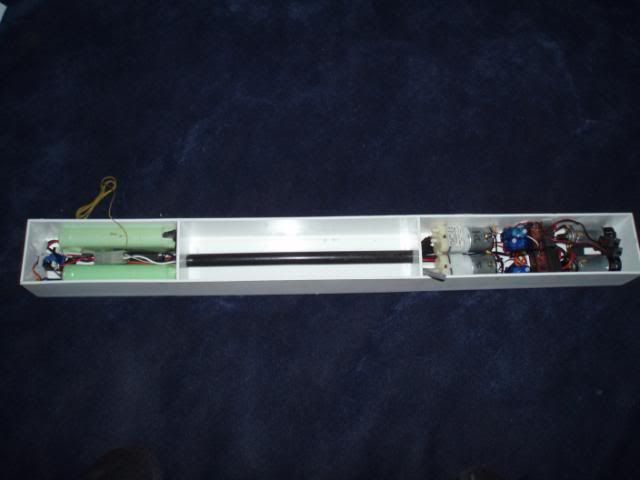

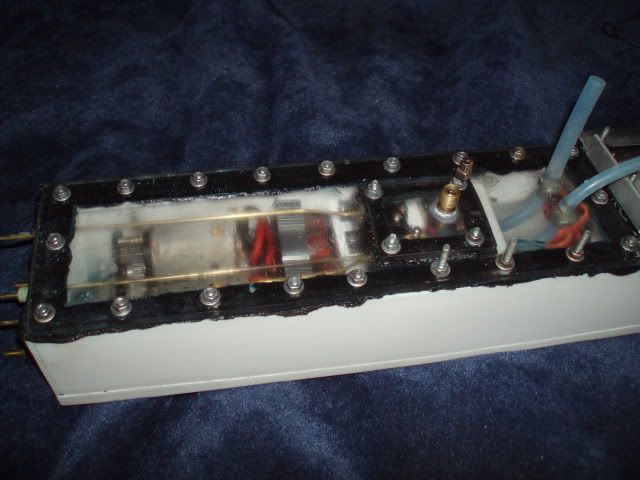

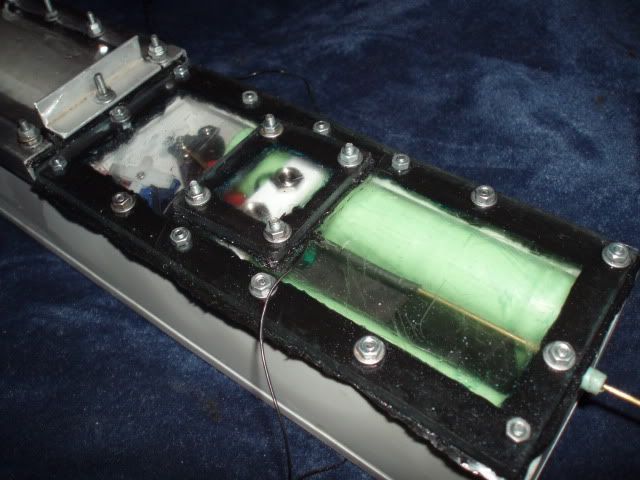

Ok this is what I have got to fit into my dry area.

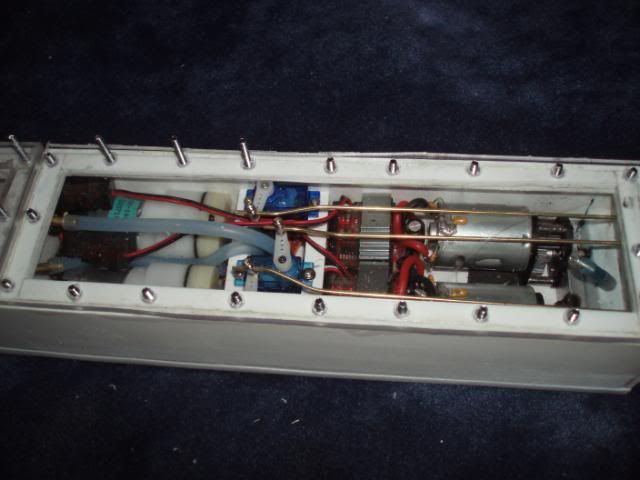

2 x 7.2 stick batteries

2 x electric motors and gear boxes

2 x ESC's

2 x Air pumps

1 x receiver

4 x servos

And still leaving enough room fo my ballast tank

Will it all fit?

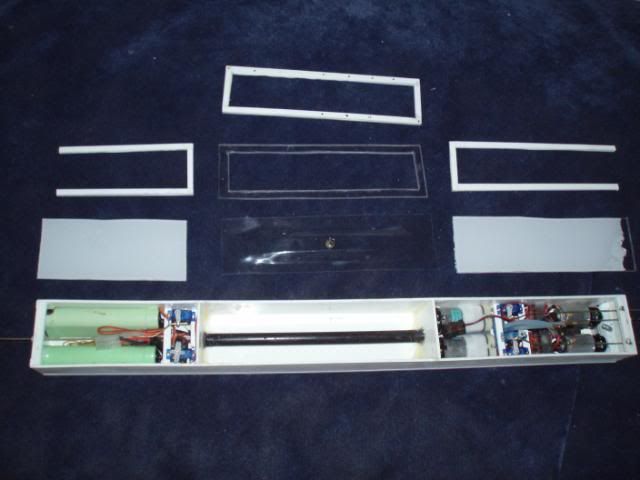

2 x 7.2 stick batteries

2 x electric motors and gear boxes

2 x ESC's

2 x Air pumps

1 x receiver

4 x servos

And still leaving enough room fo my ballast tank

Will it all fit?

Comment