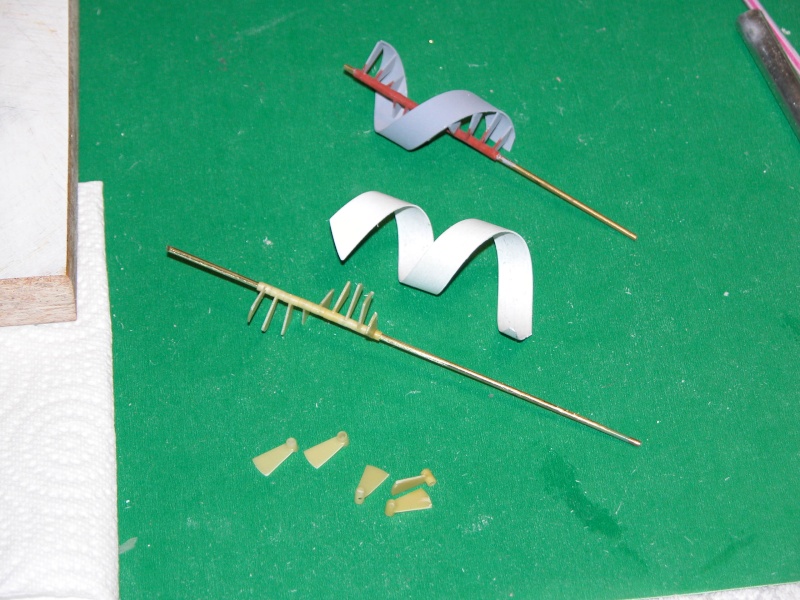

Pictures below show the process of creating the new scoops.

The old shark fin and the new with circular cross section

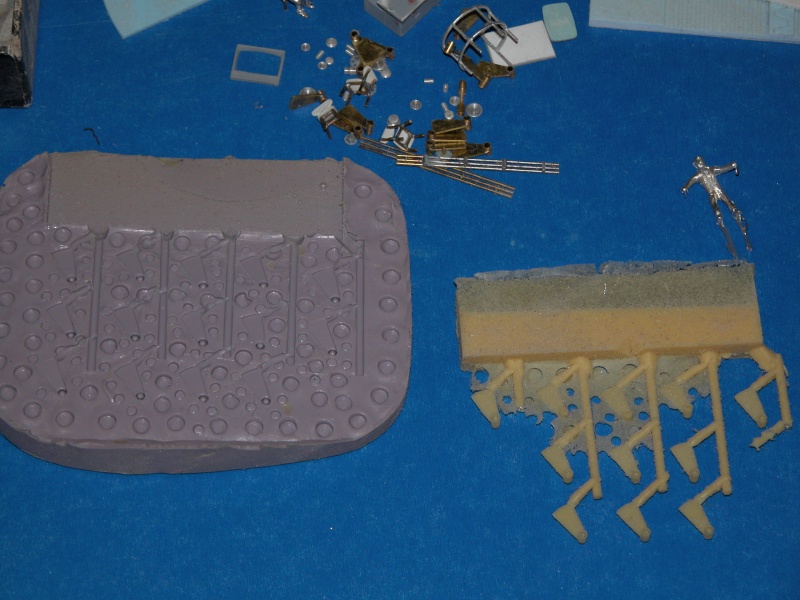

Scoop Root adapted to hull shape

The inlet was opened up with a handheld grinder.

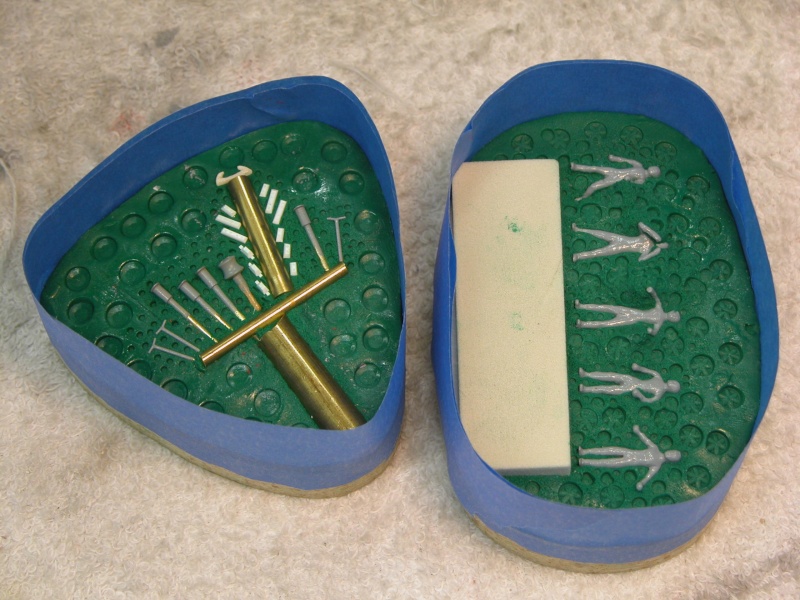

Grating test fitted (to small on next two pictures)

All seems smoothed out with filler (grey on top of scoop)

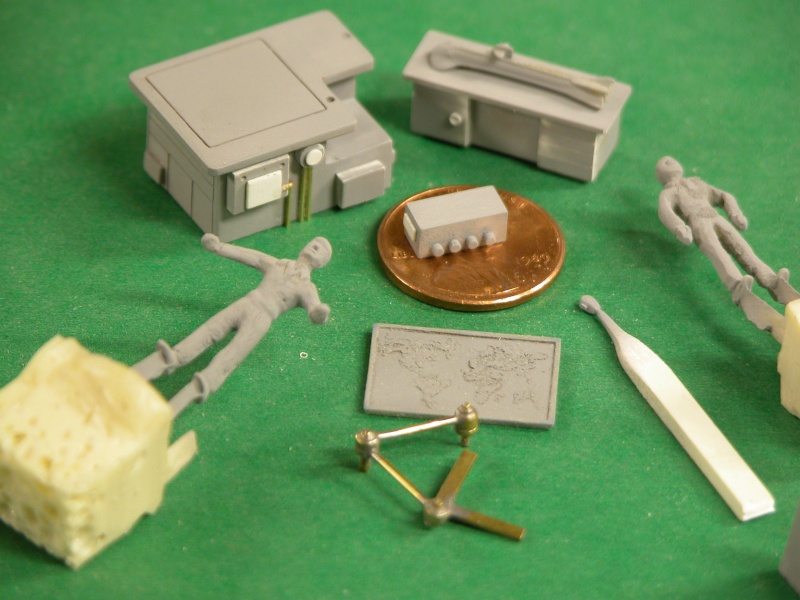

Finished scoops, painted and with new grating

Leave a comment: