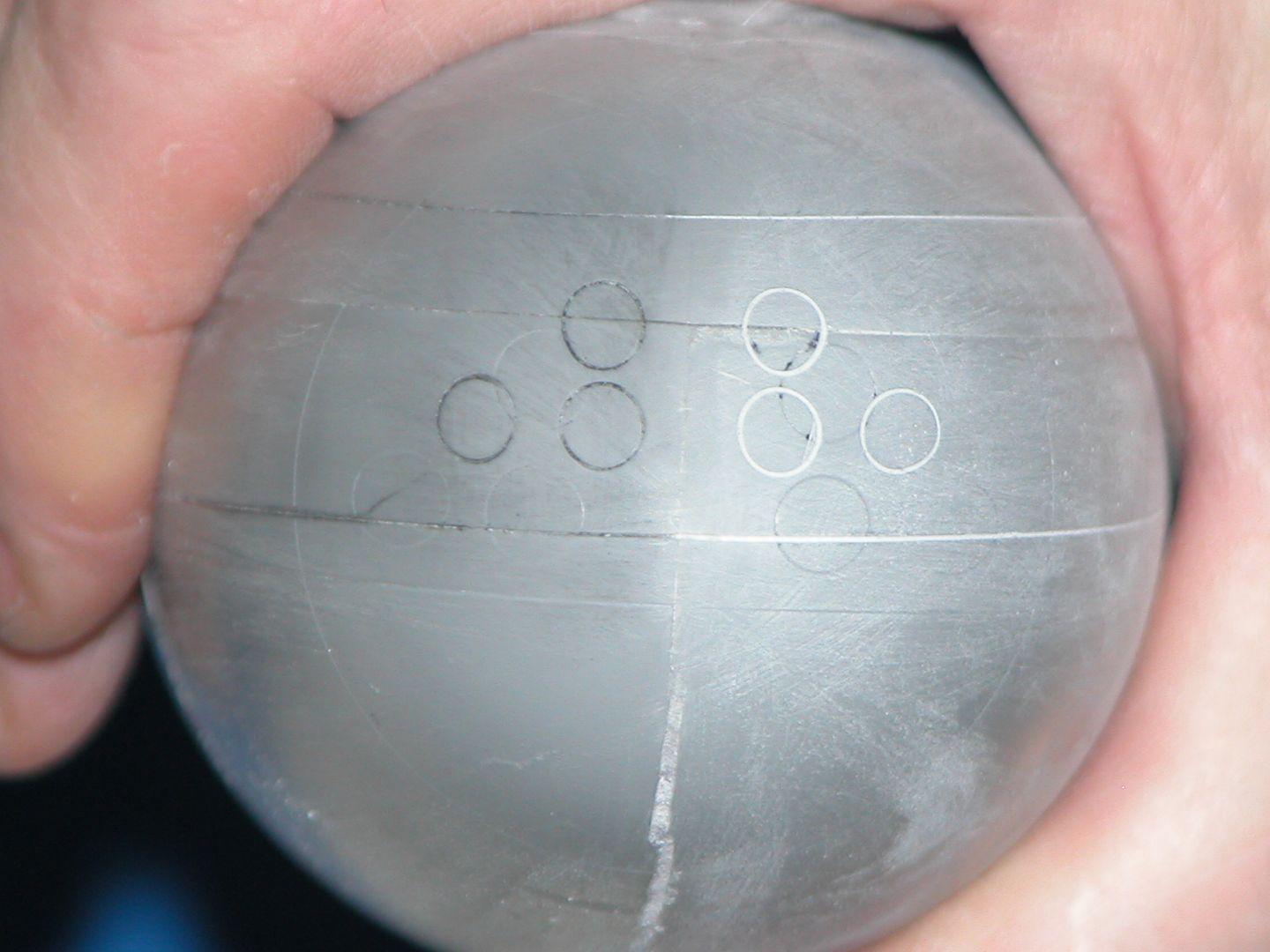

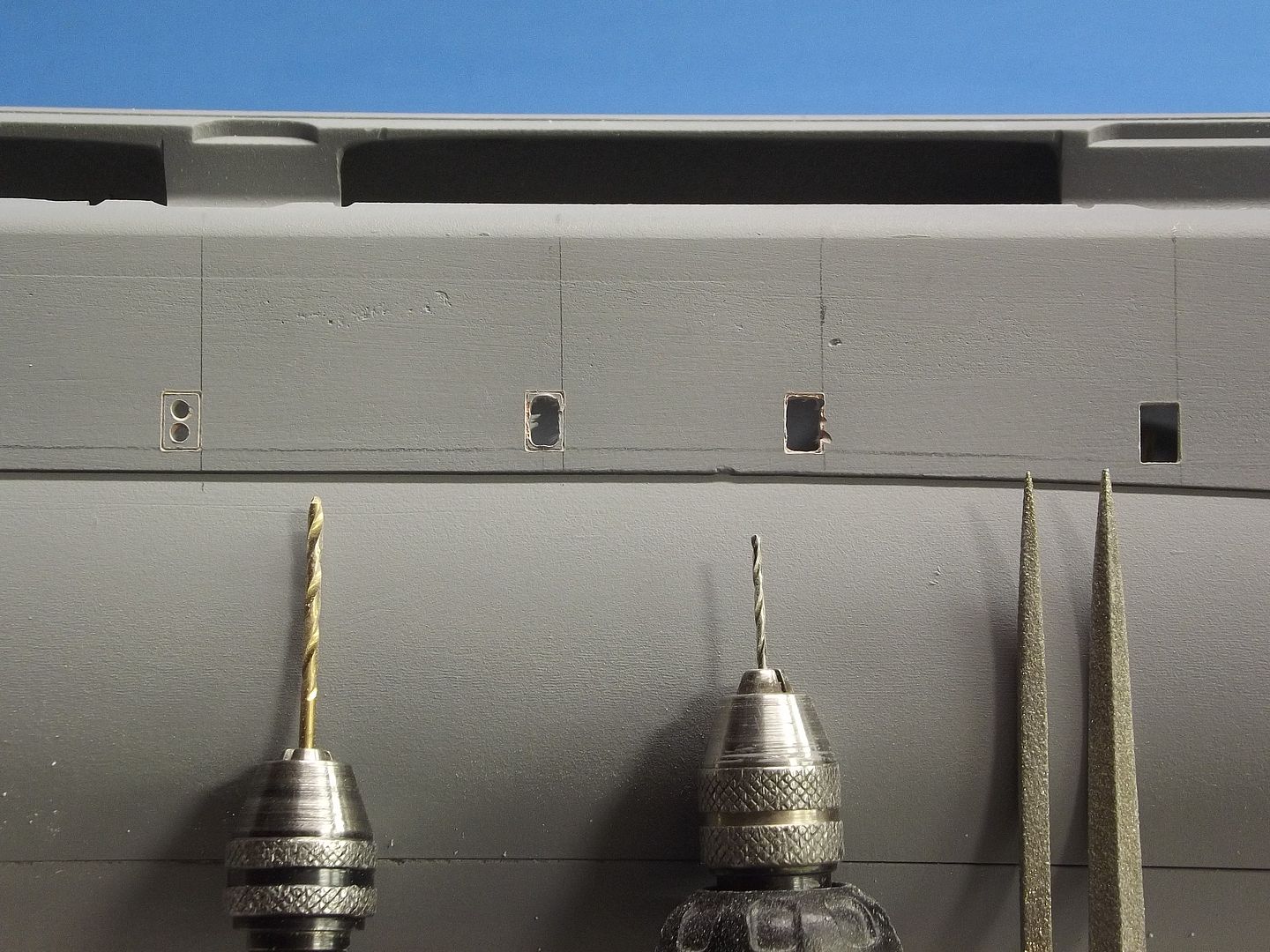

Every time I try to open up the limber holes on a sub it looks like I did it with an air hammer. I'm just not good at doing this. What is the secret of making nice holes? Do you use a metal guide, special tools, CNC mill - what?

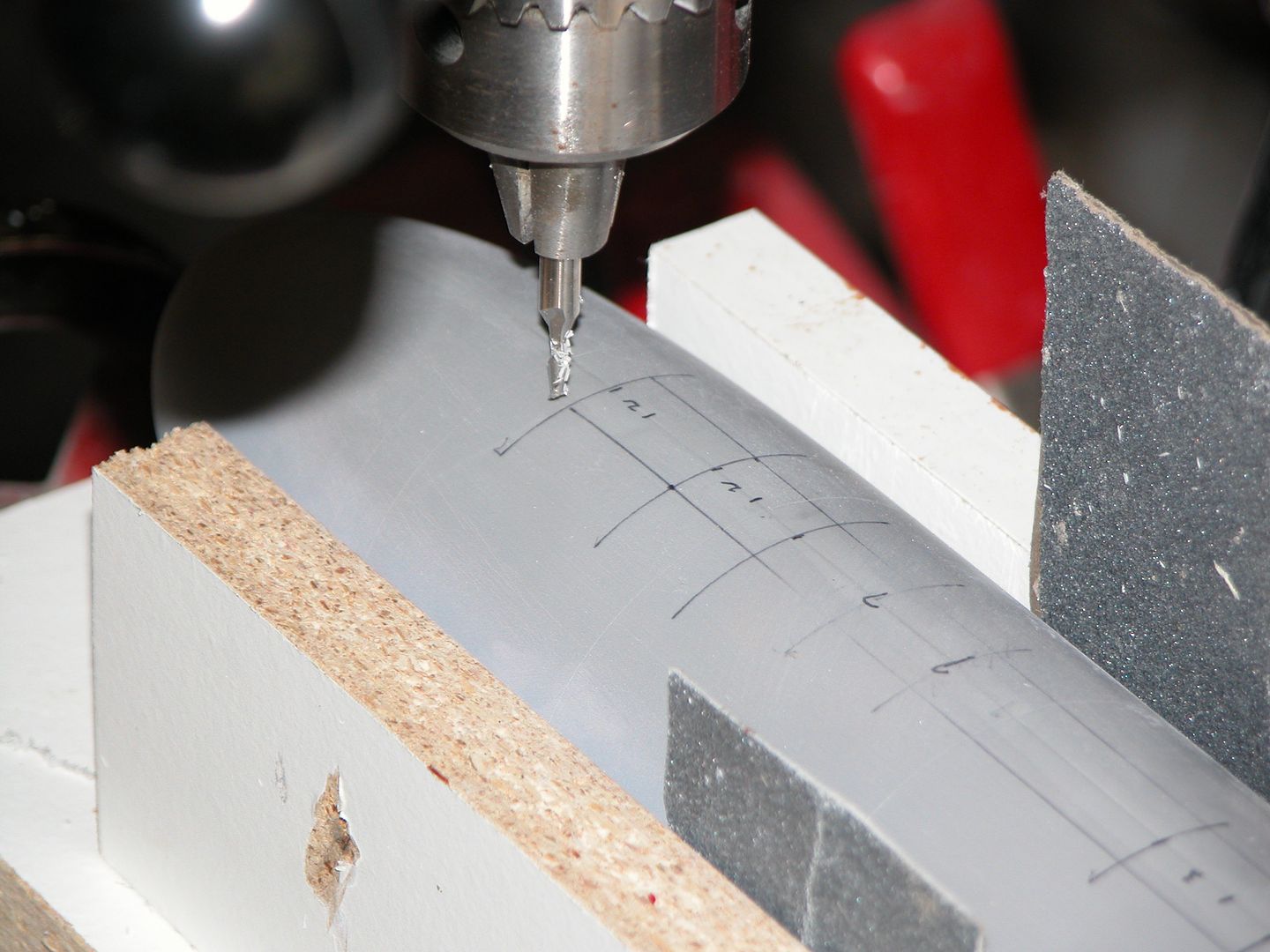

A friend of mine and I are slowly working on a Sheerline Type 2D and we're using a mill - not CNC - to open up the holes. We've been working on it for over two years now with no immediate end in sight. Every time I read some build thread where the builder says something like, "I opened up the bazillion vent holes in a couple of nights." and the results look perfect I just shake my head and wonder - how the @#$# did he do it? - here's looking at you, Bob - I love your work on the OTW Type XXIII.

Help - please,

Dan

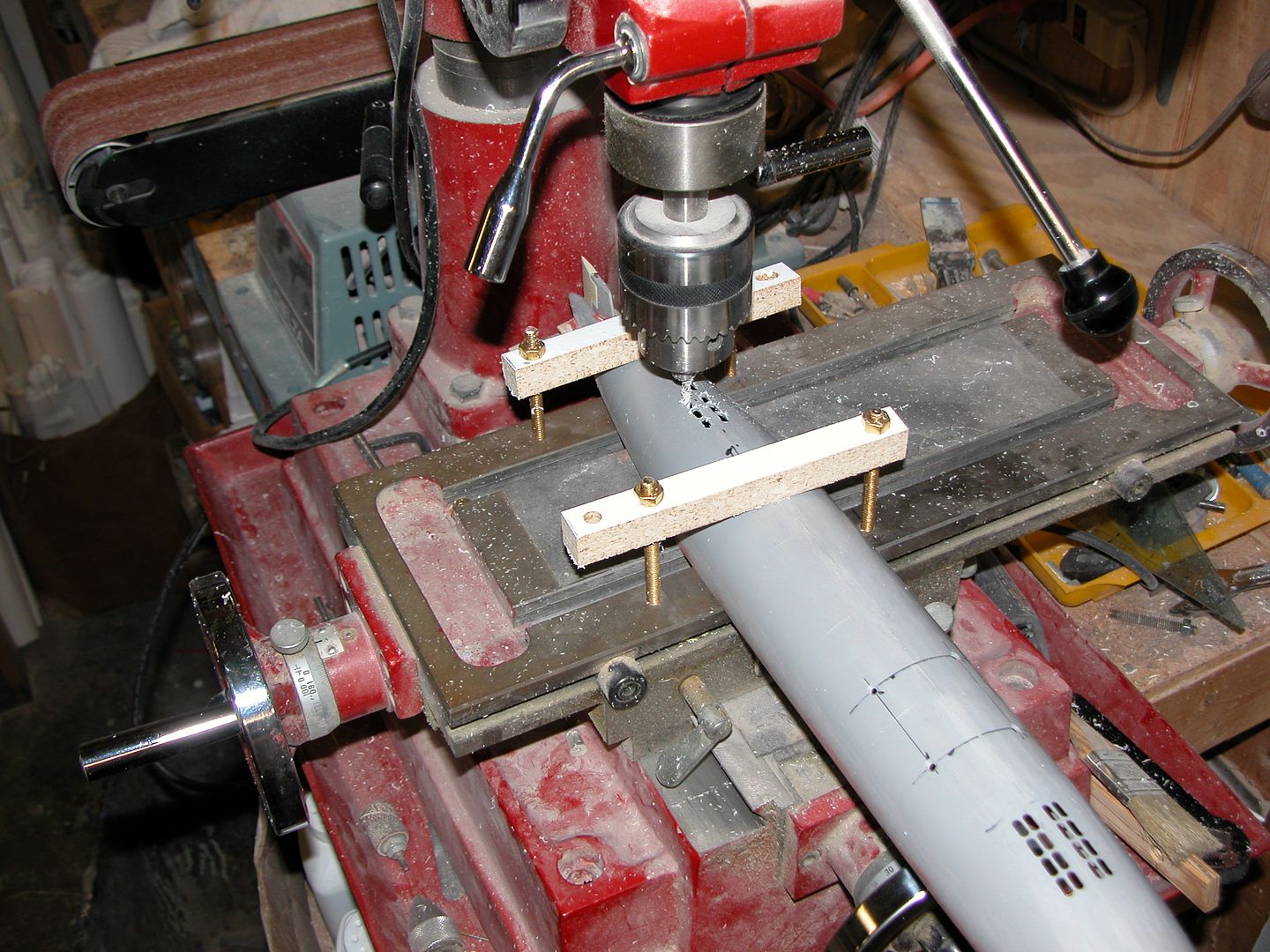

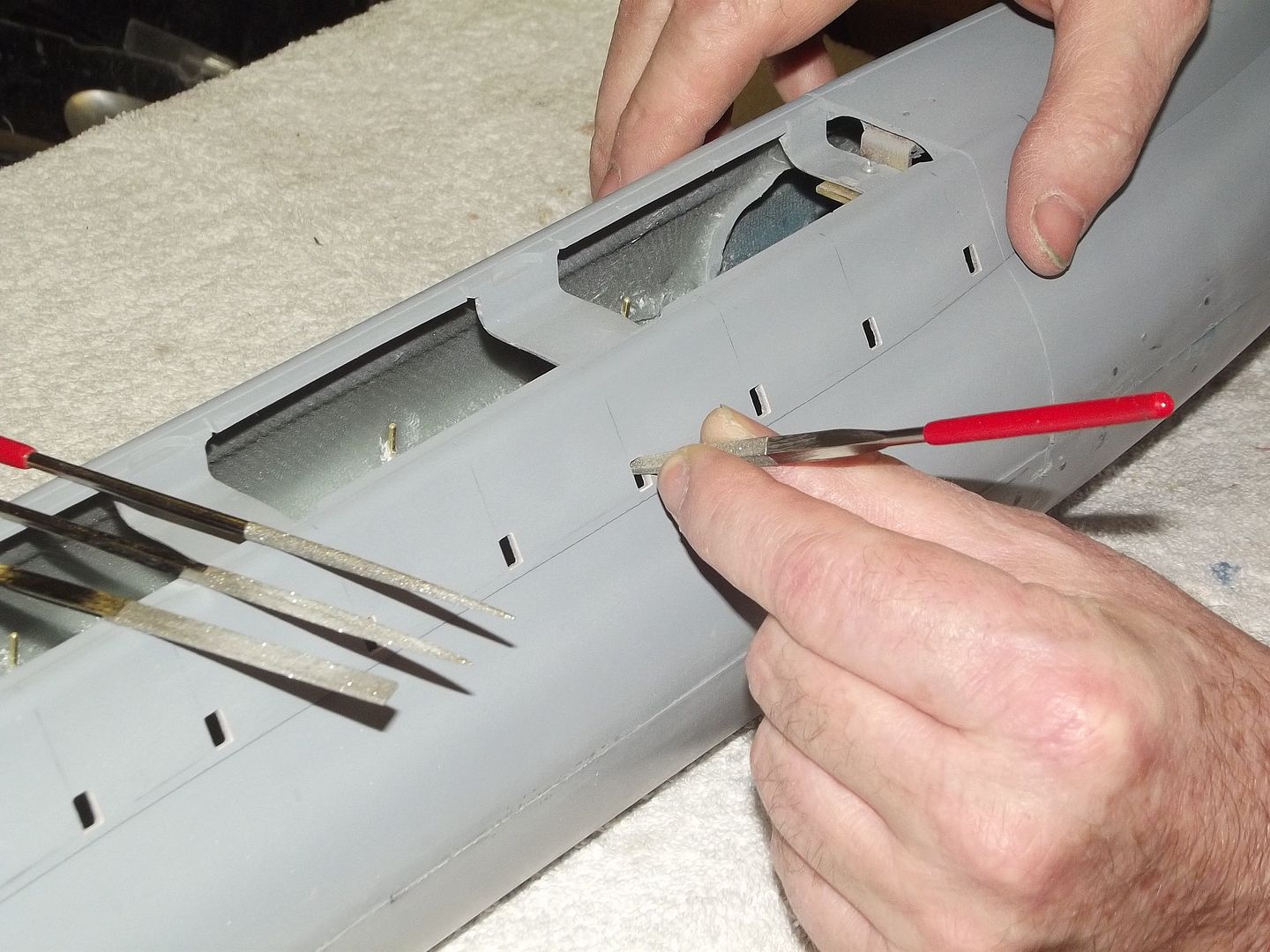

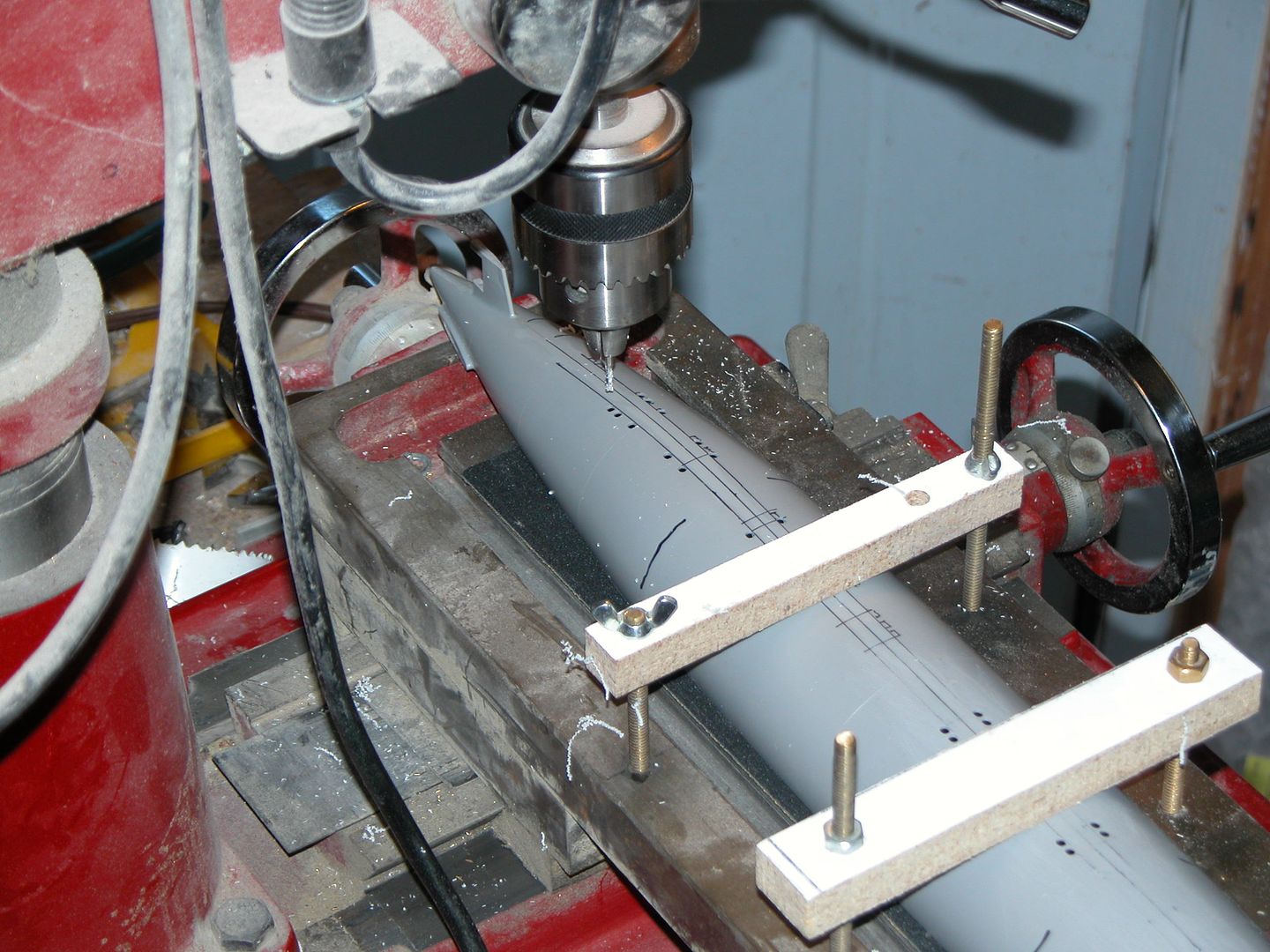

A friend of mine and I are slowly working on a Sheerline Type 2D and we're using a mill - not CNC - to open up the holes. We've been working on it for over two years now with no immediate end in sight. Every time I read some build thread where the builder says something like, "I opened up the bazillion vent holes in a couple of nights." and the results look perfect I just shake my head and wonder - how the @#$# did he do it? - here's looking at you, Bob - I love your work on the OTW Type XXIII.

Help - please,

Dan

Comment