I have a Bamboo P1S and it's great.

Khim

Nov 30 DT Gathering: PLA+ question

Collapse

X

-

Like a lot of things, you get what you pay for. The X1C is an excellent printer and outperforms the very expensive FDM printers I used and maintained at work during my last few years before retiring from CT to AZ.

We had four Raise3D Pro2's, two of which had a nearly 3' high build volume. The standard Pro2 printed half as high and cost $3k each. Full-size Pro2s were $6k. I re-wrote many of their Chinglish procedures and forwarded them to the company's US rep in LA. He offered to give me a great deal, but I passed. They've repeated many of their previous mistakes with their new Pro3. Their forums are packed with disillusioned buyers for good reason. Raise3D overpromises and under-delivers consistently. While I was able to keep them running -after performing a variety of after-market mods, nobody should have to modify a 3 or 5 thousand-dollar printer to get reliable performance. Ever.

Bambu seized the market several years ago with multiple innovative features Raise3D couldn't, (or wouldn't) even try to match at <1/4 the price.

Purchasing the X1C from Bambu with an enclosed build volume allows you to print the higher temp filaments with a better surface finish than what you are used to. Some of the high-temp filaments can give off nasty fumes, but I don't know how well their filter works. A few hours perusing their forums should indicate if they work well enough or need supplemental ventilation. Some people are more sensitive than others to fumes.

I switched to resin printing several years ago and never looked back. I mostly print 1/72 hulls for display. The <50 micron detail gives a much smoother surface, requiring far less time to prepare for assembly and painting. I use low odor resin and print in a temperature-controlled garage, which allows year-round printing in AZ. Speed is improved, but FDM printers are faster. Detail is the most important thing for my requirements.

Due to demand, I'm getting ready to purchase a larger printer and can connect it to an outside exhaust if needed. It allows printing of (2) one-piece hull sections 13" tall simultaneously, which meets my needs for more efficient production with less labor involved. Phrozen Sonic Mega 8K S 15" LCD 3D Printer â Phrozen US

A large Block V, USS Arizona (SSN-803) is just one of the hulls I have in design right now. I was able to have dinner with the CO and ten of the crew when they were in AZ for a goodwill tour last month. The CO promised me some reference photos after looking at some shots of my progress to accurately build the new four-tube VPM, (Vertical Payload Module) module, since there are no photos out yet due to it being the first to incorporate it. The only references are NAVSEA / EB renders, and they don't offer enough detail. The MBT flood ports are modified as well. The boat should be wet in two years.

In summary, follow your wife's rudder orders! She obviously has your best interests at heart and you've more proved your dedication to 3D printing. You'll be amazed what the X1C can do - especially with LIDAR, spaghetti detection, and video/status streamed to your phone! The AMS seems like a waste of money, but if you need colored filament, it's a good thing.

Good luck!

CCLeave a comment:

-

My new Bambu X1C just showed up this afternoon. I’m running my first ABS-GF print now… I’ll let you know how it goes.Leave a comment:

-

CC Clark,

I am now considering the new Bamboo Lab printer.

Bamboo Lab XIC! Based on what I am reading here, this may be the printer that you have? If so may I aske you what slicer you are using with your printer

My wonderful wife told me to purchase the best, but I keep trying to save money and it seems like I always pay the price in the end...

Any information you might share would be greatly appreciated.

Anyone who has a Bamboo Lab XIC 3D Printer can sure chime in! Thank you...

Rob

"Firemen can stand the heat."Last edited by rwtdiver; 12-08-2024, 06:48 PM.Leave a comment:

-

You're more than welcome Rob. I hope it helps anyone who likes to keep important 3D printing info in an easy-to-find place.Leave a comment:

-

Hi CC,For those using FDM printers, this is a handy Materials Guide bookmark:

Ultimate 3D Printing Material Properties Table

That chart that you put up is very helpful! I have been using Simplify3D for years and have never seen the chart. Again, thank you for taking the time for posting it up.

Rob

"Firemen can stand the heat."Leave a comment:

-

Thank you everyone. All of this has been very useful snd most appreciated.Leave a comment:

-

For those using FDM printers, this is a handy Materials Guide bookmark:

Ultimate 3D Printing Material Properties TableLeave a comment:

-

As mentioned, unless you design your own hulls, you are limited to whatever the thickness the original designer used. If it's a small model with a 1mm hull, you can upscale it to increase the thickness only.

3mm wall thickness is sufficient for a 5-6' model if the material is strong enough. ABS is pretty tough. Test-print a hull section and determine if it is thick enough for your needs.

CCLeave a comment:

-

You are kind of dependent on the designed thickness of the model. 3mm is pretty thin and 6mm is too thick. Also print with 100 percent infill and I use at least 2 loops of wall. Helps if there is reinforcement where the parts join and a lip on top and bottom sections.Leave a comment:

-

Type7 - for subs in the 4’ - 6’ length range, could you tell me what thickness you are using or recommend for ABS hulls please? Thank you.

Leave a comment:

-

Bamboo Labs's printers out-perform the $6000 Raise3D FDM printers I started with (at work) at a fraction of the price in everything but build volume. IF I were to do any more FDM printing, Bamboo Labs models would be my first choice. They are excellent for ASA and other harder-to-print materials.Thank you CC Clarke - Iâm thinking I will eventually wind up with ABS but I would still like to see what the PLA+ does. Fortunately my friendâs printer is a Bamboo printer and has filters etc. so he can do the ABS. Lots of time because this is a long-term project. Currently working on a different sub.

Last edited by CC Clarke; 12-03-2024, 11:01 AM.Leave a comment:

-

Thanks again everyone.

Rob, I did join the dive tribe a while back but every time a dive tribe gathering is scheduled there seems to be something else that I scheduled beforehand! Hopefully I’ll be able to join in and listen during the coming months! Thank you for the info on that sub!

Type7 - unless recently introduced PLA+ proves to have substantial heat resistance and is less susceptible to moisture I suspect I will wind up using ABS as well. I think the PLA+ is worth testing though since they seem to be recognizing that the heat issue is a problem for many people.Leave a comment:

-

I have switched from PETG to ABS. ABS prints very well with an enclosed printer, does not need to be heated. The printer does need to be in a ventilated room, the fumes are not good.Leave a comment:

-

Thanks Timothy, sounds like you have a good plan!Thank you all.

Rob, having lived in Arizona for over 50 years I have a clear understanding of the heat problems there :-) Living in Western, MA now, my heat concerns are not quite as severe LOL. Nonetheless, even here we have warmer days.

As I read and hear modeler‘s experiences with different 3-D media, I see a lot of varying opinions. as a result I think, for me, the best approach will be to print sample hull sections in PLA+, PETG, and ABS and subject them to heat exposure while checking for warping, brittleness etc. I do not do 3-D printing myself but my friend is very heavily involved with it and keen to experiment as well. I’ll report back results here.

By the way, I very much enjoyed your comments on the gathering video and sure would like to know what the submarine was behind you on the screen - beautiful!

Tim

The submarine you are referring to is the British HMS Stickleback. If you are interested in 3D printing out this submarine the STL files can be found using the listing below. Timothy, you might want to consider joining the Nautilus Dive Tribe? Great bunch of guys, and they may be a great resource for you as you move through the hobby... :-))

You can also check out Nautilus Drydocks 3D print files similar X Class boat. I have several of Bob's STL files, and that are really great...

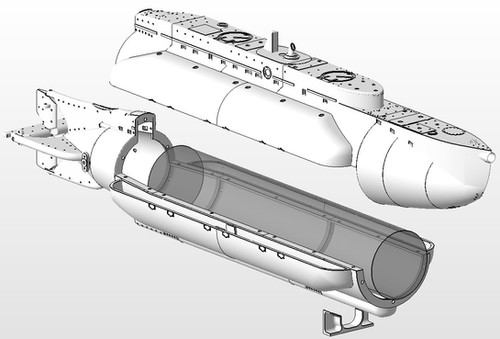

Yet another superb 3D file set thanks to the creative talents of Randy Sanders. The X class was a World War II midget submarine class built for the Royal Navy during 1943–44. Known individually as X-Craft, the vessels were designed to be towed to their intended area of operations by a full-size "mother" submarine – usually one of the T class or S class – with a passage crew on board, the operational crew being transferred from the towing submarine to the X-Craft by dinghy when the operational area was reached, and the passage crew returning with the dinghy to the towing submarine. Once the attack was over, the X-Craft would rendezvous with the towing submarine and then be towed home. The craft was about 51 ft (16 m) long, 5.5 ft (1.7 m) maximum diameter and displaced 27 long tons (27 t) surfaced and 30 long tons (30 t) submerged. Propulsion was by a 4-cylinder Gardner 4LK 42 hp diesel engine, converted from a type used in London buses and a 30 hp electric motor, giving a maximum surface speed of 6.5 knots (12.0 km/h; 7.5 mph) and a submerged speed of about one third of that. The weapons on the "X-Craft" were two side-cargoes – explosive charges held on opposite sides of the hull with two tons of amatol in each. The intention was to drop these on the sea bed underneath the target and then escape. The charges were detonated by a time fuse. The craft were fitted with electromagnets to evade detection by anti-submarine detectors on the sea bed and also with sonar and a periscope. This set of files will allow you to print out your own hull for a beautiful representation of this craft in 1/24 scale, netting an overall length of approximately 650mm (25.6") and with a beam of 84mm (3.3"). This size makes it perfect for the Nautilus Drydocks 250 Series EasyDriver for RC operation. Max part height is 160mm.

Yet another superb 3D file set thanks to the creative talents of Randy Sanders. The X class was a World War II midget submarine class built for the Royal Navy during 1943–44. Known individually as X-Craft, the vessels were designed to be towed to their intended area of operations by a full-size "mother" submarine – usually one of the T class or S class – with a passage crew on board, the operational crew being transferred from the towing submarine to the X-Craft by dinghy when the operational area was reached, and the passage crew returning with the dinghy to the towing submarine. Once the attack was over, the X-Craft would rendezvous with the towing submarine and then be towed home. The craft was about 51 ft (16 m) long, 5.5 ft (1.7 m) maximum diameter and displaced 27 long tons (27 t) surfaced and 30 long tons (30 t) submerged. Propulsion was by a 4-cylinder Gardner 4LK 42 hp diesel engine, converted from a type used in London buses and a 30 hp electric motor, giving a maximum surface speed of 6.5 knots (12.0 km/h; 7.5 mph) and a submerged speed of about one third of that. The weapons on the "X-Craft" were two side-cargoes – explosive charges held on opposite sides of the hull with two tons of amatol in each. The intention was to drop these on the sea bed underneath the target and then escape. The charges were detonated by a time fuse. The craft were fitted with electromagnets to evade detection by anti-submarine detectors on the sea bed and also with sonar and a periscope. This set of files will allow you to print out your own hull for a beautiful representation of this craft in 1/24 scale, netting an overall length of approximately 650mm (25.6") and with a beam of 84mm (3.3"). This size makes it perfect for the Nautilus Drydocks 250 Series EasyDriver for RC operation. Max part height is 160mm.

Rob

"Firemen can stand the heat."

Last edited by rwtdiver; 12-02-2024, 06:05 PM.Leave a comment:

Leave a comment: