Well after tooing & froing I finally made my decision on the next boat for my fleet. An Akula from Sheerline Models in England. It was a close call on the 31 inch Disney Nautilus by Scott Brodeen but the size, inclusions and research led my descision to the Sheerline kit of the Akula. I also looked at the scale ships kit as well but as the one from Chris came with a wtc and running gear bar the esc, reciever and servos it was a no brainer for me and the wallet. Plus keeping thigs in one delivery under $1000 AU helps avoid all those BS import duties and fees our federal & state officials like to apply.

Now I have to say that Chris from sheerline has been great to deal with and that his passion for the models he does shows in his service, correspondence and delivery of the end product. It's people like David, Caswells, Chris and others that help nurture and keep us in the hobbies we do. But enough butt kissing...

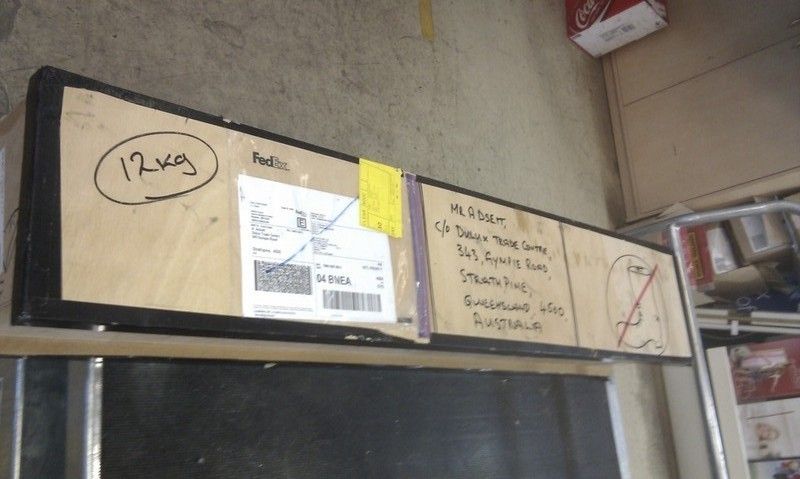

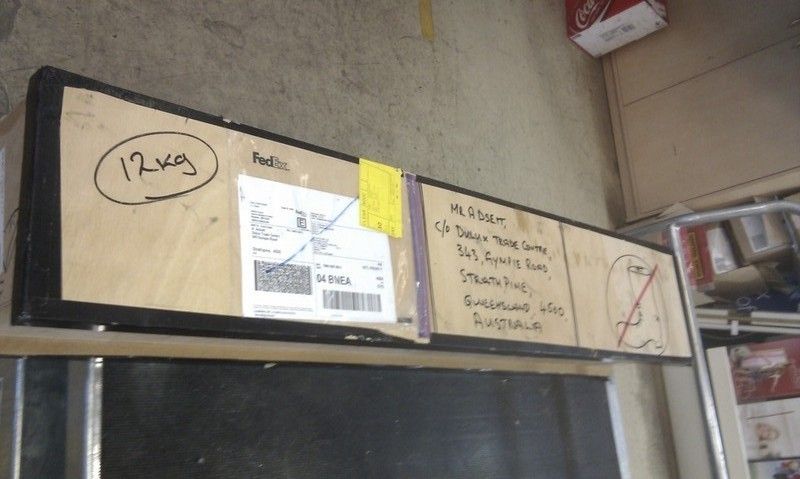

This is how the kit turns up form Chris... I had it sent to my work because I didn't like the idea of it sitting at the front door left unattended as I'm pretty sure it wouldn't have been around when I finally got home...

and how it looks inside the box...

and this is whats under all that bubble wrap, foam & packing... Everything is bagged and labeled separately. The prop shaft, mounting block and propeller are all supplied ready to fit. Even the push rods are pre shaped along with an assembled boat stand out of timber and as I suck at wood work I'm really liking that addition. Chris even supplies the battery and ballast. Please forgive my enthusiasm regarding this kit but as it is only my third rc sub and it being a grp one to boot is for me exciting...

Obviously the wtc is different than what David produces but reading what is said about it from forums from over in England it looks good. What I have looked at so far with it looks pretty impressive and adds another flavor to the platter of learning in the rc sub smorgasbord.

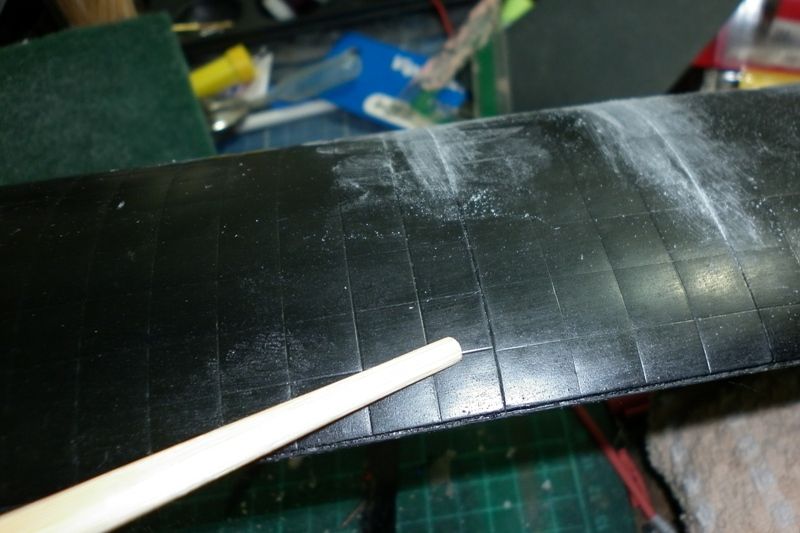

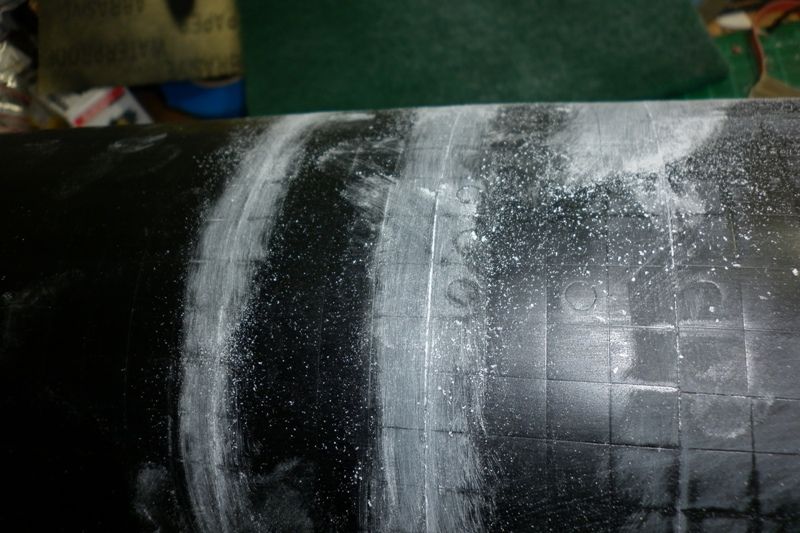

As for the sub itself it looks pretty solid too. In one of the emails I asked about a mast kit etc to which Chris replied straight up saying that he didn't produce one. All he does is do a good reliable kit that people can get in the water and enjoy. I'm pretty confident I can knock up the masts for it and I might even tackle some of the other hull features.

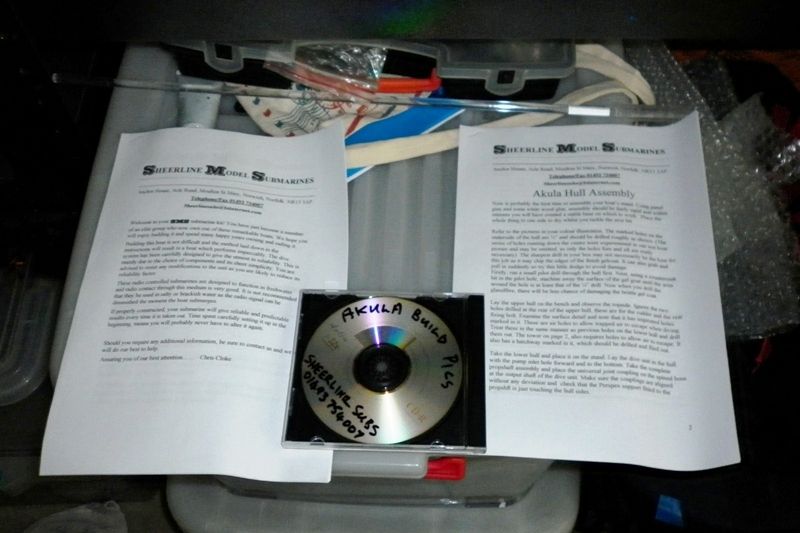

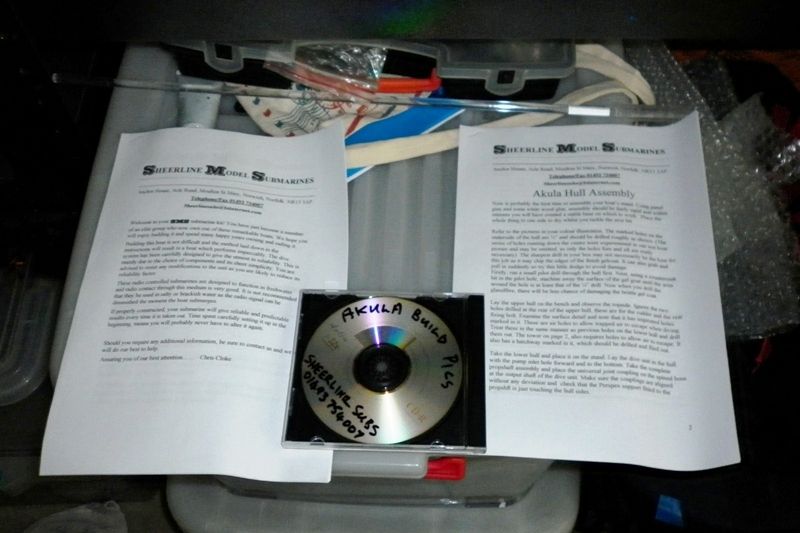

There are two separate instruction guides. One for the model itself and the other is for the wtc along with a cd of pictures to go with the guide/instruction books

As this will be my first grp model I am still getting info on what are the best adhesives available down under. Chris has suggested I don't use any epoxy based glues as this is a polyester based resin grp. I know a good quality ca glue is a given but I need to source some good two part stuff. If I were to put a time frame on this kit I would be confident in saying that the basic sub being assembled, primed, tested, ballasted would be in the lake in less than three weeks just working on it at night. As for the proper hull painting and weathering I reckon maybe a week longer weather dependent. So all thing going to plan I should be starting the clock this coming week end.

Now I have to say that Chris from sheerline has been great to deal with and that his passion for the models he does shows in his service, correspondence and delivery of the end product. It's people like David, Caswells, Chris and others that help nurture and keep us in the hobbies we do. But enough butt kissing...

This is how the kit turns up form Chris... I had it sent to my work because I didn't like the idea of it sitting at the front door left unattended as I'm pretty sure it wouldn't have been around when I finally got home...

and how it looks inside the box...

and this is whats under all that bubble wrap, foam & packing... Everything is bagged and labeled separately. The prop shaft, mounting block and propeller are all supplied ready to fit. Even the push rods are pre shaped along with an assembled boat stand out of timber and as I suck at wood work I'm really liking that addition. Chris even supplies the battery and ballast. Please forgive my enthusiasm regarding this kit but as it is only my third rc sub and it being a grp one to boot is for me exciting...

Obviously the wtc is different than what David produces but reading what is said about it from forums from over in England it looks good. What I have looked at so far with it looks pretty impressive and adds another flavor to the platter of learning in the rc sub smorgasbord.

As for the sub itself it looks pretty solid too. In one of the emails I asked about a mast kit etc to which Chris replied straight up saying that he didn't produce one. All he does is do a good reliable kit that people can get in the water and enjoy. I'm pretty confident I can knock up the masts for it and I might even tackle some of the other hull features.

There are two separate instruction guides. One for the model itself and the other is for the wtc along with a cd of pictures to go with the guide/instruction books

As this will be my first grp model I am still getting info on what are the best adhesives available down under. Chris has suggested I don't use any epoxy based glues as this is a polyester based resin grp. I know a good quality ca glue is a given but I need to source some good two part stuff. If I were to put a time frame on this kit I would be confident in saying that the basic sub being assembled, primed, tested, ballasted would be in the lake in less than three weeks just working on it at night. As for the proper hull painting and weathering I reckon maybe a week longer weather dependent. So all thing going to plan I should be starting the clock this coming week end.

Comment