Now, on to one of the more challenging pieces I’ve taken upon myself to build; the dihedral fins. Not cut and dry respectively speaking like say, the rudders, we have many compound and complex curves in this baby. Starting from the hull, we have a “normal” shaped fin that blends into a tapering housing that ends in a bulbous pressure vessel-ish nozzle shape. This end assembly has 3 discharge points: fat line sonar, thin line sonar, and a third which comes off the blended nozzle of which I have absolutely no idea of which function it serves. But then that’s probably why I’m still alive, because I don’t have all the answers to the mysteries that this boat holds!

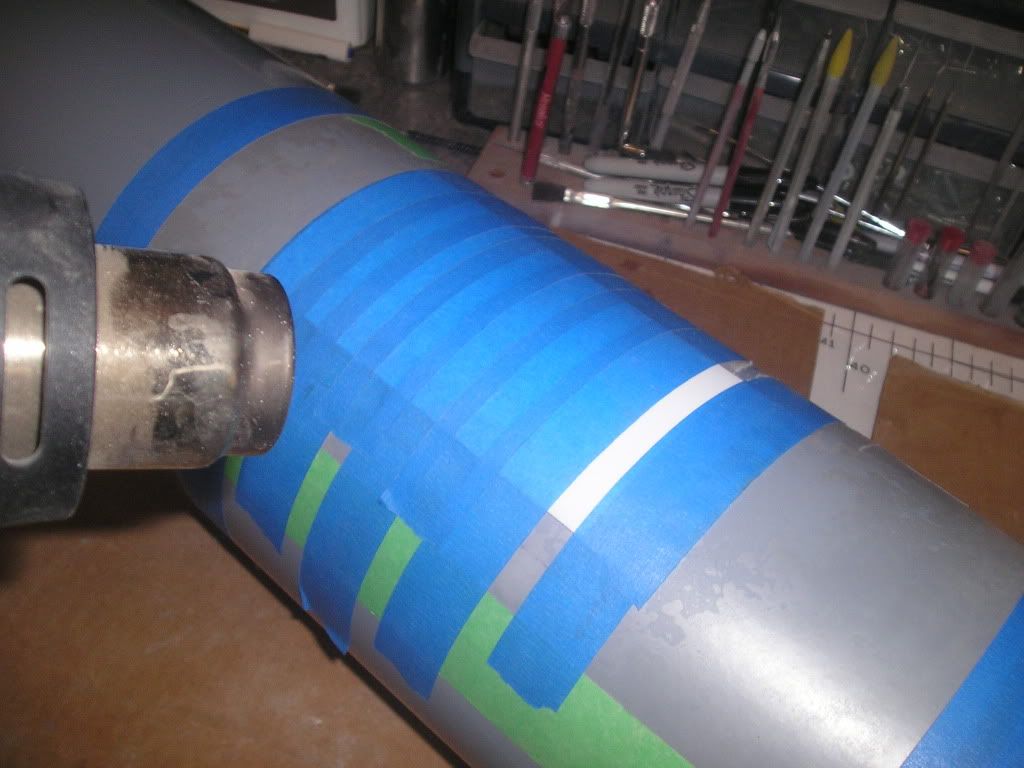

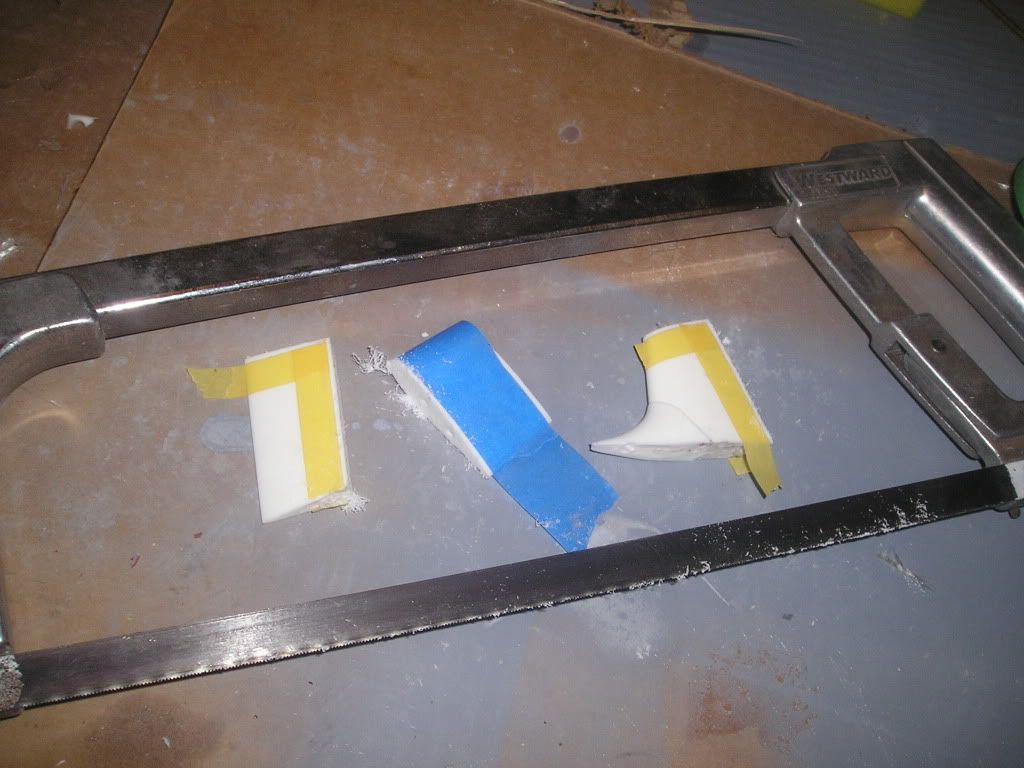

Starting with the nozzle, it is machined on my lathe and attached to 2 brass tubes using CA and baking soda.

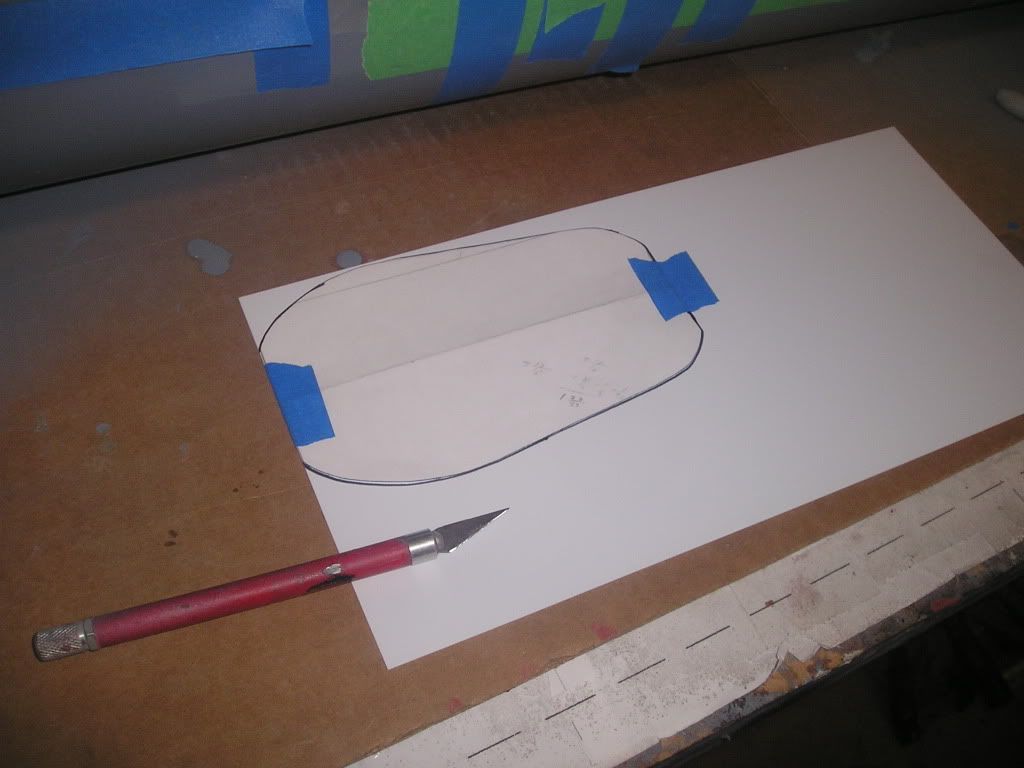

The same process is used for the regular part of the fin, except I’m using Bondo instead of foam. Much quicker and more solid, I just wait until the Bondo is half cured then follow the fin profile shapes with a sharp knife: a very smooth process!

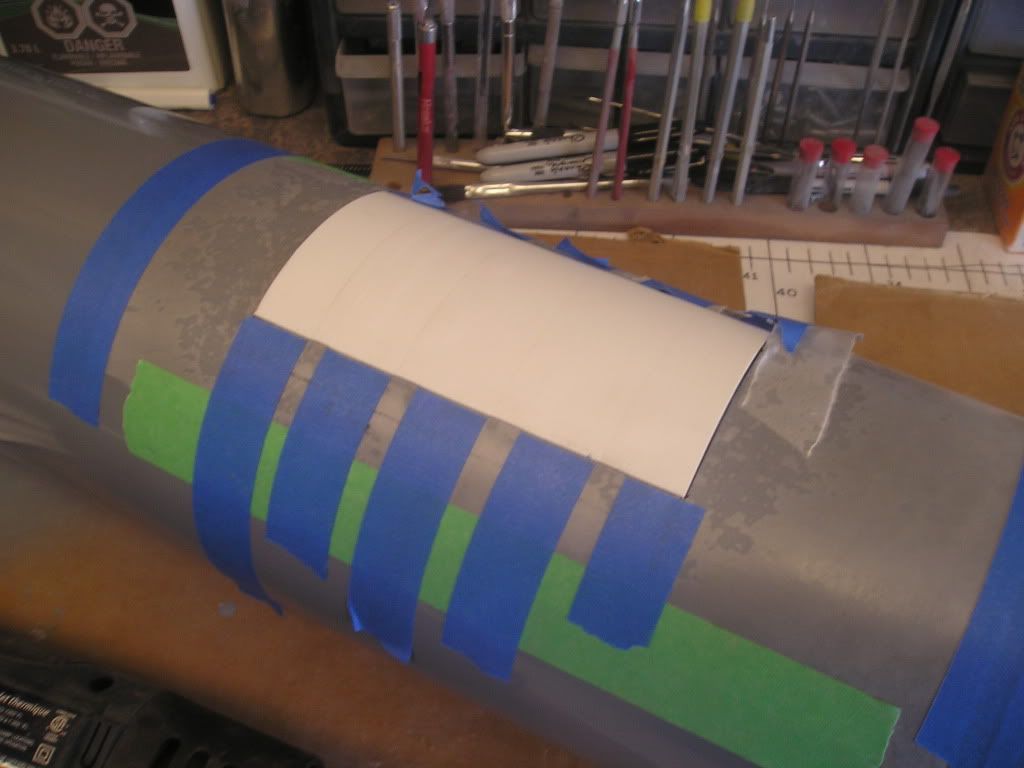

CA solidified cardboard is used to finish the taper shape.

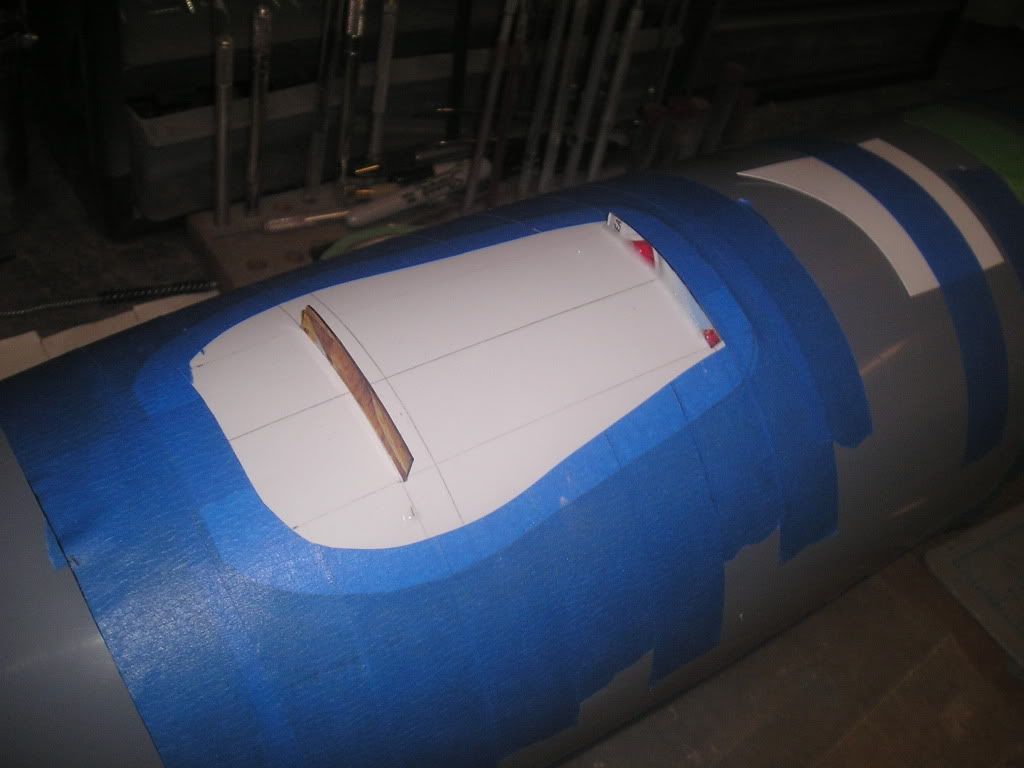

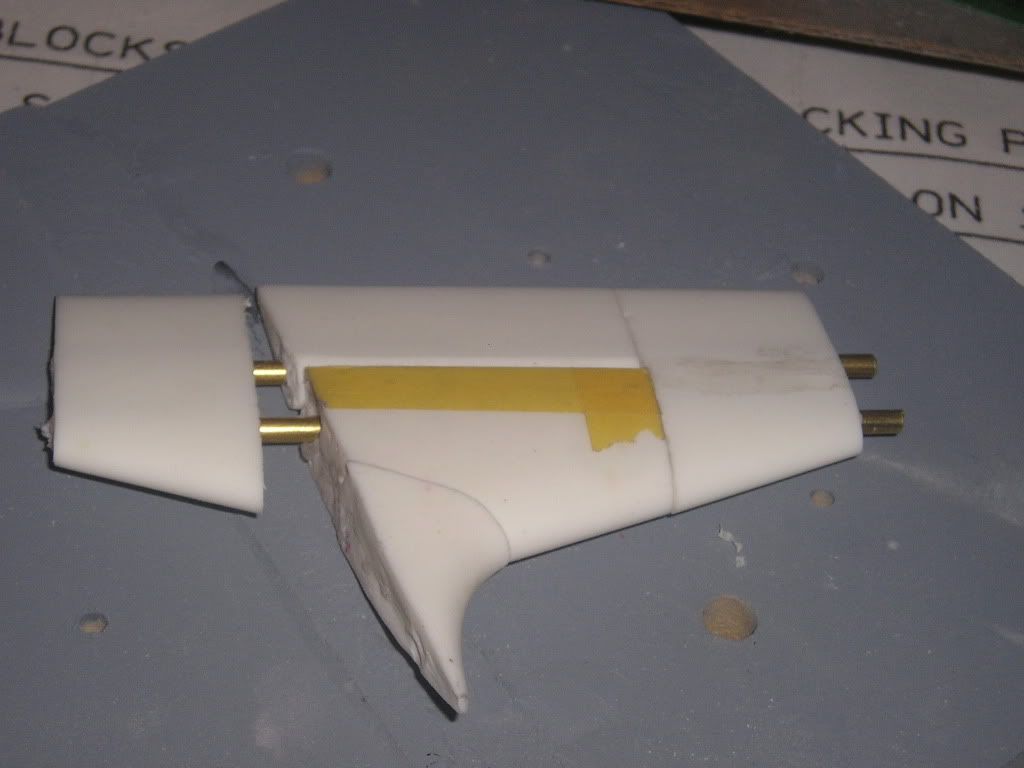

The parts glued together and in primer. There was lots of filling and flaw fixing here. I must have broken the taper off 4 times and re-glued it to get it right!

Starting with the nozzle, it is machined on my lathe and attached to 2 brass tubes using CA and baking soda.

The same process is used for the regular part of the fin, except I’m using Bondo instead of foam. Much quicker and more solid, I just wait until the Bondo is half cured then follow the fin profile shapes with a sharp knife: a very smooth process!

CA solidified cardboard is used to finish the taper shape.

The parts glued together and in primer. There was lots of filling and flaw fixing here. I must have broken the taper off 4 times and re-glued it to get it right!

.

.

Comment