She's a brute. Love the Russian philosophy you used in building her.

Japanese BI I-25 in 1/72

Collapse

X

-

-

WTT? Yeah.

Good sound engineering: provision for battery ventilation during charging, auxiliary access points, and compartmentalization. Good stuff, Oztruck. And a severe testing-qualification protocol. You are a careful, methodical type.

Only fly in the ointment is the antenna. Keep in mind that any break in the antenna insulation will be a flood-path for water to get onto the receiver board. I've seen it happen! Provide a stud interface between receiver and exterior portion of the antenna and you'll be good.

So far this is the best read on the site.

David,Who is John Galt?Comment

-

Very interesting built.

Your model is very nice.

Your "Water Tight Thing" is very similar to the one I built for my first sub :

My personnal website : http://www.loubet-modelisme.com

My personnal website : http://www.loubet-modelisme.comComment

-

The Antenna post that David puts into his SubDrivers™ appear to be cast into the resin end-caps, which isn't an option in this type of application.

What part should Oztruck use?

How would it best be sealed?

What should the antenna length be outside the WTT? (Oztruck can help by letting us know what RF band he's using. The optimum length is related to the radio frequency being used.)Comment

-

The antenna lug is not cast as an insert. First I drill through the bulkhead with a 7/64 drill, then I cut threads through the hole with a 6-32 tap, I then run a length of 6-32 all-thread through the hole with about 3/8" sticking proud of the wet and dry sides, and apply CA to hold fast and make watertight the stud . Make up fasteners to the internal and external lengths of antenna as required.

Punch your hole through the auxiliary lid.

David,Who is John Galt?Comment

-

Sorry for being slow in getting back to you on this, I have been interstate and away from my computer.

Thanks David for the heads up on the Ariel and the problems I might come across.

At the moment I am using 36MHz but so does a lot of surface runners where I sail/sink, been thinking of going 40MHz.

On my other sub I have sealed the end of the Ariel with shrink tube filled with silicon but I can see it could be a problem.

If I was to run the Ariel up to a water tight stud that passes through the water tight thingy and attach my Ariel to it, do I cut the Ariel to a convenient length on the inside and then add the rest to the out side.?

I have been told not to cut the Ariel or join it, is that true?Comment

-

Back to the hull.

I went to a tire fitter the other week and asked him for some old wheel weights and Schroeder valves, I had $10 in my pocket but after telling him what I was going to do with them he said I could have them for free, It's good when good things happen.

I melted down the wheel weights and poured the lead into a mold 2" wide and 18" long, let it cool. I then cut it up to fit where it will work best. I then installed the lead ballast and the "water tight thingy" holders. I made them using "L" shape aluminum, I also put some foam in areas where I knew it would be hard to do after the thingy was in place.

The lead was primed and painted before being installed and it and the foam are held in place with silicon then hit with a bit of undercoat.

Comment

-

Just as long as the internal length of antenna plus the external length of the antenna add up to be the length of the original, fresh-out-of-the-box receiver antenna, you're as good as gold!Sorry for being slow in getting back to you on this, I have been interstate and away from my computer.

Thanks David for the heads up on the Ariel and the problems I might come across.

At the moment I am using 36MHz but so does a lot of surface runners where I sail/sink, been thinking of going 40MHz.

On my other sub I have sealed the end of the Ariel with shrink tube filled with silicon but I can see it could be a problem.

If I was to run the Ariel up to a water tight stud that passes through the water tight thingy and attach my Ariel to it, do I cut the Ariel to a convenient length on the inside and then add the rest to the out side.?

I have been told not to cut the Ariel or join it, is that true?

Cut, splice, heat-shrink, molest, and verbally abuse that antenna all you want. Just, at the end of the day, have no breaks in the insulation on the wet portion of antenna; insulate well around the wet side of the antenna lug; and keep the installed total antenna length equal to its original length, you can't go wrong. Cut and solder away without fear or embarrassment!Who is John Galt?Comment

-

-

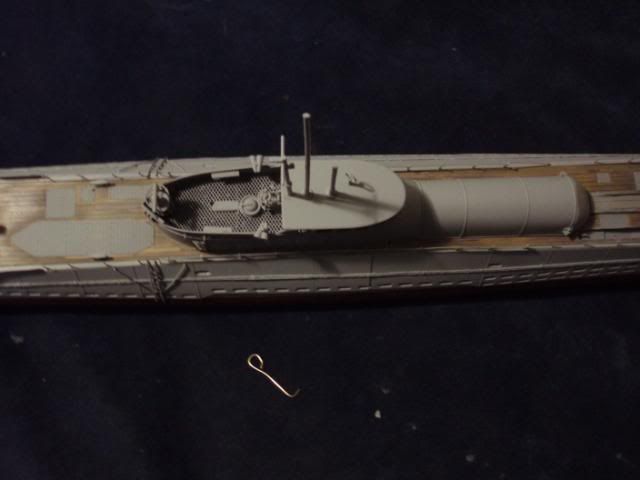

Splashed a bit of red paint on the hull, added the sail numbers.

Fitted the water tight thingy and developed a fitting system for the decks.

In the photo there is a brass "KEY" for pulling the hull out when fitting/removing the decks.

There are 4 springs that pull the hull in and when the deck is installed they pull the hull into the deck and give a good solid join.

Going this way I can still have entry into the hull and w.t.thingy,have a good strong hull with no twisting but, when needed can spread the hull just enough to remove/replace the w.w.thingy.

Comment

-

Boy, am I having fun with this!

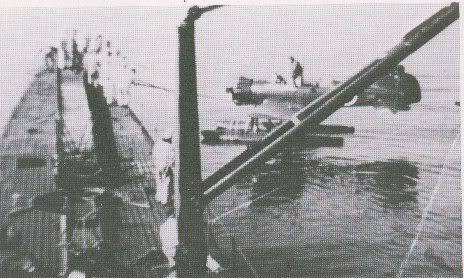

Got the Glen float plane stuck together and painted over the long weekend (Our Queens Birthday)

Very happy with the quality and fit of the kit.

I built into the catapult stand a rare earth magnet and placed with super glue a couple of metal washers on the ramp.

Strong enough to hold the plane on the ramp but still easy to remove when not running on the surface.

Comment

Comment