It's O.K. Mike, sometimes it is fun to poke at David just to see to watch him growl.

Dave have you seen this?

Collapse

X

-

Schools started moving away from manual/practical skills teaching in the 80's. They concentrated on design instead, manufacturing industry was to be dismantled and shipped over to China, India, South Africa, or anywhere you could find people willing to work for a bag of chips.

In place of that, our economy would become 'service' based. A few high end engineers would be kept employed, designing and coming up with ideas, but the heavy end of engineering would be done overseas. No more dirty fingernails for us.

The folly of that policy is now starting to be felt, a service based economy means low skilled, low paid work, that's if you can get it. Your national economy is heavily influenced by external factors.

The big money can be found in the so called 'banking industry' (thinking they misspelt banking), but is nothing more than legalized theft. Parasites feeding off the backs of the people that really do make wealth by creating the things that make life comfortable.

They knew how to deal with these people in Iceland, they prosecuted the bankers for fraud and put them in jail, where they belong.Comment

-

I think that as any society moves towards a more automated future, be it any industry, hobby, or otherwise, a society that simple embraces the new with no consideration to the old / more manual methods is a society / business model that will ultimately fail.

In my business, I'm continually staggered by younger graduates we get (and at mid 40 I'm not old), that are completely flummoxed when tasked to "think" about a problem that does not neatly fit into an off the shelf model they want to run / have been trained to run. Automation for the masses in my view leads to a lack of critical thinking about problem solving. In a jam - when the **** hits the fan, all organisations can benefit of the advantage of people trained / skilled in more manual approaches to problem solving. Look at any redundancy / fail safe systems in any industry and you will find KISS basics (even if applied through latest technology) at play.

On the hobby front, I see instant gratification types come and go. Hobbies per se are conditioning people towards cheap off the shelf products that are RTR. That conditioning comes about within a business model that feeds the notion that we are now all time poor. Well time folks is all about priorities. You want to fill your life with electronic garbage / junk TV, sure you won't have time to immerse yourself in the craft. It's rare to find a new comer that can scratchbuild, and those who have invested the time in the craft of scratch building I find are a dying breed. 5 years ago I scratchbuilt a 1/72 light carrier (Guispeppi Garibaldi, and a 1/72 Cruise ship Silver Cloud). Both models are large (2.5m and 2.2m long respectfully and chock full of details). I still managed full time work, home duties, games and sporting fixtures with kids, date nights with the wife, and pretty much had a balanced life. Yet in my home you won't find cable TV, X box or some other game console, and the free to air TV is on only to record documentaries. You will find my kids engaged with Technical lego.

The craft still has relevance, even for those who only have time to assemble rather than build. I find thankfully, a lot of guys who come through my workshop for help, leave with an appreciation of that. At its basic entry level, the craft should impart a skill set that can make assembly rewarding and enjoyable which achieves an otherwise superior result. Learning how materials come together, how tools work, even how to apply paint, all valuable stuff, and all of little relevance in the RTR world.

Cheers

JohnLast edited by Slats; 01-30-2015, 10:08 PM.John Slater

Sydney Australia

You would not steal a wallet so don't steal people's livelihood.

Think of that before your buy "cheap" pirated goods or download others work protected by copyright. Theft is theft.

sigpicComment

-

Ps.. I'm not on this board much (or for that matter), any board much any more. I'm back at grad school working my butt off, whilst working fulltime, and enjoying kids, family stuff and church and community groups I'm involved in. (I'm no hero - I just for now have shifted priorities). When I do hit the workshop, and I make sure I do, its quality time. Whilst I presently can't churn out the models that I once did, I can enjoy step by step moments of quality building. I'm presently working on a scratchbuilt 1/72 scale expedition cruise ship the MS bremen. The original plank on frame hull I did a few years back. I did a deal with a craftsman here that now supplies a GRP hull for those who can't build a hull. (photos soon). He did such a great job I'm using a GRP hull for my model.

As both a scratch-builder and assembler, I shun the mass produced world of ship and sub models. I want my models to have a craft story in them. This is why I buy gear from Joel and David - there is something intrinsically beautiful in "hand built" structures. I will respect technology (I respect my Apple computer), but I'll never love it.John Slater

Sydney Australia

You would not steal a wallet so don't steal people's livelihood.

Think of that before your buy "cheap" pirated goods or download others work protected by copyright. Theft is theft.

sigpicComment

-

Stop messing about - just get a Sub-driver!Comment

-

Thanks Mike will do.

Yes I'm alive. Just - working on a Doctorate in Health Economics. Another few years yet.

Next sub assembly will be David's GRP Albacore - if ever gets of his arse and finishes it.

I have a 3" SD that I'll deck out my way for the boat.

Cattle prod time Mike, I want that boat this year. He has done the Type 9 gear so there should be nothing in his way to finishing it.

Best

JohnJohn Slater

Sydney Australia

You would not steal a wallet so don't steal people's livelihood.

Think of that before your buy "cheap" pirated goods or download others work protected by copyright. Theft is theft.

sigpicComment

-

(cowering in corner of room, shaking, in fetal position)Thanks Mike will do.

Yes I'm alive. Just - working on a Doctorate in Health Economics. Another few years yet.

Next sub assembly will be David's GRP Albacore - if ever gets of his arse and finishes it.

I have a 3" SD that I'll deck out my way for the boat.

Cattle prod time Mike, I want that boat this year. He has done the Type 9 gear so there should be nothing in his way to finishing it.

Best

JohnWho is John Galt?Comment

-

Yeah bull**** - Merriman cowering in corner of room, pigs fly, Santa's real! Yet if you can manage it Mike, you could charge admission to see such a sight. At 50 cents a view you could turn an easy $10mil bucks.John Slater

Sydney Australia

You would not steal a wallet so don't steal people's livelihood.

Think of that before your buy "cheap" pirated goods or download others work protected by copyright. Theft is theft.

sigpicComment

-

I've seen him like that!

When Ellie (4'6" and 80lbs) starts on him! (6' 3" 260lbs+) whimpers like a baby, thumb sucking - all that stuff! It's a sight to behold for sure! She's a bit like that ol' lady on Laugh-in, beats the crap out of him with her handbag!Stop messing about - just get a Sub-driver!Comment

-

you promised not to tell!Who is John Galt?Comment

-

1/48 Type VIIC Plastic Kit from Arkmodel

Make it simple, make strong, make it work!Comment

-

Well that seems more cost effective than me flying across the globe and buying a baseball bat.

BUT seriously David - this project has been going on and on. PLEASE FINISH THIS UP.

Mike customer here with CASH. Also what's left to do on this project can't be much.

Best

JohnJohn Slater

Sydney Australia

You would not steal a wallet so don't steal people's livelihood.

Think of that before your buy "cheap" pirated goods or download others work protected by copyright. Theft is theft.

sigpicComment

-

Gents,

Donít want to tear open old wounds but this guy is using molding techniques that I have never seen used before.

On another forum (SC) I did ask him to explain what he was doing but he wasnít so keen to telling me, he would do so when he had some more time. Ok fair enough but I know when Iím told to bugger off.

But then I turn in a little pittbull, when looking at the pictures I noted a bucked metioning ***mwollflocken, found out that it was Baumwollflocken, cotton flocks. That is used as a filler in adhesive putties to impart strength to the joint.

I had a key word now, then I did what Iím good in bitbulling the www and I found the technigue on this site (I think it's a site made for Mr Greenman)

The new stuff (for me at least) starts at #13 it explains the use of the cotton flocks, and the white balls on top (that intrigued me the most in his pictures) itís called "poraver". I left the first five pictures out (got a message that 10 was the max allowed).

Grtz,

Bart

Friday, January 3, 2014

Making Cowl Molds

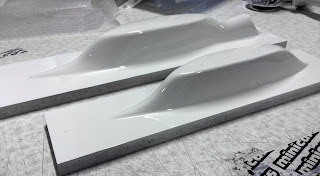

This is a short description on how I make my outrigger cowl molds. FYI. :)

#1. My preferred method is to use Kolb styling clay to form the basic cowl plug. Thats the same material and technique as I used when doing the 1/10 Volvo racing body some 15 years ago (link). The styling clay is the same that is used in the car industry when doing prototype designs at Volvo etc.

#2. When working with styling clay you heat the clay up to about 60+C in a owen and the clay softens so you can apply it etc. When cooled down to less then 25 deg you can start shaping it. The shaping is done with a combination of different special tools that I have made myself (copied from a guy that works at Volvo design). You also use other tools like profiled templates etc. Search for "styling clay" on Google and you get plenty of info - like these...

#3. When done with the shaping the clay plug is removed from the shape board and attached to std white laminated shelf board and a small bottom radius is added so it will be easier to mold.

#4. The 45 plug in the back and a 21 sized "180 deg wrap around exhaust" plug in the front.

#5. You can somewhat see that the 21 plug (bottom one) have a concave recess on the right rear part. That is to make more room for the wrap around exhaust.

#6. You need to have a couple of degrees of angle on the sides (minimum) as otherwise it will be hard to get the mold off the plug and also removing the finished molded cowl from the mold.

#7. You can hardly see it, but look at the center-line drawn on the base board. To the very front where you normally cut of the finished cowl I have made a small groove. That groove is just about visible on the finished cowl and there is one made to the mold in the rear also. That is really helpful (I think) when actually aligning the cowl to be fitted on the boat tub.

#8. The styling clay is a bit soft so its painted with 2K basecoat and 2K paint or clearcoat to get a smooth glossy finnish that will be easy to polish and mold.

#9.

#10. On the sides of the base board some additional base boards are attached to form a box around the cowl plug. The sides are about 15 mm higher then the highest point of the cowl plug.

#11. A soft clay is being used in all the corner joints (blue). Then its being prepared with wax (this + this) and release agent (PVA).

#12. Mold epoxy gelcoat brushed on.

#13. Mold epoxy resin mixed with cotton flock makes the corner fillets. Then I forgot to take pictures of the thin fiberglass cloth being applied though... But you use a couple of 163 g twill weave fiber glass cloth and epoxy resin to make a hard backing on the mold gelcoat and the filled corners as in this picture.

#14. Directly when your done with applying the two layers of fiber cloth (before it has set) you mix up a material called Poraver with epoxy resin and a small amount of foaming agent (about 55 g epoxy resin per 1L of Poraver) and start filling the box up... When that has hardened over night you sand the bottom flat and add a couple of layers of fiber glass and epoxy resin to seal the bottom of the mold. Leave to completely set for a couple of days.

#15. Remove the newly made cowl molds from the cowl plug and clean it out with water. Then carefully smoothen the surface with wet sandpaper and water. When that is done use your favorite polishing compound and polish the gelcoat. Done. Now you can start preparing your mold with wax etc... Good Luck With Your Own Molds! :)

Practical wisdom is only to be learned in the school of experience.

"Samuel Smiles"Comment

-

Practical wisdom is only to be learned in the school of experience.

"Samuel Smiles"Comment

Comment