Hi,

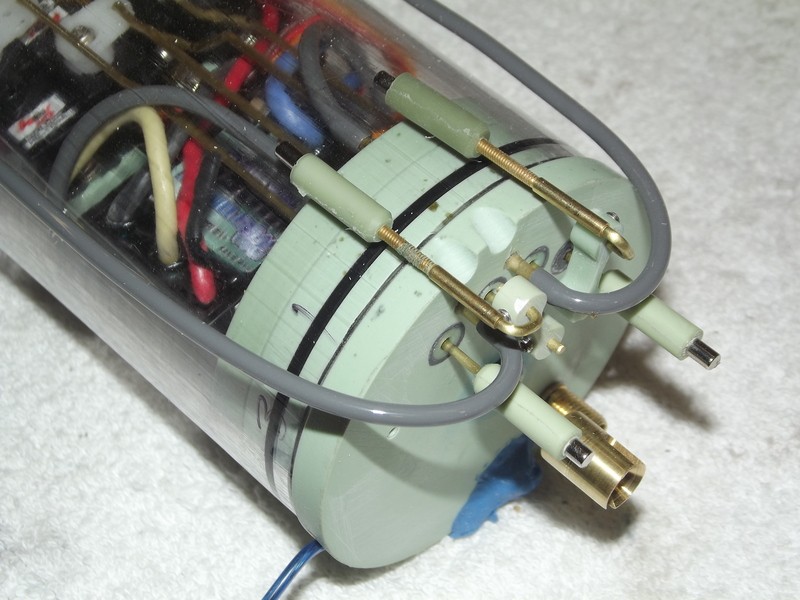

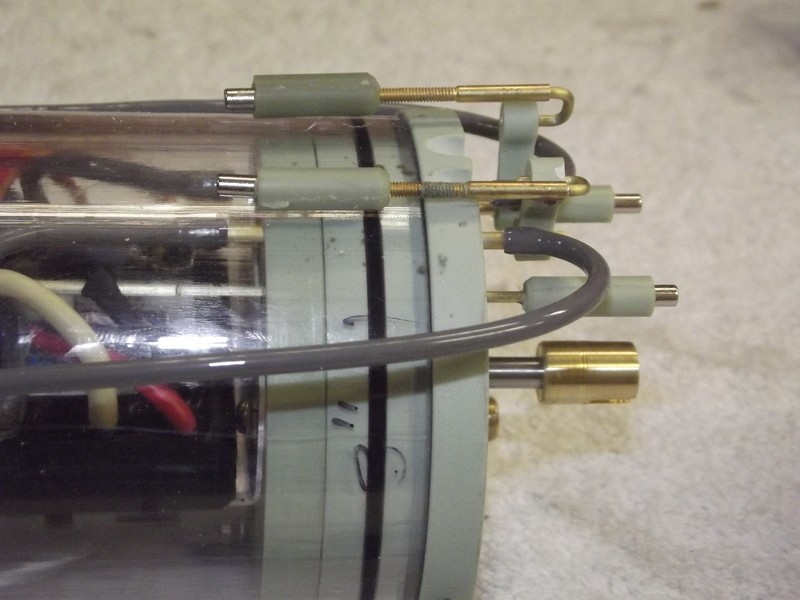

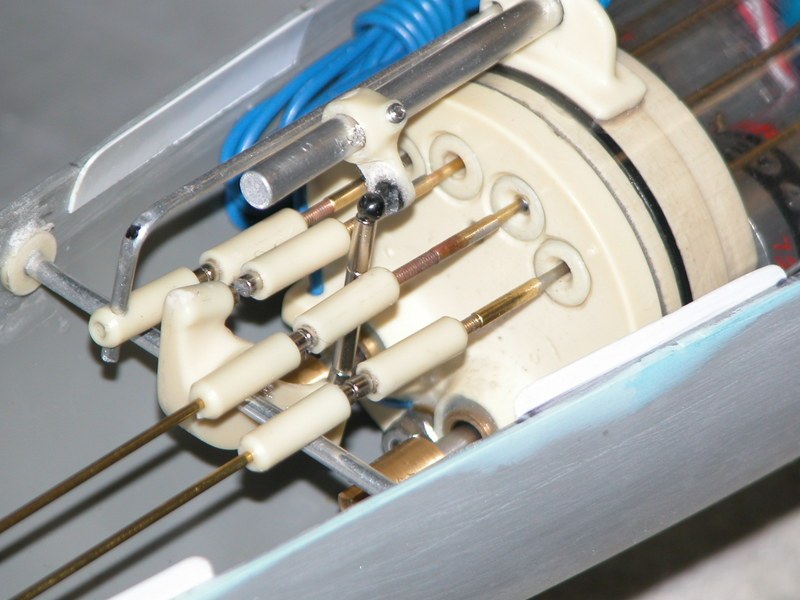

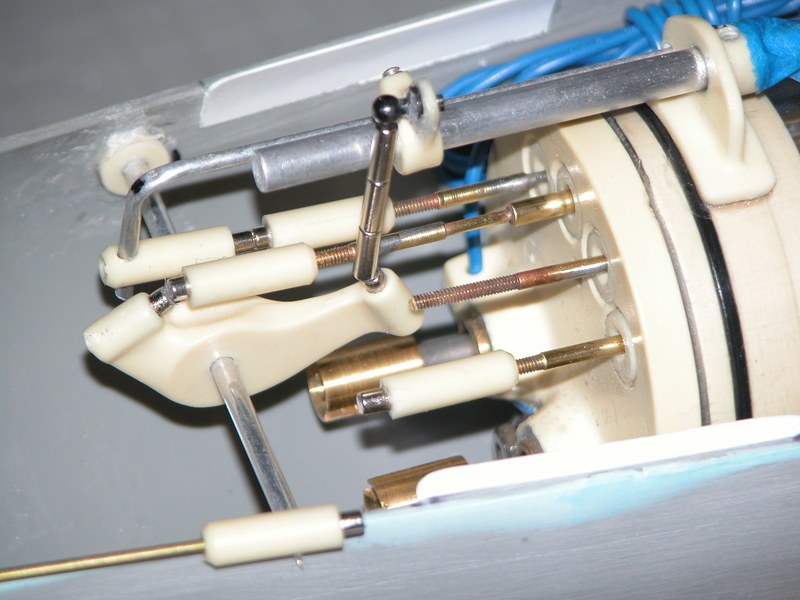

How is the rear control arm R15, attached to the square tubing shaft, L7, that operates the rear dive planes?

The instructions indicate "weld", but I have no idea what that means.

I doubt you can solder it to the shaft, if the brass insert is hot enough to solder it will certainly melt the plastic arm.

I was thinking of JB weld but it doesn't really work well in this application.

Also, is there any advantage to gluing the hull sides together rather than just screwing them together.

Thanks,

Jon

How is the rear control arm R15, attached to the square tubing shaft, L7, that operates the rear dive planes?

The instructions indicate "weld", but I have no idea what that means.

I doubt you can solder it to the shaft, if the brass insert is hot enough to solder it will certainly melt the plastic arm.

I was thinking of JB weld but it doesn't really work well in this application.

Also, is there any advantage to gluing the hull sides together rather than just screwing them together.

Thanks,

Jon

Comment