With my Snapmaker 2.0 now failing to print adequate ABS structural parts, and with all that OT I've been working since January, I bit the bullet and ordered this:

Bambu Lab X1-Carbon Combo 3D Printer

Got here yesterday (6 days from China). Takes about 30-45 minutes to set up. I'll leave it up to you to see what it came with, but I also ordered 3 additional ABS spools to use in that AMS unit. I prefer ABS due to it's finishing/Strengthening capability with an Acetone Vapor bath.

I "print build" most everything now but a hull itself because I prefer GRP hulls, period. If I were to do that I'd bite the $$ bullet and use the more expensive PA-CF (Nylon Carbon Fiber).

Here's why: Bambu Lab X1 Carbon 3D Printer Review | Prints Nylon

My No. 2 priority (after Functionality) Is Durability, Cyberdyne Systems Model 101 TERMINATOR grade survivability.

Set up and use is so freakin' easy even a Boomer like our "resident Luddite" can do it! It walks you through it. Even if something goes south, it will not only tell you, but it points to steps to resolve the issue.. The 4 Spool AMS holder automatically knows color and type of filament is loaded when you use Bambu's Filament. Which I will as I'm guaranteed it's engineered for the product. Look, I dig $$ is a factor, but so is loss due to wasted time. MY time. This thing just takes all the guess work out!

I'm not going to go through the Specs/features like an Ad here, you can do that at their website and/or YouTube. But if you're looking for a new printer, tired of tweaking (understand if that's your thing), or wasting more time to get that print, then take a hard look at this. In my not so humble opinion if you can live with a 256mm3 Build volume, you can get a hull diameter on the order of 10" if you want.

If you're new to filament printing, take a GOOD look at this brand, seriously. Even the entry level would be adequate for those that would print PLA hulls. I jumped to the Flagship only because I wanted the flexibility of printing most any material tailored to a requirement. Of course the discretionary spending OT $$ helped.

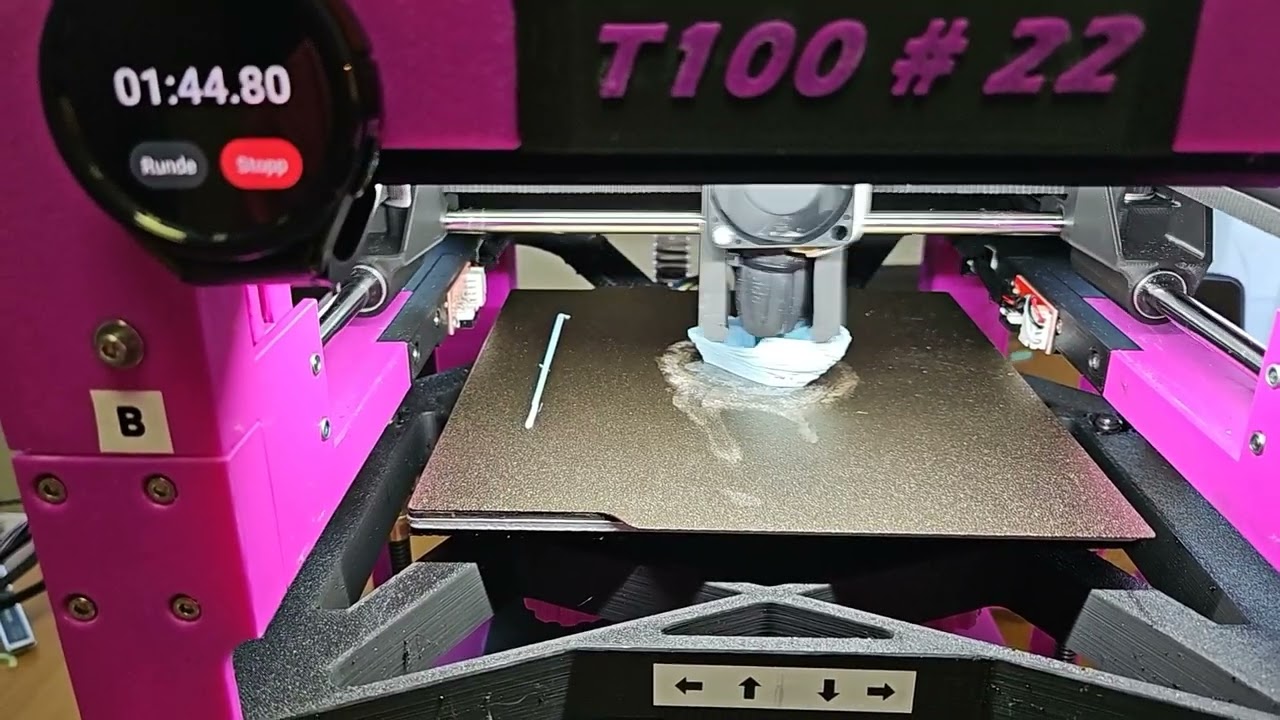

Ran the ubiquitous #3DBenchy test. Default settings with their PLA Basic Filament This thing is fast. 25 minutes! It was just so darn easy! Allowing it too cool it practically fell off the build plate!

I don't normally "rave" about products, doing so only when I really feel it's worth it. This is worth it.

Right now I'm having an old spool of generic ABS+ drying in it, yes it will dry your filament too, which I just discovered is actually critical for good prints. The AMS Spool holder has room for desiccant allowing your filament to be ready to go. FWIW, I also purchased a 2 spool filament dryer.

I'll give updates on this new printer journey, and may give a walk through at a Dive Tribe should Bob permit.

I yet to load and look at it's slicer, the Bambu Studio, I'll let you know about that.

I'm compiling a list of the "good" YT videos worth watching to share on this as well.

But I'm really excited about this one folks, more so than in a while with filament printing.

The Snapmaker is now slated for CnC or laser engraving only lol!

Bambu Lab X1-Carbon Combo 3D Printer

Got here yesterday (6 days from China). Takes about 30-45 minutes to set up. I'll leave it up to you to see what it came with, but I also ordered 3 additional ABS spools to use in that AMS unit. I prefer ABS due to it's finishing/Strengthening capability with an Acetone Vapor bath.

I "print build" most everything now but a hull itself because I prefer GRP hulls, period. If I were to do that I'd bite the $$ bullet and use the more expensive PA-CF (Nylon Carbon Fiber).

Here's why: Bambu Lab X1 Carbon 3D Printer Review | Prints Nylon

My No. 2 priority (after Functionality) Is Durability, Cyberdyne Systems Model 101 TERMINATOR grade survivability.

Set up and use is so freakin' easy even a Boomer like our "resident Luddite" can do it! It walks you through it. Even if something goes south, it will not only tell you, but it points to steps to resolve the issue.. The 4 Spool AMS holder automatically knows color and type of filament is loaded when you use Bambu's Filament. Which I will as I'm guaranteed it's engineered for the product. Look, I dig $$ is a factor, but so is loss due to wasted time. MY time. This thing just takes all the guess work out!

I'm not going to go through the Specs/features like an Ad here, you can do that at their website and/or YouTube. But if you're looking for a new printer, tired of tweaking (understand if that's your thing), or wasting more time to get that print, then take a hard look at this. In my not so humble opinion if you can live with a 256mm3 Build volume, you can get a hull diameter on the order of 10" if you want.

If you're new to filament printing, take a GOOD look at this brand, seriously. Even the entry level would be adequate for those that would print PLA hulls. I jumped to the Flagship only because I wanted the flexibility of printing most any material tailored to a requirement. Of course the discretionary spending OT $$ helped.

Ran the ubiquitous #3DBenchy test. Default settings with their PLA Basic Filament This thing is fast. 25 minutes! It was just so darn easy! Allowing it too cool it practically fell off the build plate!

I don't normally "rave" about products, doing so only when I really feel it's worth it. This is worth it.

Right now I'm having an old spool of generic ABS+ drying in it, yes it will dry your filament too, which I just discovered is actually critical for good prints. The AMS Spool holder has room for desiccant allowing your filament to be ready to go. FWIW, I also purchased a 2 spool filament dryer.

I'll give updates on this new printer journey, and may give a walk through at a Dive Tribe should Bob permit.

I yet to load and look at it's slicer, the Bambu Studio, I'll let you know about that.

I'm compiling a list of the "good" YT videos worth watching to share on this as well.

But I'm really excited about this one folks, more so than in a while with filament printing.

The Snapmaker is now slated for CnC or laser engraving only lol!

Comment