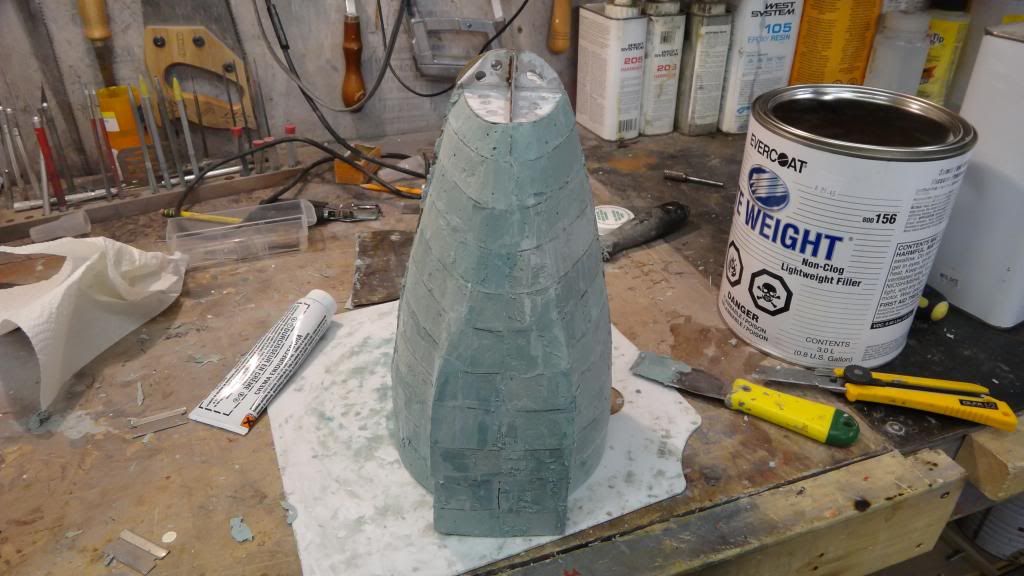

Alright, Alright. The plan this weekend is to cut the pressure hull in two, mount and center the halves in the metal lathe and put a machined finish on. We're going to go hardcore precision on this foundation and I can't get that with my baseball bat copy attachment because the Evercoat surface is too hard and the attachment isn't rigid enough. Gotta start somewhere again and it might as well be there.

Joel

Joel

Comment