As I stated in Marks Skipjack thread I received mine, along with all the required additions last week... Since Mark has posted pictures of the model kit out of the box, the instruction, decals etc I won't clutter the place with more of the same. For me this will be a fairly straight up assembly project. Why...? Well to be honest, there ain't much extra to do on the thing. David and those folks at Moebius did a you beaut rip snorta of a model kit!! That is why. For many reasons a lot of styrene kits need after market parts to get them right. Others just need them for that extra bling but not this one.

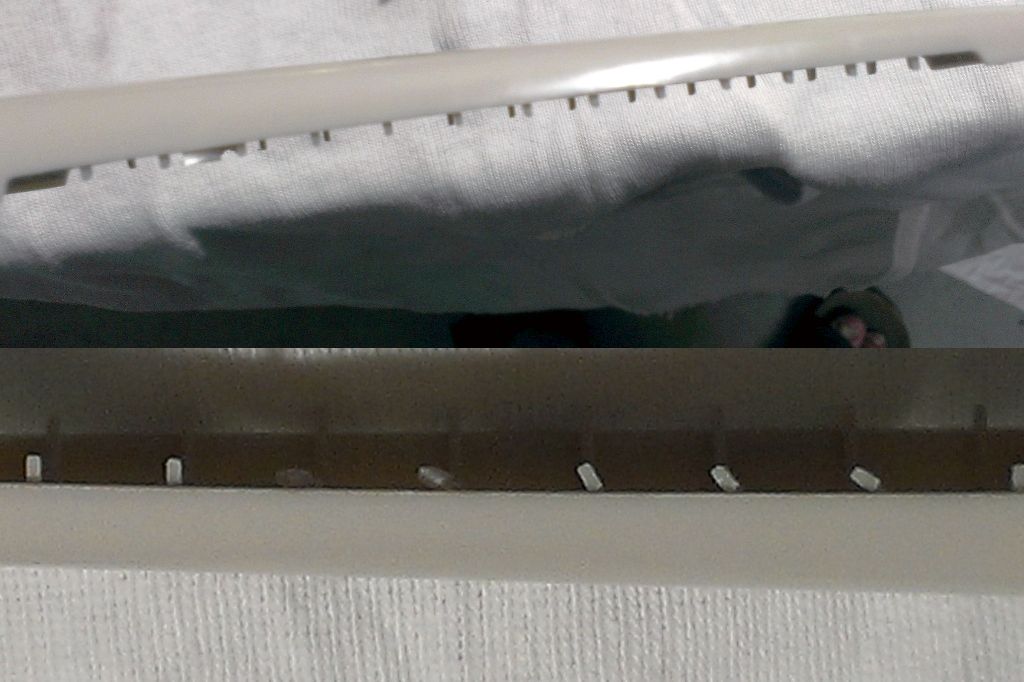

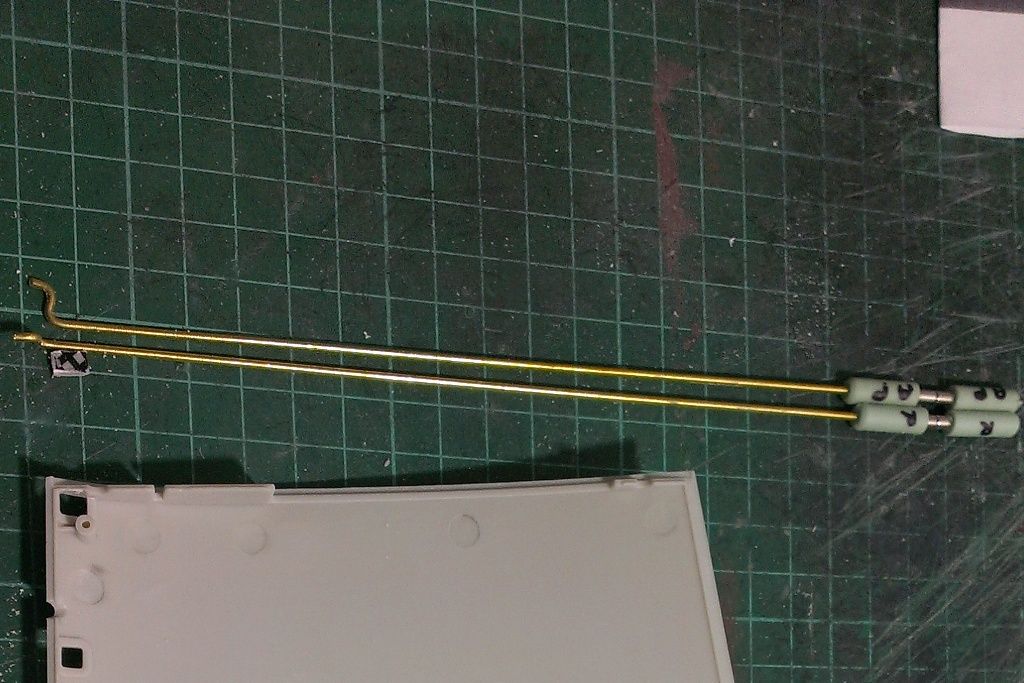

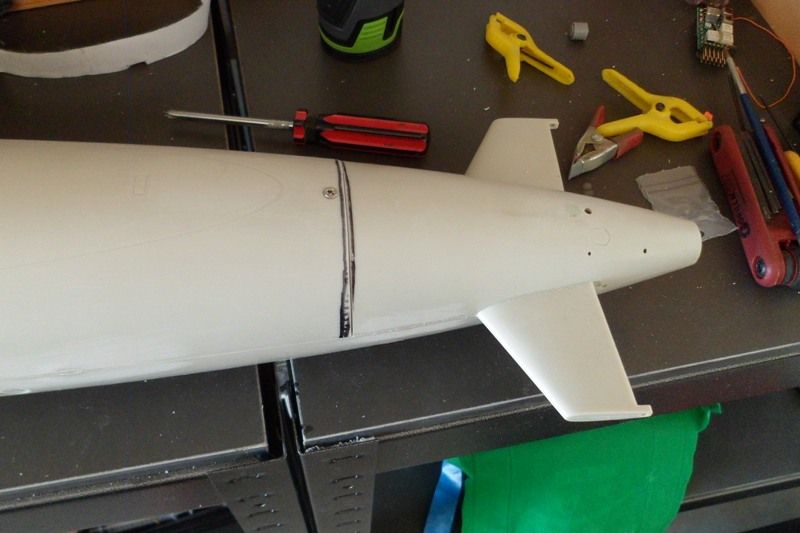

To be honest I very nearly shelved the project to start my TOS 1/350 'E' from round 2 but the allure of another sub one out. Also the fact that it took almost 5 months to do my 1/350 refit with lights additional interior detail and all the aztek paneling done by hand/airbrush. But I dally and dither so back to subject... Saturday was a day of finalizing the purchase of extras e.g. push rods, prop shaft, receiver, battery etc. Then it was wash and clean time for the parts bot from Davids fittings kit and the model proper. For the resins I use a general purpose thinner and then a wash in warm water with a cream cleanser with the aid of a toothbrush and scourer. The styrene parts get the same minus the gp thinners. Then all the parts are layed out to dry over night and with the weather we have been having down here this summer, over night is over kill!

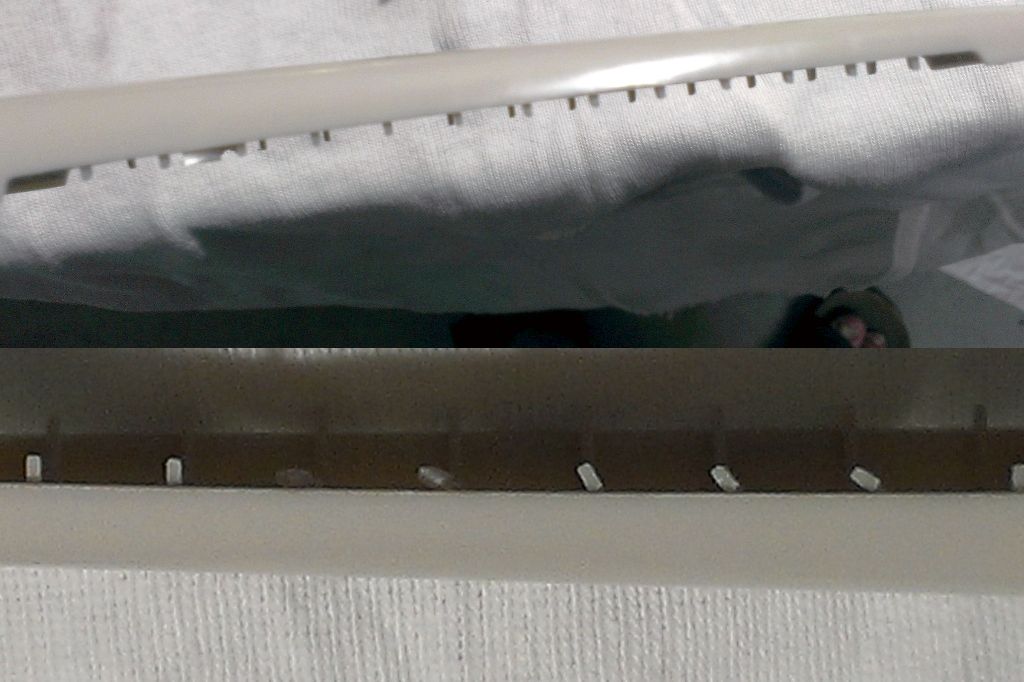

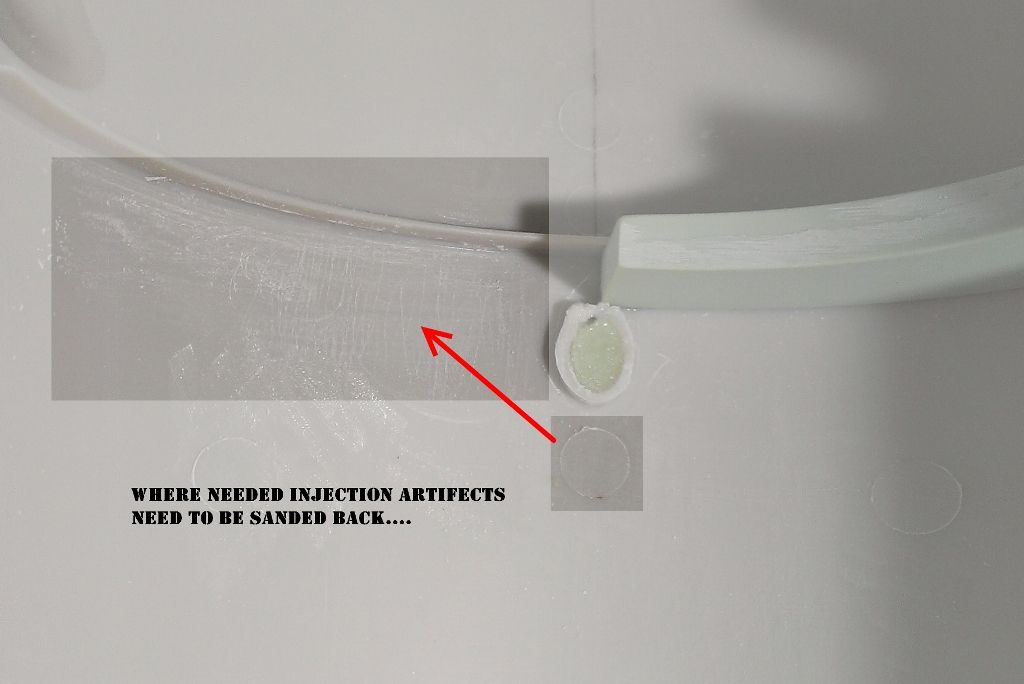

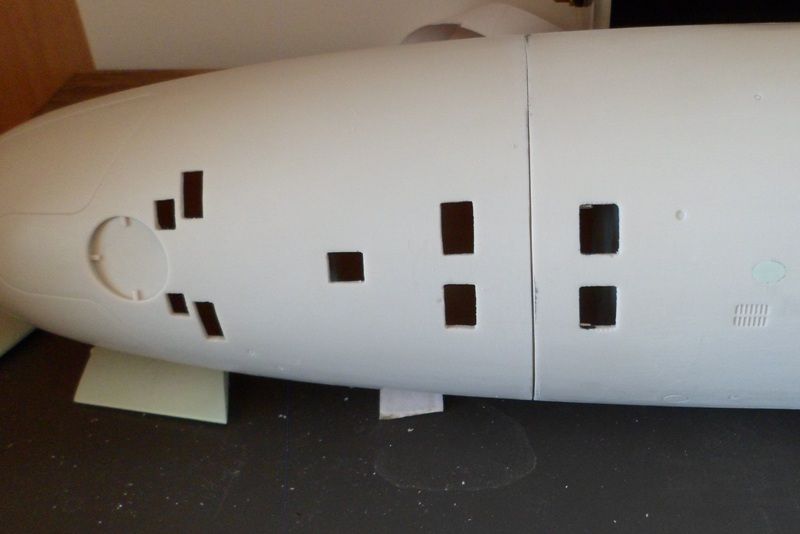

Sadly before I began washing things I needed to do some repair work to the model as some of the exhaust fairing ribs were damaged in transit

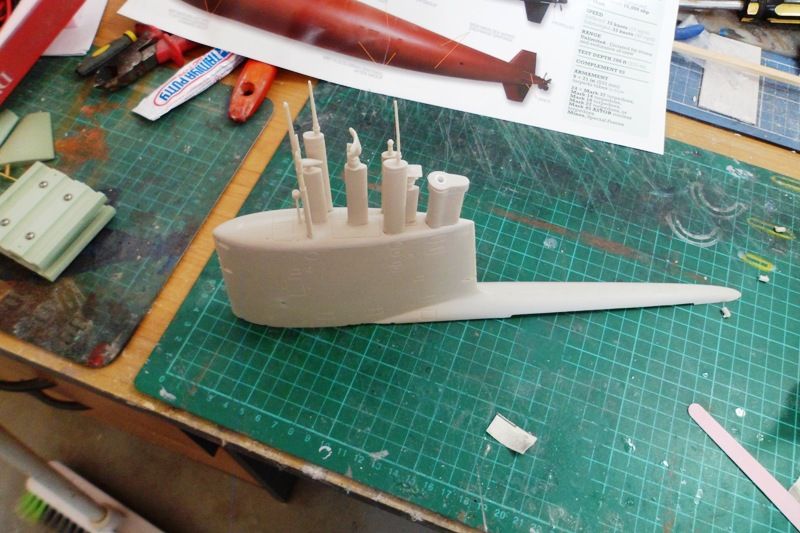

By the way David Kudos on the fittings kit too...

I forgot to take some pics of the styrene washing process. I will say I was surprised at how much mold release agent was still on the styrene parts, so they took some cleaning to get the water to flow down the hull as a sheet rather than rivulets on speed.

To be honest I very nearly shelved the project to start my TOS 1/350 'E' from round 2 but the allure of another sub one out. Also the fact that it took almost 5 months to do my 1/350 refit with lights additional interior detail and all the aztek paneling done by hand/airbrush. But I dally and dither so back to subject... Saturday was a day of finalizing the purchase of extras e.g. push rods, prop shaft, receiver, battery etc. Then it was wash and clean time for the parts bot from Davids fittings kit and the model proper. For the resins I use a general purpose thinner and then a wash in warm water with a cream cleanser with the aid of a toothbrush and scourer. The styrene parts get the same minus the gp thinners. Then all the parts are layed out to dry over night and with the weather we have been having down here this summer, over night is over kill!

Sadly before I began washing things I needed to do some repair work to the model as some of the exhaust fairing ribs were damaged in transit

By the way David Kudos on the fittings kit too...

I forgot to take some pics of the styrene washing process. I will say I was surprised at how much mold release agent was still on the styrene parts, so they took some cleaning to get the water to flow down the hull as a sheet rather than rivulets on speed.

Comment