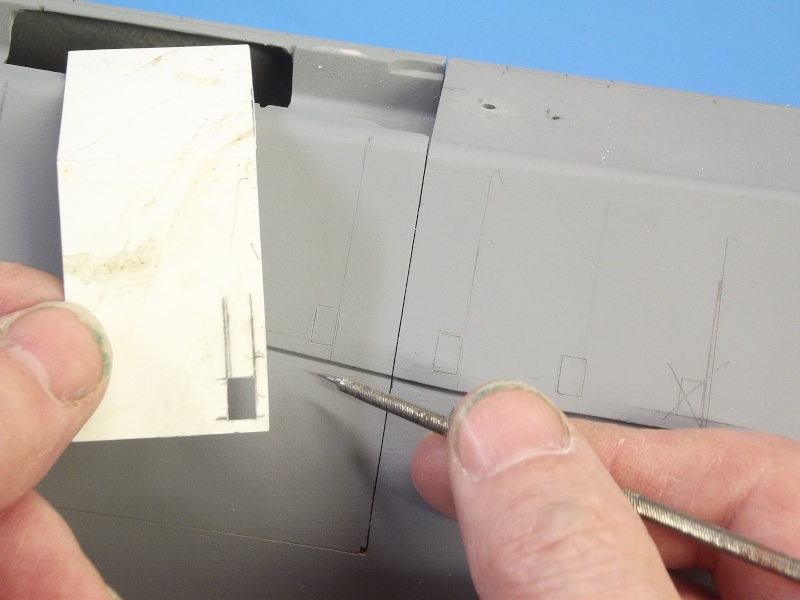

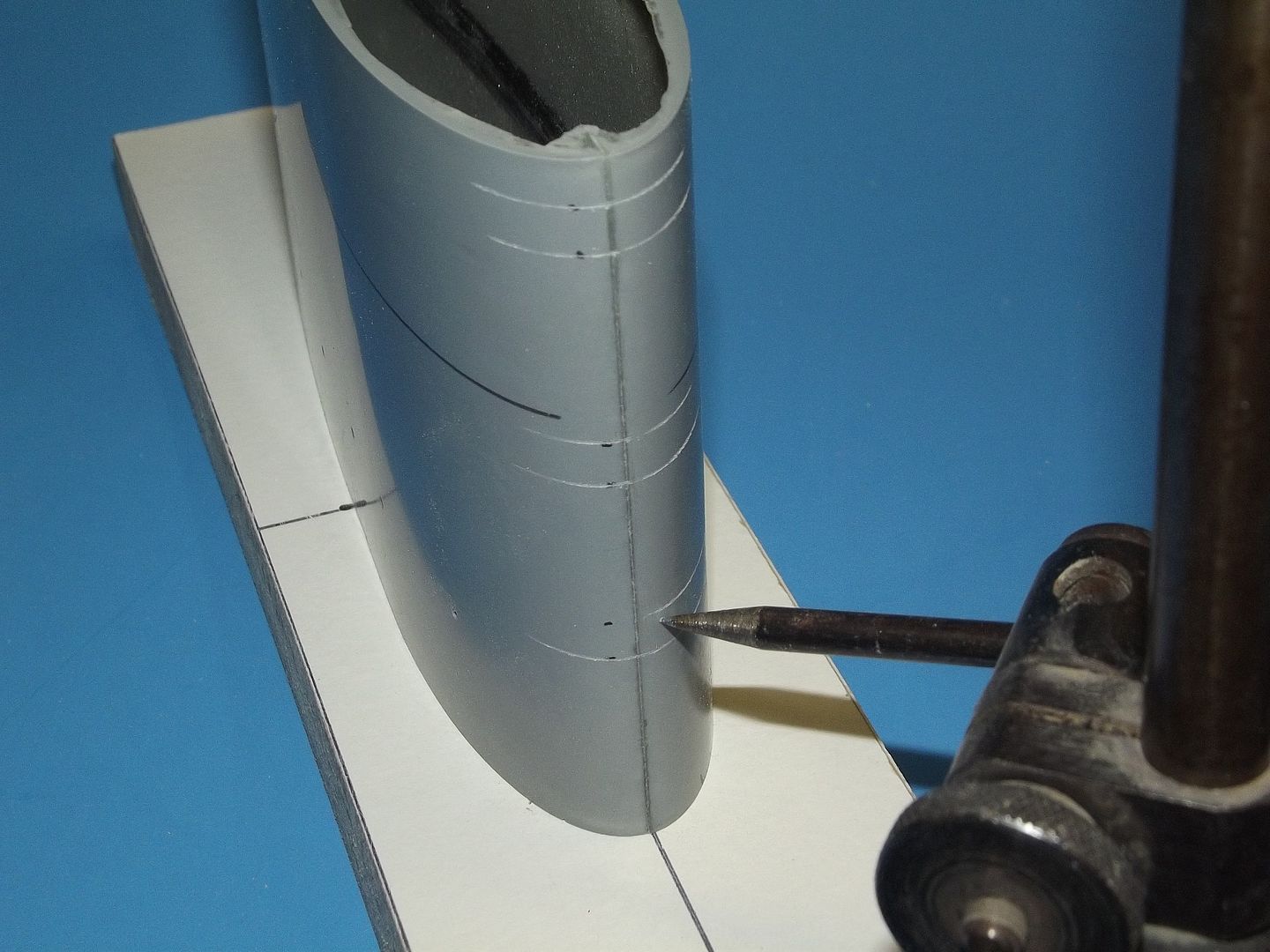

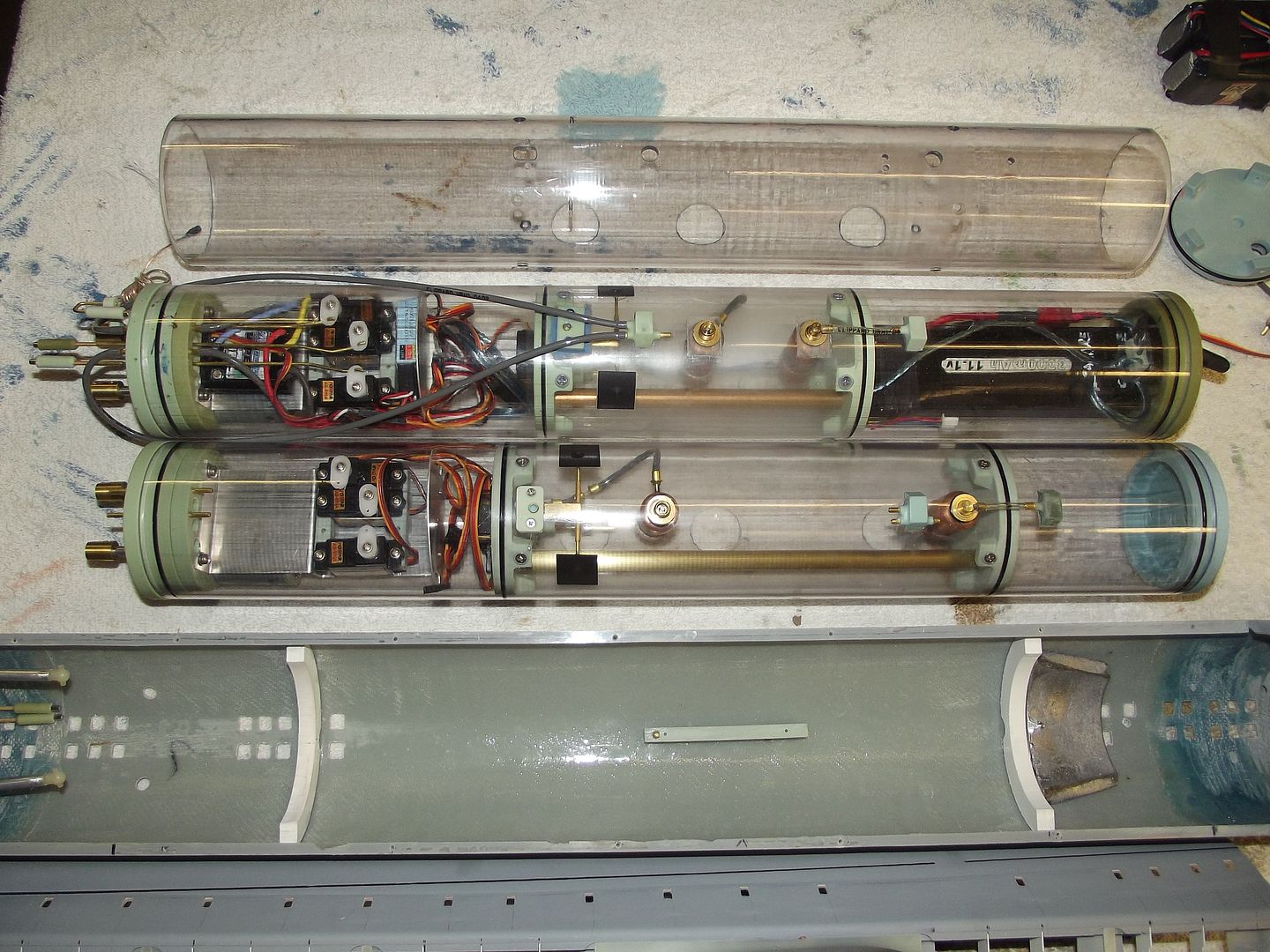

As the forward and after bulkheads (end caps in Eurobabble) are registered by their flanges against the ends of the cylinder, that takes care of longitudinal (axial) registration. So, that leaves radial (twisting of the bulkhead in relation to the cylinder. I just eye-ball them, but have on occasion simply put an alignment bar across both the cylinder and outboard edge of the bulkhead flange. Align the two portion of bar, and the bulkhead is perfectly radially aligned with the cylinder.

M

M

Comment