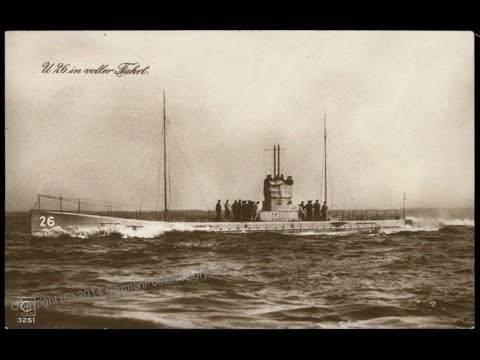

A very detailed deck plan.wonder where you got it. But is that a u 23 class? I only know the knife -stern from earlier boats with open rudder gears and the upper rudder. A puzzling spot it seems.

Jörg

Scratch Build project SM U-23 Class World war one U-boote. Zero Bubble model design.

Collapse

X

-

Thank you Dave!

Meticulously reading your last post while enjoying a well-deserved hot meal, i immediantly noticed you prompted ZB-1/2, a victim i have already received but not yet guttet and glued back together from small pieces. I however had the pleasure to check over your early ZB-1 (!) and give some surplus commentary here and there.

I also wonder will you ever get to spell my name correctly

The rounded stern looks about right, but i think there was a rectangular frame around the rods as U23 class lacked the upper rudder. There is that dock photograph of an u 35? With that frame removed. Besides, open machinary looks cooler!

Stay Busy

JörgLeave a comment:

-

Thanks Rob,

Appreciate the comments. It's pretty quiet here most of the time. I think a few people check in now and then. As mentioned last week, mainly the creation of some small parts and a lot of symmetry checking. All my previous boat have been modern nuclear types out of PVC pipe and so symmetry was something that really only occurred around the front and back. With this boat the symmetry needs to be checked everywhere, it is a fair bit more work and can be harder to spot and deal with sometimes. Apart from this its mainly small parts checking and adjusting.

The back end needed some work done on it as I didn't have the rear section of the top deck closed off. I took a block of Renshape and glued it in under the rear part of the middle raised deck and then placed some other blocks around the side to beef it up before sanding it back. This would need a fair bit of sanding. Once again this is an are in which the drawings are a little vague. They show an outline of the stern section with a curve and another over the same area shown a distinct pointed surface. I have gone with a more rounded back end, bringing the raised deck on a little further distancing it from the vertical position of the rudder shown with the brass pipe. These early U-boats featured an exposed Rudder tiller section with the exposed push rods exposed immediately before the deck starts. I can only assume this is to make them more accessible if there is a steering failure however they could also suffer more immediate damage in an attack.

In this image you can clearly see the fillet around the edges of the vertical and lower deck. An ongoing effort to get a smooth transition happening. The small block placed on the side needed some extra back up in the form of filler liberally applied and sanded back. Symmetry was check with a paper profile cut out and flipped either way to ensure consistency.

This actually took lots of goes to get the surface just right. Also the Renshape at the very stern of the boat needed some extra filler pushed in underneath and then some smoothing out at check that the deck remained level all the way around the wraparound. Further filler in the seams between the side upright and the top deck.

A shot of grey primer to give a lay of the land and show up all the stuff id rather wasn't there... Torpedo tubes look pretty good. What strikes me about this design is that if you look at the drawings there is very little surface detail on the lower side decks. Just the twenty or so access panels and points to mount the radio antenna's and that's about it really.

in the meantime i have been doing some design modifications to the the ZB 1/2 endcap. Some minor modifications to the gearbox housing and an Oil lite design change to improve reliability and durability. This was done through feedback from Zero Bubble's Official Chief Tester, Jorg Happrisch. (It's important that you get a German to do this, they are meticulous!)

Front torpedo tube doors next week.

Dave H

Leave a comment:

-

Great job! All those fine derails and those many structured surfaces simply "cry" for airbrush preshading!Leave a comment:

-

Hello all,

For the past 6 weeks the greater Sydney region has been in lock down. So there has been plenty of workshop time. Now my school which is outside the Sydney region (Hunter valley) has also gone into lock down with two COVID cases in my school. I am now housebound ,so when not teaching I can build, amongst other things. Have for the part little while been working on small pieces and finishing them to as high a finish as possible to make way for the next stage which will be the tooling and mold making. So not so much making major parts but attention to detail with tiny things and getting surface and textures looking nice. The vertical deck sections are going to require a whole heap of extra sanding and filing to get the fillet between them to behave. At the moment there is a bit too much of a clear distinction that there is a bead of filler in the middle.

Clearly visible is the fillet of filler sitting in the corner. It has been hard to smooth the edges of the fillet to blend into the vertical and horizontal surface with out sanding too much of the Renshape around it and accidentally creating low spots at the edges running along the hull. I also cut off the narrower section of Renshape at the front of the hull and replaced it with a proper shaped larger piece that then received the scribing treatment.

A couple of weeks earlier I had built the Rudder, just out of Renshape, I didn't bother printing this one as I didn't need an exact copy. The Rudder I believe follows along the lines of a normal ships Rudder design of the time. Initially when I built it It featured the smooth consistent surface of a fin as I would have built it as though on a modern SSN. But this is from 1912 and it s going to require just a little further investigation to see if I had got the shape right. The Rudder features a hole through the top section that is for the rudder shaft to come down through the hull. Curiously on earlier German submarine there was actually a vertically mounted rudder in the upper hull section. On the U -23 class this was not carried on and it had a conventional ships rudder. (I believe.)

I would need to take the curve off the top of the Rudder to give it a tighter fit under the stern however there has been some time between this pic and how. After some research, once again looking at old pics and doing the best i can looking at the drawings I seems that the Rudder structure is depicted, so I decided that I would go with some kind of framework that would certainly give the pieces come 'character' if anything.

So I drew the profiles of the structure that I could see in the rudder. This looks like depressed panel sections that make the Rudder looks like it has a sagging covering. I believe may have been a popular construction method at the turn of the century. I decided that the simulate this I would cut recessed sections, the best way to do this would be on the milling machine.

Bigger milling bit and wider cuts. Once done I would fillet filler around the edges to create a gradual transition.

Clearly visible is the brass rod that is the rudder shaft. On early U-boats of the U-23 class the push rods for the Rudder protruded up above the hull and could easily be serviced if needed. The push rods dissapeared into the raised deck section. As you can see the raised deck at the back needs some work. More on that later.

The rudder before any filler placed around the sides of the recessed sections. I mocked up the stern shaft assembly on dozens of occasions to work out alignment and fit. As you can see the props are too close the swinging rudder. They will be moved forward to just clear it. The stern gland is also too long. will deal with that later.

Filling around the sides of the recessed sections leads to a smooth transition for the rubber. Then shots of spray putty and then primer. I intend on creating a small extra piece that will be molded and fitted into the skeg to hold the lower bracket for the exposed shaft. I'm jumping ahead of myself here. This is how the stern bits look at the moment.

More later, in the meantime a little video of the build...

This video shows the development of an RC model kit from initial concept to masters and patterns, then tooling and finished kit.

This video shows the development of an RC model kit from initial concept to masters and patterns, then tooling and finished kit.

David HLeave a comment:

-

Hello all,

Thanks Rob, I appreciate the comments and to know that the build log is inspiring someone. Das Boot, yeah its not a bad view of the backyard and the slowly going green pool over the winter. The full sun coming in the morning is also quite nice.

After sanding back the sides and checking for symmetry with the side decks, I then made a start on the vertical deck sections that join the side and raised middle deck sections. This would require the lower decks to be pushed in and be snug with the profile of the raised bulkheads for the upper deck section. This would allow the vertical deck sections to sit on top and sit next to the edge of the middle deck on either side creating a seam that would be pointing upward along the length of the upper middle deck. With the fitting of these vertical sections you would have the final close out of the hull and would no longer have access inside the hull.

German U-boats at the start of the war were characterized by large drainage slots that ran along the lower corner of the joint between the outer deck and the sides. These occur a regular intervals and I was keep to put this design detail into the masters. So I took left over Renshape strip and cut the right width with a wider section increasing towards the bow. Then after a lot of fit and slight sanding and adjustment, matched the piece in the correct spot and then drew a line along the bottom to mark and mill the slots. I marked out evenly the position of the slots and then set the piece inside the jaws of my mill and worked out I would move the mill bit down about 1 mm to create the slot. I didn't want to go through the other side.

In the shot below I had marked out the location of the vents but had not milled them yet. The slight recessing of the milled vents will allow the detail to be transferred to the silicon mold and the customer will simply have to drill and file out the slots from the impressions. These will certainly aid the evacuation of air during the dive. The rim of the vertical strip is higher then the middle deck, more sanding once glued down.

The side decks were glued down and then had a seam of filler around the outer side edge that would eventually get rounded. The challenge with the corner of the deck and vertical section is that there is a radius where the slots meet. I needed to lay down a bed of filler but not get the filler into the slots. Once the sides were glued down I placed some tape on the lower deck and the vertical strip to allow only a narrow channel for the filler. Then wiping some filler into the corner I went along before the filer had time to set and with a wire plucked out any filler that had filled in the slots. The rest would be up to the sand paper.

more next week.

David HLeave a comment:

-

David,

Your submarine is a masterpiece! Your scratch building capabilities is to be admired! Your attention to detail certainly shows in your craftmanship, and your unlimited patience!

Following your build certainly does inspire me to do better! My wife (Retired 32 years teaching school) always tells me, patience will enhance the final results! Thank you very much for sharing this project with our group David!

Rob

"Firemen can stand the heat"Leave a comment:

-

Hi all,

Thanks for the feedback, Jorg. On earlier boats there was the upper framework directly above the planes and even a second plane directly above. I can only think that the frame work was designed to give the crew some idea of where the planes were underneath when docking at a port to make sure that the wharf or pylons didn't bump up and damage the planes that weren't visible. On this class (U-23 class) I am pretty sure that they didn't have an extra set of planes at the front at least unlike the U-9 class. I don't think the planes need a huge amount of travel either way..

The frame work in front of both the forward and stern planes I am confident was to guide mine cables around the outside of the planes and then off the back off the boat so that nothing got snared on a bracket of part of the planes. I could easily see a cable getting wedges in between the plane and the hull at where the shaft exits.

So many times i have laid the outer lower decks in place. The top deck being glued down a while back. Before I glue down the sides I need to check the relative distance either side of the upper deck and make sure they are symmetrical. If one side featured distances that were too far out then I would need to sand back, or if only a small distance I could easily fill but reducing is always easier than adding. So after checking up and down the length of the hull either side it soon became apparent that one side, port was wider than the starboard side around the amidships. This was also confirmed by the side decks. They are mirror image of each other and one overhung the port side more than the starboard. The middle region amidship up to nearly 10 mm variation. this would mean sanding back about the edge and bringing down this measurement so that there simply wasn't greater beam on one side than another.

It became clear pretty soon that I would have to do some aggressive sanding back on the port side and that i could easily sand through to the thin sheet balsa and blow a nice large gap Titanic style. As a result I sprayed some expandable polyurethane foam like I did on the stern end. This wold reinforce the balsa and create a supporting layer if I did need to exceed the sides and i wold be able to resin and glass over the top of it. So i would go hard with the sander and then measure to check as I cams slowly closer to having both sides, even.

I really had to grind down to the frame and into the polyurethane filler foam. This was bought the deviation down to less than a mm. I have also had to make sure that I managed to keep the curve of the hull going. I also ran the sanding block over the top of the frames as I also needed to make sure that they were also level.

Using a thin layer of weave allows to cross the gap between areas where there are voids under the frame and where there are gaps in the foam. Then lots and lots of sanding then filling in low points and then once again, sanding, sanding. In the meantime I have started working on the side vertical strip that join the lower hull deck on the side to the raised upper middle deck. This will eliminate seeing the framework the last visible parts of the inside of the hull.

I need to work on the side strips and mark out and cut the drainage holes and vents on the side. These vents are a distinctive feature of World war One U-boats.

Side next week.

David HLeave a comment:

-

Hey Dave!

I believe the wider outline of the presumed 2 diveplanes being a protective panel installed on top of the actual plane, somewhere half-way between plane and deck. Take a look at the "Das Werk" U-9. Edit WRONG,see below

Planes look nice, but how much downward angle do they offer.they must have had a cutoff to the inner stern.

Cylinder has arrived, however i need to fetch it from the parcel bureau as i am in holidays right now.

+++ correction after some research +++

There was a frame of steel tubing around the plane.some srof net/mine protection. The plane pivot was located halfways between deck and keel level.

Jörg

Last edited by JHapprich; 07-16-2021, 08:32 AM.Leave a comment:

-

Hello all,

Hi Jorg, Thanks however i think that if I were to use fabric to create a texture the weave would be too big. Thinking of Germany right now with all that flooding..

So I now started working on the Stern planes. One of the things I have noticed about the planes on these U-boats is that they are small. I just wonder how effective they would have been. So the stern planes are mostly rectangular. I decided to go with Renshape once again. I could have printed them but they are a pretty simple shape and creating two opposite pieces really isn't a big deal. So I took apart of the flat strip of Renshape that I had cut for the deck. About 3 mm thick it is an ideal thickness to start off with .

As I have found throughout the build process, the drawings that I have, lack consistent detail. Photo's have also hindered this section of the boat. The drawings show what look like two individual sizes of stern planes and the side view and section show little information about the height of the stern planes up along the side of the hull. I do know that they are above the stern glands where the shafts exit the boat but how far above?

So I traced out the shape of the profile and marked it out on the piece of Renshape. I then cut around with a knife and repeated the process. I then spent a bit of time sanding and smoothing the overall shape and then repeating the process again with the other side, constantly checking the symmetry with each other. The thickest point of the stern planes will be where the pivot occurs.

The inner forward edge of the plane is angled inwards. I believe this is because the pivoting moment of the plane will mean that if there is not an angled surface then it will hit against the angled surface of the hull and restrict the upward movement of the plane. I will be mounting the planes slightly outwards on the shaft to clear the hull anyway.

I then marked out the pivot point and where the hole would go. So I then set up the drill press and drilled a 1.5 mm hole along the thickness of the piece.

I then took the time to mark out and drill the shaft holes in either side of the hull. I marked down the side of the hull and made sure that the holes were the same distance back either side of the

stern of the boat. This was the last major drilling operation that needed to be done before I could close up the hull with the three deck sections.

The rear inner surface is slightly angled for the same reasons as the inner surface forward of the pivot.

More next week.

david hLeave a comment:

-

Good work! You could even mimic an actual canvas surface by pressing the warm styrene into a fabric sheet.

JörgLeave a comment:

-

Good work! You could even mimic an actual canvas surface by pressing the warm styrene into a fabric sheet.

JörgLeave a comment:

Leave a comment: