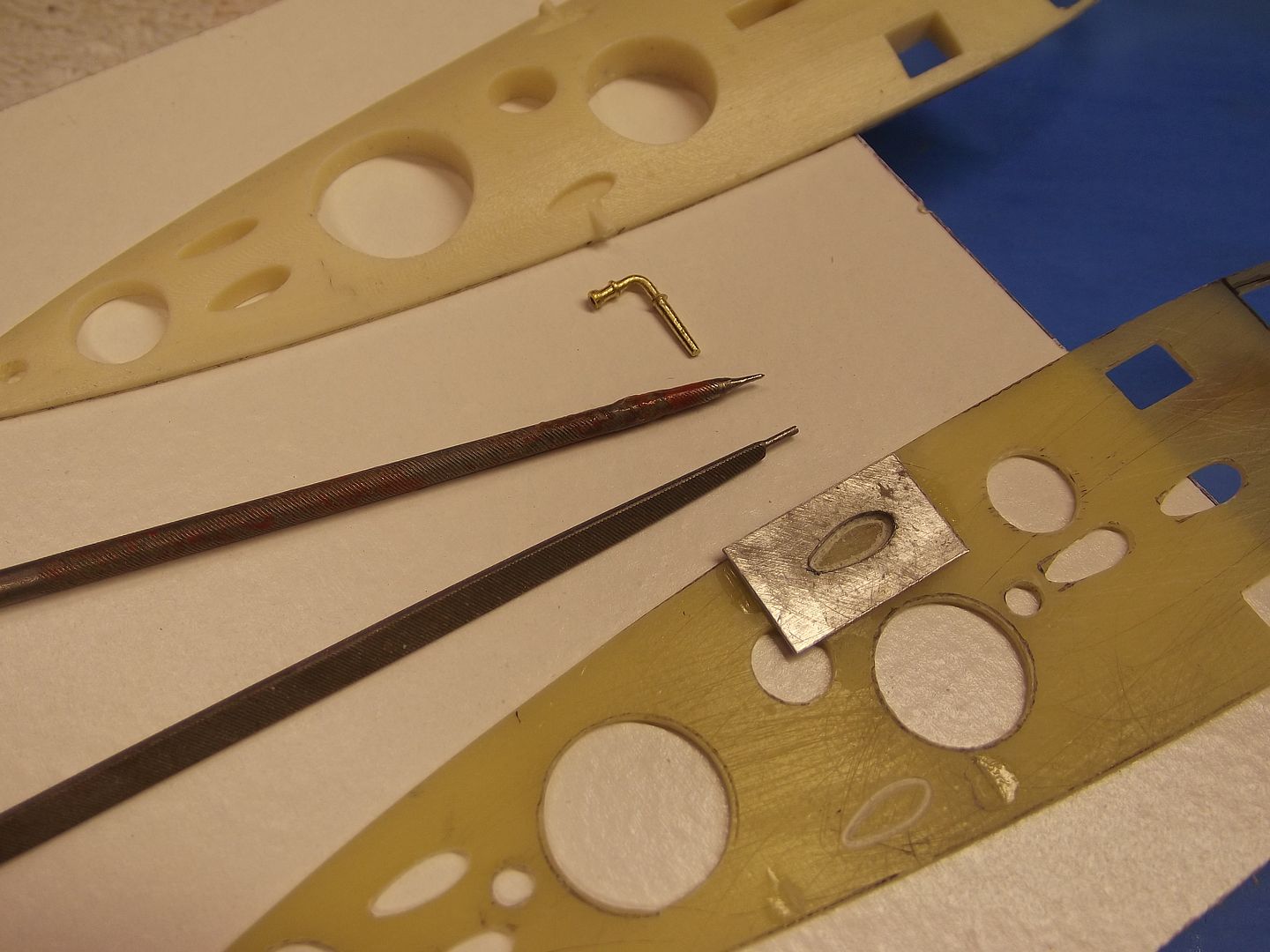

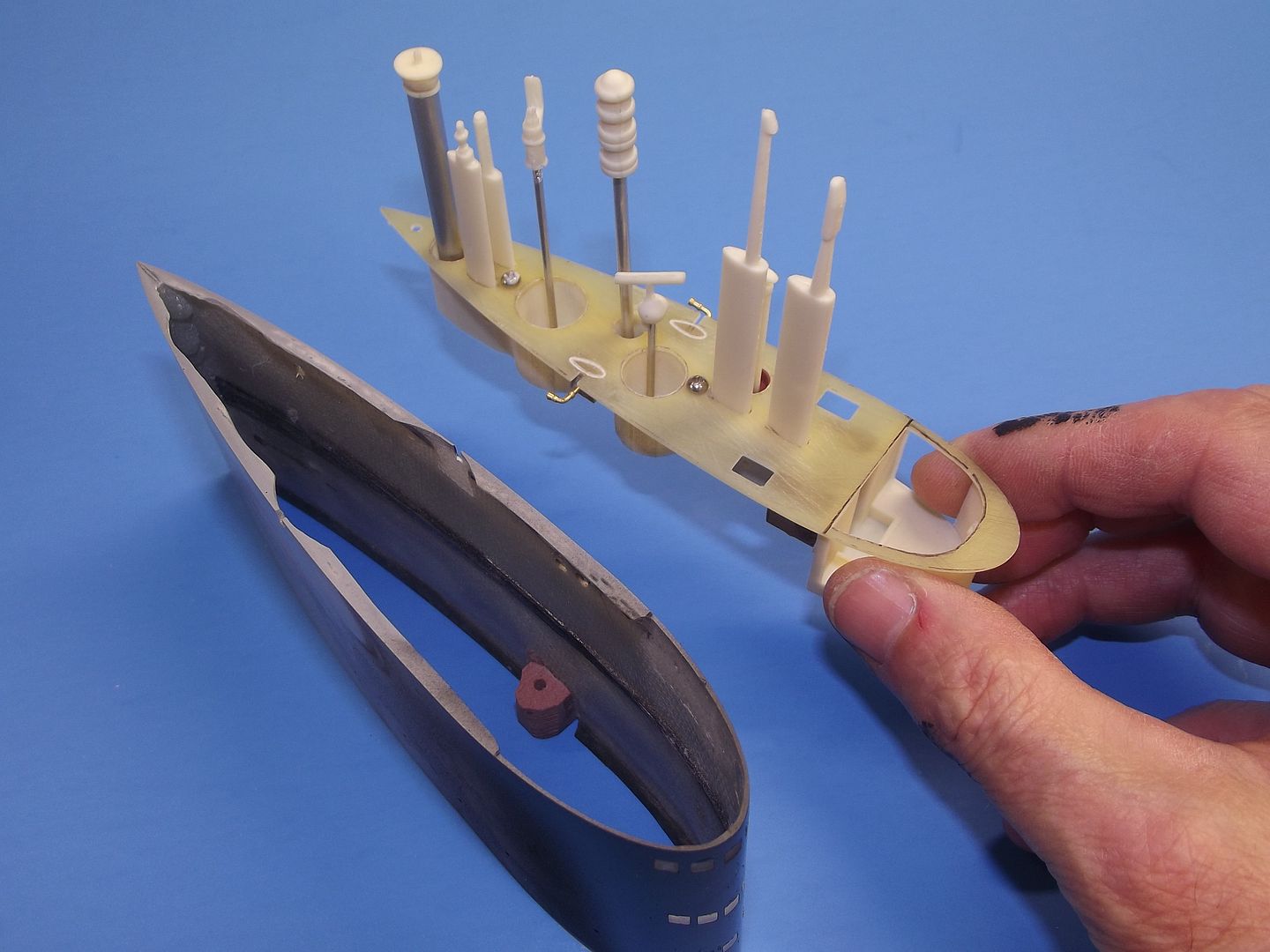

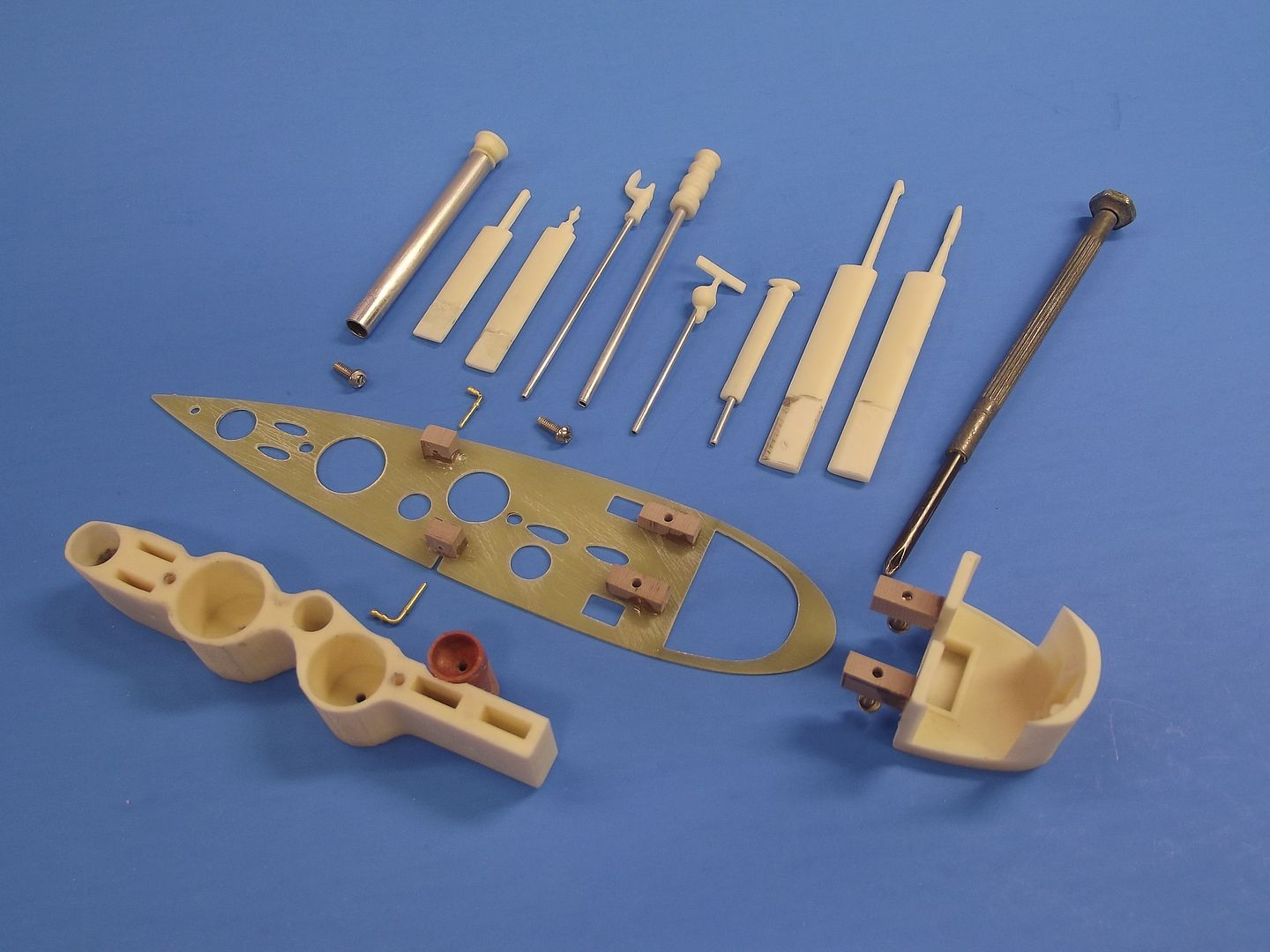

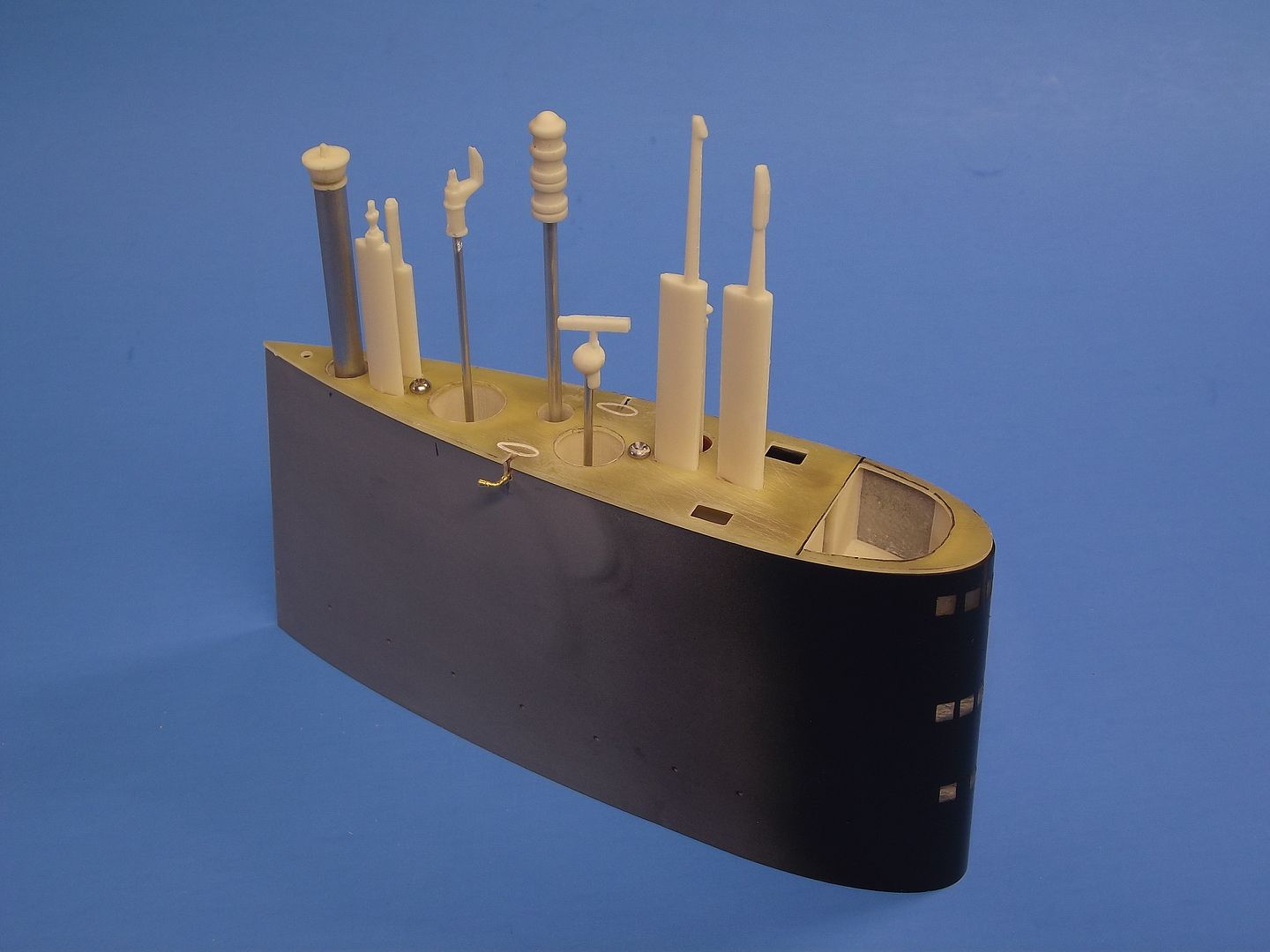

First of all, beautiful model with a beautiful fit and finish. I'm very impressed by how precisely the photo etch fits into its allotted grooves. Actually the PE is magnificent in its own right.

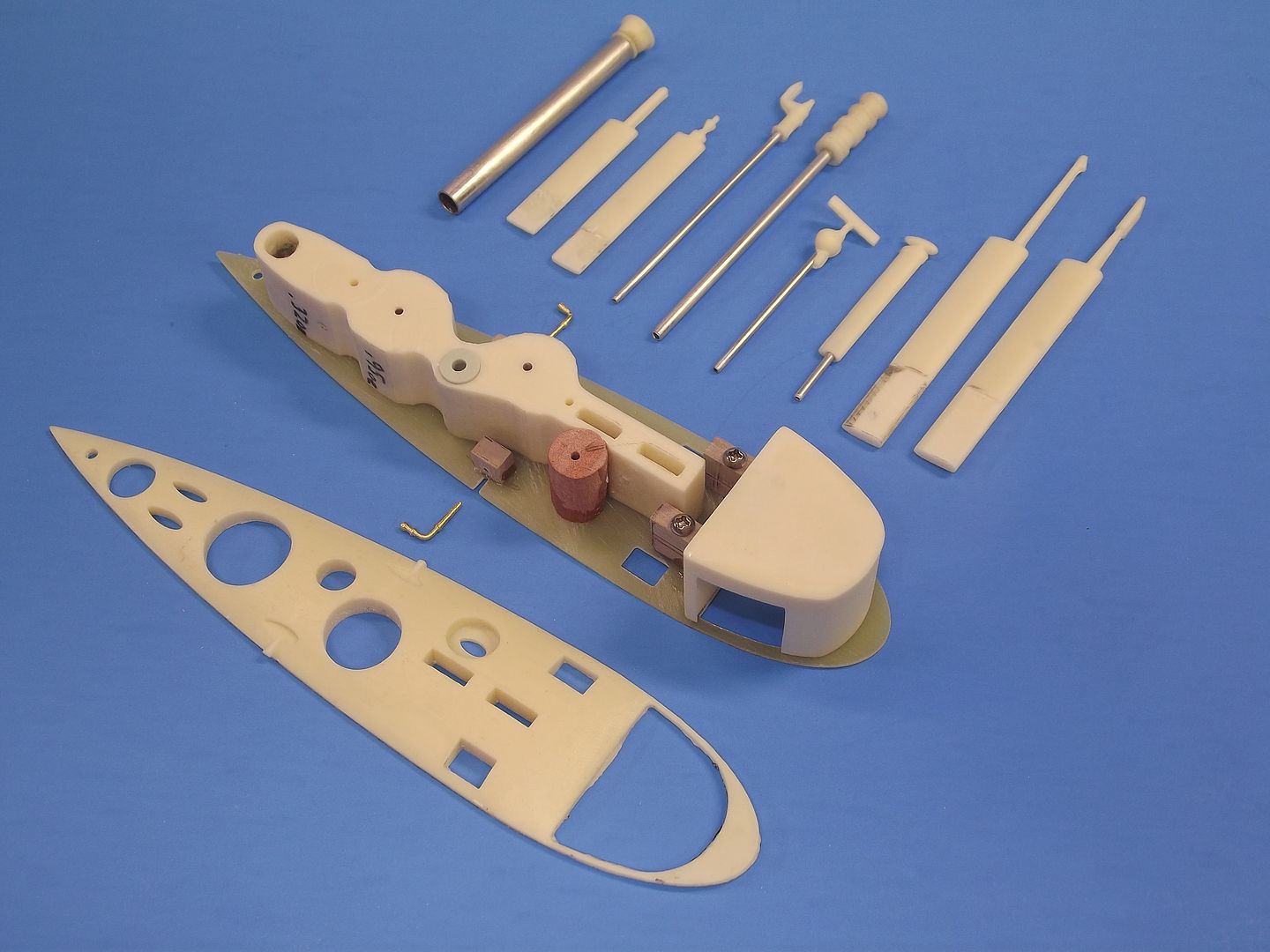

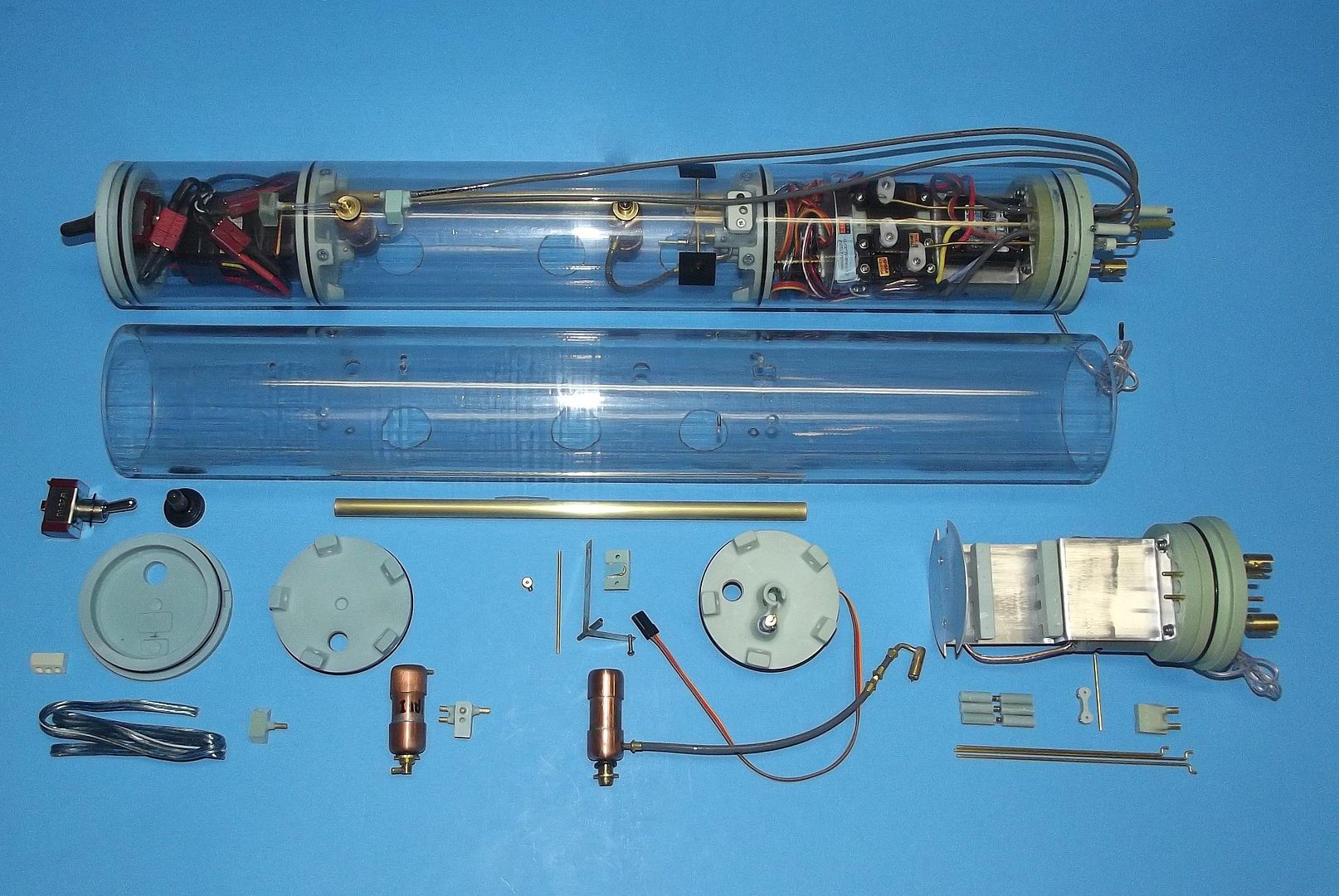

I have a couple questions directed at either Dave if he knows or Andreas. First, what type of surface coat (gel coat) is applied to the layup? And second, what method of layup was used for this model? Hand laid? Vacuum bagged?...etc

Thx, Joel

I have a couple questions directed at either Dave if he knows or Andreas. First, what type of surface coat (gel coat) is applied to the layup? And second, what method of layup was used for this model? Hand laid? Vacuum bagged?...etc

Thx, Joel

Comment