Hey all, thanks for the kind words!

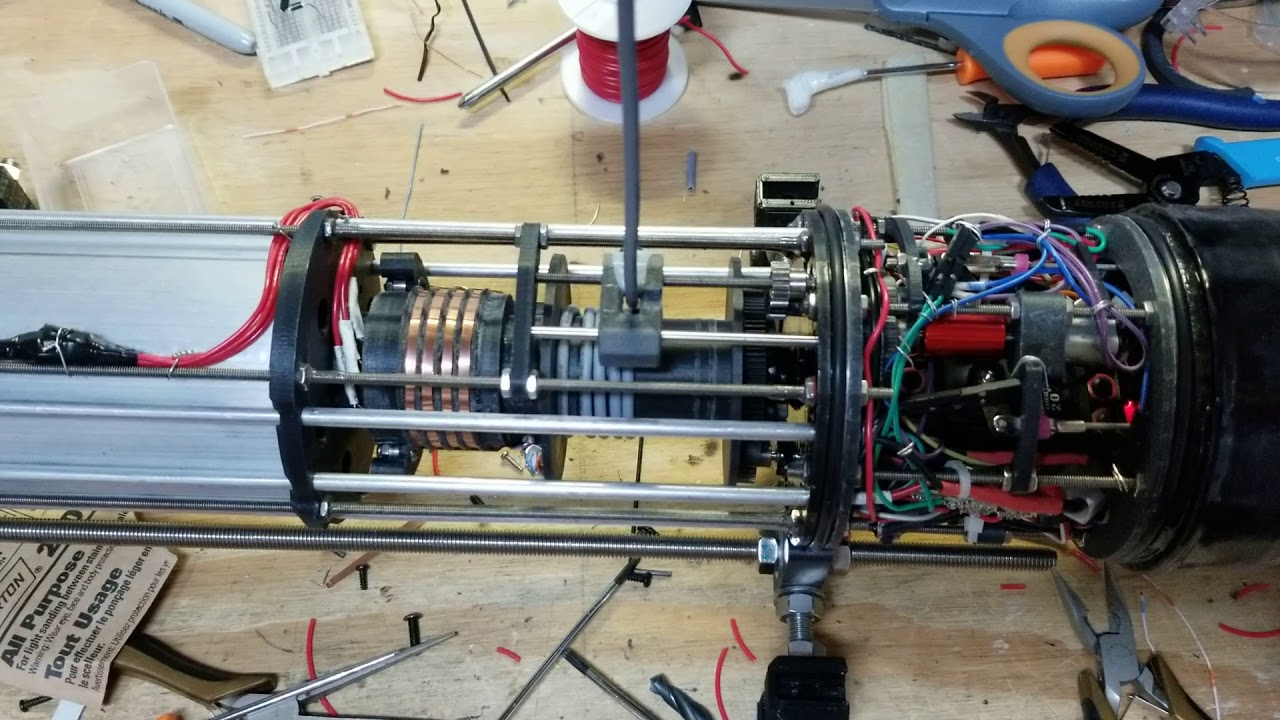

The Ballast tank is of the piston variety, similar to those used by Engel. A piston, attached with a threaded rod (PTFE coated one in my case, runs easy though the lead nut), moves in and out to displace the water. The motor is run through a gear reduction, pictured below, to increase torque. There are limit switches (see the one mounted in the photo already posted) that stop current flow to the motor when the extremes of the tank are hit. Since the limit switches do not have the current capacity to run the motor when operating at peak without burning out, I modified some relay units and wired up the limit switch output to those (indicated in the photo below).

The lead nut/spur gear assembly pictured above is inserted into that bearing in the bulkhead next to it (its a press fit). this allows the lead nut to spin freely, while the gear can ride up against the large bronze thrust washer when spinning so it doesn't get caught up or lock up.

I've also included a video of an initial test run of the motor assembly, which shows pretty well the motion.

Edit - can't post the video from work. I'll upload it when I get home.

-Derek

The Ballast tank is of the piston variety, similar to those used by Engel. A piston, attached with a threaded rod (PTFE coated one in my case, runs easy though the lead nut), moves in and out to displace the water. The motor is run through a gear reduction, pictured below, to increase torque. There are limit switches (see the one mounted in the photo already posted) that stop current flow to the motor when the extremes of the tank are hit. Since the limit switches do not have the current capacity to run the motor when operating at peak without burning out, I modified some relay units and wired up the limit switch output to those (indicated in the photo below).

The lead nut/spur gear assembly pictured above is inserted into that bearing in the bulkhead next to it (its a press fit). this allows the lead nut to spin freely, while the gear can ride up against the large bronze thrust washer when spinning so it doesn't get caught up or lock up.

I've also included a video of an initial test run of the motor assembly, which shows pretty well the motion.

Edit - can't post the video from work. I'll upload it when I get home.

-Derek

Comment