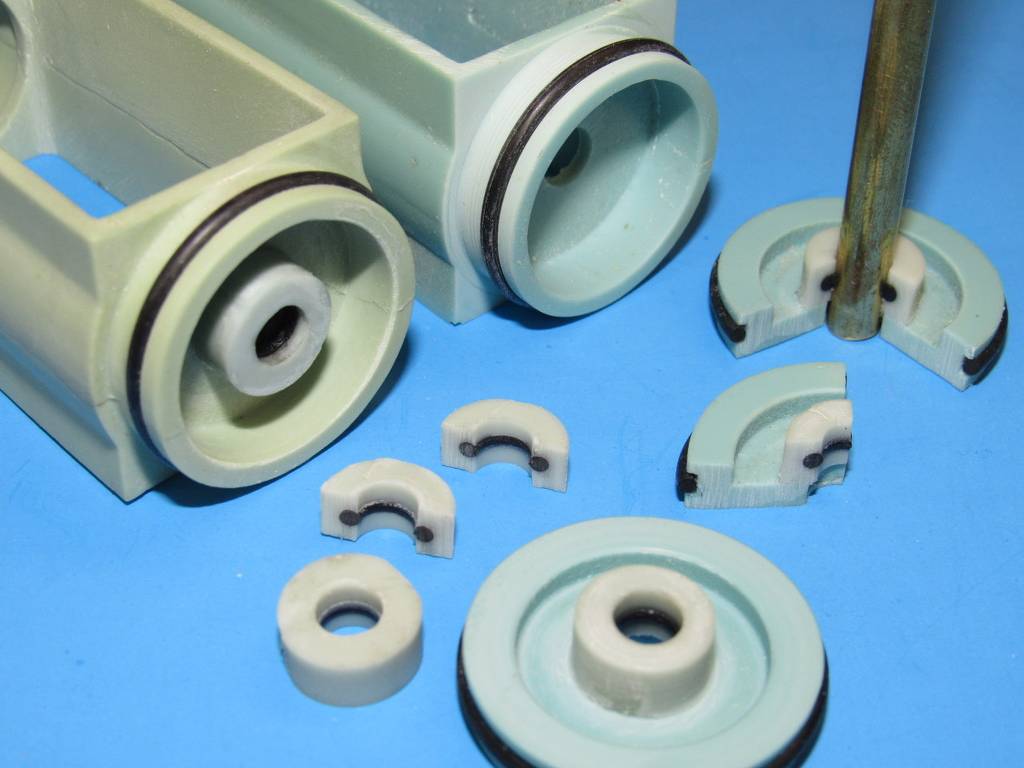

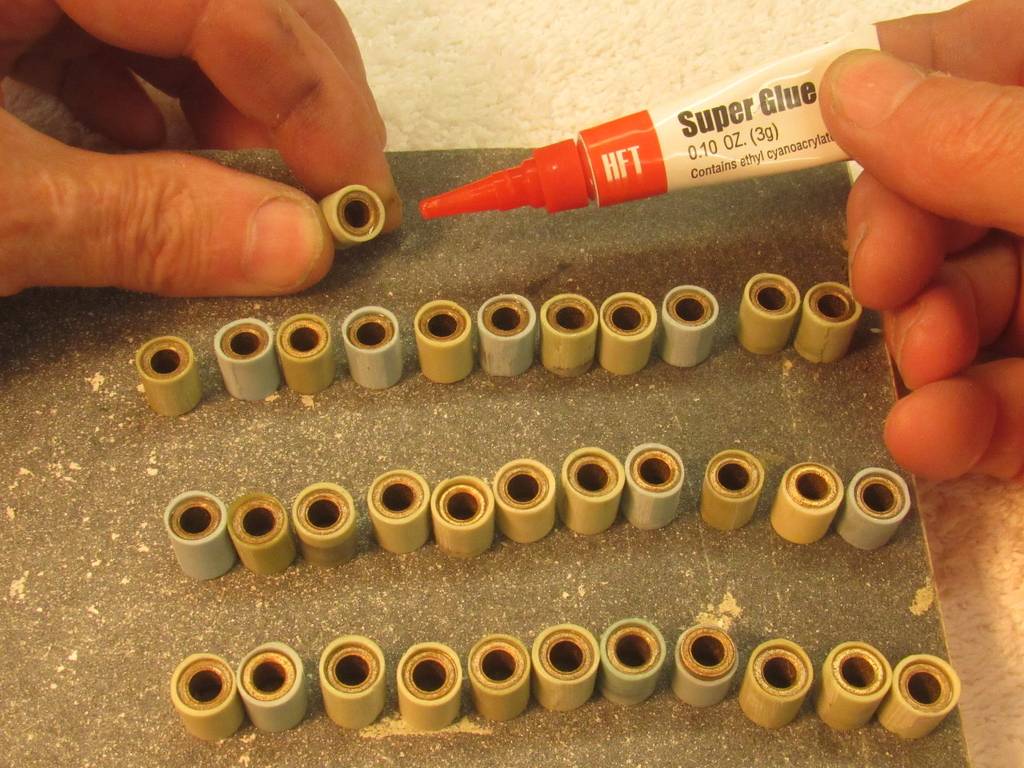

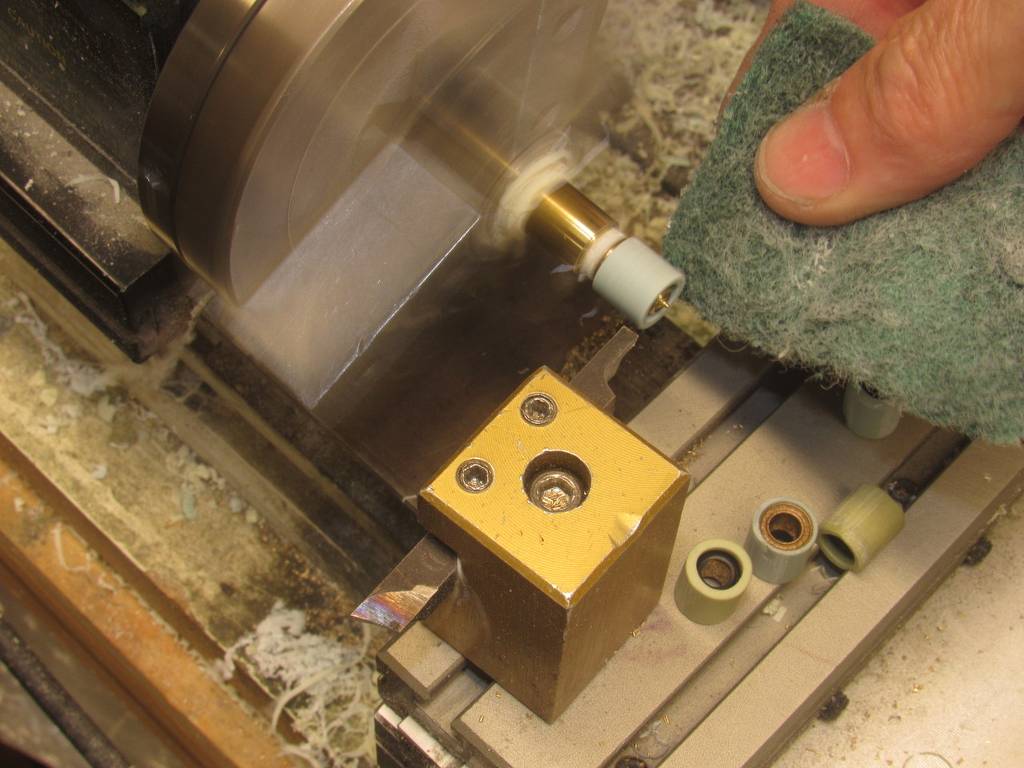

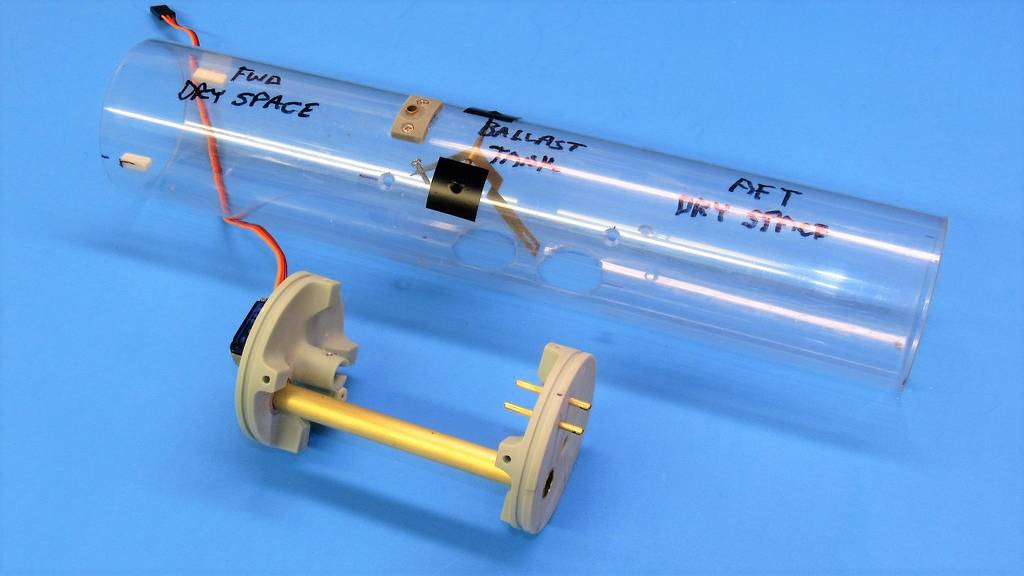

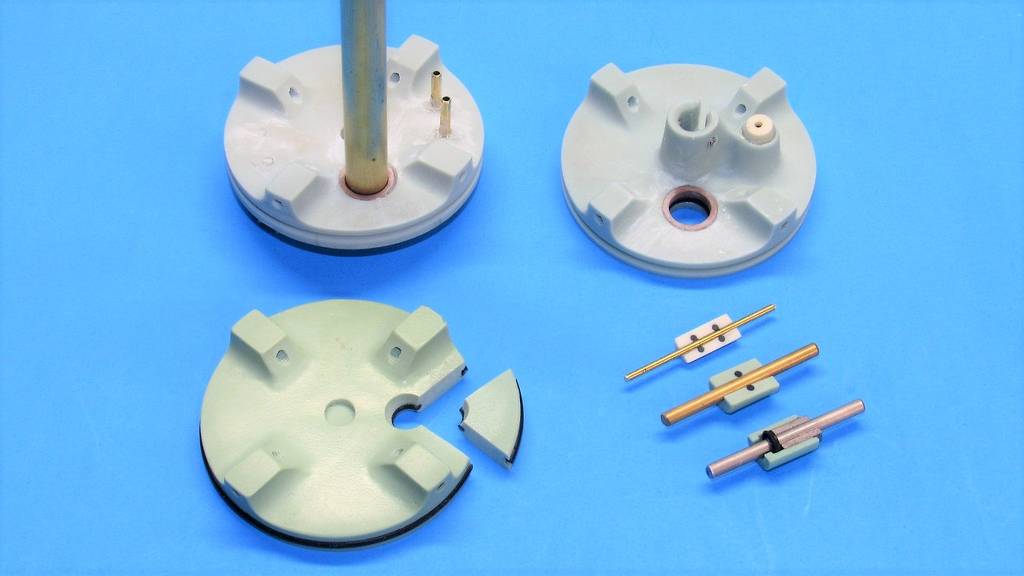

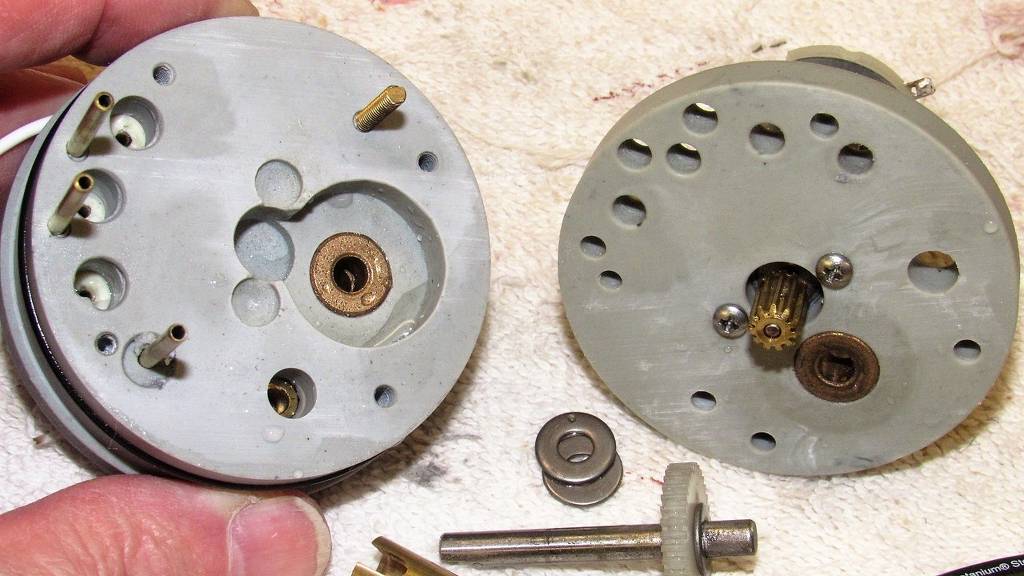

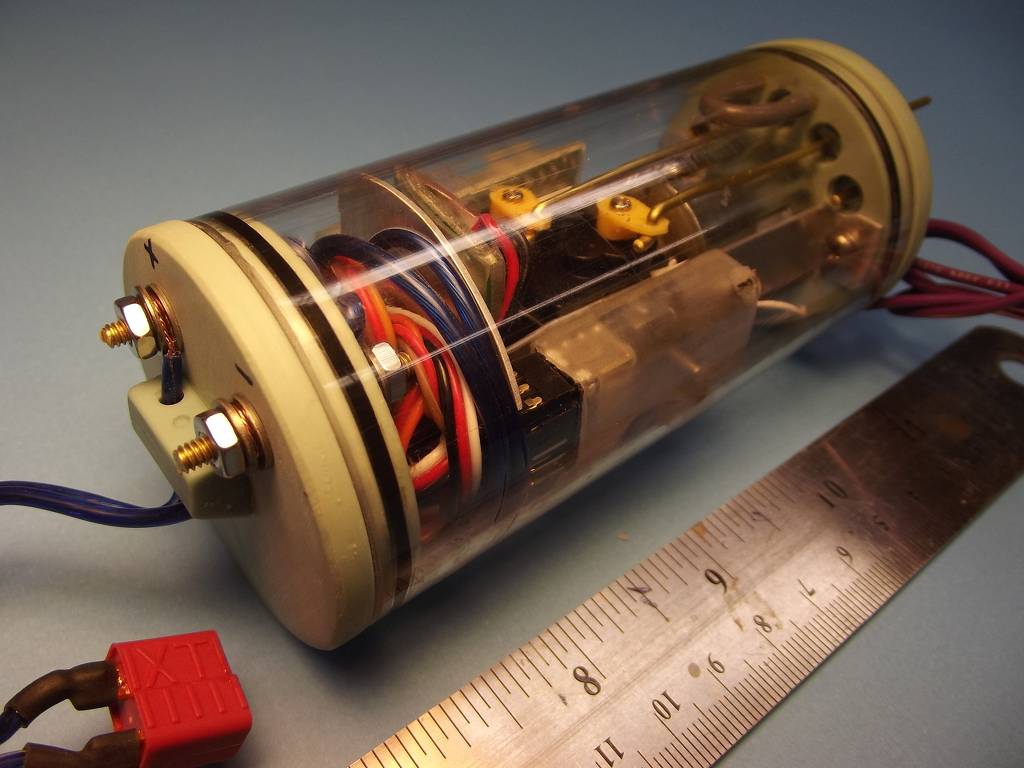

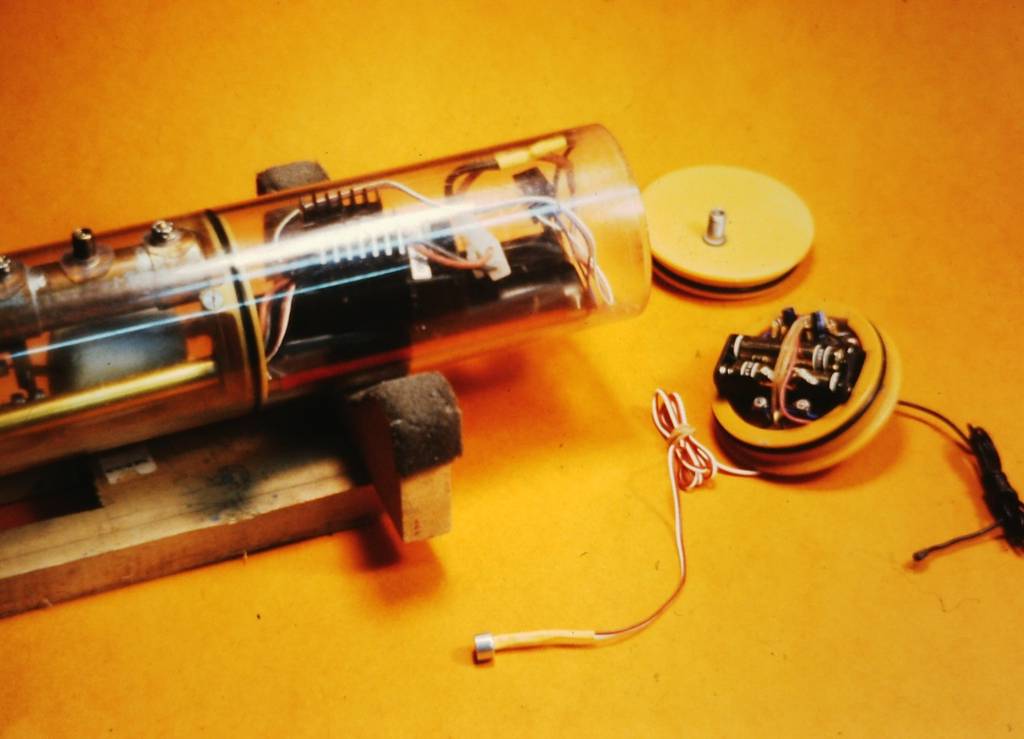

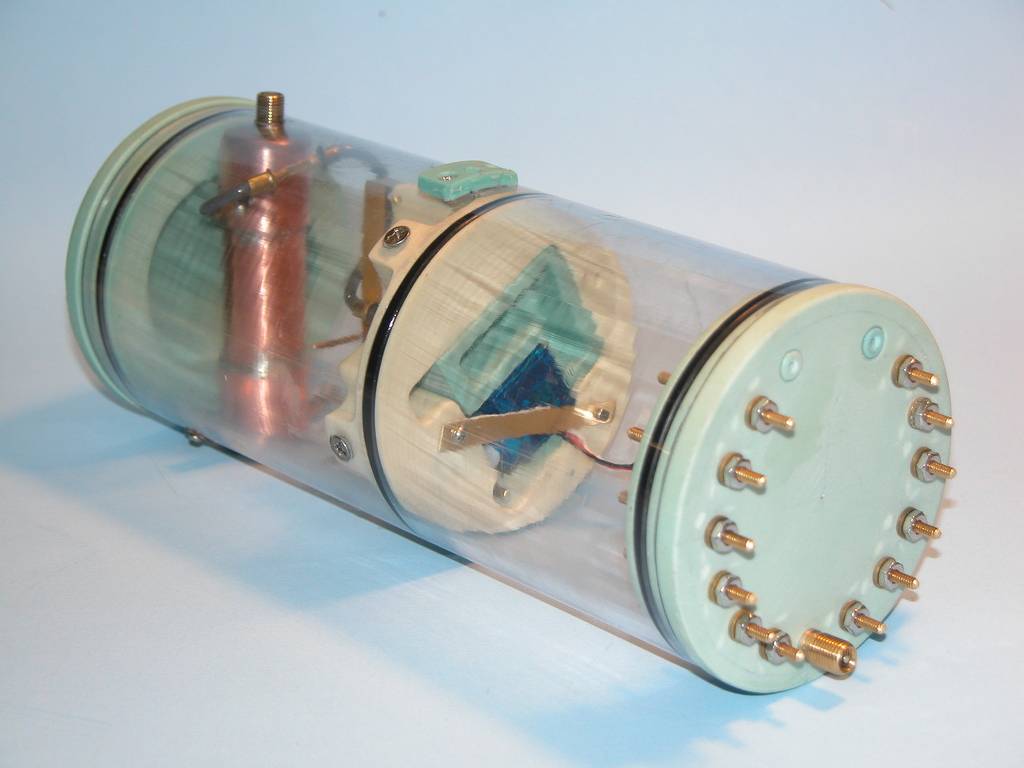

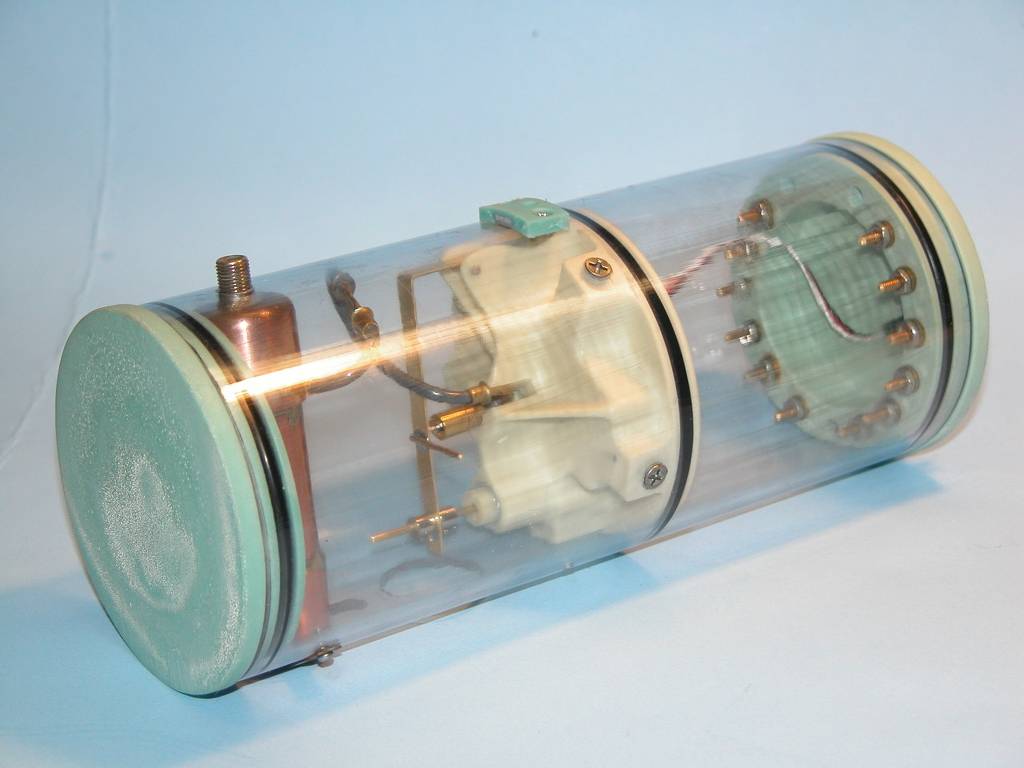

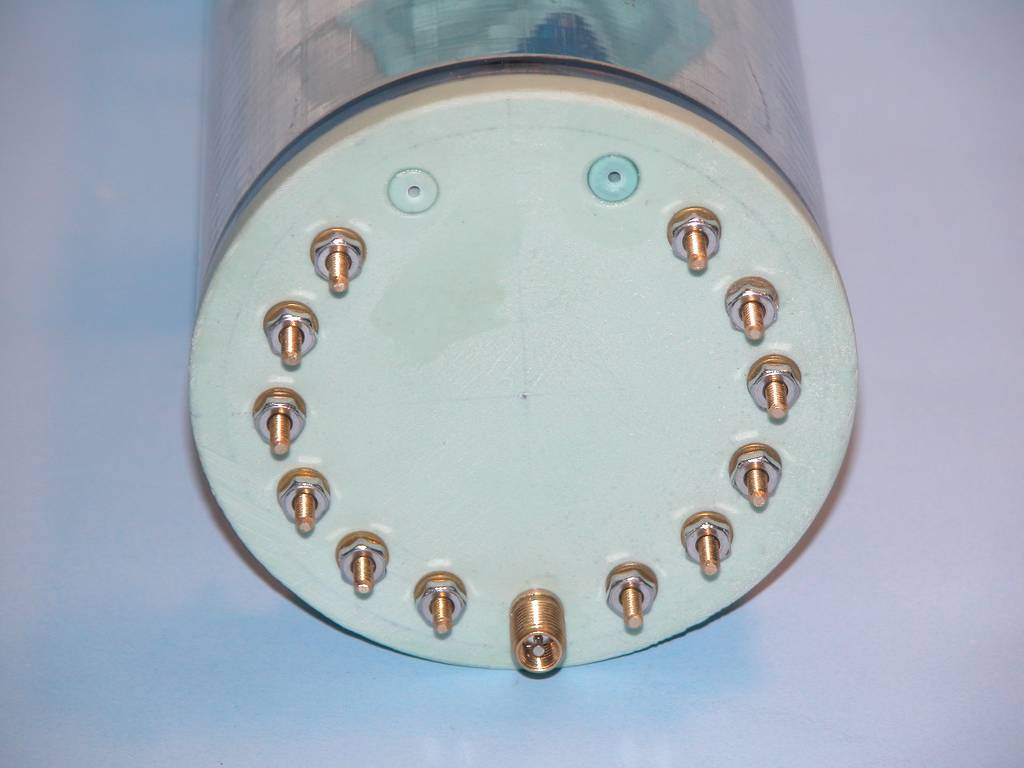

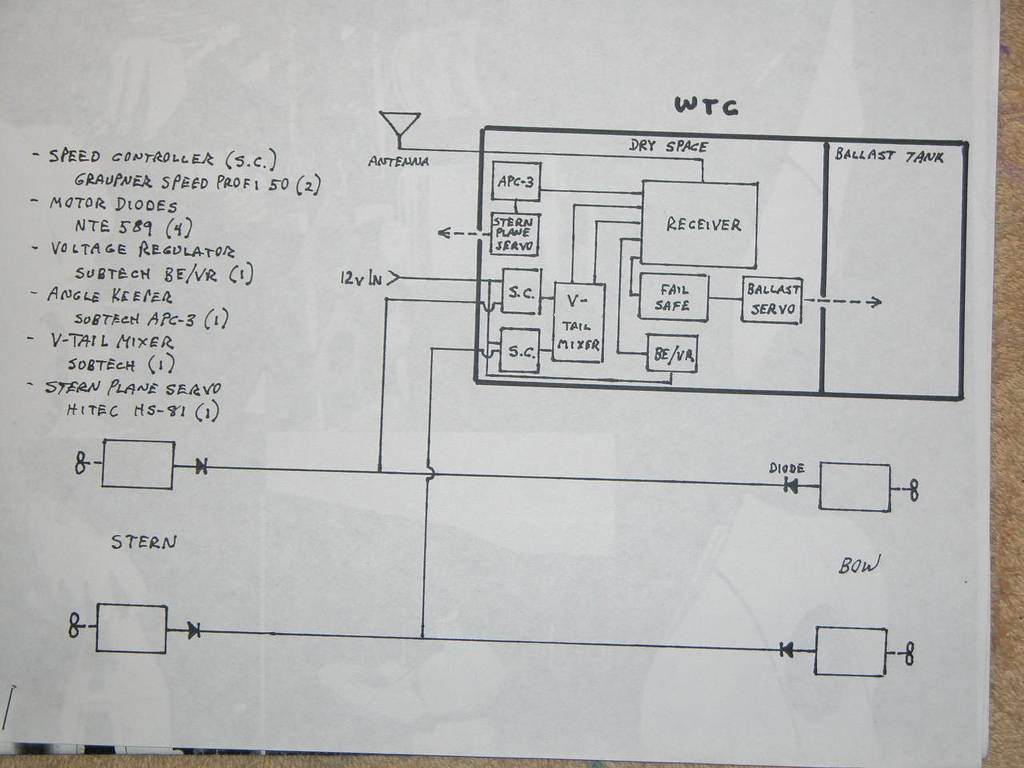

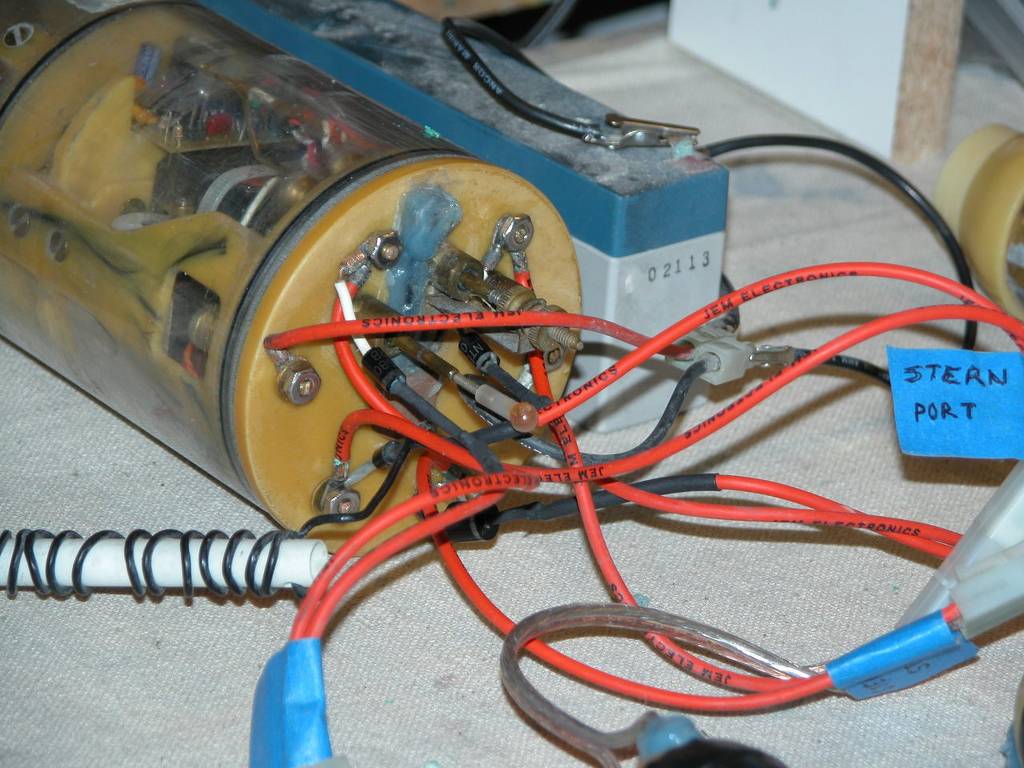

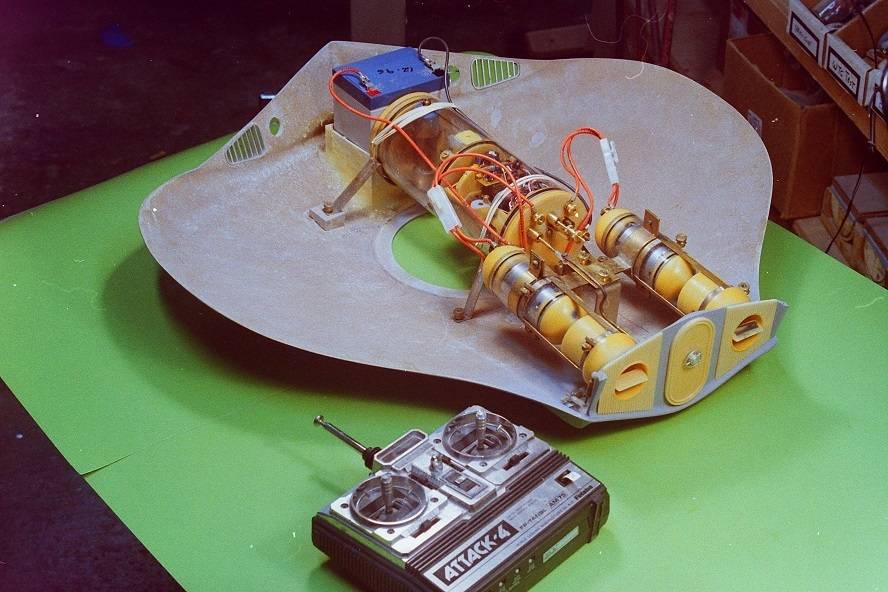

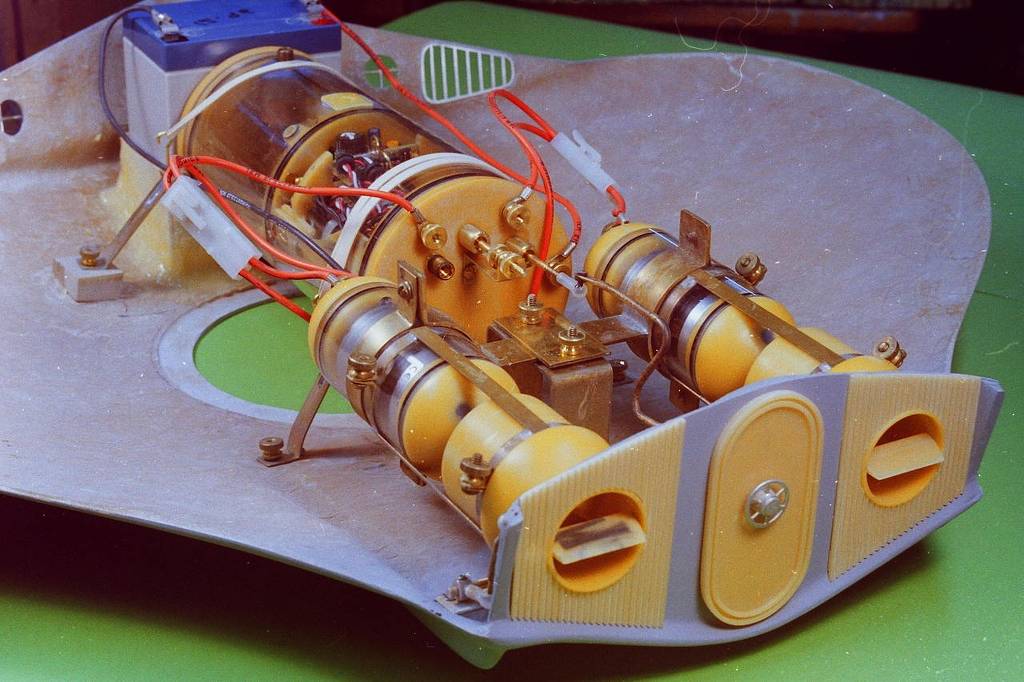

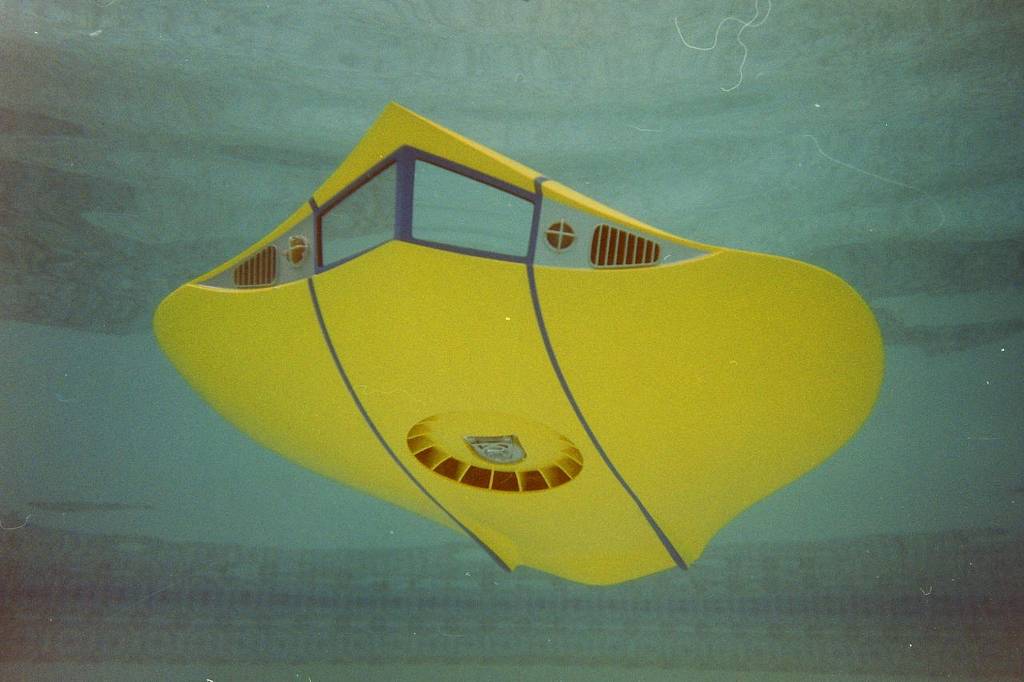

Water tight seals and electrical pass-throughs

Collapse

X

-

Tags: None

-

Comment

-

Comment

-

A little AID's ridden stinky pus never hurt nobody!

(You ain't lived till you slipped on a Jack-Brown mask previously used by a three-pack-a day smoker, who never used a tooth-brush, and chewed and spat tobacco during the dive)

Pussy!

DavidWho is John Galt?😂 1Comment

-

David,

Need you expertise again!

Looking at the above Video, would you suspect that the seal could be the culprit as to my leak problem?

Thanks David.

Rob

"Firemen can stand the heat."Comment

-

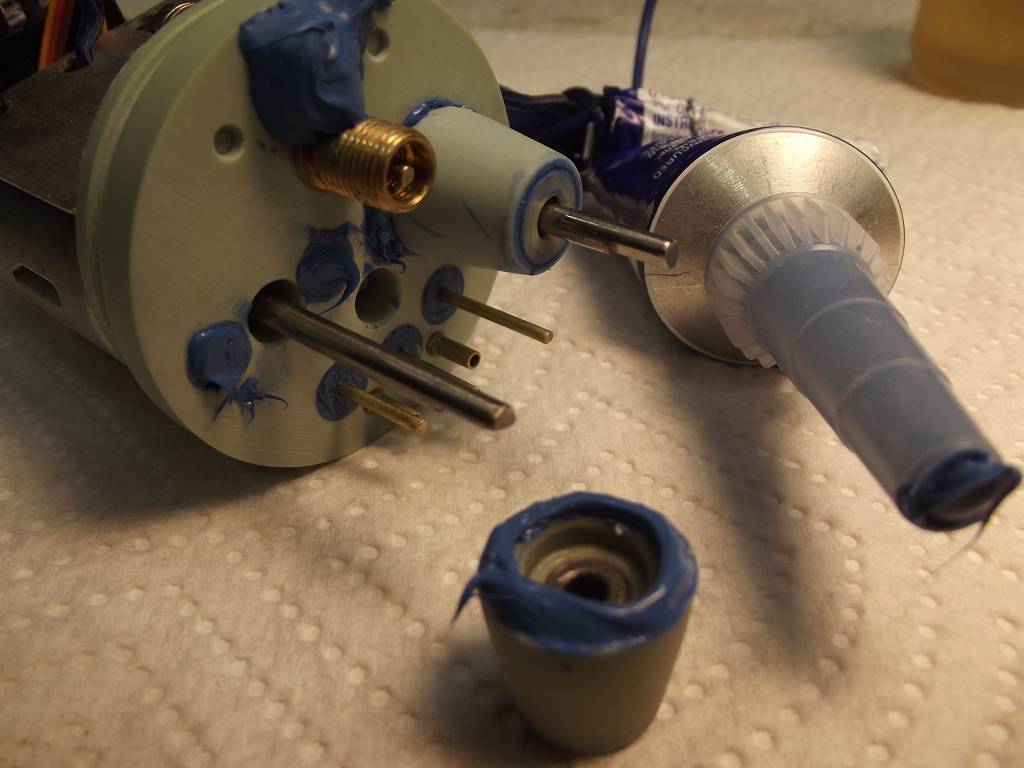

I'd guess that the linkage shaft is deformed or scratched over the surface area that is interfacing with the seal, but just in that one small section of stroke. Really weird.

You can either hit up Jason at ngencylinders@gmail.com to get a new linkage shaft sent over, or just build one yourself. It's standard 1/8" brass tube, sealed and crimped at one end and drilled with a 5/64 hole. It would take about 2 minutes to make a new one and you should be on your way...Comment

-

Likely -- and this applies to cup type seals mostly -- if there is a large enough clearance between rod and seal body bore, and the skew of the rod as it passes through the seal body is excessive -- as clearly is the case with this very shortly coupled pushrod to the rotary arm of the servo -- then the rod will 'pinch' the cup seal to one side, unseating the other side of the cup away from the rod, forming the leakage path.David,

Need you expertise again!

Looking at the above Video, would you suspect that the seal could be the culprit as to my leak problem?

Thanks David.

Rob

"Firemen can stand the heat."

co

The servo is too close to the seal body, Rob. Either move the servo back some to reduce the skew or get one of Bob's rack-and-pinion linear servo attachments to completely eliminate the skewing of the rod.

Keep plugging away, pal. You'll lick this thing.

DavidWho is John Galt?Comment

-

Thank you David,

Likely -- and this applies to cup type seals mostly -- if there is a large enough clearance between rod and seal body bore, and the skew of the rod as it passes through the seal body is excessive -- as clearly is the case with this very shortly coupled pushrod to the rotary arm of the servo -- then the rod will 'pinch' the cup seal to one side, unseating the other side of the cup away from the rod, forming the leakage path.

co

The servo is too close to the seal body, Rob. Either move the servo back some to reduce the skew or get one of Bob's rack-and-pinion linear servo attachments to completely eliminate the skewing of the rod.

Keep plugging away, pal. You'll lick this thing.

David

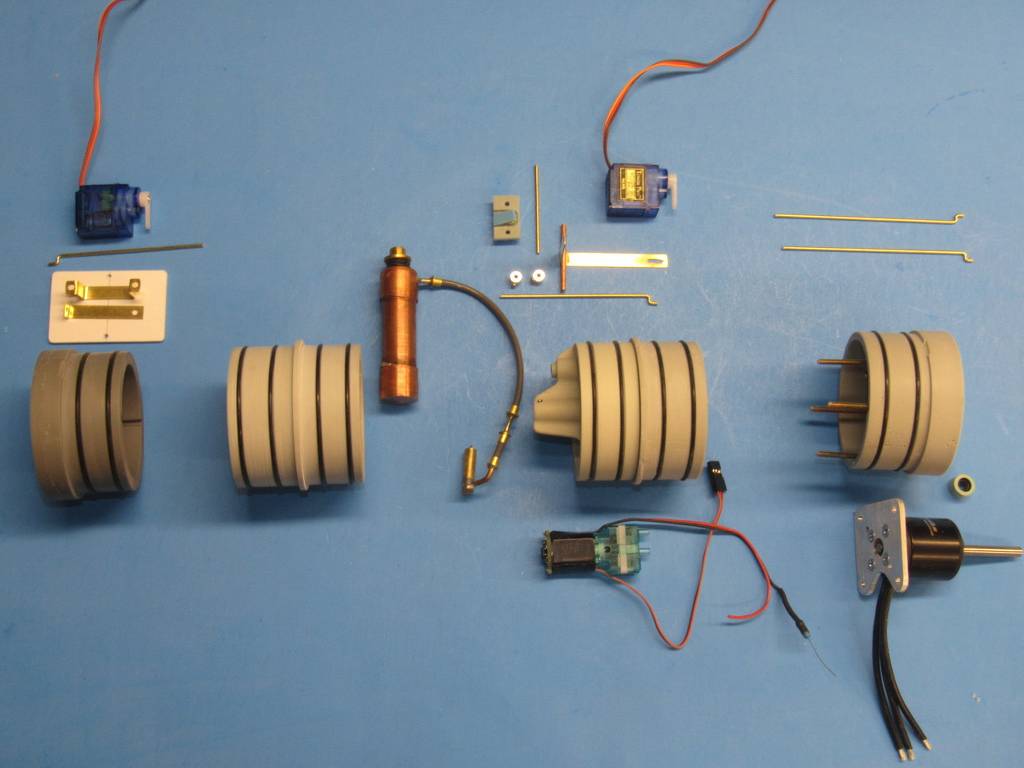

This is one of Bobs new 300 series Easy Driver cylinders. The servos are built into the end caps, and there is no way of removing them to move them back withou destroying the end cap.

I do have one more idea which I will try.

Rob

"Firemen can stand the heat."Comment

-

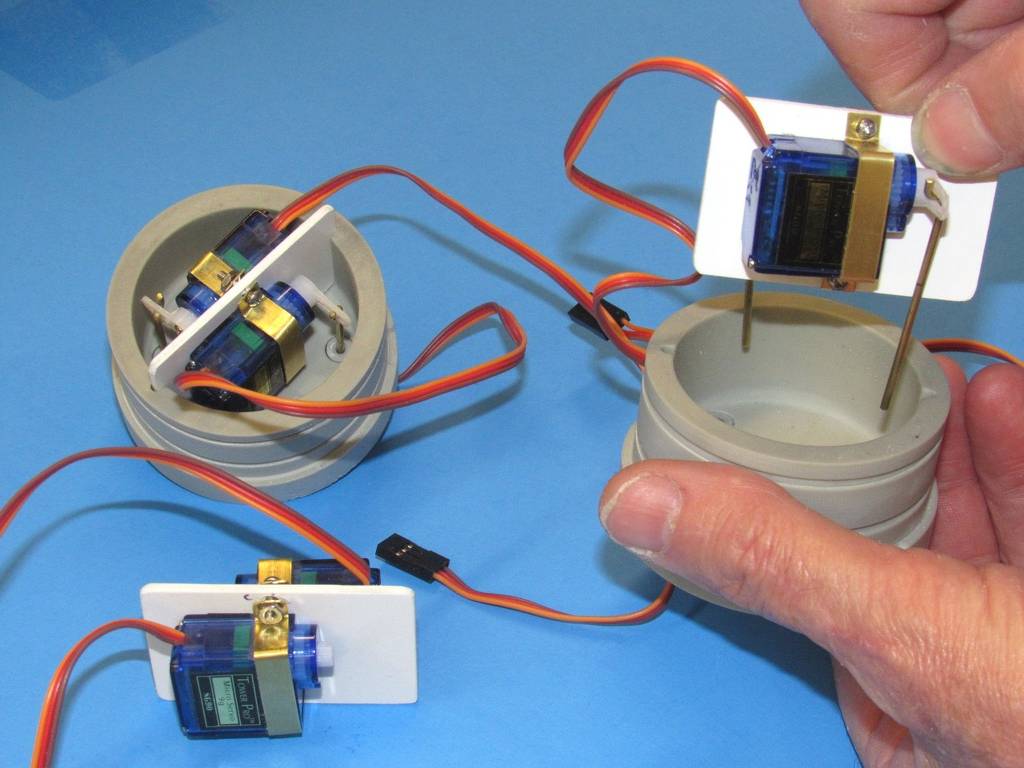

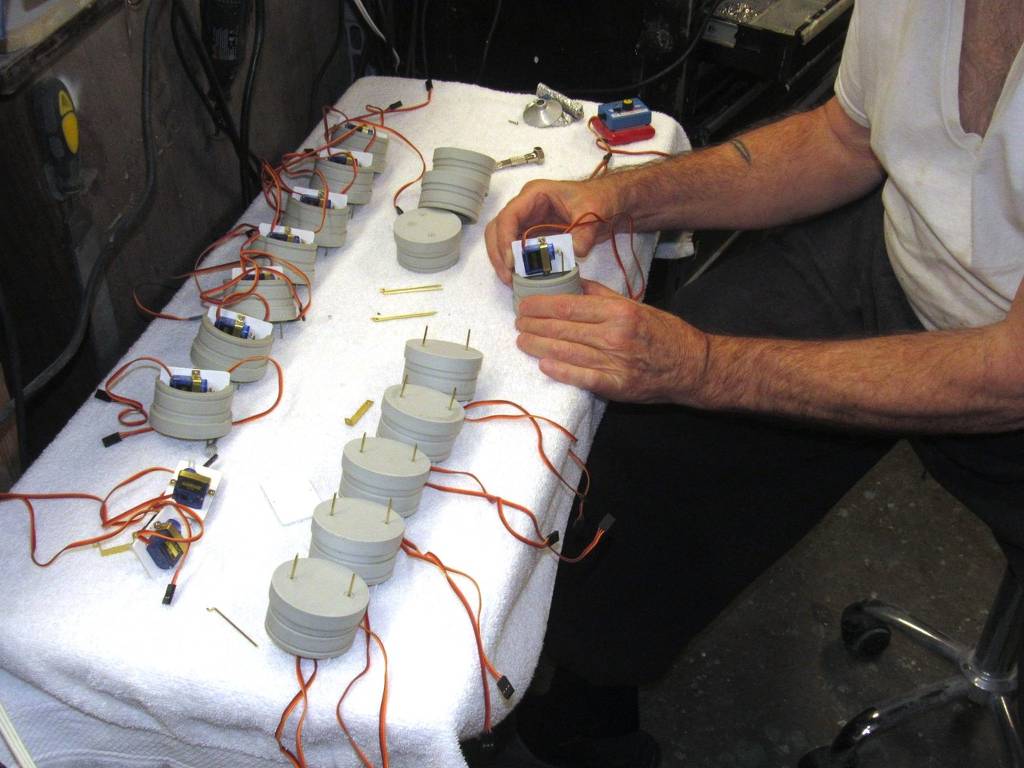

Do this to the servo arm -- it will translate the rotational component of the servo arm to a more linear travel. Note that the modified servo output horn has been machined with a long slot, replacing that array of pushrod mounting holes. The slot, in rotation, acts as a cam permitting the pushrod to truly travel linearly without any significant skew/lateral motion. This permits use of the servo up butt-tight with the seal body without ill effect.

Thank you David,

This is one of Bobs new 300 series Easy Driver cylinders. The servos are built into the end caps, and there is no way of removing them to move them back withou destroying the end cap.

I do have one more idea which I will try.

Rob

"Firemen can stand the heat."

Who is John Galt?

Who is John Galt?Comment

Comment