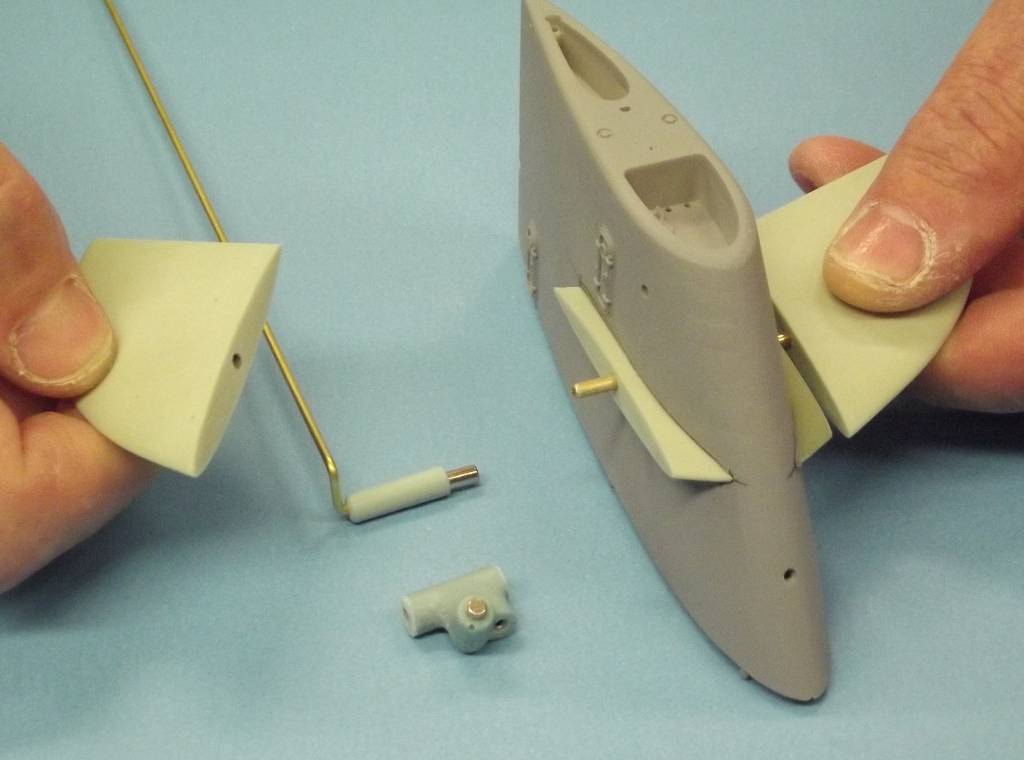

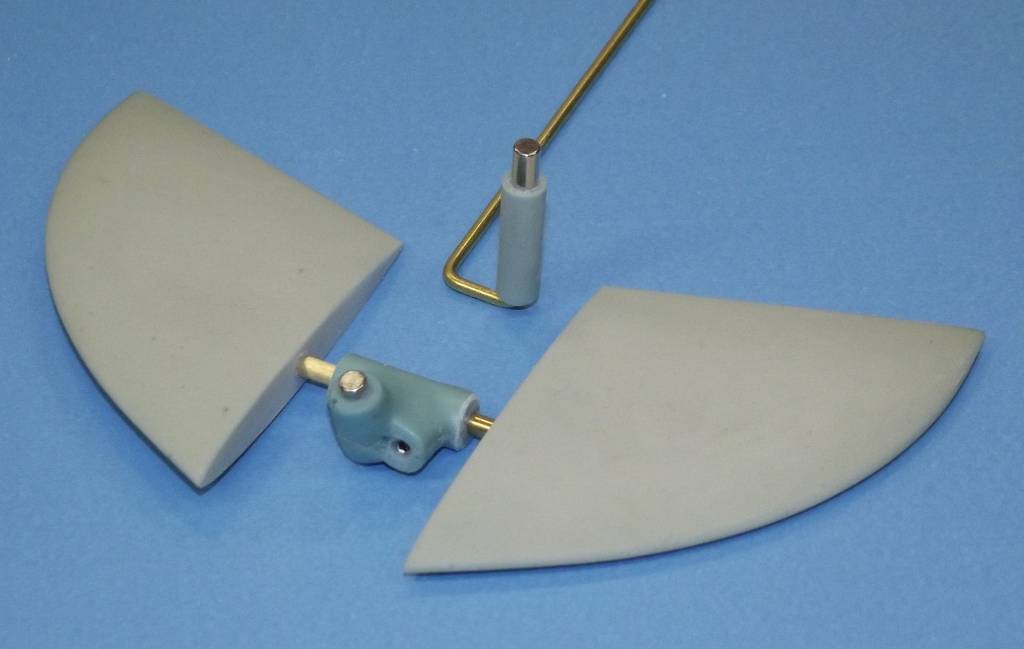

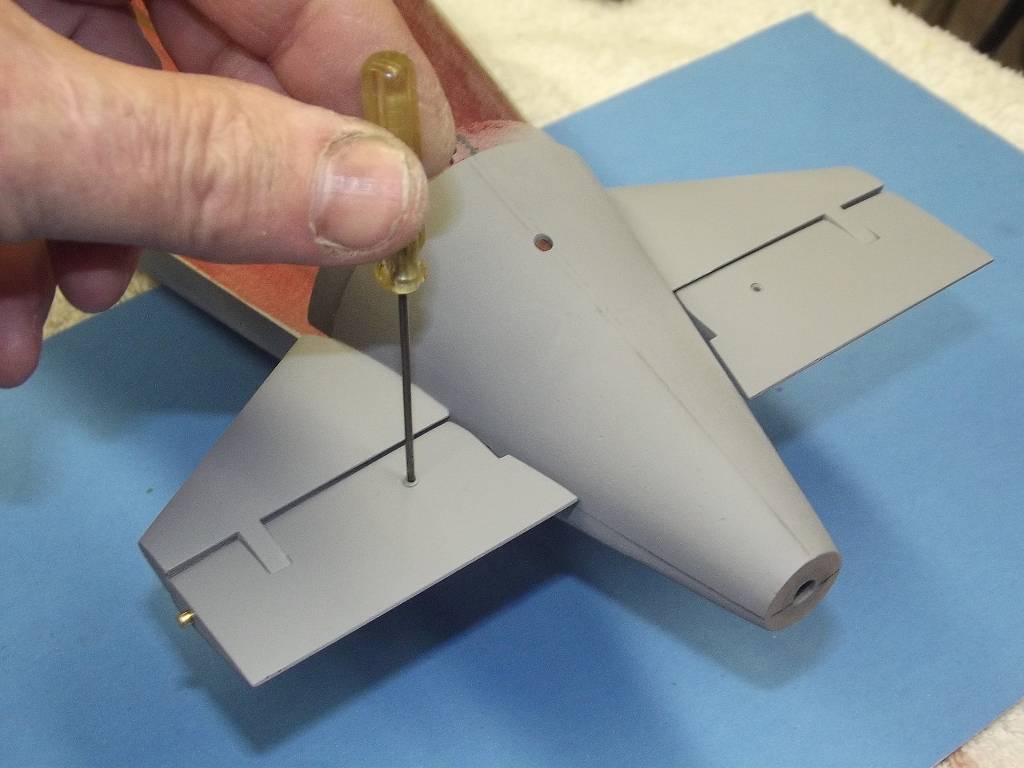

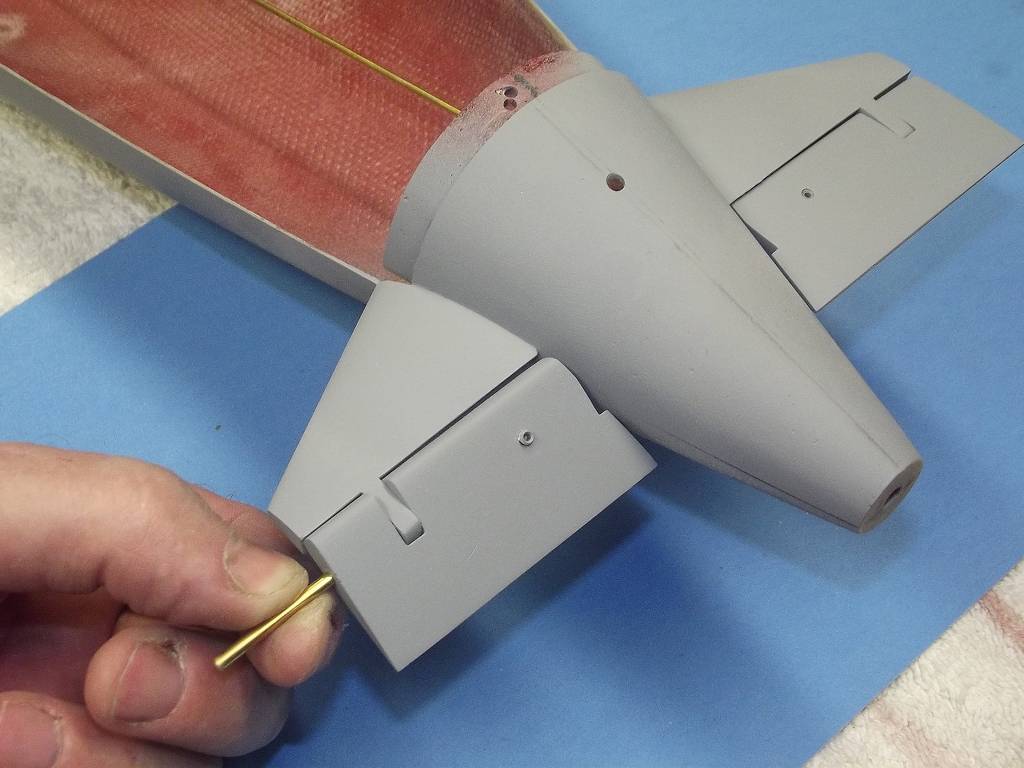

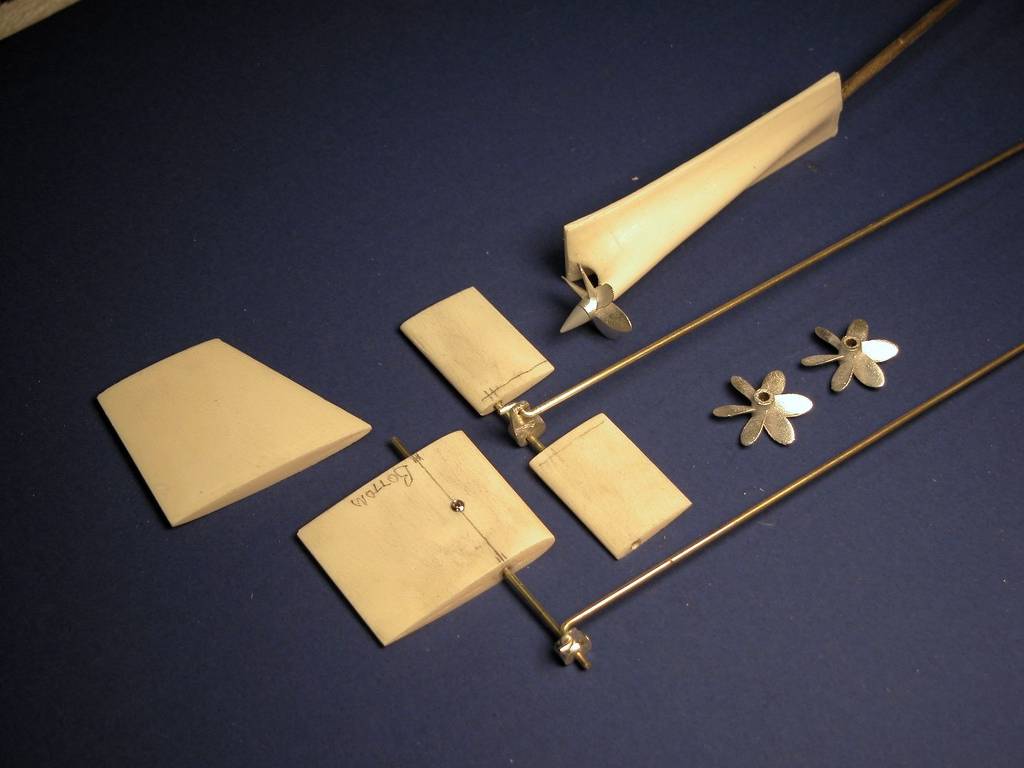

I have a really simple question. I've been building models a long time, including submarines. One detail I have always struggled with is how to attach resin, plastic, 3D printed etc. Dive planes and Rudders to a shaft (usually brass). The most obvious method is to put superglue on the shaft and quickly slip the control surface over it but it can often end with the glue setting before you get it in the optimal position or the glue gets pushed out of the way as you push the pieces together resulting in little to no bond at all and a blob of glue at the exit point where you probably don't want it.

What methods have worked for you?

Thanks

Jason

What methods have worked for you?

Thanks

Jason

Comment