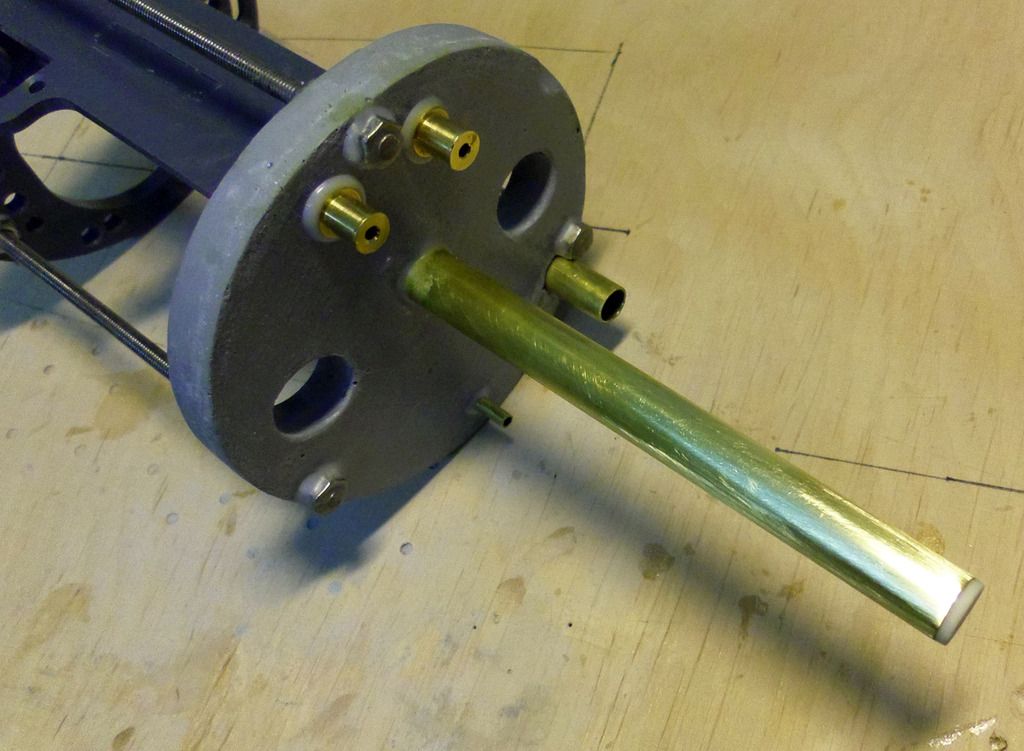

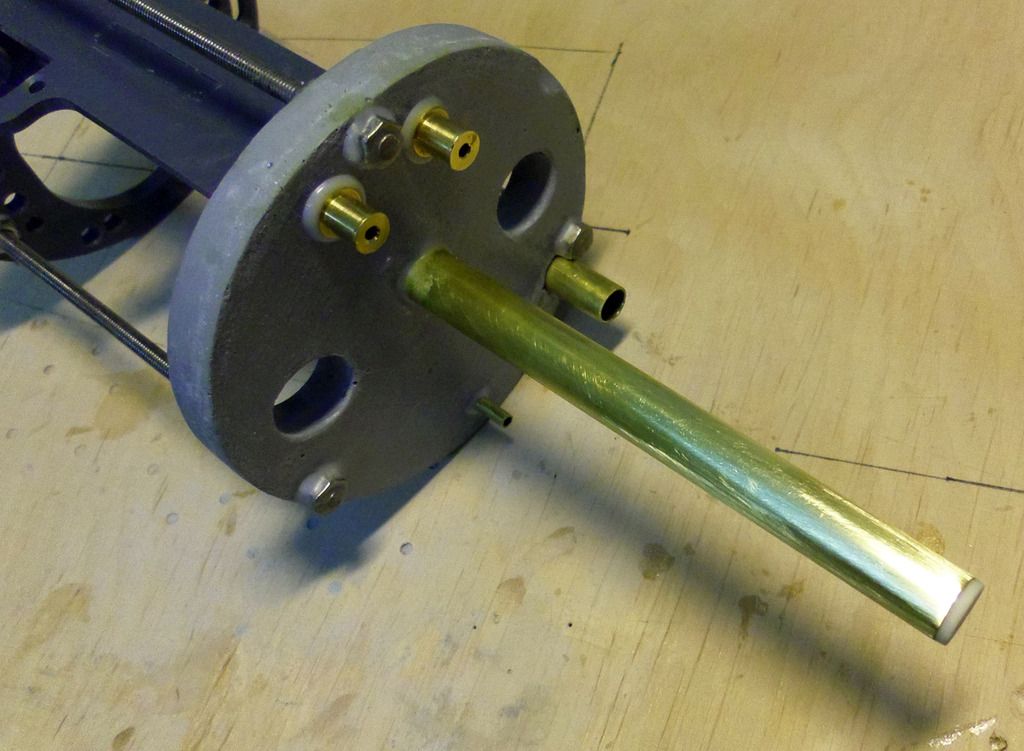

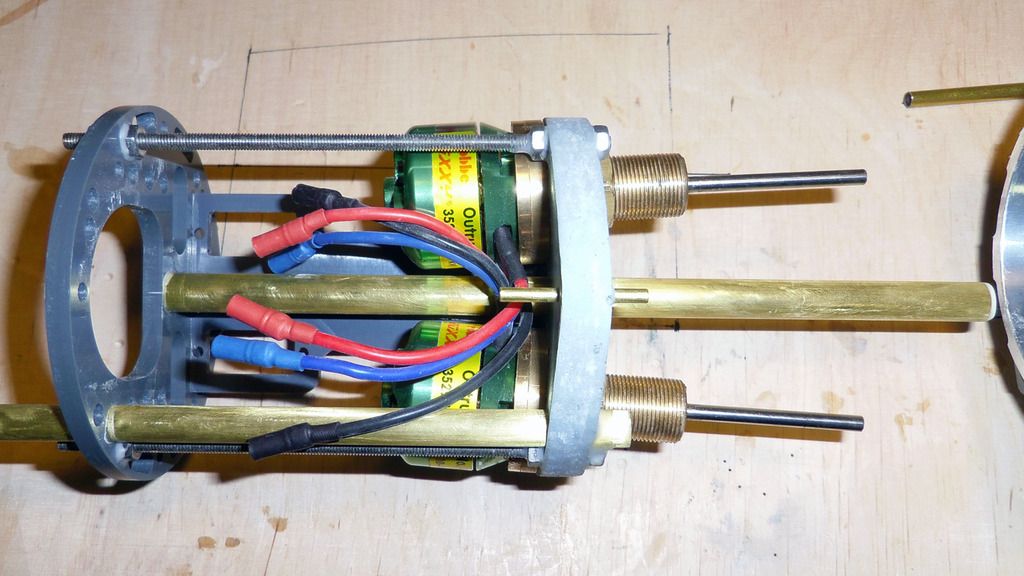

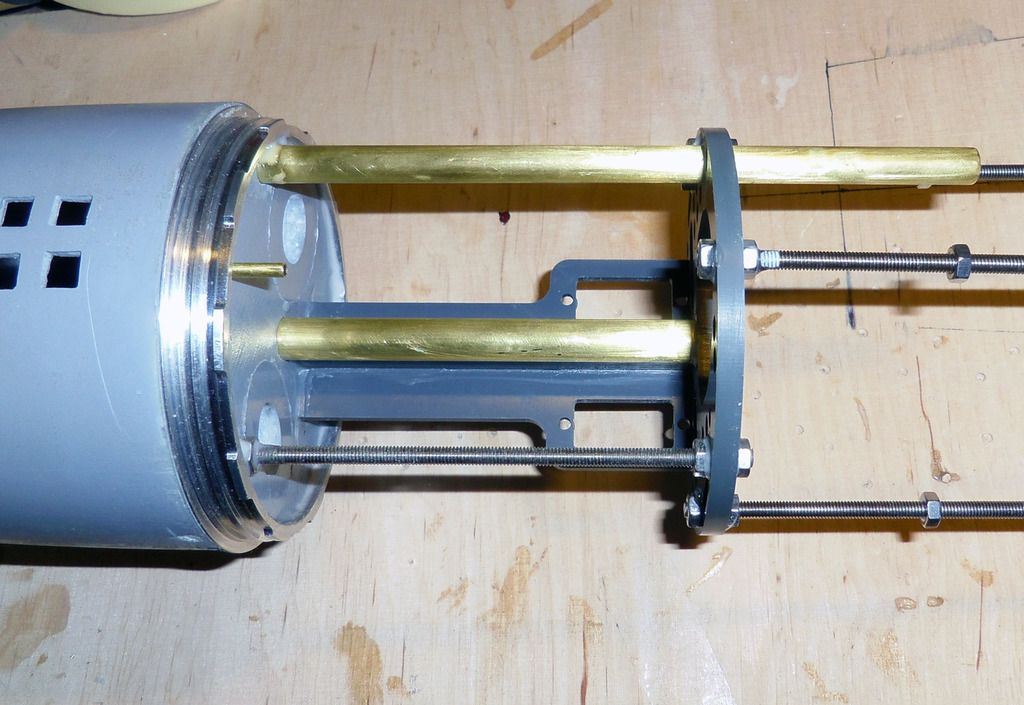

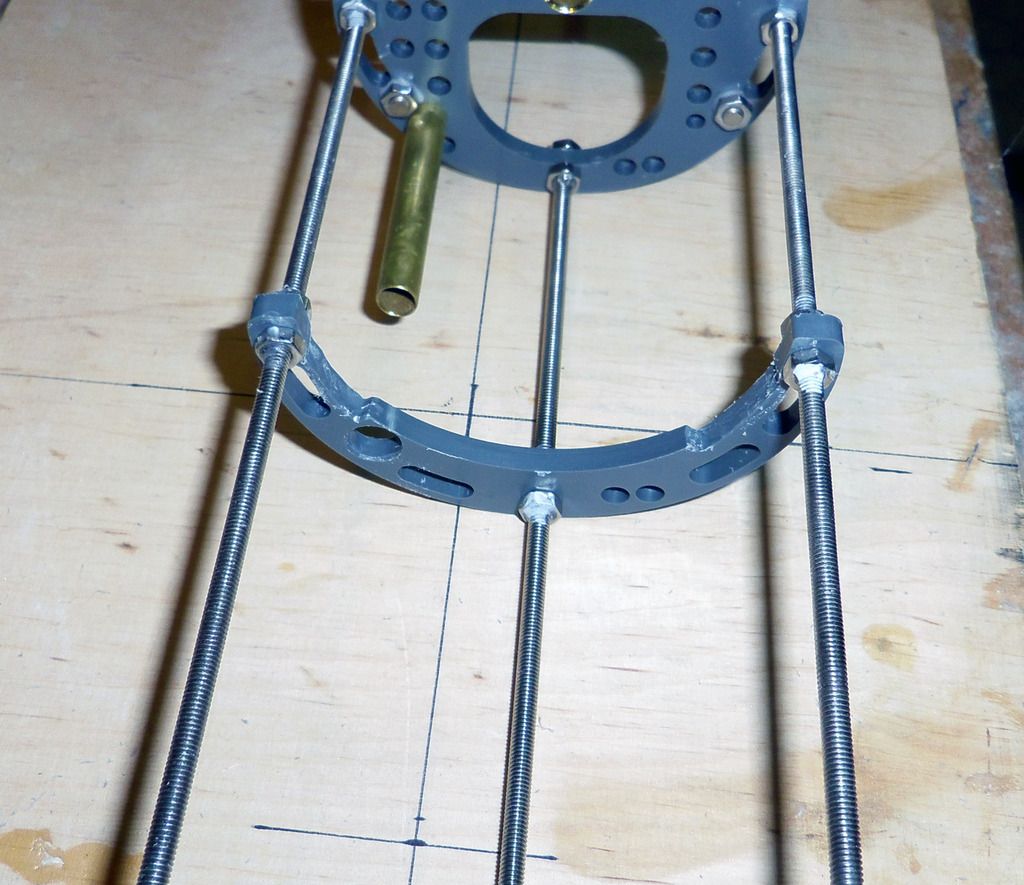

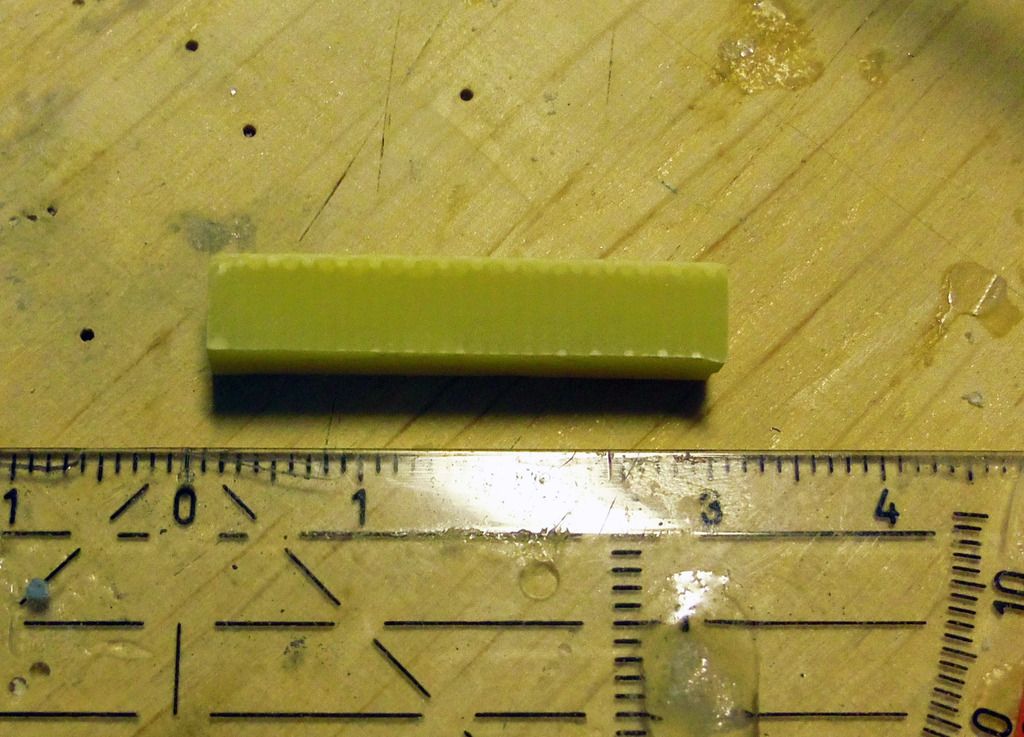

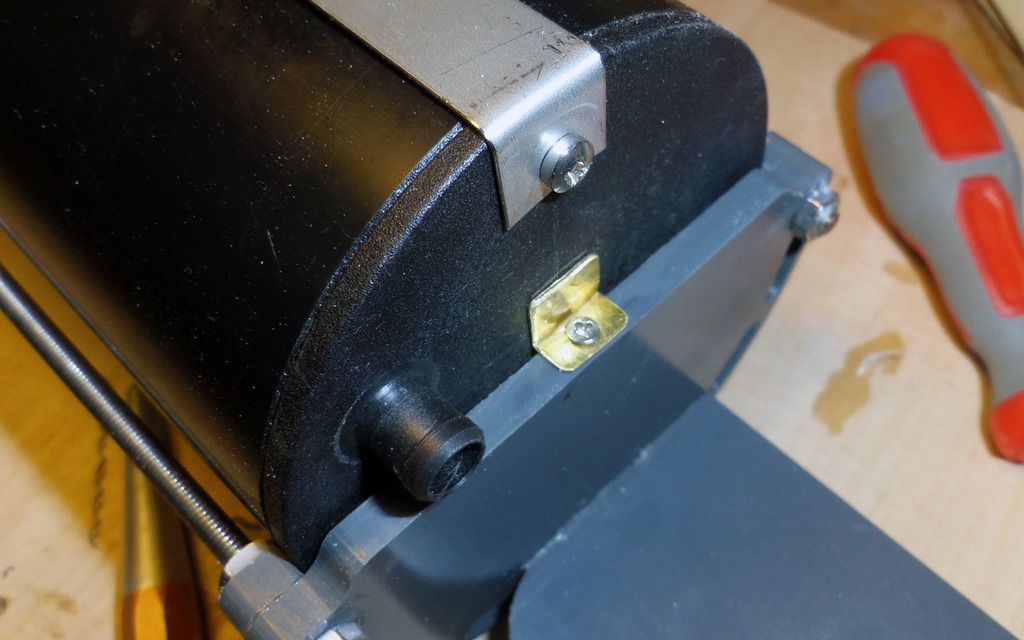

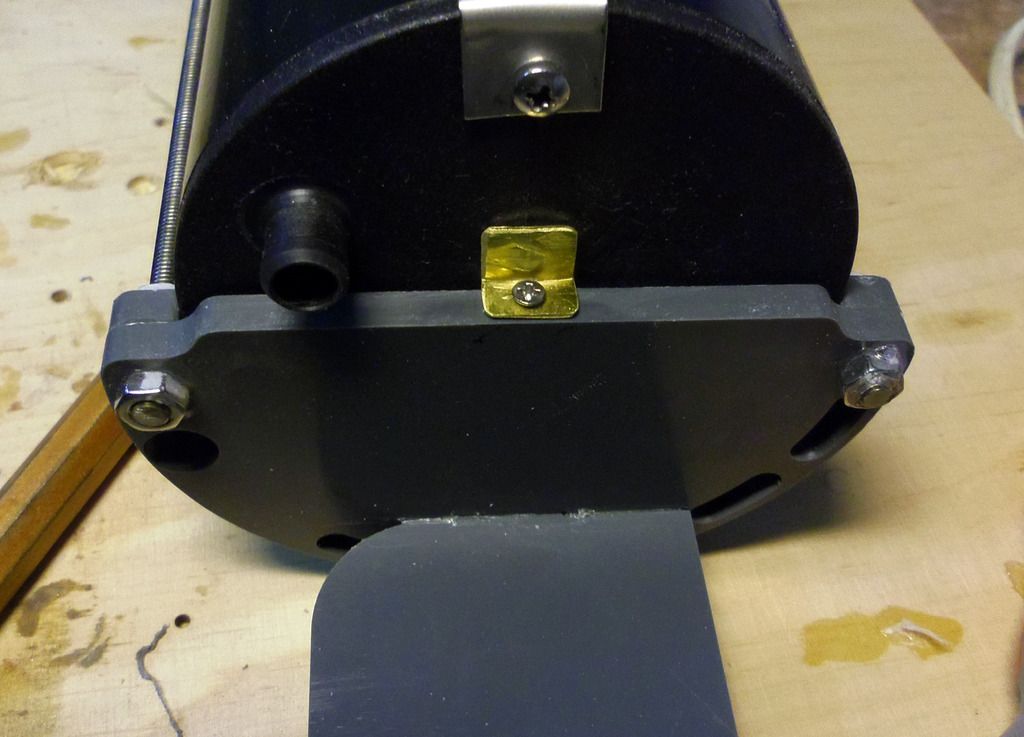

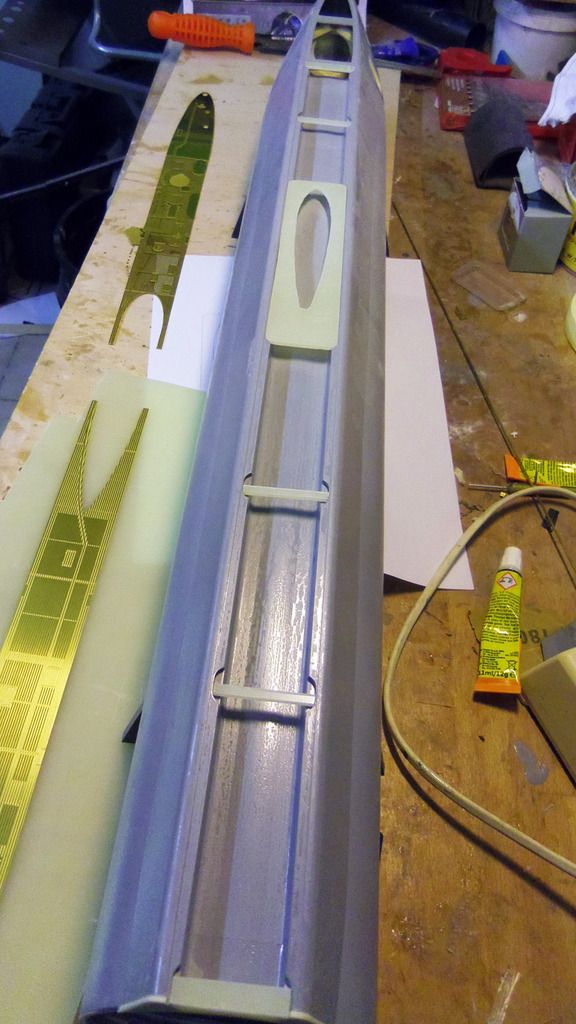

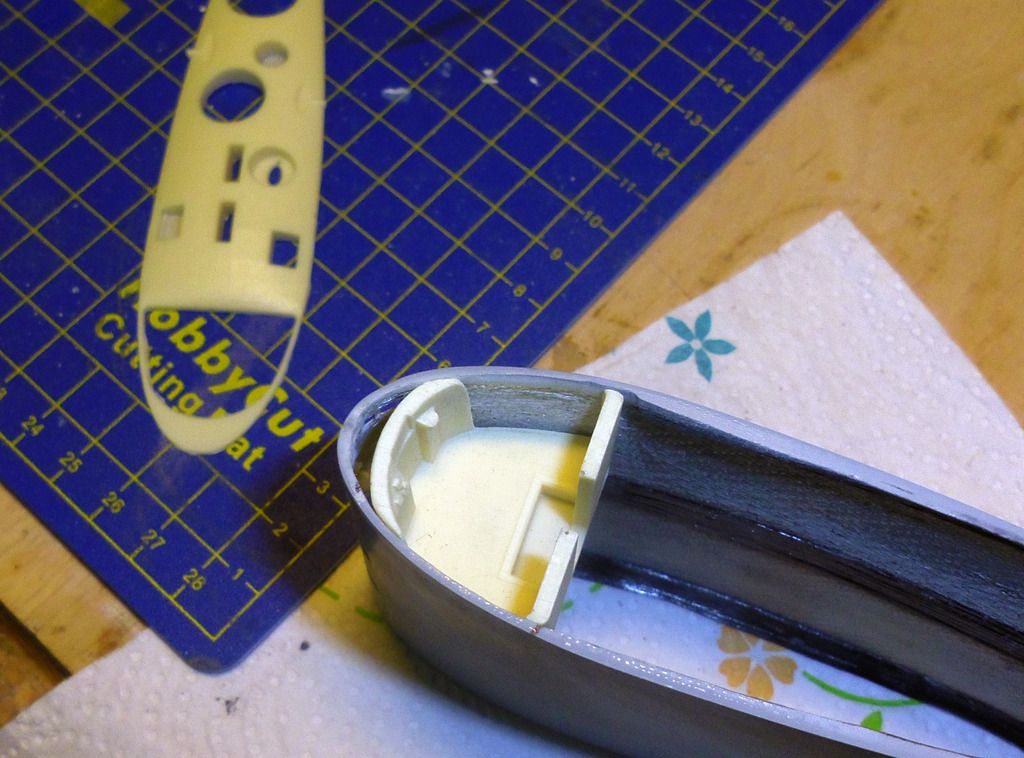

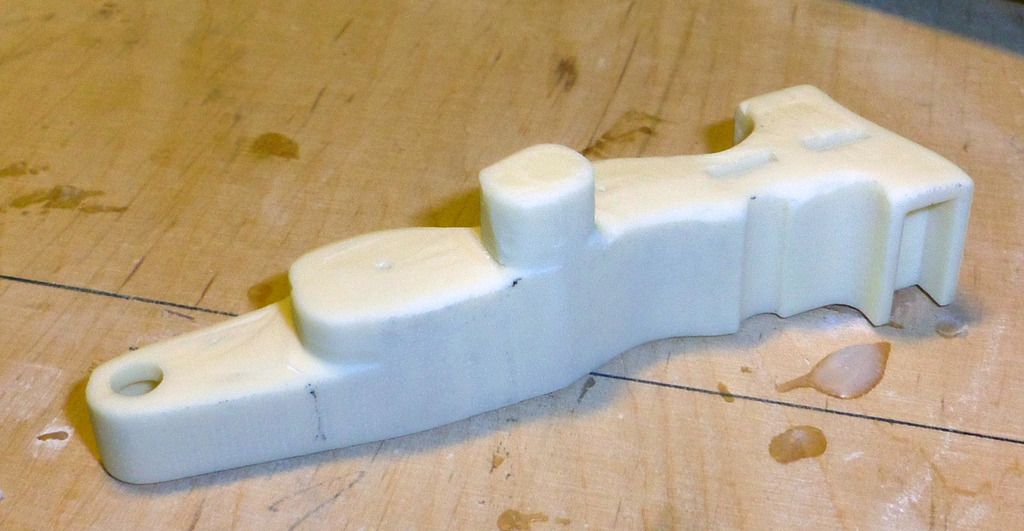

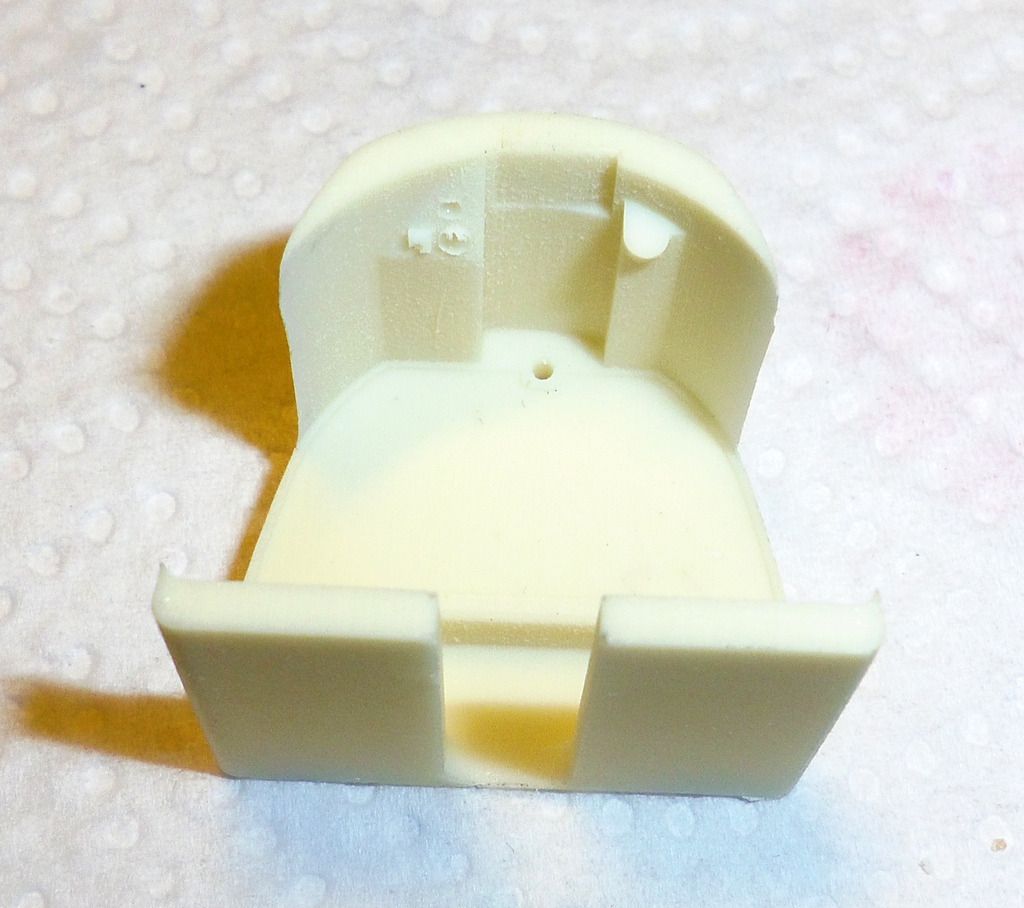

To finalize the first interior section, the tube fort he thread rod oft he piston tank is glued shut with the resin pug. In addition the connectors fort he rubber bellows fort he push rods (Engel-Modellbau) are glued into position:

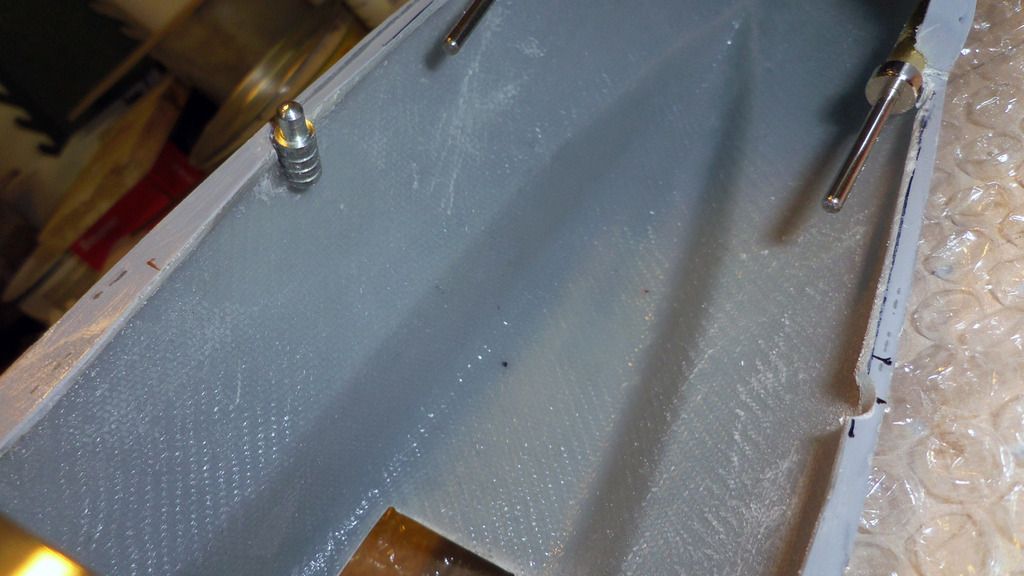

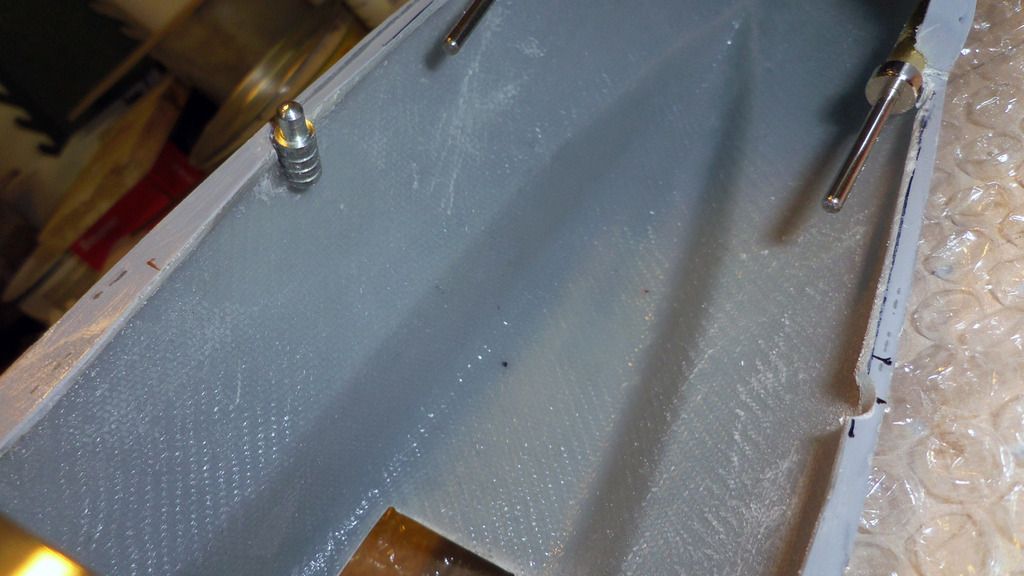

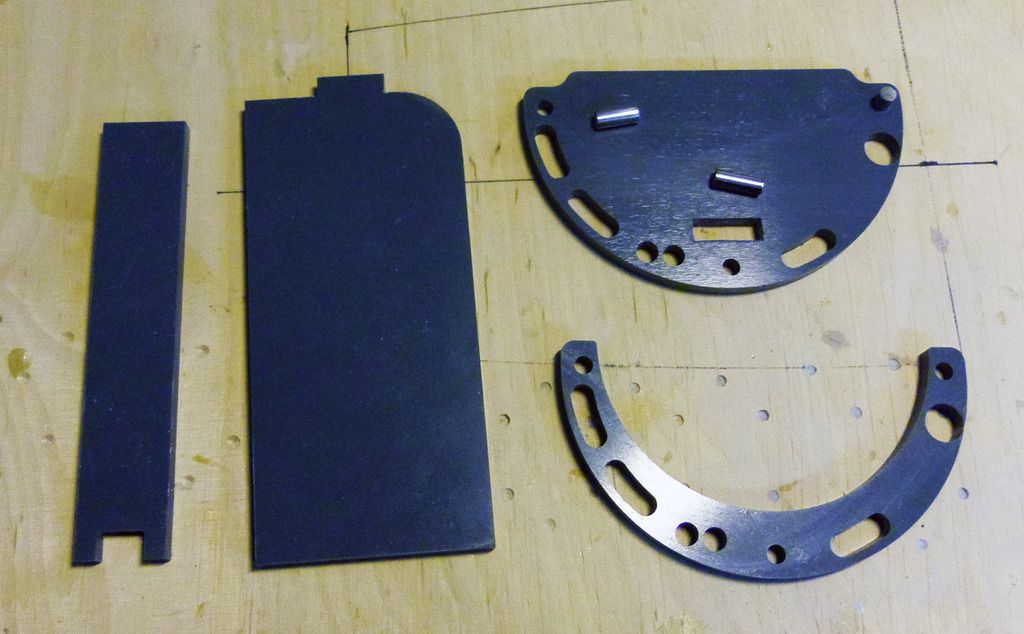

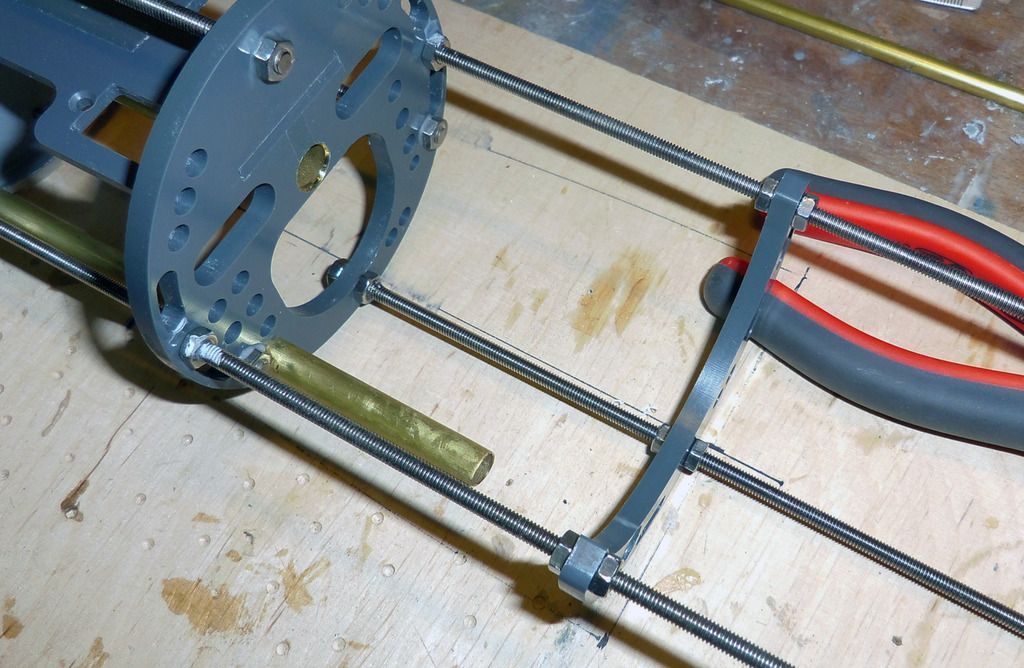

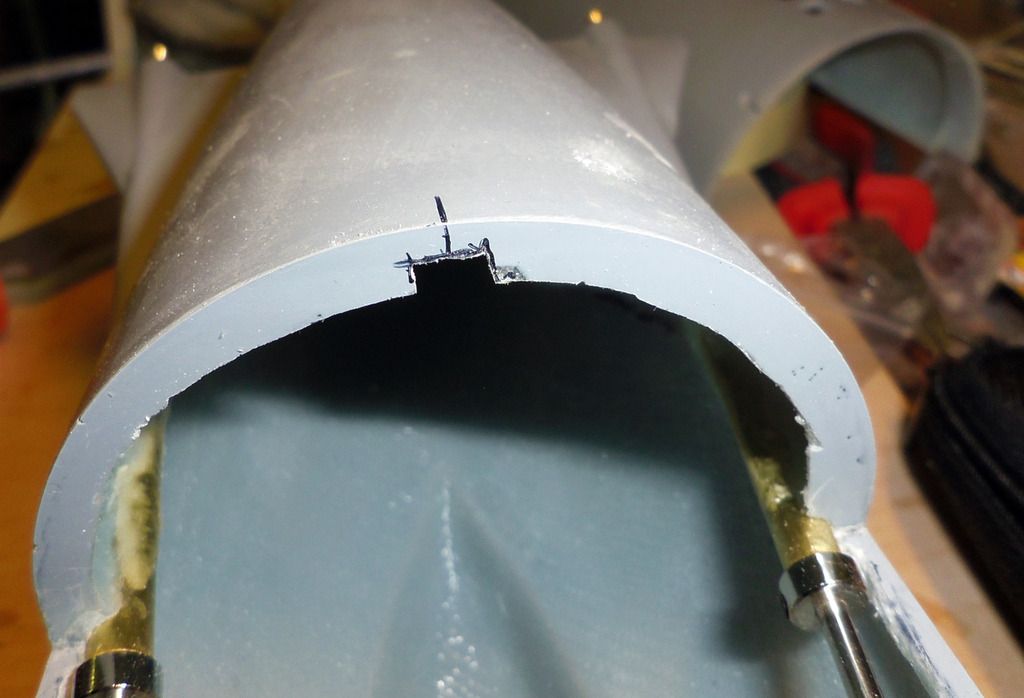

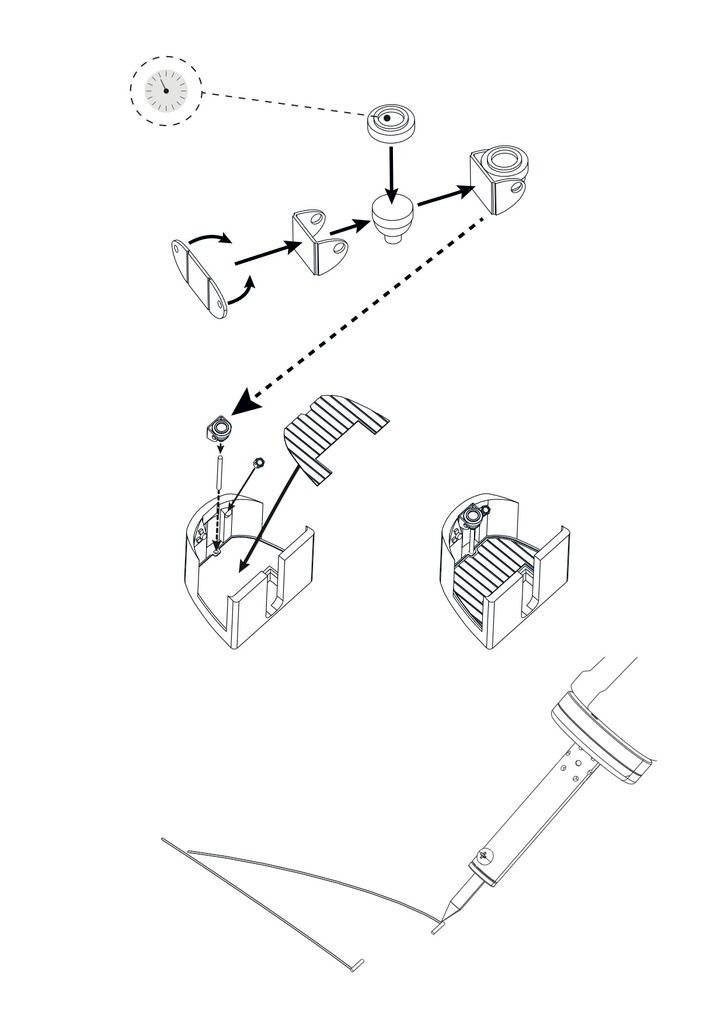

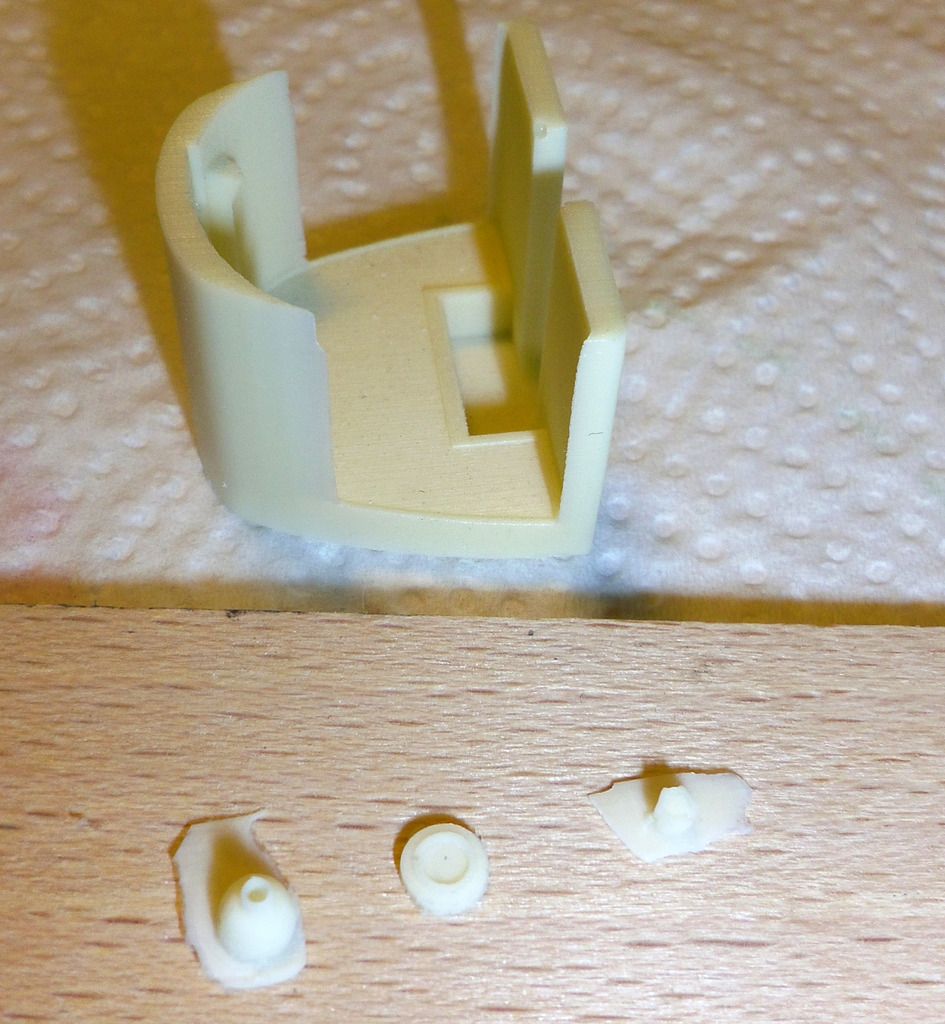

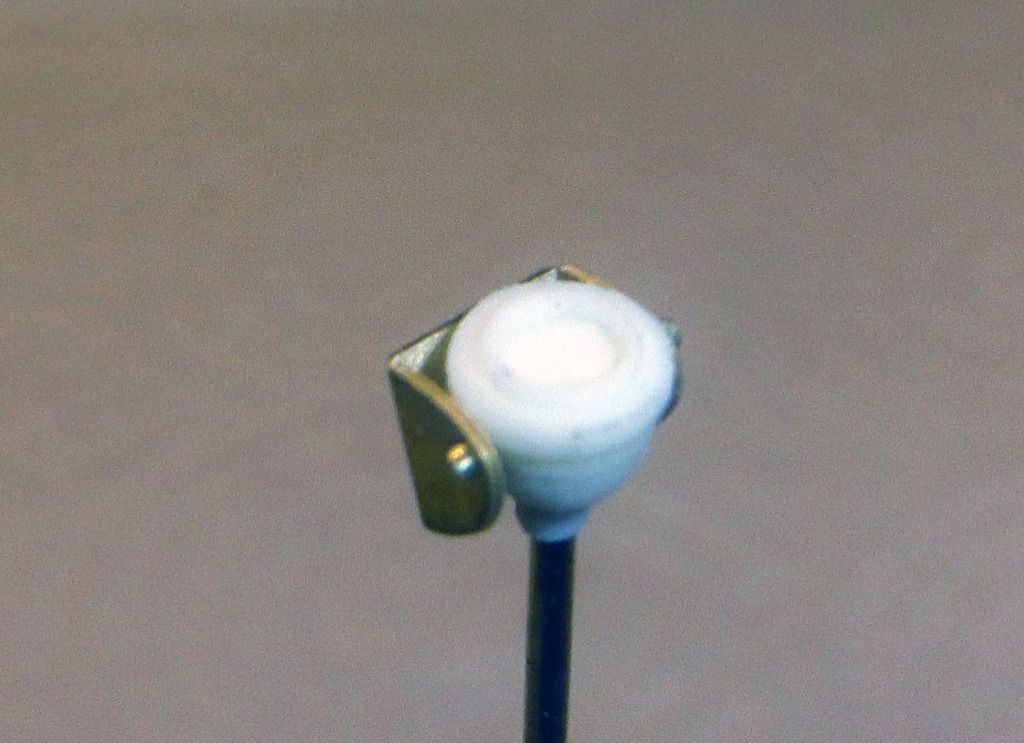

Then the plug-in mounts of the service hatch are installed. I use aluminum pins and sockets originally intended to be used for moulds, but brass pins and sockets are equally suited:

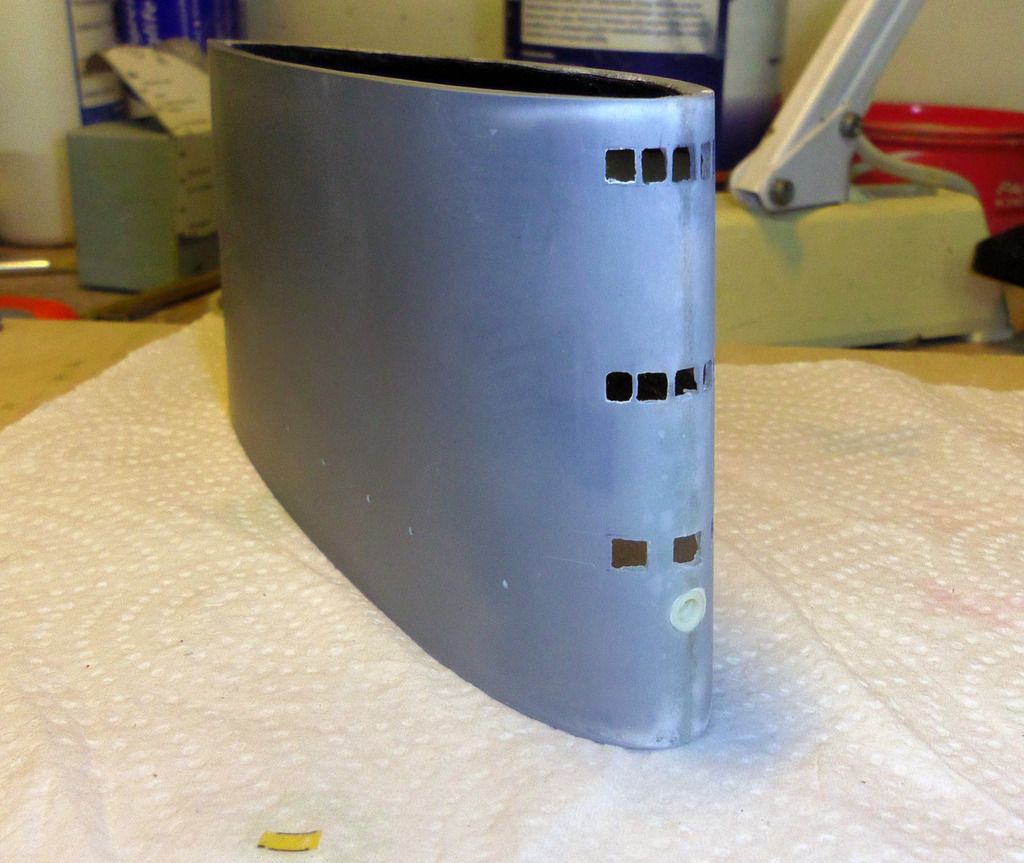

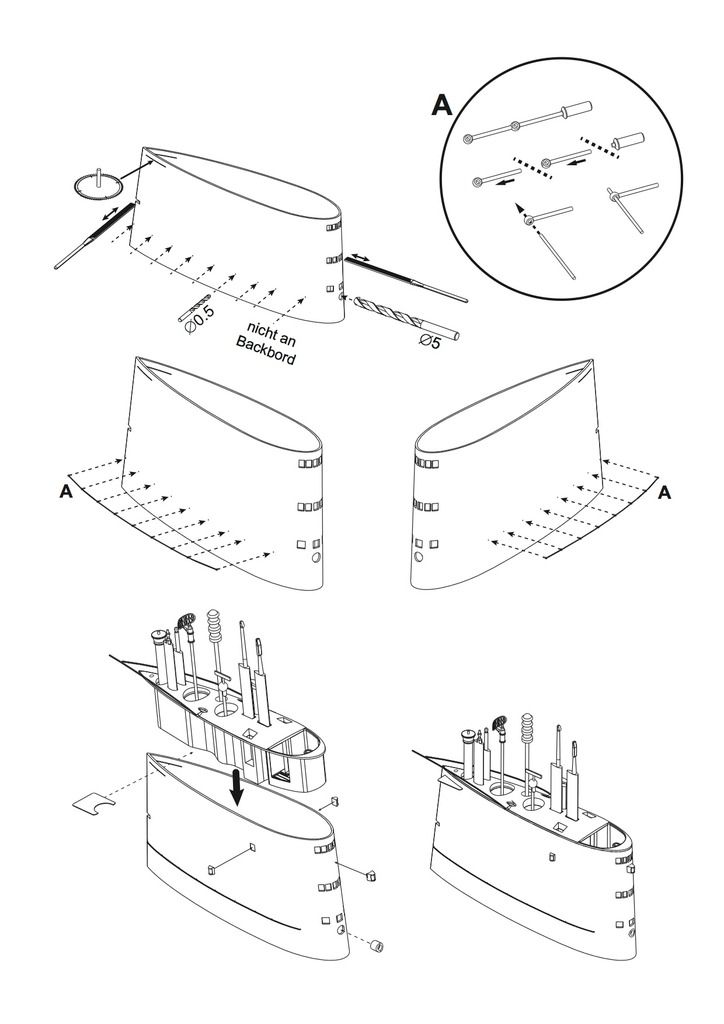

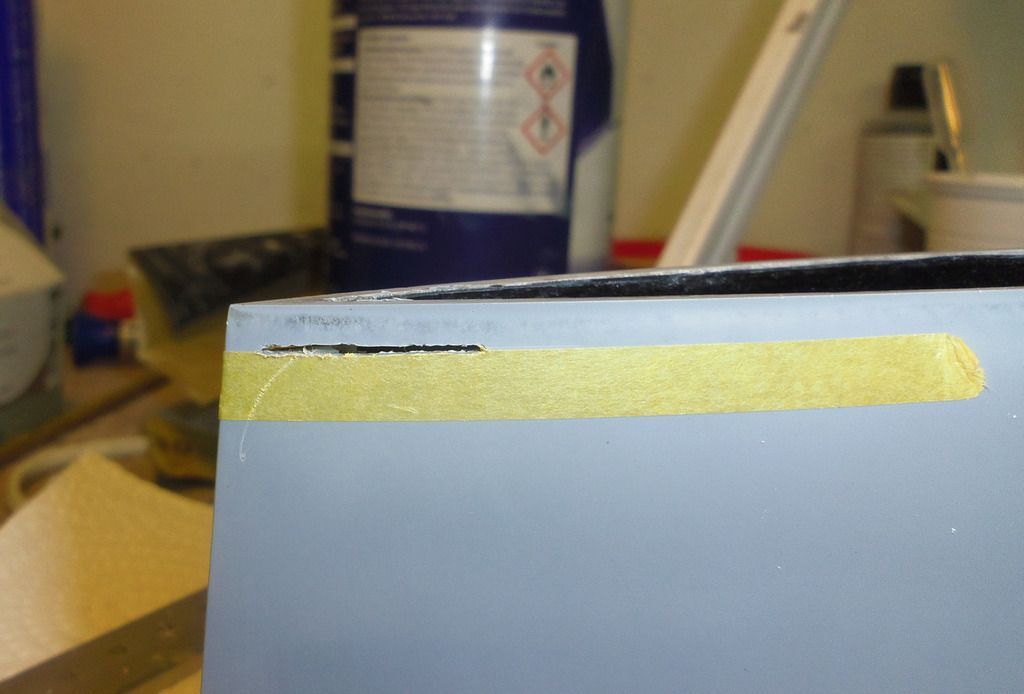

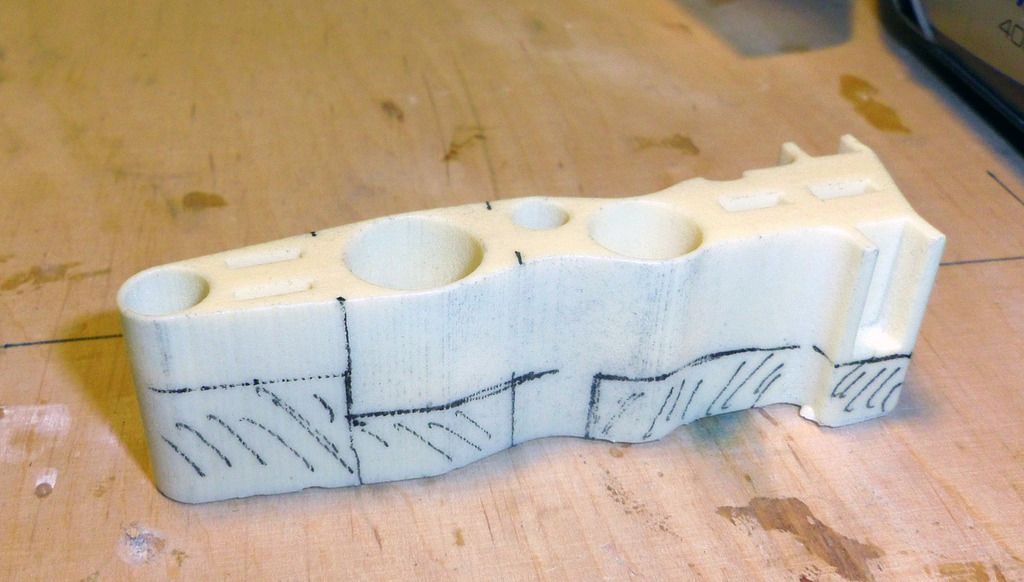

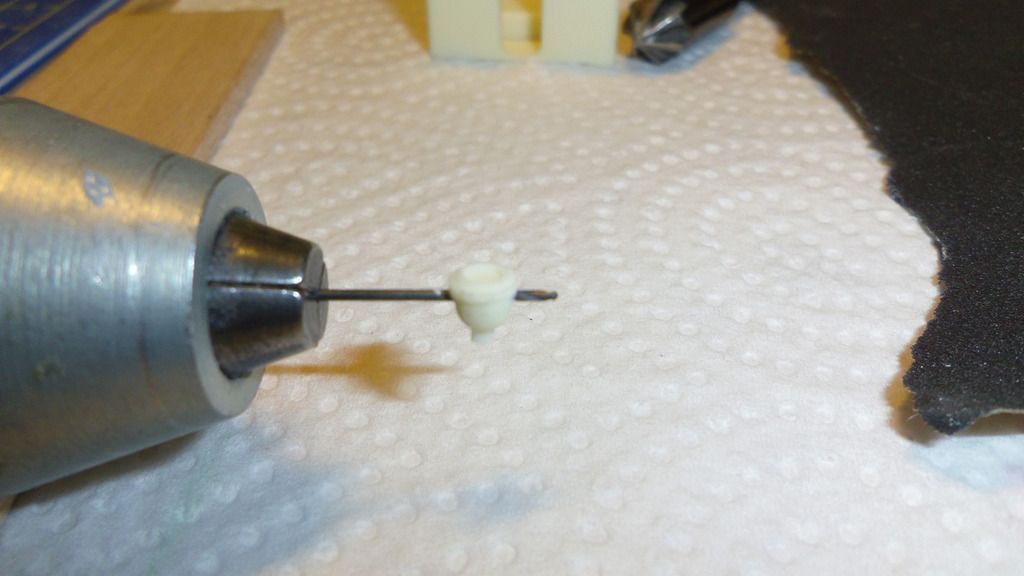

The position of the pins is marked on the edge of the stern section, drilled and filed. The pins are the preliminarily fixed using superglue:

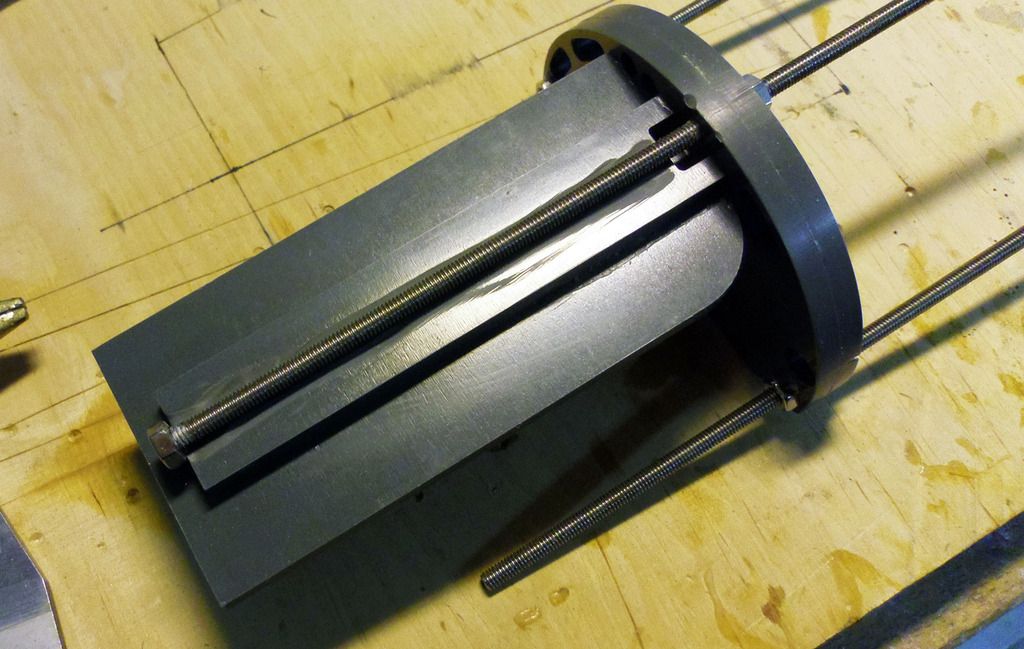

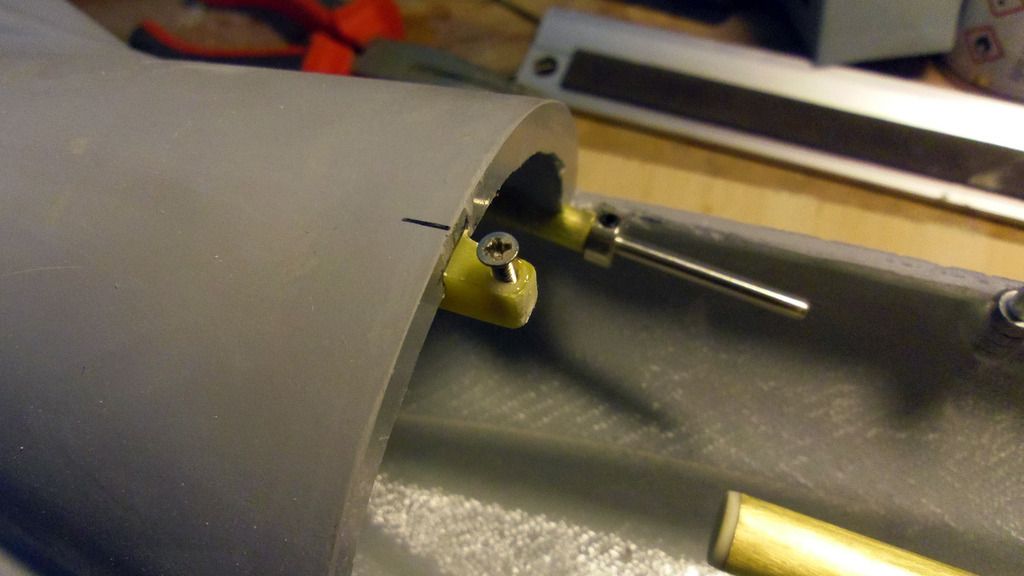

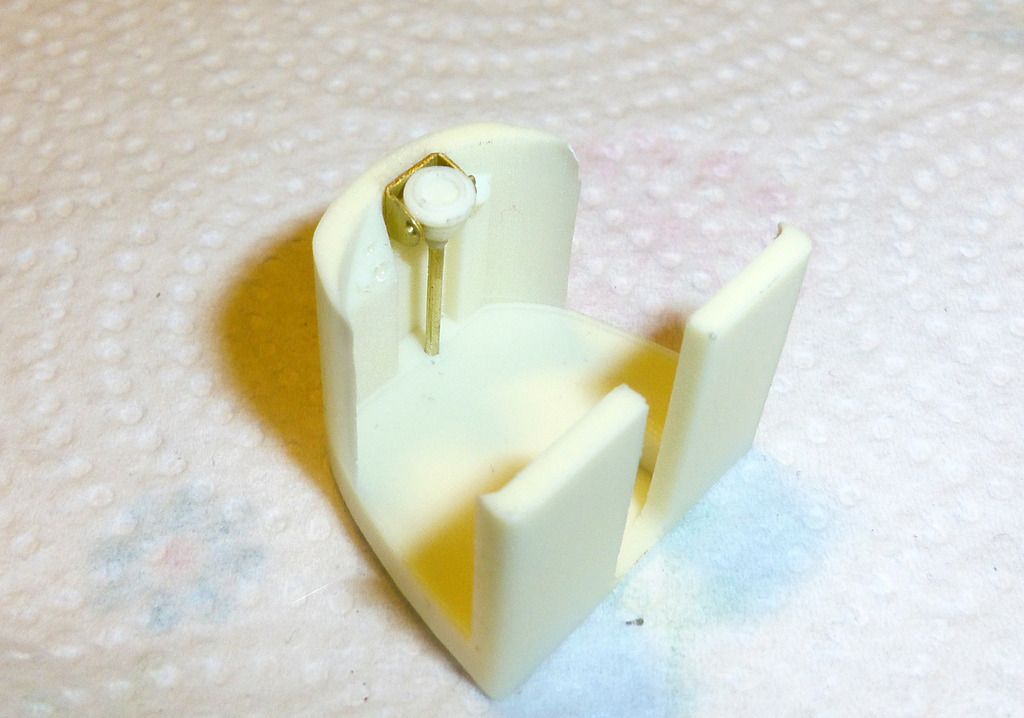

Then the pins are finally glued into place using again epoxy:

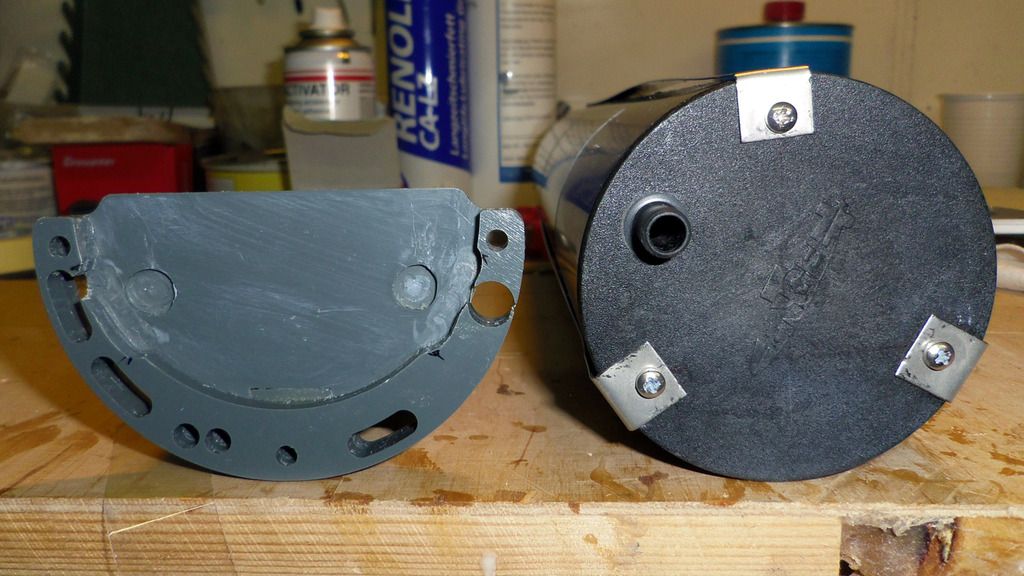

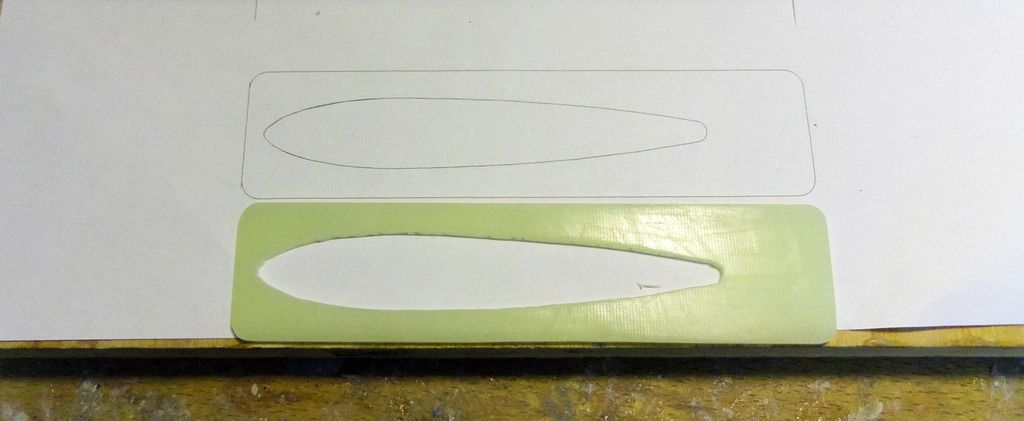

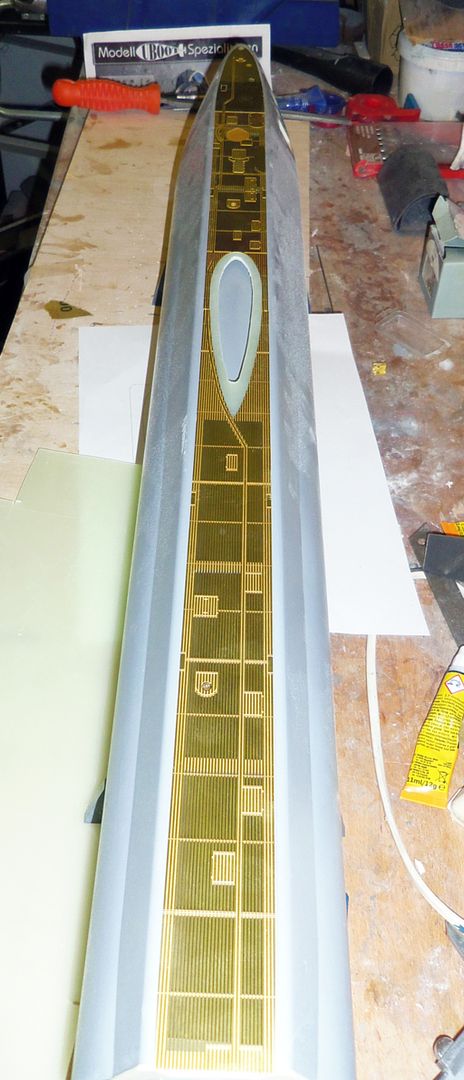

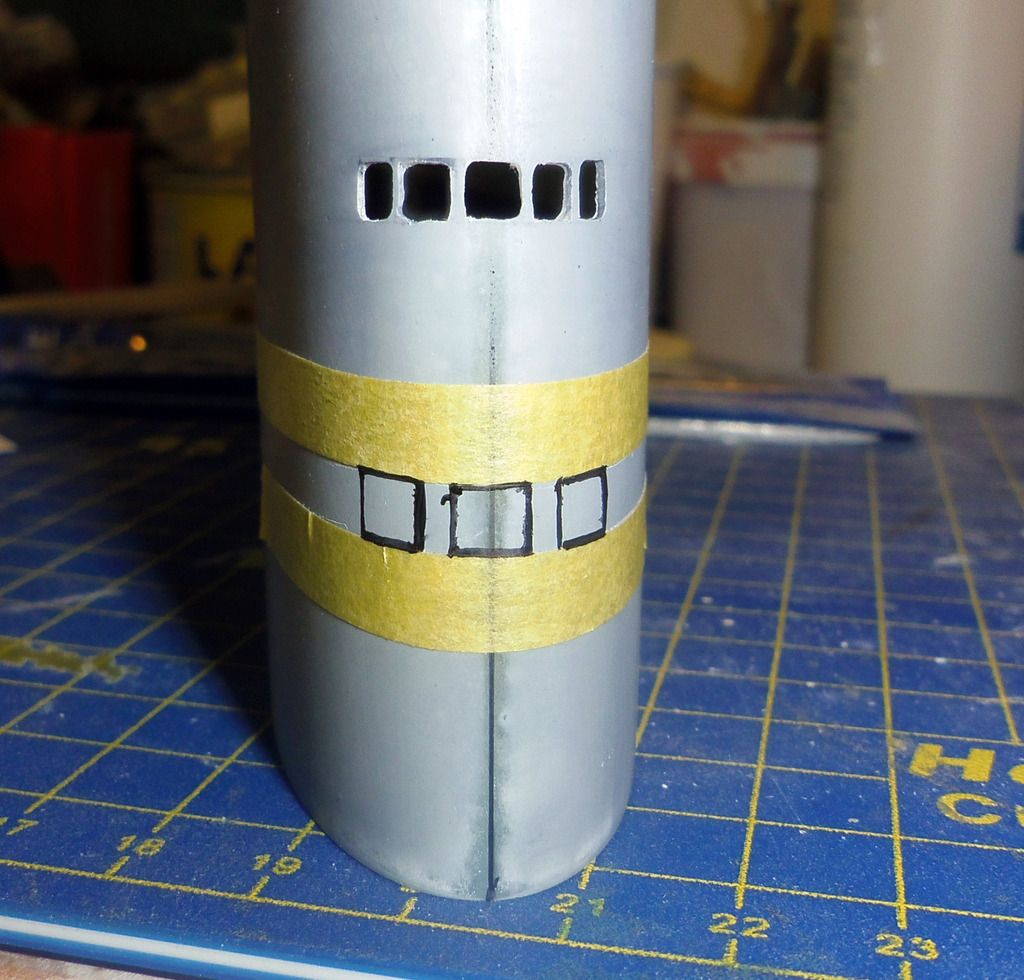

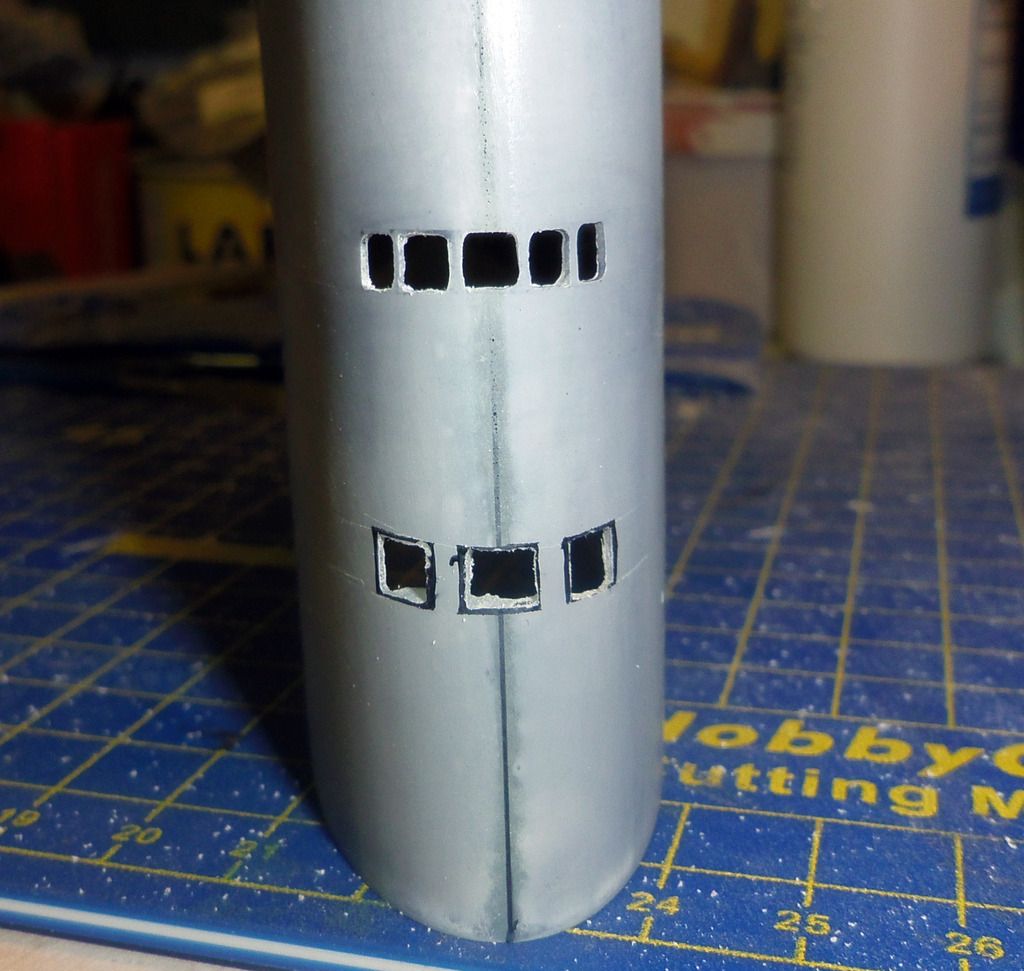

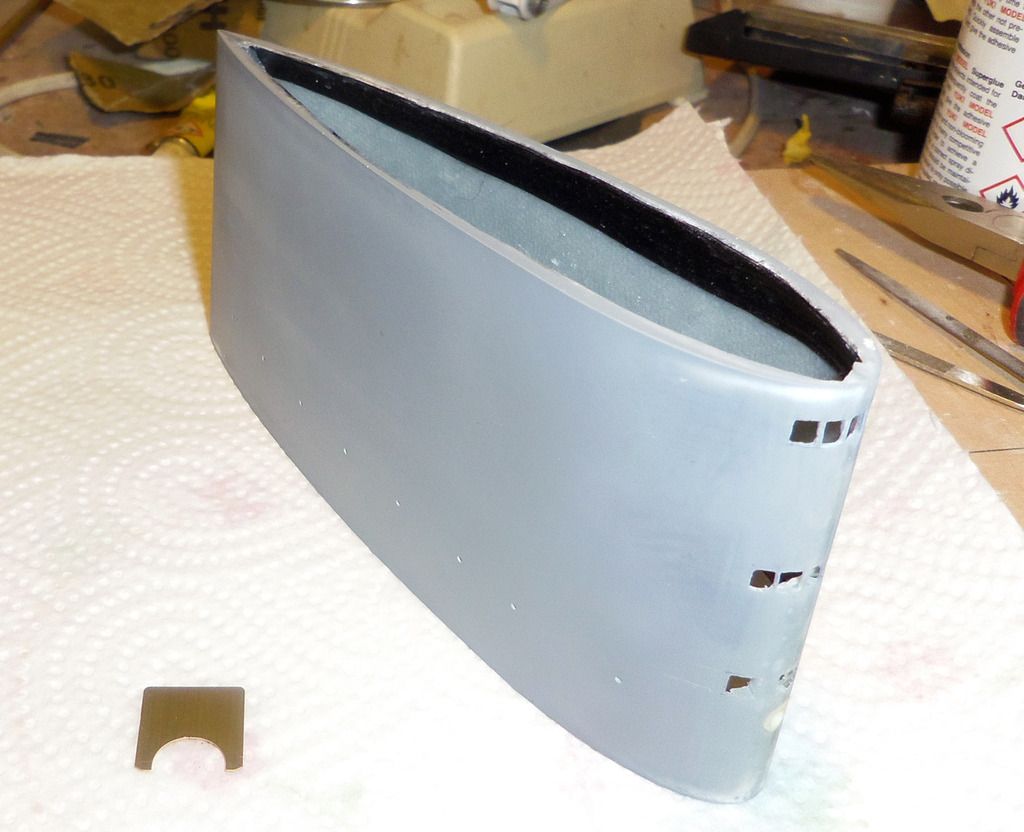

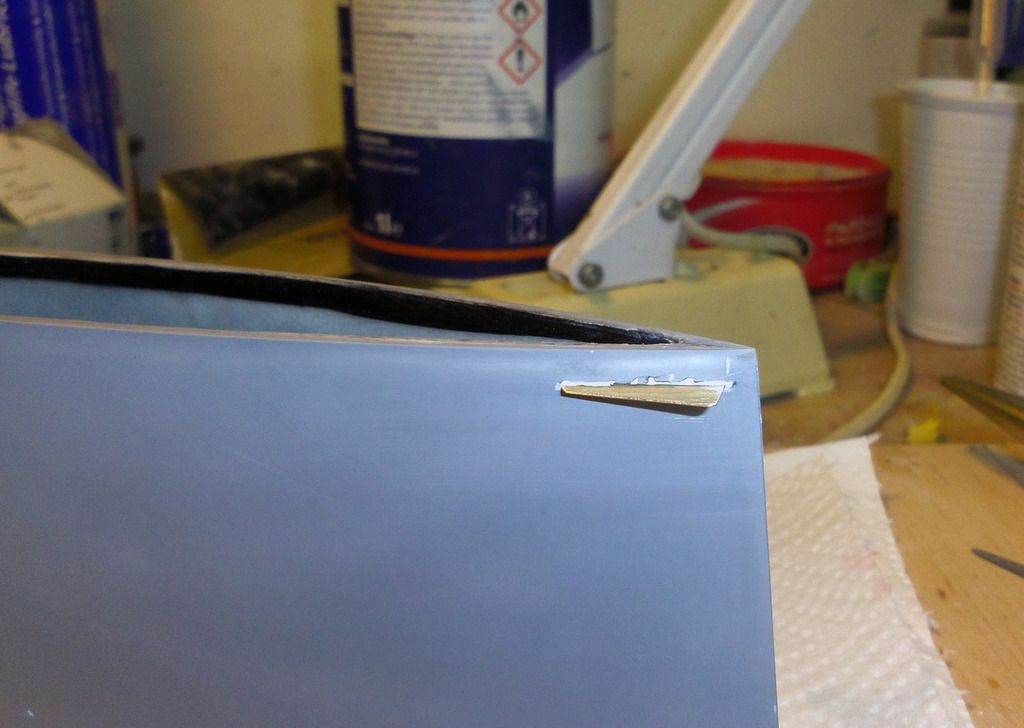

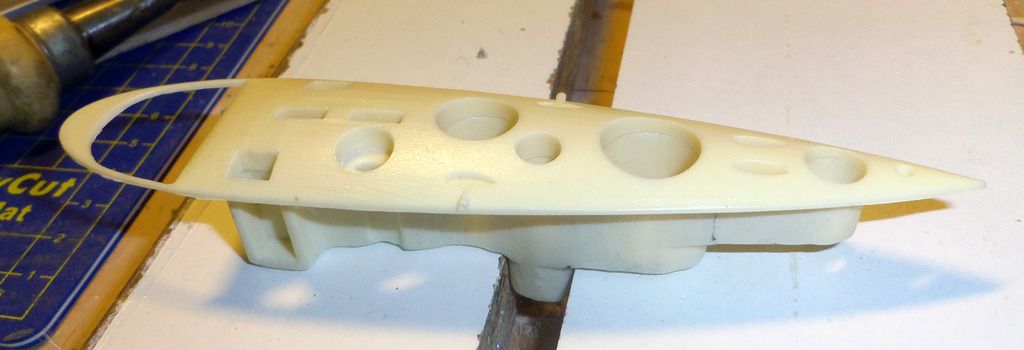

The positions for the sockets are marked on the hatch, drilled and filed:

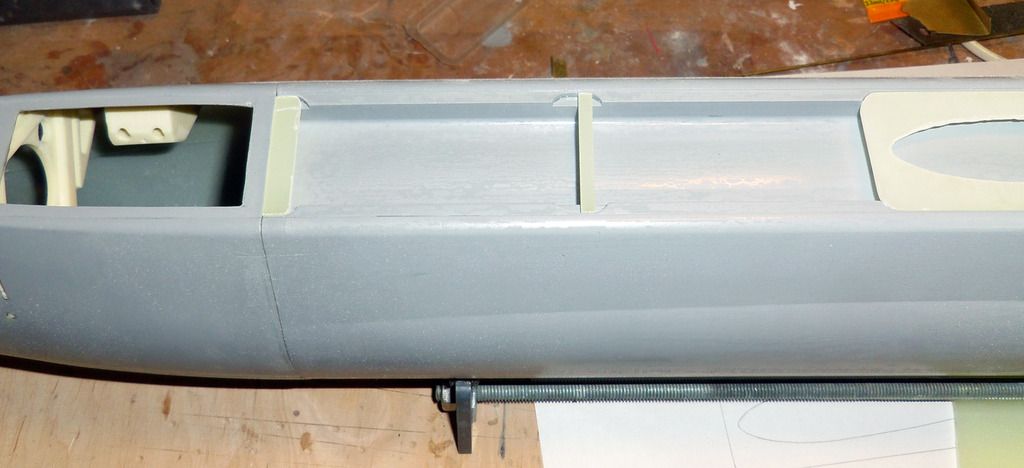

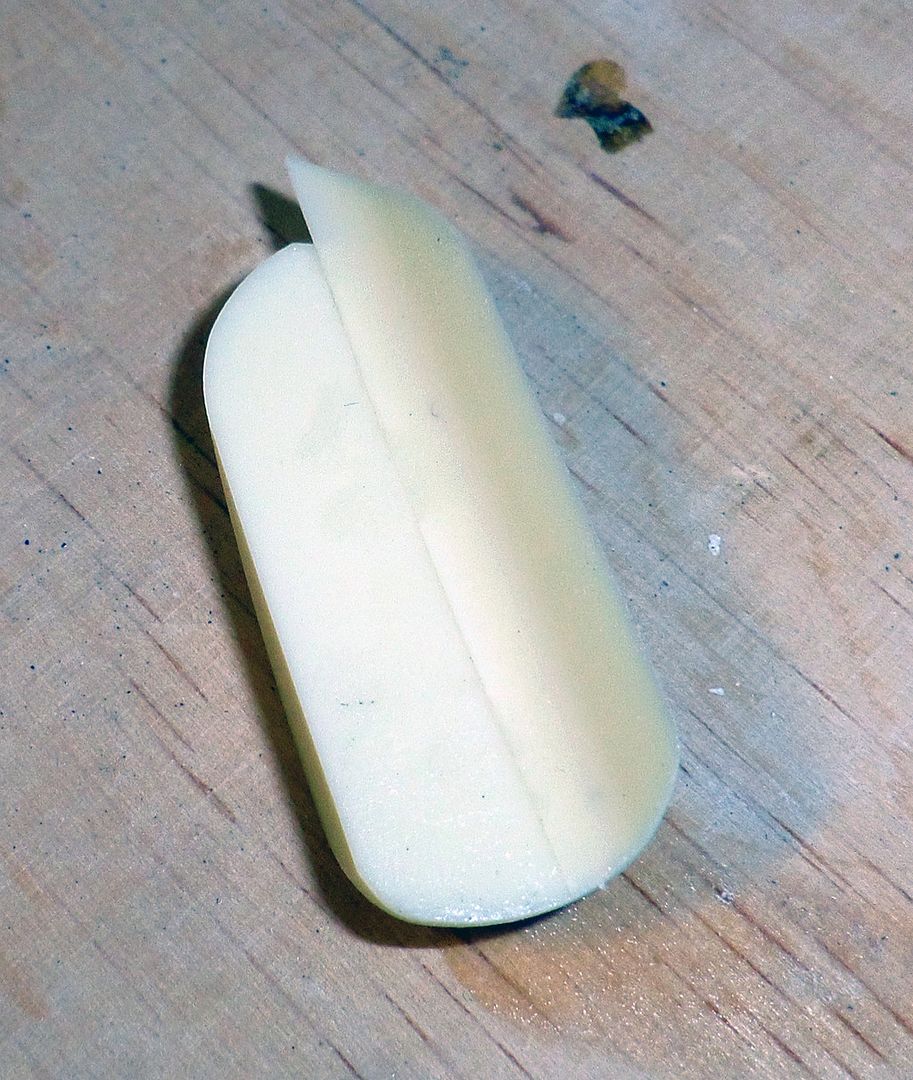

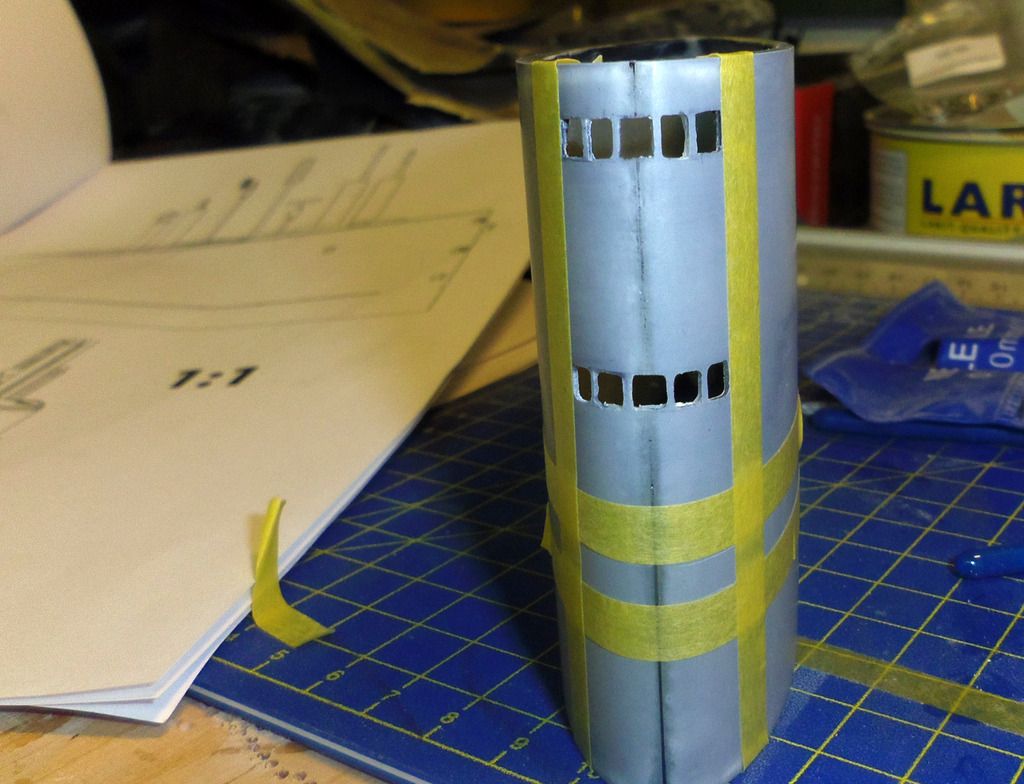

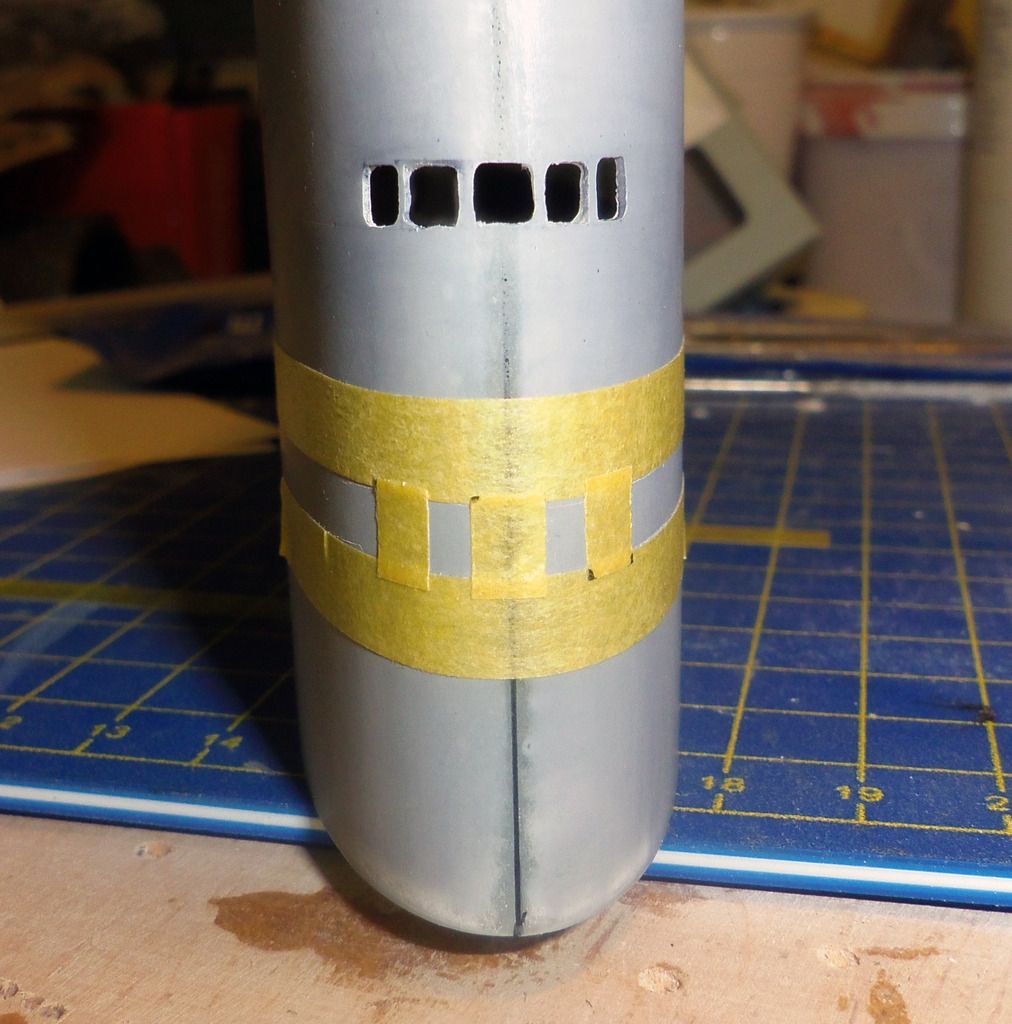

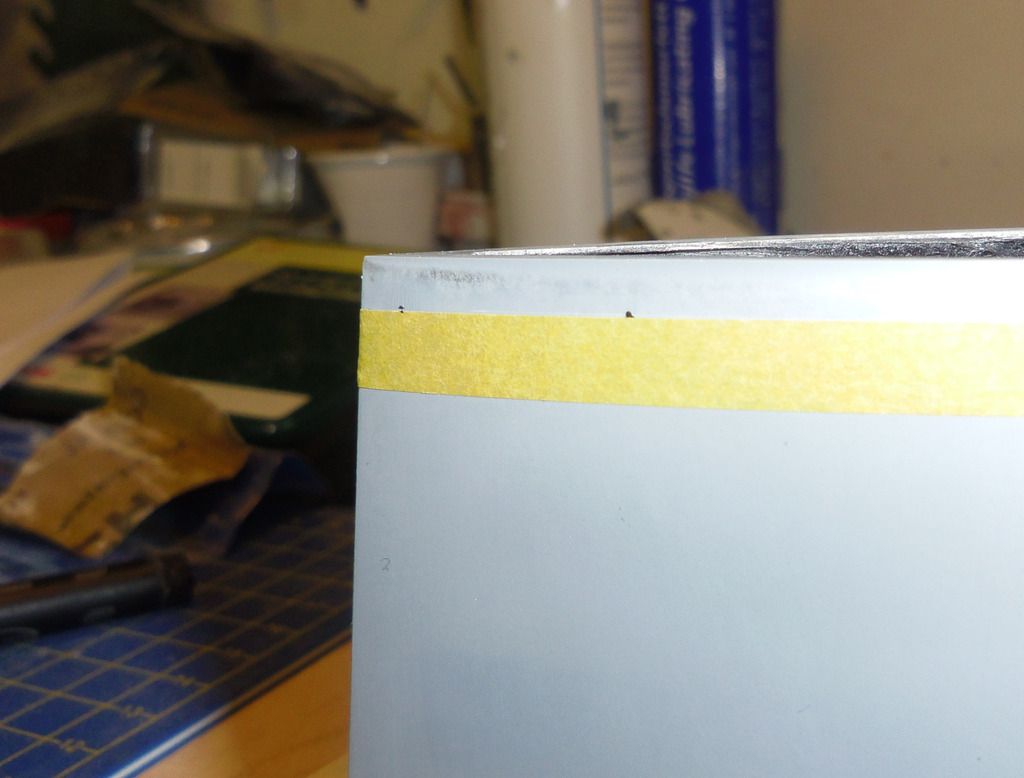

The pins are treated with a release agent (Polyvinyl alcohol), the sockets put on, the hatch installed and fixed with adhesive tape:

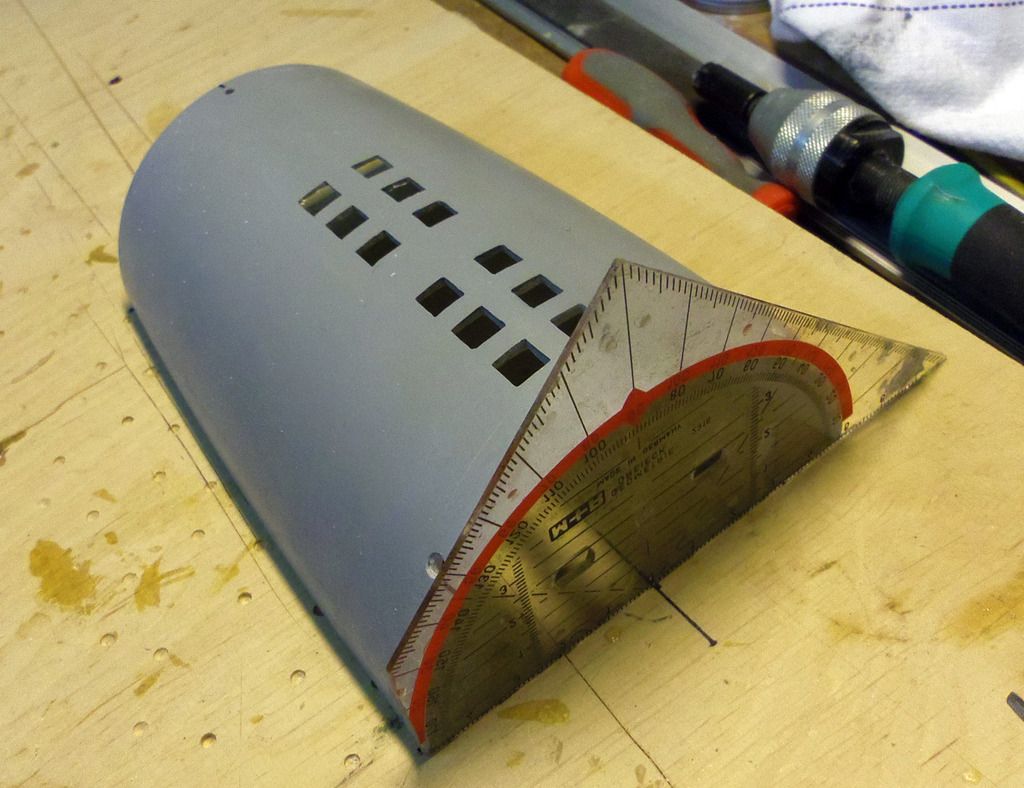

Then the sockets are glued into place using epoxy:

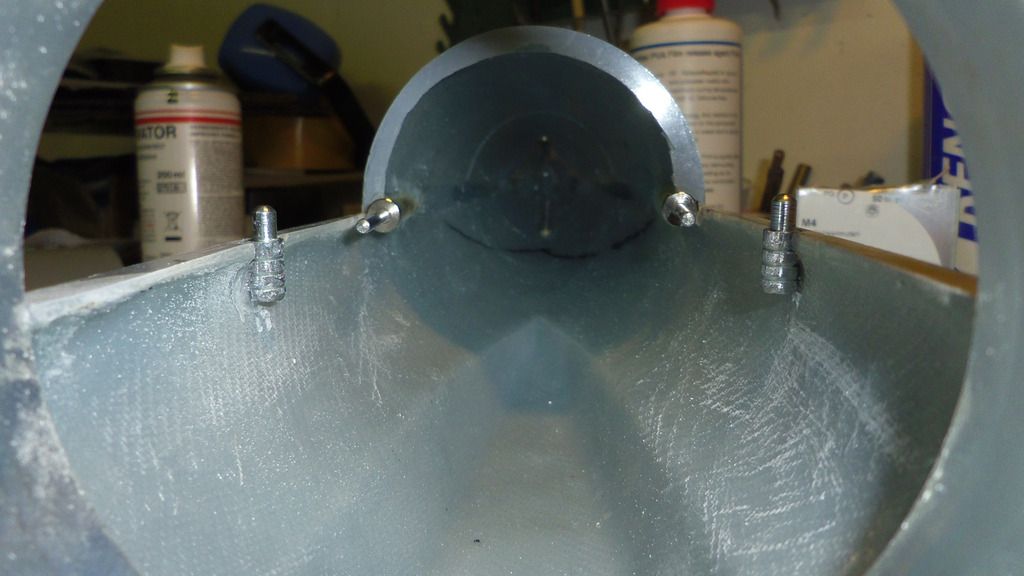

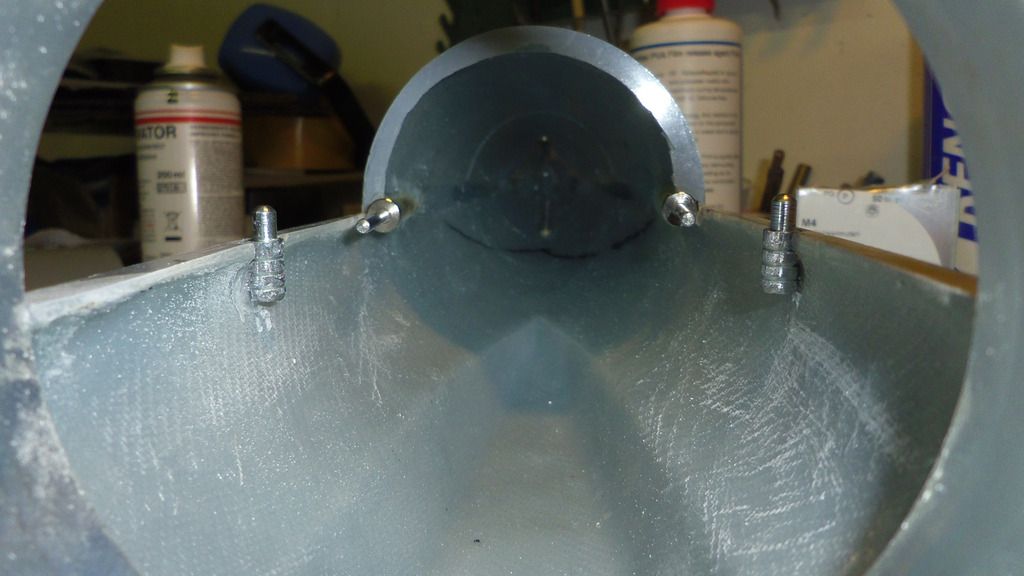

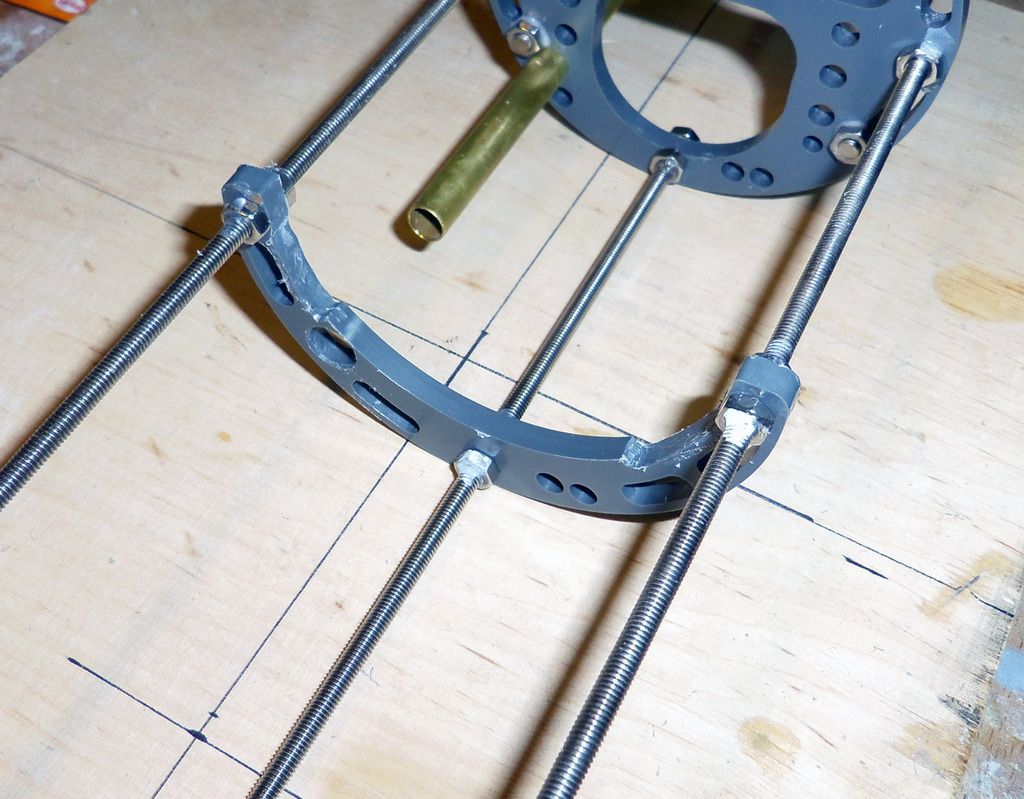

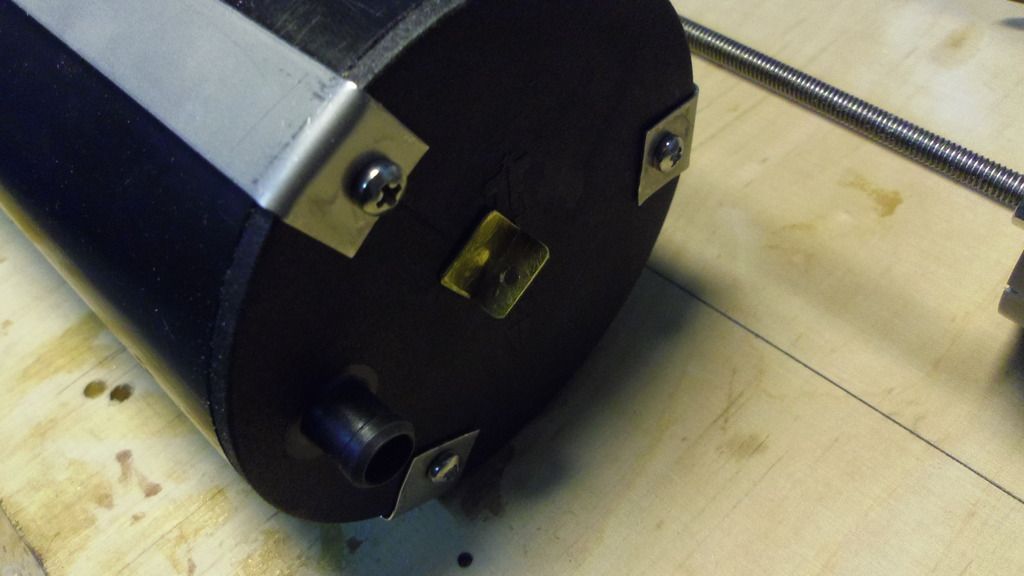

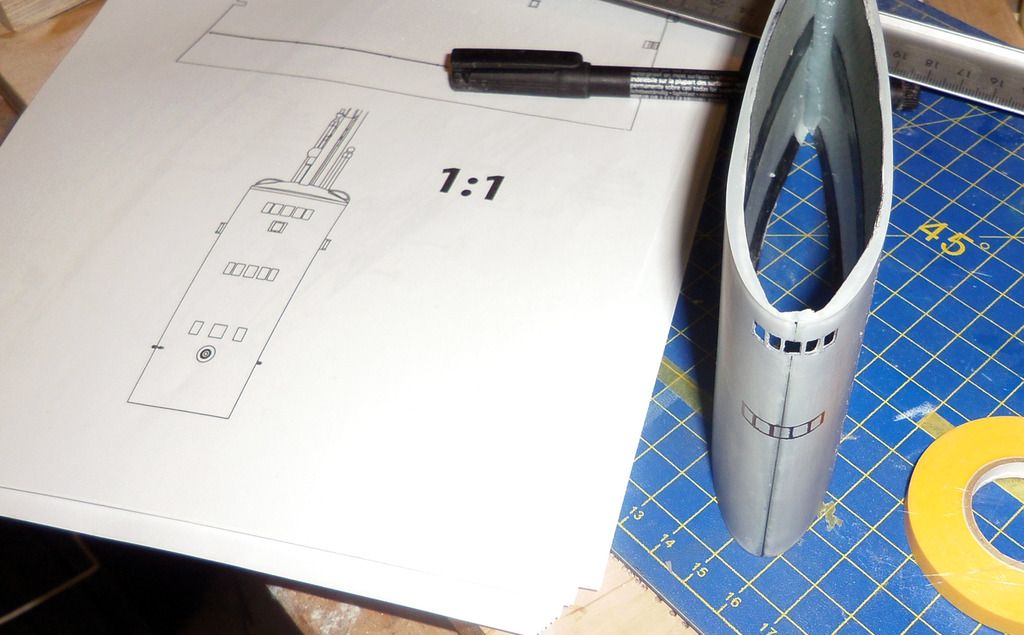

Then the plug-in mounts of the service hatch are installed. I use aluminum pins and sockets originally intended to be used for moulds, but brass pins and sockets are equally suited:

The position of the pins is marked on the edge of the stern section, drilled and filed. The pins are the preliminarily fixed using superglue:

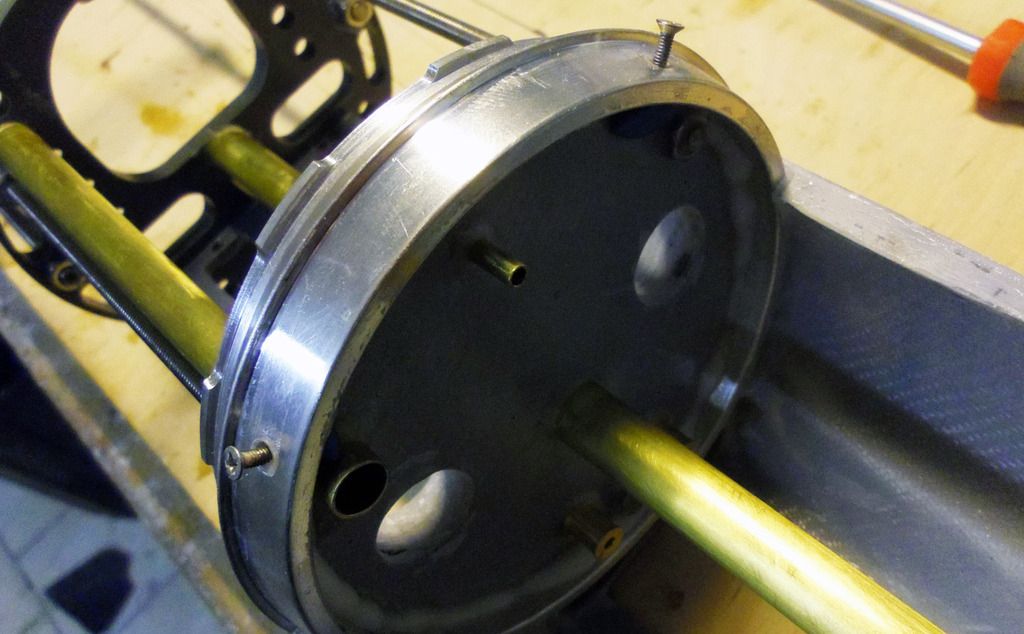

Then the pins are finally glued into place using again epoxy:

The positions for the sockets are marked on the hatch, drilled and filed:

The pins are treated with a release agent (Polyvinyl alcohol), the sockets put on, the hatch installed and fixed with adhesive tape:

Then the sockets are glued into place using epoxy:

Comment