Looking Good! Soon you will have the biggest gun on the lake.

M 1

Collapse

X

-

-

Next time someone points out it takes 42 muscles to frown, point out it will only take 4 muscles to b1tch slap them if they tell you how mnay muscles you need to smile:popComment

-

Will you make the gun elevation mechanism functional?

BTW, Still got that wtc for the Type VII?Make it simple, make strong, make it work!Comment

-

Will tie up another channel, and another servo needed, so CBA!. I have thought about connecting it to the rear planes which will be for trim. surfaced i could then wiggle the gun a bit.

I have and you are welcome to it, couldn't get it workingNext time someone points out it takes 42 muscles to frown, point out it will only take 4 muscles to b1tch slap them if they tell you how mnay muscles you need to smile:popComment

-

-

Planes installed, and plane guards, it was dremel and Ungar day yesterday, and some bending.

Need to clean it up, and also make the hookups. got a load of wheel collars, so more soldering, bending and cutting coming up.

Oh yeah, the rear looks kind of skewed. The props and planes are all square, its the very tail of the hull which is at an angle. I hadn't noticed while i was doing the rough sanding work, but now it stands out. It's UP on the starboard side, or skewed anti clockwise. The fact the rear planes are at different angles makes it look worse than it really is.Last edited by Albion; 11-30-2013, 11:07 PM.Next time someone points out it takes 42 muscles to frown, point out it will only take 4 muscles to b1tch slap them if they tell you how mnay muscles you need to smile:popComment

-

Trying to figure out the vent and drains!

The plans I have show a number of small similar sized round items on deck area. Some of these I think are depressed cleats, and some vents, so going to drill all of these out

The ballast tanks are for and aft, near the control surfaces and seem to be either side of cl. So thinking two rectangular cut outs fore and aft, with maybe some thing token, in the middle so the wet hull drains. Anyone got better information before I start hackingNext time someone points out it takes 42 muscles to frown, point out it will only take 4 muscles to b1tch slap them if they tell you how mnay muscles you need to smile:popComment

-

Gong Xi Fa Cai, Chinese New Year here so had a long weekend, most eaten up by domestics, eating, drinking and watching Seattle humiliate Denver. Managed a small amount of me time.

Got the drain holes rough cut, some vents (but need more). Fabricated a hold down for the Sub driver and got the propshafts shortened and couplings roughly in place. Right now this is fitted with a Foxtrot sub driver which has three shafts. The pair of shafts are high up and hence a bit of offset from the prop shafts. Hope its not too noisy. Surprisingly its very tight in there with a 2.5" cylinder. I have the sub driver as low as possible with both ends just clear of the bottom of the hull. The Vent valve and snort manifold sit up inside the narrow part of the superstructure and requires some grinding away of the glass to give clearance. Long term i will get a standard twin shaft 2.5" Sub Driver. Will probably see how the Type IX one pans out or even go with a long 2" (seaview) to avoid the clearance problems and getting a fully submerged ballast tank in surface trim. I remember the issues that Slats had with his O Class, and i think i could have a similar scaled down issue

I dumped it in the bath tub with a small amount of lead in the belly to see if my dimensional estimates for tank location worked, and it was close enough.

Next step is to get some foam in there, fix some ballast then fabricated the linkages, and give it a live ballast test

Last edited by Kazzer; 02-06-2014, 03:48 PM.Next time someone points out it takes 42 muscles to frown, point out it will only take 4 muscles to b1tch slap them if they tell you how mnay muscles you need to smile:popComment

-

That set-up will be quite noisy, ideally you require a sliding spline between the couplings.

Alternatives could be rubber tube couplings or ball and cup. Worth looking at model car hardware, plenty of good stuff available, and cheap.Comment

-

You are probably right. Originally I thought the coupling hubs on the prop shaft would be further back , and the sub driver would sit further forward giving less angle on each joint.

Looks like a bespoke sub driver maybe needed sooner rather than laterNext time someone points out it takes 42 muscles to frown, point out it will only take 4 muscles to b1tch slap them if they tell you how mnay muscles you need to smile:popComment

-

Don't think that will help you really- seems to always be an issue getting good alignment in these small hulls with a twin prop set-up.

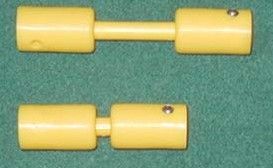

SHG do these CV style couplings, they're inexpensive and will run smoothly out of alignment. http://www.shgmodels.com

Comment

-

Albion

Get those 'orrible red things outa there!

You need to get a nylon dog bone (we sell 'em) and then cut it in half. The cut a length of aluminum tube and superglue these dog bone bits into the tube. I'll take a picture of mine later. Gotta take my lovely dog for a walkies first!Last edited by Kazzer; 02-06-2014, 04:53 PM.Stop messing about - just get a Sub-driver!Comment

-

I think the SD with the motor bulkhead for the new 1/72 Revell of German, Type-9 kit would be nearly perfect for this.

MWho is John Galt?Comment

-

I think the SD with the motor bulkhead for the new 1/72 Revell of German, Type-9 kit would be nearly perfect for this.

MWho is John Galt?Comment

-

i know i know, let see your pictures first tho , hey heyAlbion

Get those 'orrible red things outa there!

You need to get a nylon dog bone (we sell 'em) and then cut it in half. The cut a length of aluminum tube and superglue these dog bone bits into the tube. I'll take a picture of mine later. Gotta take my lovely dog for a walkies first!

My drive shafts are 4mm, i need hubs to fit, these fit. I did try drilling out some of the dumas hubs, but the drill wandered and i ended up with a mess. I dont have a lathe here in Singapore, only get to use one when back in UK, which is occasional. So for now this is what ive got. I guess the SHG would be easy enough, get a 3/4mm one and ream out the 3mm to 1/8"Last edited by Albion; 02-09-2014, 11:35 PM.Next time someone points out it takes 42 muscles to frown, point out it will only take 4 muscles to b1tch slap them if they tell you how mnay muscles you need to smile:popComment

Comment