Indeed. Well anyone can book up a schedule of events they 'plan' to attend. Then when the day looms- the cat ate my sub!

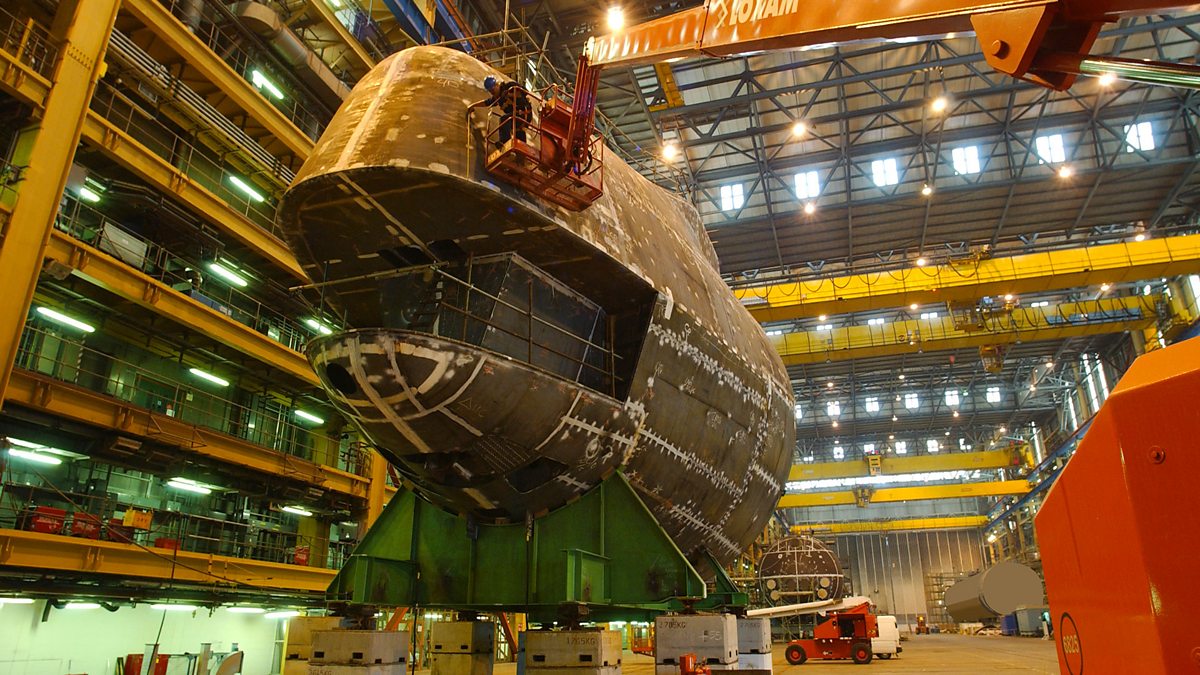

Notice how the delivery schedule is over a fortnight after the auction ends. Are they delivering it by canal barge?

Notice how the delivery schedule is over a fortnight after the auction ends. Are they delivering it by canal barge?

Comment