Been a bit slow to post a note on my new Revel Gato I finally started a week or so back after completing my diversionary projects. My plan is to have it ready for the Canberra sub-regatta at Easter, which gives me just nine short weeks...

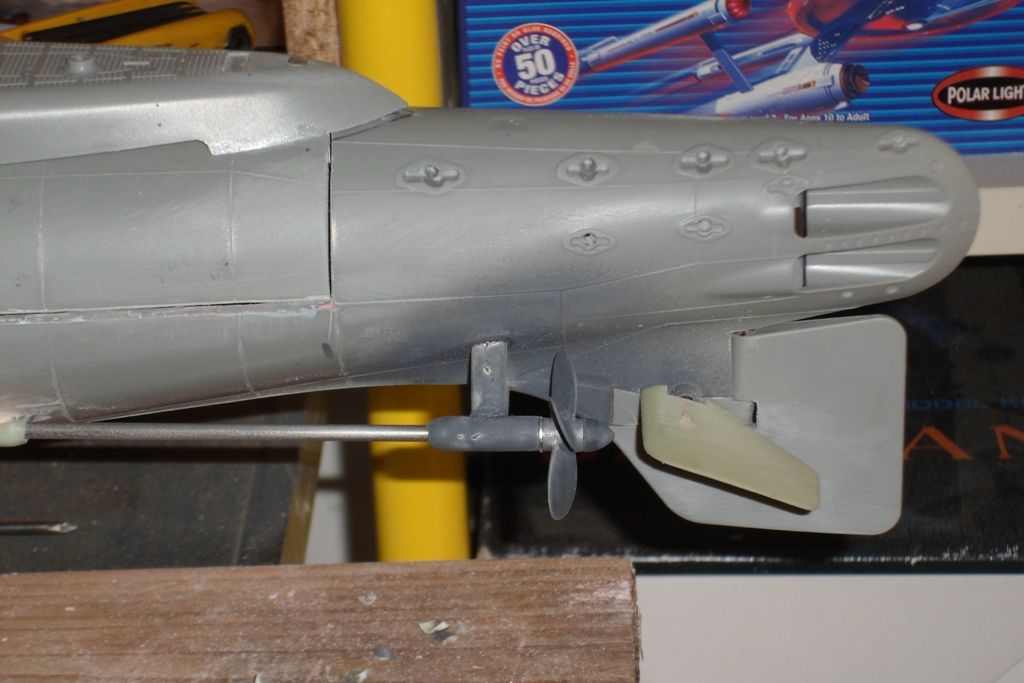

At this stage I won,t bore people with another run of pictures showing various parts of the model carved up. I can however say that I'm at the stage where most of the hard yards are done with the main lower hull assembled and trimmed of excess plastic fat, the deck pieces all assembled. The next phase is some filler work then glueing the deck down ready for the dreaded hull split.

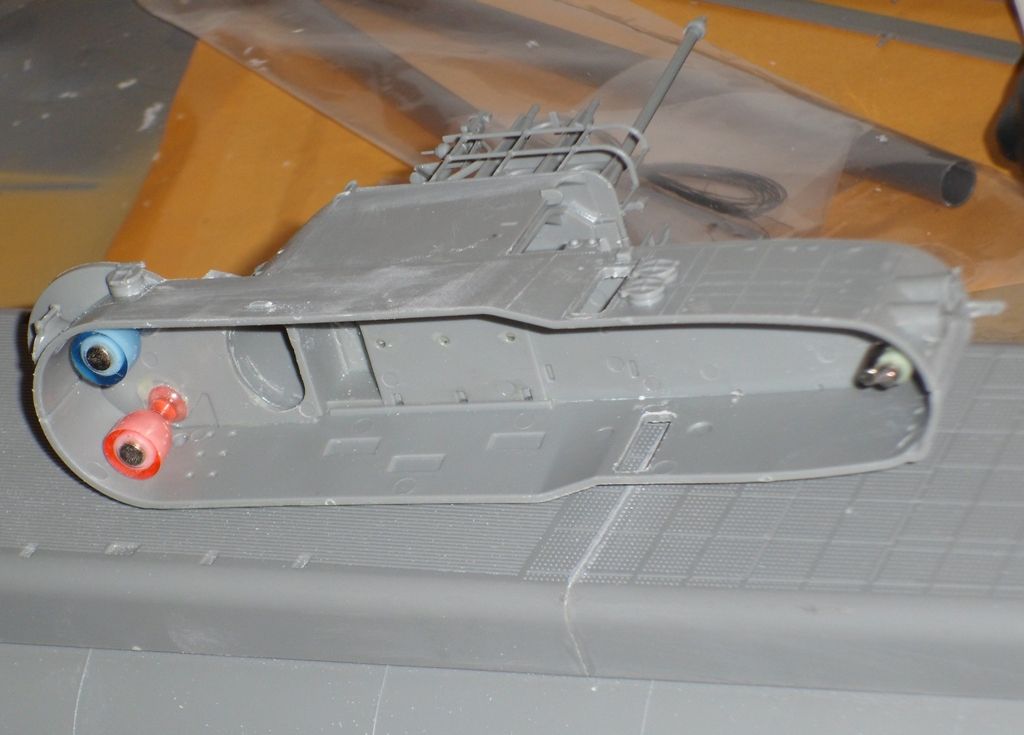

this one is with the sas subdriver so glueing the conning tower down isn't really an option. I no longer have that model at hand but fortunately I have the previous ones photos and notes on its assembly to pave the way for this one.

At this stage I won,t bore people with another run of pictures showing various parts of the model carved up. I can however say that I'm at the stage where most of the hard yards are done with the main lower hull assembled and trimmed of excess plastic fat, the deck pieces all assembled. The next phase is some filler work then glueing the deck down ready for the dreaded hull split.

this one is with the sas subdriver so glueing the conning tower down isn't really an option. I no longer have that model at hand but fortunately I have the previous ones photos and notes on its assembly to pave the way for this one.

Comment