Dear Guru of Everything Known to Man and More, AKA HWSNBN,

What brand of solder do you use for making handrails and such on your fine fighting vessels? The material is to be 0.030" K&S brass rod. Where do you get it?

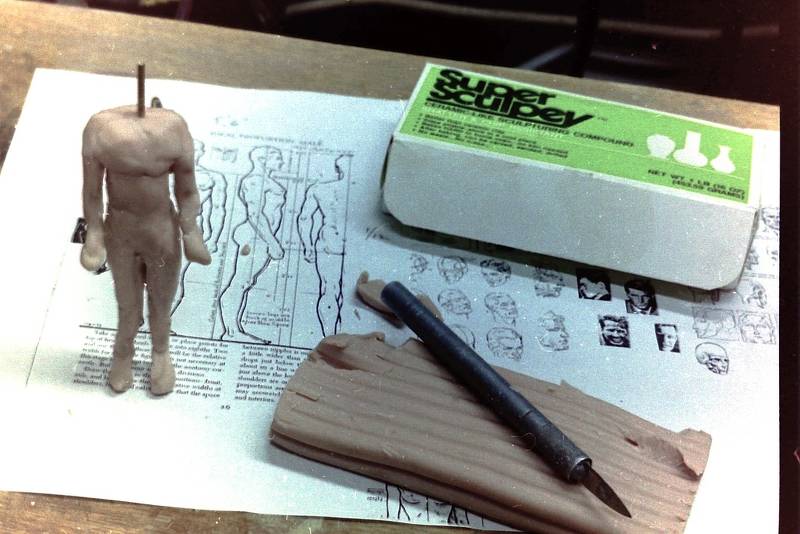

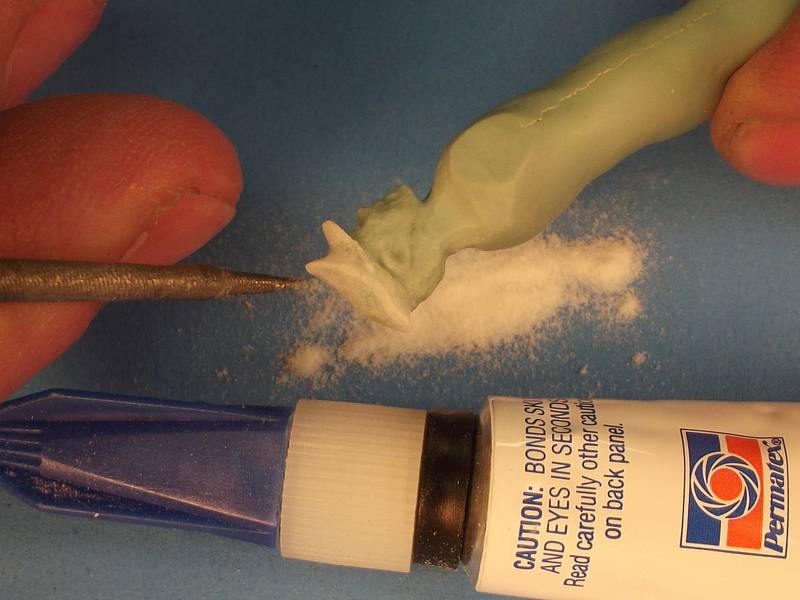

What would you use to sculpt blast bags on 5" guns on 1:96 scale skimmer gun mounts? Looking for something better to use than body filler type products.

Thank you for your assistance in many things!

A Grateful Unwashed Mass participant

What brand of solder do you use for making handrails and such on your fine fighting vessels? The material is to be 0.030" K&S brass rod. Where do you get it?

What would you use to sculpt blast bags on 5" guns on 1:96 scale skimmer gun mounts? Looking for something better to use than body filler type products.

Thank you for your assistance in many things!

A Grateful Unwashed Mass participant

Comment