If guess work, at least the jig will assure symmetry between the two shafts -- they will be wrong... equally!

David

Scratch Build project SM U-23 Class World war one U-boote. Zero Bubble model design.

Collapse

X

-

Ah, got it. So, good set of plans is imperative otherwise it is a lot of guess work?

Leave a comment:

-

-

David,

‘great jigs, but how do you figure or build the jig to get the torpedo doors where they need to be?Leave a comment:

-

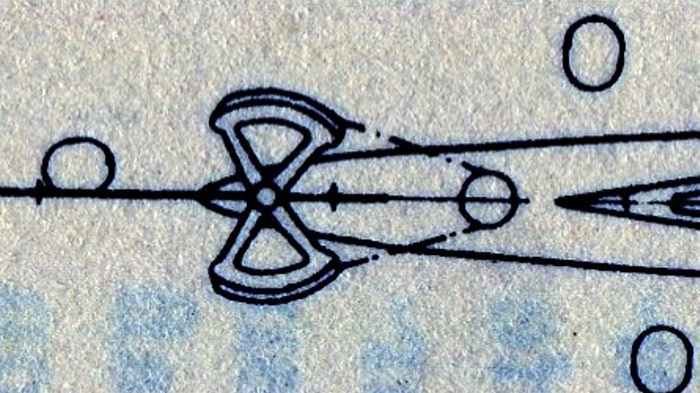

To establish the toe-in and the other off-sets of propeller shaft-to-hull-centerline hold both shafts at the correct angles in a table mounted jig that establishes the desired off-sets. Plunk the stern down onto the table, sleeve the stern tubes over the shafts, drill holes in the ass-end of the hull, and slide the stern tubes into the hull (the jig tells you where they enter the hull) and glue in place.

A variation on these torpedo tube shutter-door scribing jigs is what you're after, David.

David

Who Warships at the Alter of Rube Goldberg

Last edited by He Who Shall Not Be Named; 03-13-2021, 10:32 AM.Leave a comment:

-

Hello All,

Thanks for the pics Gantu. That is certainly a different way of doing things. I'm still awaiting to hear from DM if he has any gems about how to go about aligning shafts and working out the shaft exits without making a dogs breakfast of everything.

After grinding back the sides of the rear hull where the bottom round section of the hull transforms to the emerging Keel and adding extra polyurethane foam on the insides to support it I decided to lay up the hull once again and create the concentric profiles around the hull at the bulkheads. These help give an idea of the consistency of the hull shape and looking down the length allow you to see any areas of deviation in frame profile. I made a vertical profile that I could run a pen around to accurately get the vertical sectional profile of the bulkheads.

Once the bulkhead frames have been drawn on and lots of eyeballing later I then filled undulations and low points. Once done more sanding. Particular points are marked with pen just so that I can work reasonably quick before the filler sets. I use a plastic flat surface cut from an Ice cream container and then screed the filler over the low point in a smooth action that creates a very flat mostly smooth surface.

Here, next to the hull marked with pen is the top section of flat Renshape that will make the middle deck section and also the lower section of the small conning tower. The hooks are in place to anchor down the upside down hull in place, resting on small Renshape blocks after careful checking that the keel of the hull is a consistent distance away from the board.

I eventually came to the point where I would lay down the layer of weave that would greatly add to the rigidity of the hull and further increase and seal the hull and give a little more surface area to sand down and eliminate undulations and low points. After slowly going over the hull and sanding it back thoroughly I mixed up some further resin and brushed it onto the hull and then laid up the 6 oz weave. I did this in sections and whetted it up as I laid it down and then slowly brushed and made sure that there no bits sticking up.

Initially I laid the weave down before brushing down the hull, in order to get the fit right and minimize overlaying.

Once done and whetted up I left it outside and let it cure. Even now in March we are still getting residual summer heat , a nice 25 degrees. Once cured, I marked out the high points and then lots of sanding with 80 grit and hardboard backing it. My Biceps ain't bad. This was about an hours worth of sanding. Slowly taking it from 80 down to about 600 grade wet and dry.

Once I was happy with this I then gave a light primer coat. This spray did'nt cover over too much of the frame indications.

Once the primer is dried, it's only a light coat, then I once again marked out the high and low points in the surface that are more noticeable now with the primer and fill and sand. Repeat...

I really need to start looking at the stern shaft exists. As mentioned in the previous post, I would really love to hear from people as to strategies to make this work without making too much of a mess of the rear end.

David H

Leave a comment:

-

Hello david ,

a friend of mine do always pipes in the section and then plank the hull.

Leave a comment:

-

Hello all,

Hello HWSNBN, David, I’m not sure if you saw my request in the last thread about exit shaft locations on my U-Boat hull. Do you have any suggestions or techniques as to how to determine this without punching too many holes as a result of bad guesswork? I appreciate that you should be enjoying your retirement but I really do appreciate your advice.

thanks,

David HLeave a comment:

-

Thanks David,

No one else has given any suggestions as to the two items hanging over the front deck of a U-boat. What is interesting is how 'Das Werke' in Germany have molded them into their kit of the U-9. Before I saw this photo I though that it was a fixed piece of the hull as shown by the U-9 kit even though I had not seen them on any other photos. I am spending a bit of time looking over all the old photos that I can get and find that although photos are relatively consistent, plans and drawings are sometime contradictory. There is not a lot of detailed information on the U-23 class however there is good detail on the U-9 class and so I am trying to determine apart from obvious overall hull design changes whether there is much deviation with hull details between the two classes. I am thinking of using the U-9 class as the template for much of the detail I need to put into U-23.

So, after the filling and sanding of the hull and checking as much as possible to get the hull consistent, I was finally at the stage where I could give the hull a coating of polyester resin. This would seal the hull and also give just a little more thickness to sand back with high points and so forth. The initial layer would probably use a fair amount of resin as the Balsa acts as a sponge and really sucks it up. Once a good coat had been put down then subsequent layers would require less and this would certainly be the case when it came down to putting the weave on.

Sunning itself by the Pool. The first coat of resin has gone down and the hull is getting a distinct tan like appearance but not from the Rays. The filler doesn't absorb the resin like the balsa so you tend to have excess over these areas. You simply need to redistribute. I left the hull to dry for a couple of hours before giving a light sanding. The resin had done a good job of sealing and I could actually put the hull in the water and it floated quite nicely no leaks. No lead for buoyancy so it would easily have capsized it I weren't holding it.

I decided to give the hull a light spray of primer grey. I did this to help give a better show of the overall texture that the resin layer would give. and to see any undulations that may not show up with just lighting alone. The Grey does help you see the surface from different angles and pick up inconsistencies you may not otherwise.

In this state I noticed one thing in particular. This photo makes the hull look as though the keel is not centered. As though it is lopsided to the right. It is'nt, it's just the angle, however what I did notice over time was that the keel as it transitions to the hull and the surface area to either side of it transition to the common shape of the hull too quickly. There needed to be a much more gradual gradient change in this general area. I decided to get aggressive with it from the start and then back down on the abrasives. I started with a Rasp and some serious filing back and forth either side of the keel as it transitions to the consistent hull shape.

I then did more and more as I aimed to take the shape to a much more gradual transition. The filing was taking the profile down to the thinnest areas of Balsa, so much so that the frame work is showing through. This would require internal back up. I further spray of some of the polyurethane filler was required to back this up. I would also combine with filler.

The filler is great for reinforcing the insides when I'm grinding the outer profile to within an inch of its thickness (more like a fraction of a mm) but It will play havoc later on when i need to set up the shafts and work out where the shafts will exit the hull. This will need to be done soon and certainly before I smooth down the hull too much as I need to work out how to represent this on the mold. David, need you help on this one! I think it's going to need a bit of geometric gymnastics...

After going hard with the rasp and gradually beating the rear end into submission and an nice curve, I started the process of sanding down the rest of the hull. sanding back the primer is a good way of seeing the high and low points as the primer high points ware away quick.

As mentioned David, I will need to work out how to best determine where the shafts exit at the back of the hull. Having all that urethane filler in the back ain't helping however I have started clearing it out and will make a mock up of the stern ZB-1/2 twin shaft end cap with the precise locations of the shafts on it. I then intend on slotting it behind the bulkhead that is where it would sit. I then need to run shafts from the two points that simulate the shaft outputs on the stern end cap mock up and find where they will go out and at the same time make sure they hit the brackets. X-ray vision would be really great for this one!..

David HLeave a comment:

-

Drying out rubber mats that normally go under the feet of the guys standing watch at the battery switch-boards?Leave a comment:

-

Hello all,

True to form Gantu has been going hammer and tongs looking for pics of the U-23 class. Appreciated Gantu. Especially those bits of blueprint from what look like original drawings.

At this point some transom re-adjustment was necessary. As mentioned previously it was slightly off to the port and need to be angled over to the center line. To do this I made a cut in the keel about 50 mm forward and effectively broke the keel. I also made a cut in the transom about half way up where the top of the rudder wold be mounted and cut in a little. I then shifted the keel section, lower transom section and a small mass of Balsa and polyurethane foam sideways. I then pasted some PVA glue and pinned it down in its new position. The keel now looks much more aligned. I am certain i will have to do some more subtle work on this later but looking better for now.

In the meantime, I have a pic that I am curious about, please if any one can answer what is below that would be great. Don't be shy...

As mentioned previously, there are numerous issues with regards to photos and drawings conflicting. I have one drawing that shows two top views with the forward planes in two different positions.

So once the Keel alignment had been sorted it was back to the board to do some general checks for symmetry. I have a laser light mounted on a rafter in the ceiling and its pointing down to create a long straight line that I can use as the datum along the keel. I just have to line up the board and then boat. Rubber bands and hooks and then don't bump it.

The big "L" brackets ate so that i can run a ruler across the top of the deck and accurately measure the distance from the edge to the centre line. Made at school from the scrap bin they are made of "Jarrah" a hard Eucalypt that makes beautiful furniture but will smoke your drill bits! I will be making a piece that straddles the hull and will give an accurate perpendicular reference line along the bottom of the hull when turned up side down. This will effectively give me section lines as you cast your eye down the length of the hull being able to easily see where a profile may be out. But that's a week of so away.

Eventually I will get around the laying out the patterns on the centre deck section and then start the business of scribing. Once I do that I'm very confident a certain HWSNBN will come out of the woodwork so-to-speak and berate me on my progress. I still need to do a little investigate of layout of the deck. I am heavily going off U-9-U-19 data, there doesn't seem to be much shift or evolution in the deck design between these classes but once again I am open to anyone with anything further.. Some ZB's in background.

So after marking out any little undulations and irregularities, I put to work with filler and sandpaper. I will try my best to get as many inconsistencies out before the first layer of resin goes down and seals the hull. So here its lots of filling and lots of sanding. i have to say the boat generally looks really symmetrical, but i know that I check and check and then get to a point where I more on and any changes are not possible and then notice...

Filling, sanding, filling, sanding, repeat....

David HLeave a comment:

-

Thanks Gantu,

I've already got these pages, but appreciated anyway. Thank you Rob for the compliments.

As mentioned in the previous write up, checking for symmetry and overall consistency becomes something that I need to work on. It is still a fair war off before I get to a point where if symmetry isn't checked then the inaccuracies are irreversible. Along way off from that yet. However this not being my usual PVC pipe with turned ends Nuke boat means I need to take things methodically and carefully to check that everything is balanced.

For starters there is lots of sanding, especially along the seams where sheets meet. Once that it done then lots of filling. Being sheeted with only 2 mm thick sheet means that if a high point is higher than 2mm, I will be sanding out the sheet and just create a hole where thicker Balsa would have been great to have. I do have some Sika expandable polyurethane foam in a can that could back up behind the sheet in an area of anticipated aggressive sanding.

The completely sheeted hull with the top sheet of Renshape medium that will give all the top deck detail without much Renshape being needed. I had noticed that the Transom was skewing to one side. This area again like the rest of the hull was only lightly sheeted and so aggressive sanding would just lead to busting holes. As a result I used some of the expanding foam to bulk up this area for sanding and what i anticipate would be a bit of surgery to get it right along the keel axis line. So spray i did.

This stuff really expands a fair bit. You can see it has risen up around the height of the Bulkheads. In this pic i have already cut it back and also sanded the underside of the thin Balsa to reveal the urethane underneath. Forward of the exposed foam you can see that the balsa forms an uneven surface that I am going to have to take to later to smooth and create the gradual transition that I am after.

You can see in this pic how the rear raised keel section leading to the transom isn't in alignment with the datum line running to the bow. (Black line.) It is straight to the bend then it veers off to the left. Later on I would do a series of cuts and push the keel back to the right. The foam helps bulk up the structure and give support. The transom itself will need slight relocation. this picture really shows the rough nature of the sheeting and the need for care full smooth transition checking.

I also aligned up the stern post for where the rudder shaft would protrude upwards and marked this with a small brass tube. Here the stern back block has been glued into place. This is where I intend on cutting a section out and fashioning the stern torpedo tubes. I actually do have a good picture of this. Here i have pasted some P.V.A just to protect close the surface of the foam.

The stern plane arrangement will be different however I intend on doing the torpedo tubes like this. If only i could find a bow photo this good. I have spent some time creating a board to calibrate and check symmetry. I have made a couple of L blocks to push up against and use to measure the height and measure between to check against the axis line. This board is actually my sanding board turned up side down.

I have set up a laser line from the ceiling to shine down and get an absolutely straight axis line down the keel. then carefully take measurements from either side of the axis. Then determine where to sand or fill.

The sheeting at the very front above the tubes needs some filling in as it is recessed somewhat. that will come later. Last week I spoke of my dilemma with the bow tube design. Bernhard Wenzel, builder of the U-9 from the Sonar site and inspiration for the Das Werke kit of U-9 sent me a great little pic of the bow of one of these boats clearly showing a curved tube section. Thanks Bernhard!

Once again if anyone has good pics, I would certainly appreciate it.

David HLeave a comment:

Leave a comment: