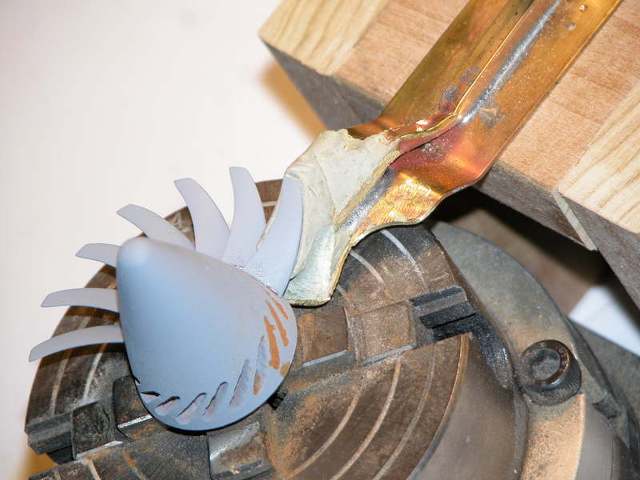

Hi! I'm refurbishing a Small World Models 1/96 Trafalgar class I built 20+ years ago and recently re-acquired. I find I am in need of reconfiguring the propulsor shaft line to a longer shaft, as well as it being of 1/8" stainless rod vs. the original epoxy filled brass tube. The rotor itself is still serviceable, but the shaft is imbedded into the hub and is too short for stand-alone use as with the original WTC. I could try to remove the shaft, but the risk of destroying the rotor is great! Is there any source for said rotor, bored for a 1/8" shaft, either 3D printed or cast? Measured OD for the blades is ~1 33/64".

Any thoughts or methods greatly appreciated!

Take care,

Bill

Comment