Oh where to begin......

I did not get the melamine board, but while at a craft store, I got a pine base (first of many mistakes). It was warped a small bit and my upright, I did not put a angle in the back for support.

I did not think that out so well. But hindsight is 20/20

CA'd a strip of 100 grit sandpaper onto the center of the board to hold it in place. I did use tape to hold it. The blade was put into the Foredom hand piece. It should have been put in deeper (another mistake).

Once cutting started, it would begin O.K., but soon several factors came into play. One the Foredom slid off center so the blade was cutting at an angle. Two the blade would pull up or down and the warped base allowed movement. Then three, the bit slid out and began to wobble.. So that gave me this:

All over the place there were gouges and butchered cuts. I was angry and I just got ticked off the more I cut. So, more work for me. Here is the aft and bow.

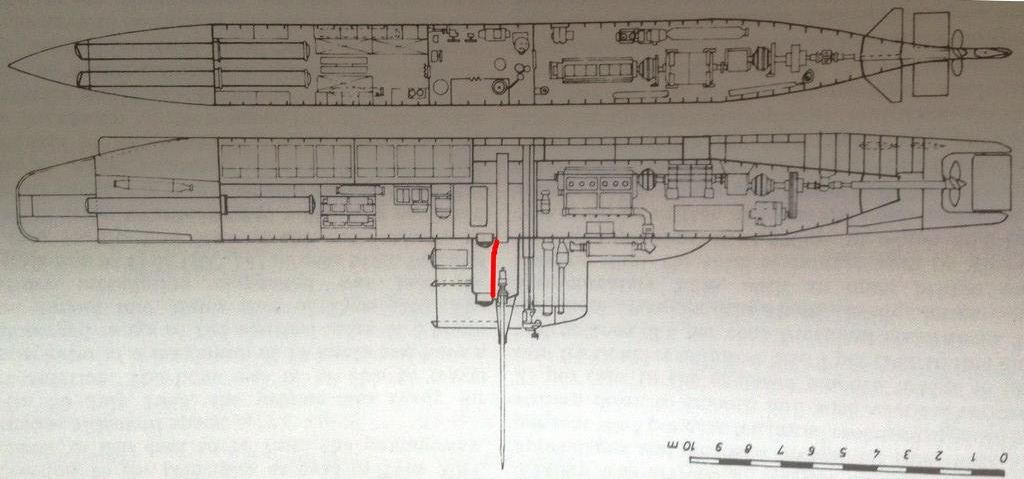

The top came off and for fun, I put the sub-driver in. Here is a panoramic, photo stitched image.

There is a lot of space in there. It is interesting to see how the model's supports came out. It held the WTC well and gave me an idea of how it would come together.

Next photo is the bow vertical cut. The aft end of the bollard is the reference point for the cut.

Before the halves were put together, I should have taken more time to remove more of the internal supports put in the sub. I thought I can just remove them later, and I can, but doing it before would be so much easier.

A couple of quick notes about the sub-driver. A look at the seals and the line of o-ring contact was real good.

But the best part for me is this modification. The SAS plumbs the air out of the WTC from the battery compartment and not the engine room. I like that better. Plus I can put a desiccant below the opening to keep things dryer.

Leave a comment: