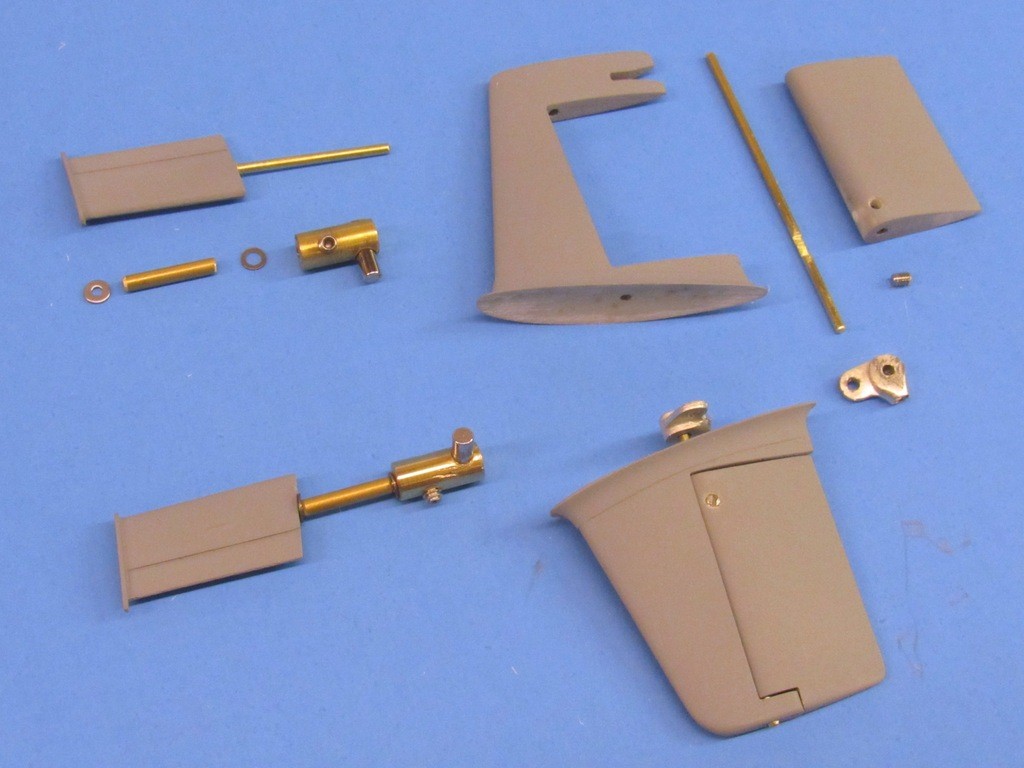

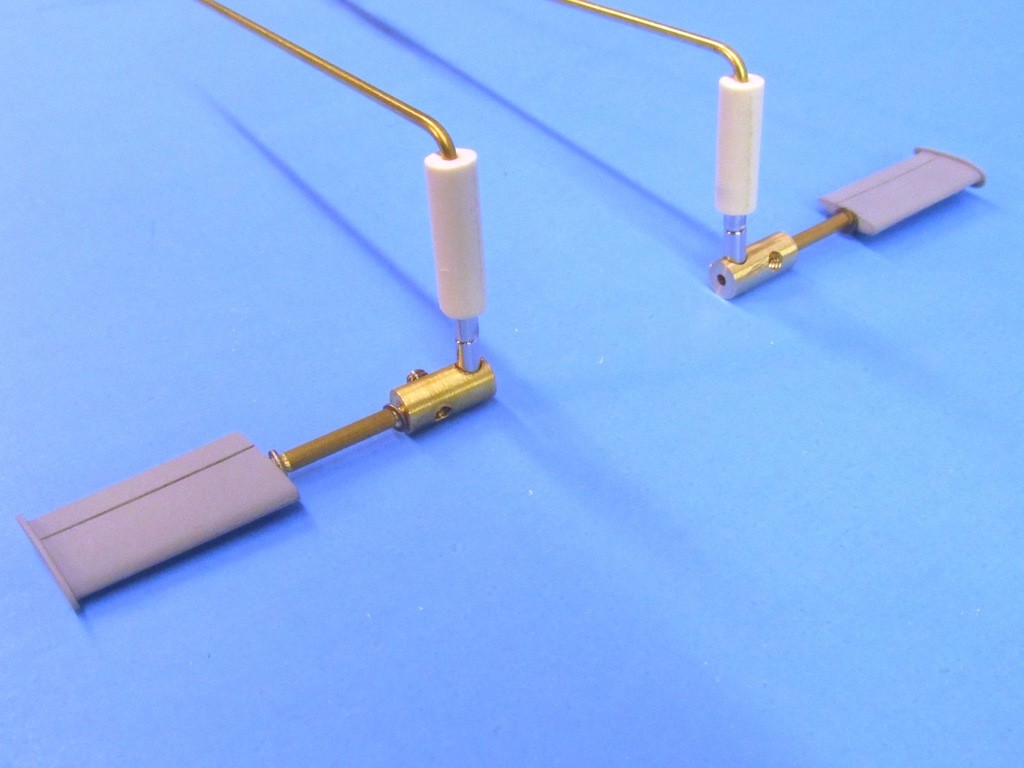

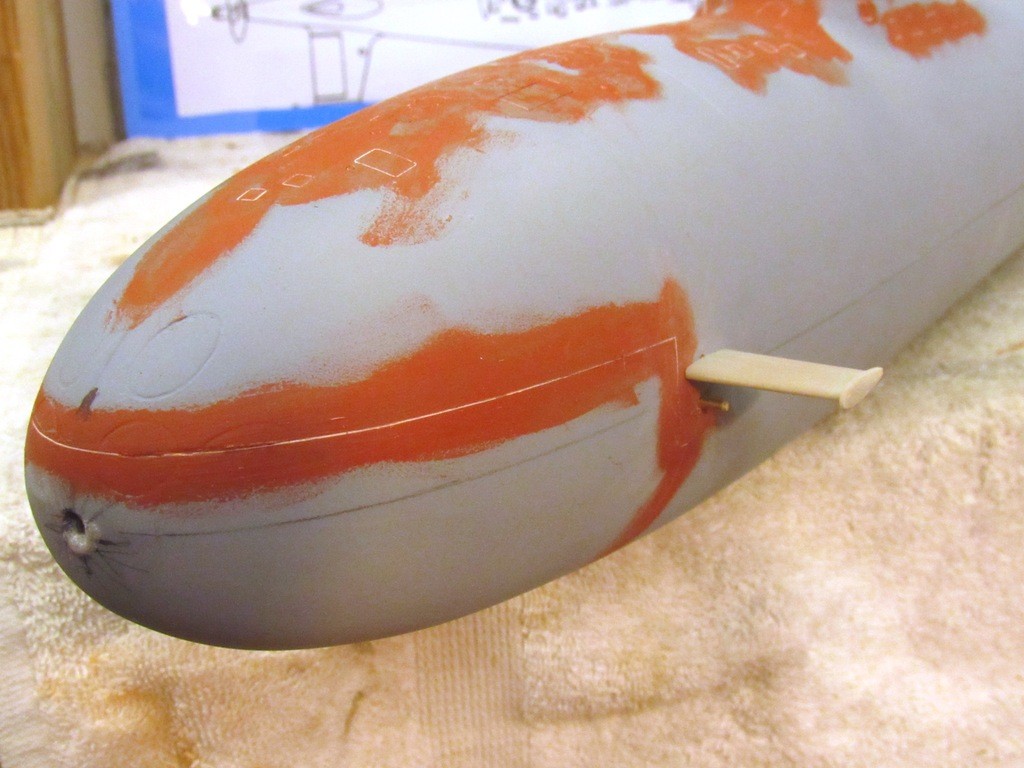

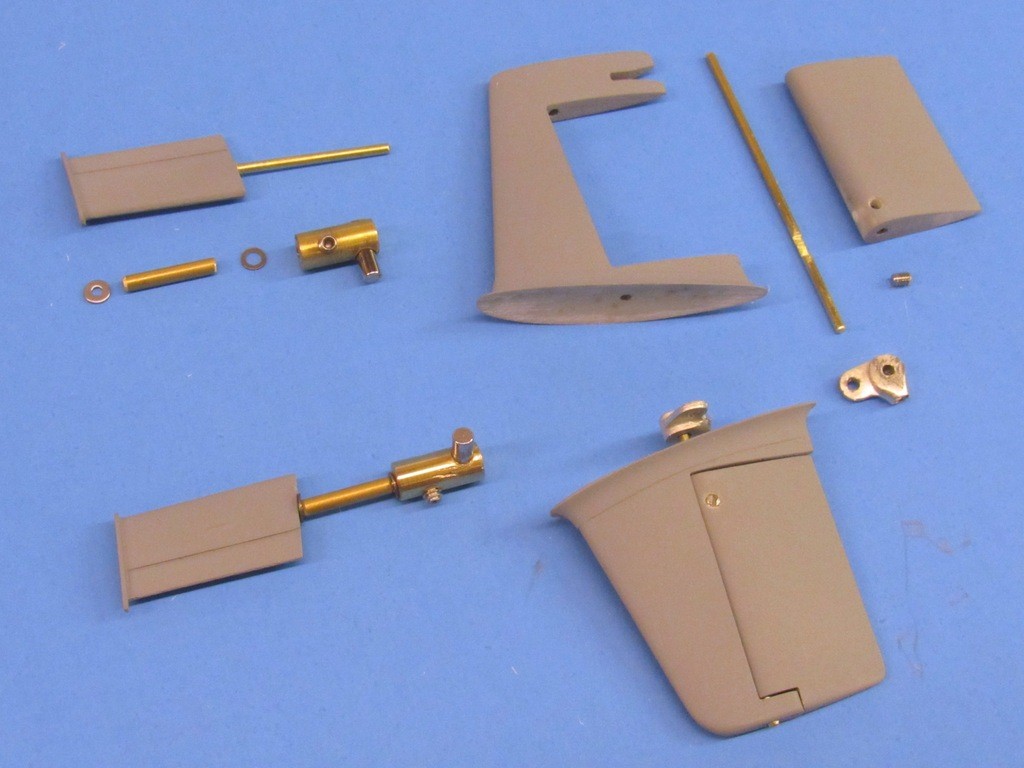

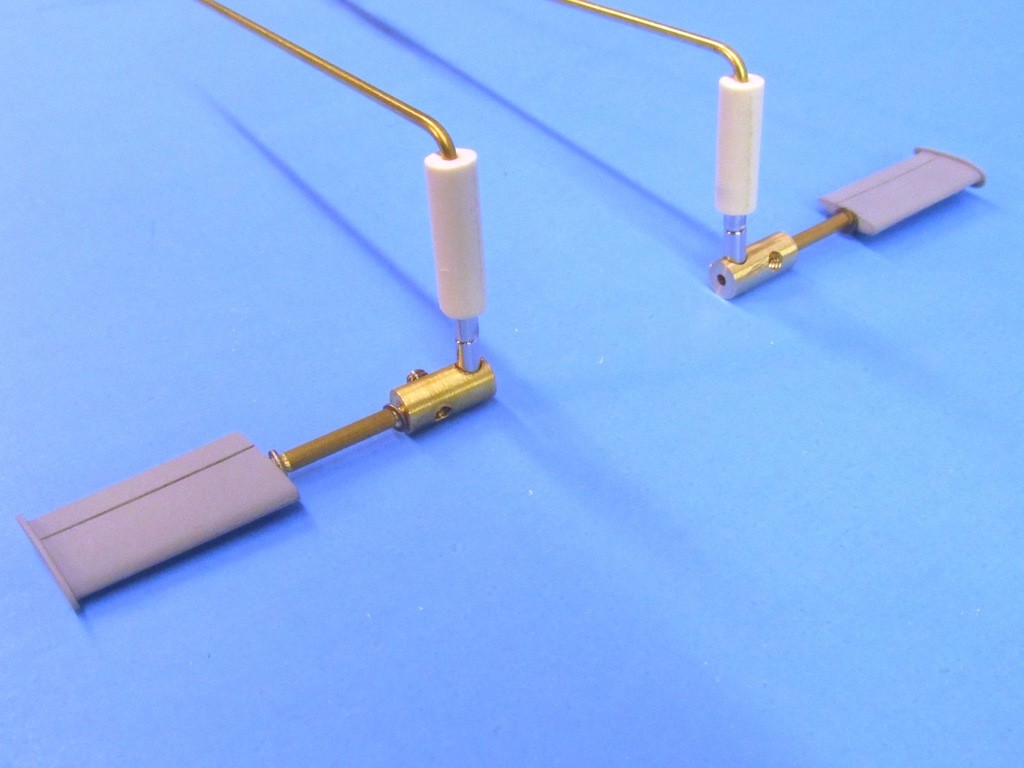

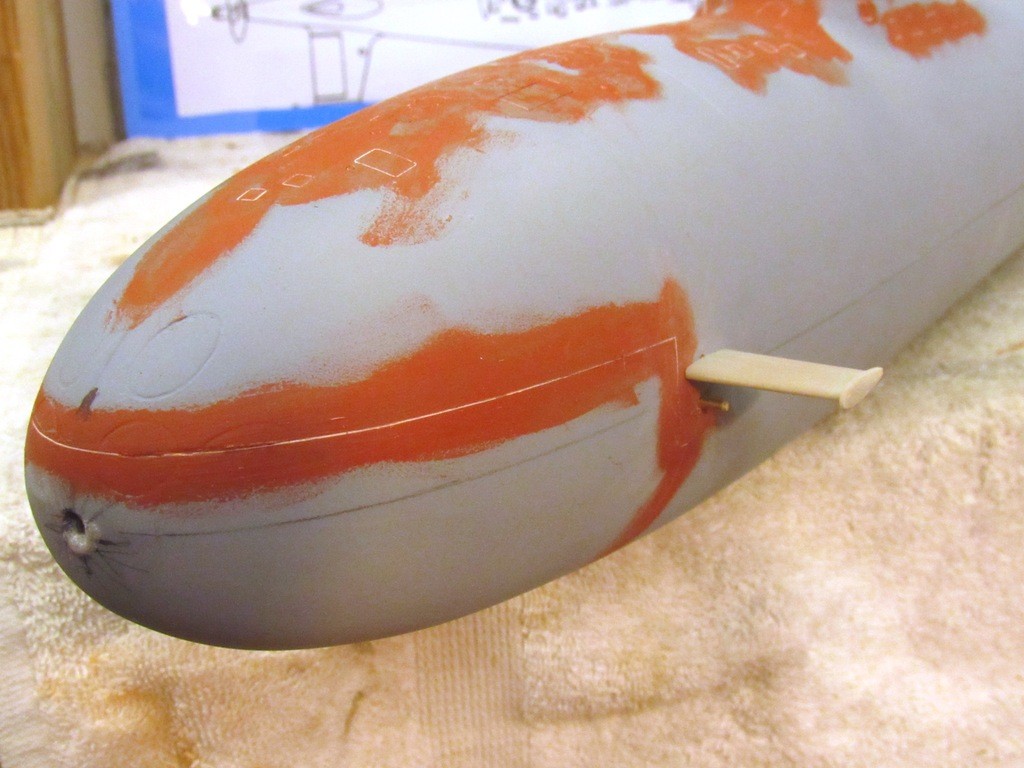

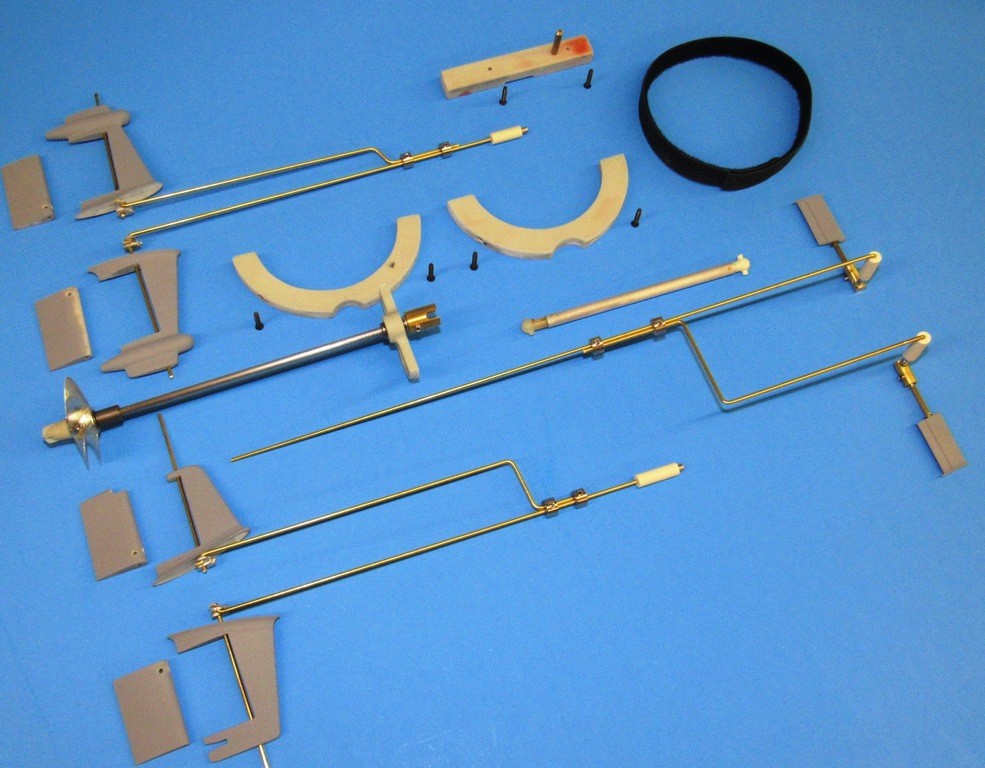

On this little 1/96 ALFA the 1/16" diameter brass bow plane operating shafts are the sacrificial element in a collision or rough handling. It's nothing to yank out the bent operating shaft (or, more likely, just bend it back) from the bow plane and replace it. The bow plane operating shaft bearing (a short length of 3/32" o.d. brass tube) is glued within the hull -- and that ain't bending!

David

David

Comment