I don't have room. Something that size is a dream.

I have the vellum. Have a 36 inch t-square but no edge to run the t-square against.

I just want to hear you yell. You can slap me on the head at Groton!

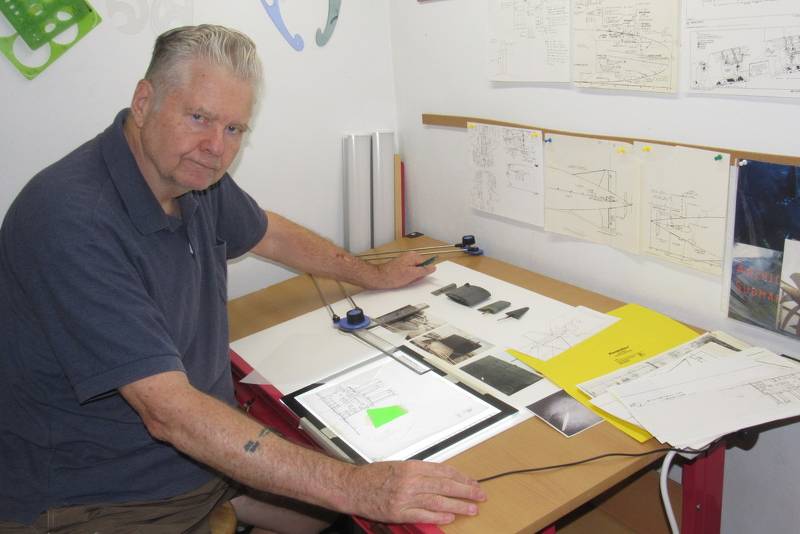

Smile David!

Lathes

Collapse

X

-

You pain in the ass! You said you didn't have any room!

Stitch three sheets together and you have your party-boat. (Why do I bother with you dopes!?).

DavidLeave a comment:

-

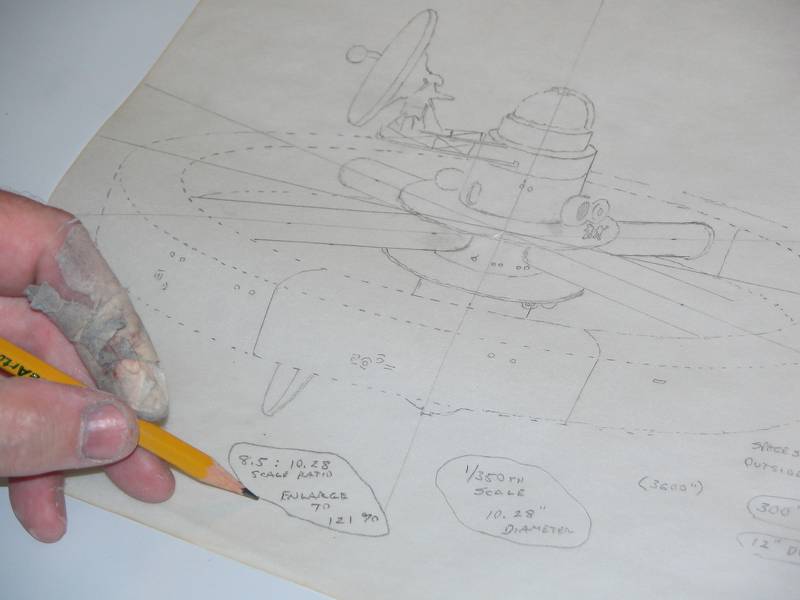

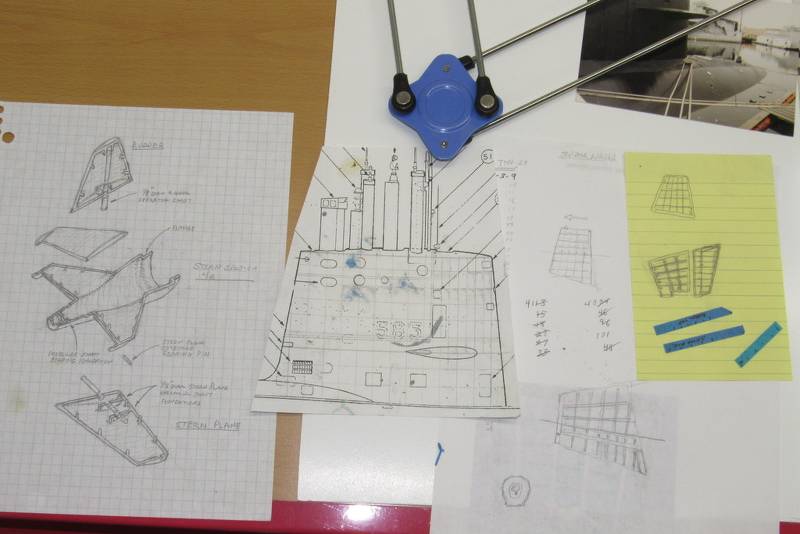

Bigger. I'm designing 36-48 inch party boats.

https://www.amazon.com/Yaheetech-Adjustable-Drafting-Drawing-Tabletop/dp/B07X1PKV6Y/ref=sr_1_5?crid=C11TPRILRM05&keywords=drafting%2Bt ables&qid=1701728055&sprefix=drafting%2Btables%2Ca ps%2C71&sr=8-5&ufe=app_do%3Aamzn1.fos.17d9e15d-4e43-4581-b373-0e5c1a776d5d&th=1

And probably one of those sliding straight edges with the pulleys on the corner.

You draw things less than 14 inches?

I just screwed on this subject.Last edited by Ken_NJ; 12-04-2023, 05:20 PM.Leave a comment:

-

Make room!Only problem I have. I'm not using a traditional drafting table. I'm using a teak dining room table. I need a drafting machine with longer arms than what I can see on Amazon. Will keep searching.

Or get a table top used for the purpose. But I have no room for another table.

How about this, pal?

Amazon.com: Frylr Inch A3 Drawing Board Drafting Table Multifunctional Drawing Board Table with Clear Rule Parallel Motion and Angle Adjustable Measuring System : Home & KitchenLeave a comment:

-

Only problem I have. I'm not using a traditional drafting table. I'm using a teak dining room table. I need a drafting machine with longer arms than what I can see on Amazon. Will keep searching.

Or get a table top used for the purpose. But I have no room for another table.Leave a comment:

-

Look under, 'drafting machine'.

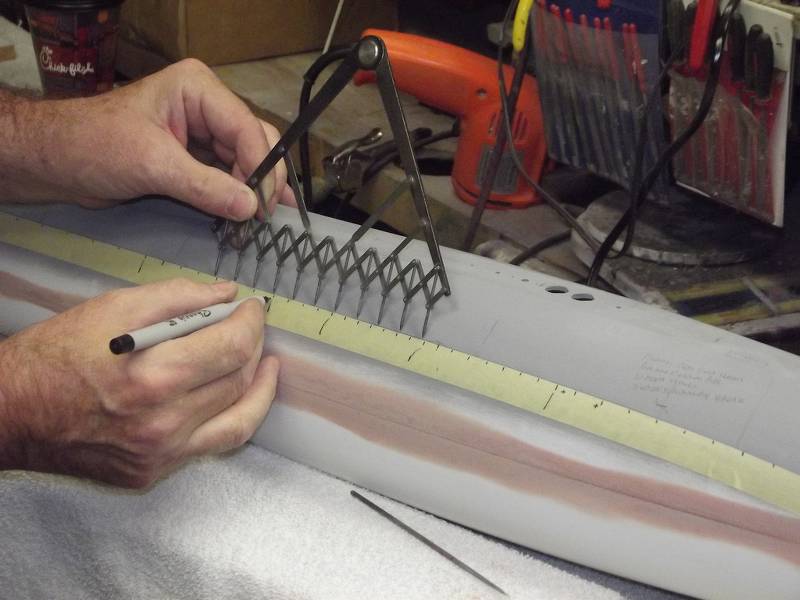

I don't have one of these! I've seen you use this elsewhere. It's a must have. Added this to my Christmas list.

If anyone else wants one of these, this is the one I added to my list.

https://www.amazon.com/Leather-Equally-Isometric-Leathercraft-Auxiliary/dp/B0BNMV854K/ref=sr_1_5?crid=WN1DPXR86HOP&keywords=spacing%2Bdi vider&qid=1701718366&sprefix=spacing%2Bdivider%2Ca ps%2C73&sr=8-5&th=1

Also have to get one of those articulating drafting arms.Leave a comment:

-

I don't have one of these! I've seen you use this elsewhere. It's a must have. Added this to my Christmas list.

If anyone else wants one of these, this is the one I added to my list.

https://www.amazon.com/Leather-Equally-Isometric-Leathercraft-Auxiliary/dp/B0BNMV854K/ref=sr_1_5?crid=WN1DPXR86HOP&keywords=spacing%2Bdi vider&qid=1701718366&sprefix=spacing%2Bdivider%2Ca ps%2C73&sr=8-5&th=1

Also have to get one of those articulating drafting arms.Last edited by Ken_NJ; 12-04-2023, 02:52 PM.Leave a comment:

-

Any idiot can push a mouse around and pick things off a menu and go, 'click'. Yikes!I like the idea of your method better! Casting. And using the tools I have. My preferred method being old school. Doing it with my hands. I'm with you!

Not so much leaving it to a computer, sending it to a printer, walking away and it's done. Yes there might be some talent that way but less satisfaction. Better building it with your own two hands.

I'll use my hand AND my brain, thank you very much!

Leave a comment:

-

I like the idea of your method better! Casting. And using the tools I have. My preferred method being old school. Doing it with my hands. I'm with you!

Not so much leaving it to a computer, sending it to a printer, walking away and it's done. Yes there might be some talent that way but less satisfaction. Better building it with your own two hands.

Leave a comment:

-

Leave a comment:

-

Added the face plate to my tool list.

Now I need to get into casting. Someday. You emailed me what to use from Alumilite.

Or 3D printing.Leave a comment:

-

Ken,

Excellent collection of measuring tools and quck-change tool holders.

One last thing to add to that managery, that will increase your productivity -- and vital if you're to make rotating holding fixtures for your bulkhead work:

A face-plate. This simple fixture attached to the head-stock of your lathe will rock your world.

David

Master of Broken ****

Leave a comment:

-

I went with this one 10 years ago. Never used it until recently after going on an accessory splurge. Can't do much without the proper tooling.

Inherited some of these from another model builder.

Made a tool tray.

And another center/chuck & tool holder.

A Quick Change Tool Post (QCTP) is a must.

After hand filing an endcap, got this 4 jaw independent chuck as recommended by David. Didn't use it on the endcap. But I now have it.

This gauge holder comes in handy for more than holding gauges.

Bit holders for the QCTP. The more you have, less pain in the a$$ to change the bits.

Good for marking up the work.

Last edited by Ken_NJ; 12-04-2023, 12:00 PM.Leave a comment:

-

Copied Dave's idea and it worked very well for me.

Will Rogers

SSBN659Leave a comment:

-

Nothing intrinsically unsafe about an older machine, they work the same as the newer ones. Just don a pair of safety specs to catch any chippings that fly off whilst turning.

Leave a comment:

Leave a comment: