The Friday before memorial Day, we got together for our Annual Trim Party. Unfortunately, the weather wasn’t cooperating here on “Lawn-guy-land” that day. Don’t get me wrong, it was outright gorgeous with the exception of the wind. Sustained winds of 20mph with gusts to 30mph are not conducive to trimming your boat as the waves at the lake were a foot or so with whitecaps and spindrift.

Actually turned out to be a good thing for me.

Capn’ Gaito invited me over to his house where lo and behold, he has an inground pool perfect for trimming a boat. So him and I headed over there to do the deed. Frank Salerno, owner of the 104” SSRN SEAVIEW, eventually showed up as well to learn how one trims the RC Submarine.

Many of you remember this SSN-591 has been a test bed for me to refamiliarise myself with my old techniques, as well new technologies having come out on my hiatus. Primarily for the ”big boat” Capn’.

This last winter I finally settled on the Design Plan for my future builds (Ballast tanks >75inł) by having decided to return to the old reliable "gas" system, but now with a “Low Pressure Blower” (LPB). It differs from Dave’s Sub Driver SAS system in that though we both directly draw air at Periscope Depth with a snorkel (like the real boats do) to the tank, I don't store the air onboard in the pressure hull as a burst to get her to PD. That's what the Propel does of course, and only when needed as she (and all my large boats) strictly use 2.4Ghz so I'm tied to the surface anyway, which I prefer. A simple Diaphragm Pump Air/Water Pump DC 12V rated 2L/Min plumbed directly from the snorkel induction to the tank with no valves, so the head HAS to be above water. This was the 2018/19 Refit so needless to say she needed to be retrimmed. Hopefully the last major trim.

Everything worked out great. While we found the surface trim was nearly the same, we discovered she was heavy at the bow, heavy overall when submerged. Easy fix!

591 Surface Trim

Submerged trim, heavy in the bow, heavy overall.

However, I also discovered, 2 outta 3 of the “new” bellows I installed for the Rudder/Stern Planes and Fairwaters pushrods had leaks. Pool water (~ 10ml not a lot) made it into the Command and Control Box, just enough to slosh around the bottom. Shame on me for not pressure testing before hand. This was discovered after the temp trim was established with foam and she suddenly shut down at PD.

Like I said, it was fortunate we had left the lake. This happening 30’ away in a lake that has a current water temp <65°of would have NOT been good for a human to rescue a submerged RC boat.

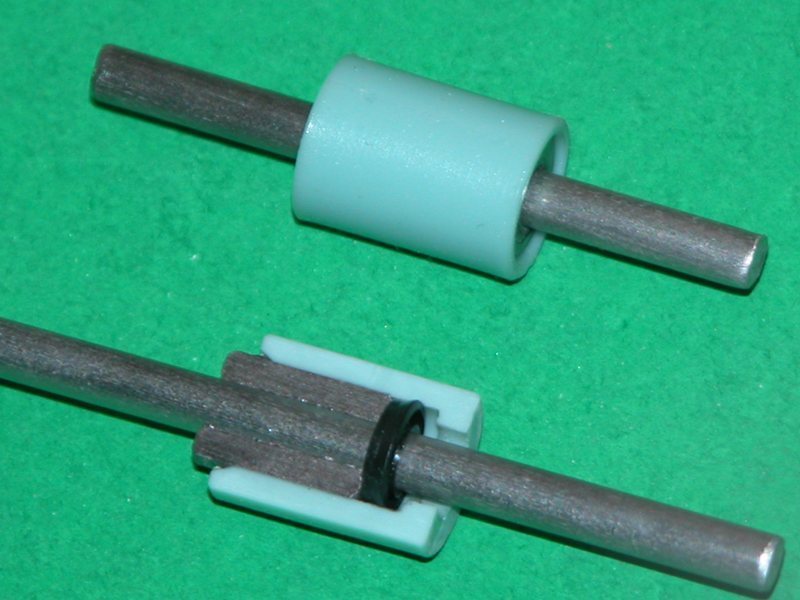

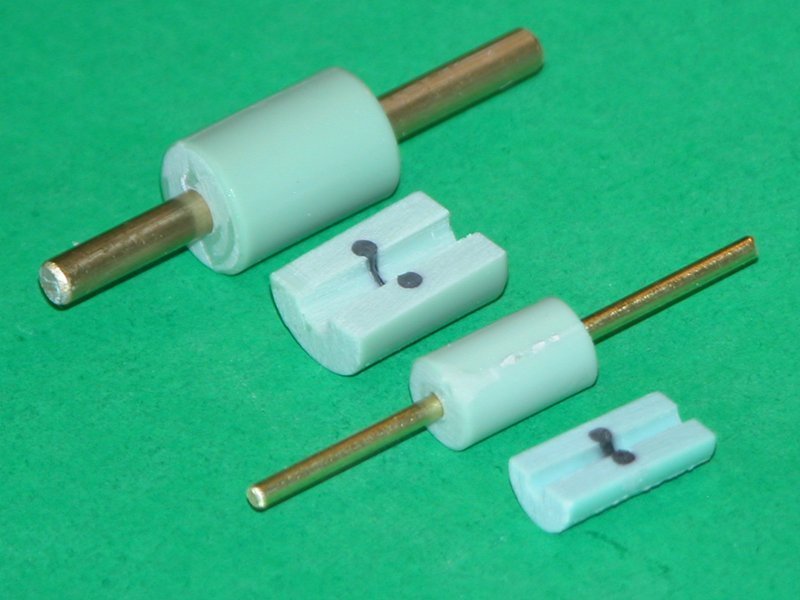

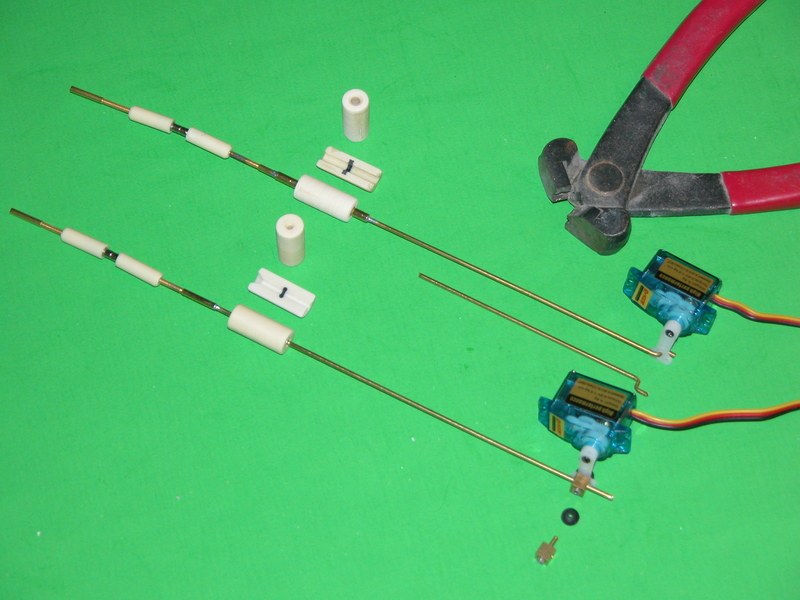

Troubleshooting on site initially lead to the 433Mhz Remote power switch failure that resides in the Power Control Box, which had NO leaks, strange. Bypassing that on shore showed everything else was fine, or so I thought. Since I don’t put anything less than a 100% operational boat in the H2O, time to go home. Okay, I can deal with that. So swap out the Remote Main Power Switch, and return to my tried and true (30+ years) of 1/8” Silicone Fuel tube Linear pushrod seals (ala Krick U25) and move on.

The new 433Mhz Remote Switch in the Power Control Box

So this past Saturday with her on the bench, I swap out the remote switch and run through a channel test, Including an A/A Bell on the throttle. When I start to apply A/B Bell on the throttle, the shaft begins spinning, fitfully, while LED’s the ESC light up flashing and I here a POP!, everything dies….WTF???

Traced the pop to one of the external 12VDC 20A Battery Fuses….weird. So I replace it just to make sure, everything back to normal but again when I reply a backing bell….POP!! Damn!! Not learning when to quit, I tried it a third time, this time backing slowly, and sure enough same POP!

Command and Control Box

So in less than 10 minutes I had pulled the old “Solid State” Brand ESC to check that. I plainly saw it had indeed been corroded by the short time it had exposed to the chlorinated pool water. As you can see there is definite residue and brown scorching in the unit. Which by the way, is NOT sealed. Not a great loss as I had this ESC since the 90’s and swapped it in when I changed from a Brushless motor in Mod II to a Brushed Motor in Mod III. It’s a Redmond 12VDC 10A RV HVAC Blower Motor donated to me years ago by the good will of Cap’n' Ray Mason.

Redmond 12VDC 10A RV HVAC Blower Motor in the Propulsion Box. Water cooled, swings a 3-1/4" screw.

The old "Solid State" ESC, don't even remember who manufactured it. The failed Remote switch above to the left. I'm guessing it fried BEFORE the 20A fuse blew when the ESC failed in the pool.

Though it's shrink wrapped you can see it's certainly not water resistant, much less waterproof.

Evidence it had a bath in the chlorinated pool water.

Plainly visible is the heat damage.

Luck has it I had just purchased two ESC’s from none other than Capn’ Martin for two other projects “on the way’s” and I almost have 591 back together for the July 23rd Regatta in Queens. This ESC is a Viper of course, so she’s waterproof.

Pre-installation surgery.

In place ready to put the rest of her together. Hoping the Engel SPC2 wasn't affected. Time will tell.

So lesson learned…….

1-Alway’s trim the boat in a “safe space” at the start of the season, even old faithful that runs without issue year after year. Murphy’s law is a “clear and present danger”.

2-They’re are two types of RC Submariners. Those who have experienced leaks, and those who will experience leaks. Use Waterproof electronics whenever possible, or waterproof them yourselves. Humiseal can be had on Amazon to conformal coat a bare board if that’s your only choice. Just make sure you mask any connectors from the Humiseal so you get a good electrical connection when installed!

3-ALWAYs stop running the boat if it misbehaves in anyway. Don’t “power through it” even if you drove 10 hours to run it.

4-Know your environment. I don't normally run in pools, my preferred boat scale limits that, so I didn't suspect the damage until later.

Many thanks to Capn' Gaito that day for his help and support.

Actually turned out to be a good thing for me.

Capn’ Gaito invited me over to his house where lo and behold, he has an inground pool perfect for trimming a boat. So him and I headed over there to do the deed. Frank Salerno, owner of the 104” SSRN SEAVIEW, eventually showed up as well to learn how one trims the RC Submarine.

Many of you remember this SSN-591 has been a test bed for me to refamiliarise myself with my old techniques, as well new technologies having come out on my hiatus. Primarily for the ”big boat” Capn’.

This last winter I finally settled on the Design Plan for my future builds (Ballast tanks >75inł) by having decided to return to the old reliable "gas" system, but now with a “Low Pressure Blower” (LPB). It differs from Dave’s Sub Driver SAS system in that though we both directly draw air at Periscope Depth with a snorkel (like the real boats do) to the tank, I don't store the air onboard in the pressure hull as a burst to get her to PD. That's what the Propel does of course, and only when needed as she (and all my large boats) strictly use 2.4Ghz so I'm tied to the surface anyway, which I prefer. A simple Diaphragm Pump Air/Water Pump DC 12V rated 2L/Min plumbed directly from the snorkel induction to the tank with no valves, so the head HAS to be above water. This was the 2018/19 Refit so needless to say she needed to be retrimmed. Hopefully the last major trim.

Everything worked out great. While we found the surface trim was nearly the same, we discovered she was heavy at the bow, heavy overall when submerged. Easy fix!

591 Surface Trim

Submerged trim, heavy in the bow, heavy overall.

However, I also discovered, 2 outta 3 of the “new” bellows I installed for the Rudder/Stern Planes and Fairwaters pushrods had leaks. Pool water (~ 10ml not a lot) made it into the Command and Control Box, just enough to slosh around the bottom. Shame on me for not pressure testing before hand. This was discovered after the temp trim was established with foam and she suddenly shut down at PD.

Like I said, it was fortunate we had left the lake. This happening 30’ away in a lake that has a current water temp <65°of would have NOT been good for a human to rescue a submerged RC boat.

Troubleshooting on site initially lead to the 433Mhz Remote power switch failure that resides in the Power Control Box, which had NO leaks, strange. Bypassing that on shore showed everything else was fine, or so I thought. Since I don’t put anything less than a 100% operational boat in the H2O, time to go home. Okay, I can deal with that. So swap out the Remote Main Power Switch, and return to my tried and true (30+ years) of 1/8” Silicone Fuel tube Linear pushrod seals (ala Krick U25) and move on.

The new 433Mhz Remote Switch in the Power Control Box

So this past Saturday with her on the bench, I swap out the remote switch and run through a channel test, Including an A/A Bell on the throttle. When I start to apply A/B Bell on the throttle, the shaft begins spinning, fitfully, while LED’s the ESC light up flashing and I here a POP!, everything dies….WTF???

Traced the pop to one of the external 12VDC 20A Battery Fuses….weird. So I replace it just to make sure, everything back to normal but again when I reply a backing bell….POP!! Damn!! Not learning when to quit, I tried it a third time, this time backing slowly, and sure enough same POP!

Command and Control Box

So in less than 10 minutes I had pulled the old “Solid State” Brand ESC to check that. I plainly saw it had indeed been corroded by the short time it had exposed to the chlorinated pool water. As you can see there is definite residue and brown scorching in the unit. Which by the way, is NOT sealed. Not a great loss as I had this ESC since the 90’s and swapped it in when I changed from a Brushless motor in Mod II to a Brushed Motor in Mod III. It’s a Redmond 12VDC 10A RV HVAC Blower Motor donated to me years ago by the good will of Cap’n' Ray Mason.

Redmond 12VDC 10A RV HVAC Blower Motor in the Propulsion Box. Water cooled, swings a 3-1/4" screw.

The old "Solid State" ESC, don't even remember who manufactured it. The failed Remote switch above to the left. I'm guessing it fried BEFORE the 20A fuse blew when the ESC failed in the pool.

Though it's shrink wrapped you can see it's certainly not water resistant, much less waterproof.

Evidence it had a bath in the chlorinated pool water.

Plainly visible is the heat damage.

Luck has it I had just purchased two ESC’s from none other than Capn’ Martin for two other projects “on the way’s” and I almost have 591 back together for the July 23rd Regatta in Queens. This ESC is a Viper of course, so she’s waterproof.

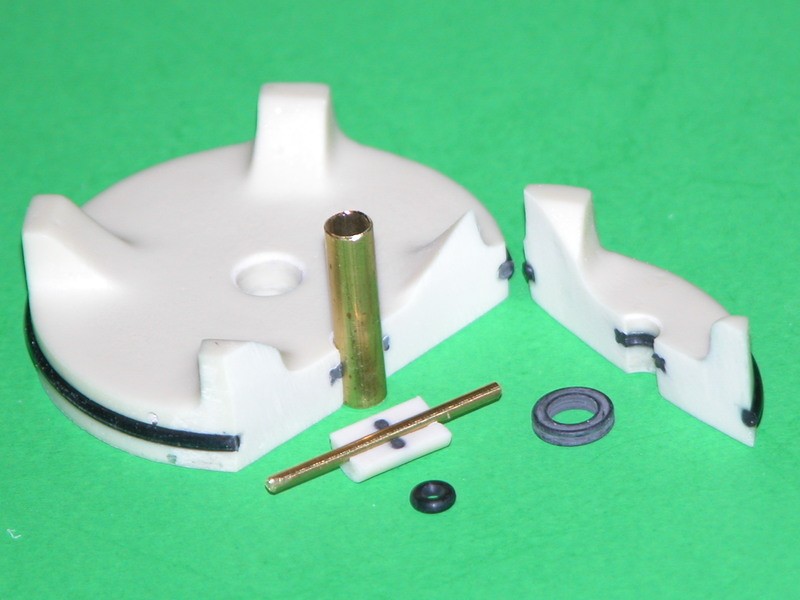

Pre-installation surgery.

In place ready to put the rest of her together. Hoping the Engel SPC2 wasn't affected. Time will tell.

So lesson learned…….

1-Alway’s trim the boat in a “safe space” at the start of the season, even old faithful that runs without issue year after year. Murphy’s law is a “clear and present danger”.

2-They’re are two types of RC Submariners. Those who have experienced leaks, and those who will experience leaks. Use Waterproof electronics whenever possible, or waterproof them yourselves. Humiseal can be had on Amazon to conformal coat a bare board if that’s your only choice. Just make sure you mask any connectors from the Humiseal so you get a good electrical connection when installed!

3-ALWAYs stop running the boat if it misbehaves in anyway. Don’t “power through it” even if you drove 10 hours to run it.

4-Know your environment. I don't normally run in pools, my preferred boat scale limits that, so I didn't suspect the damage until later.

Many thanks to Capn' Gaito that day for his help and support.

Comment