David,

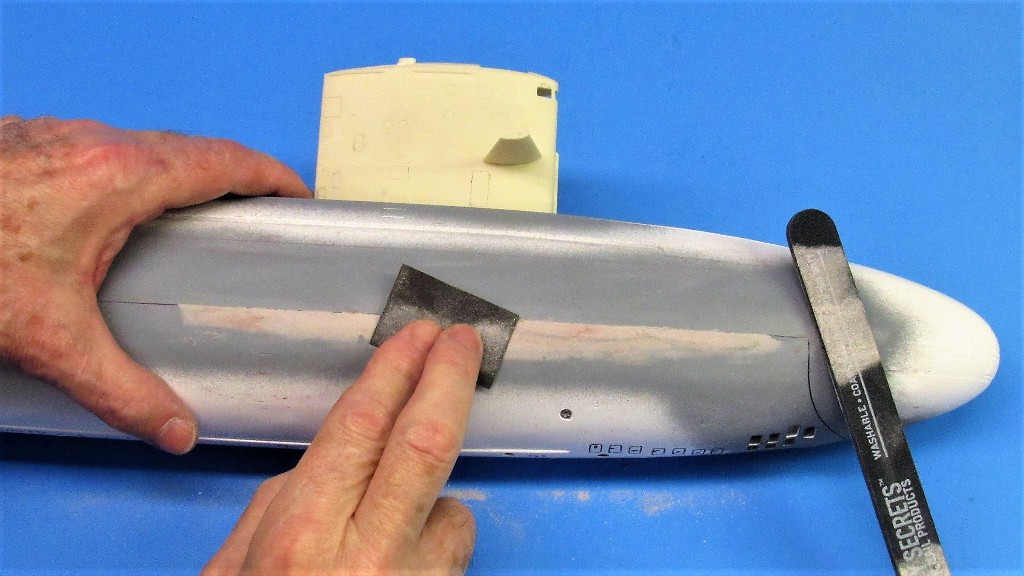

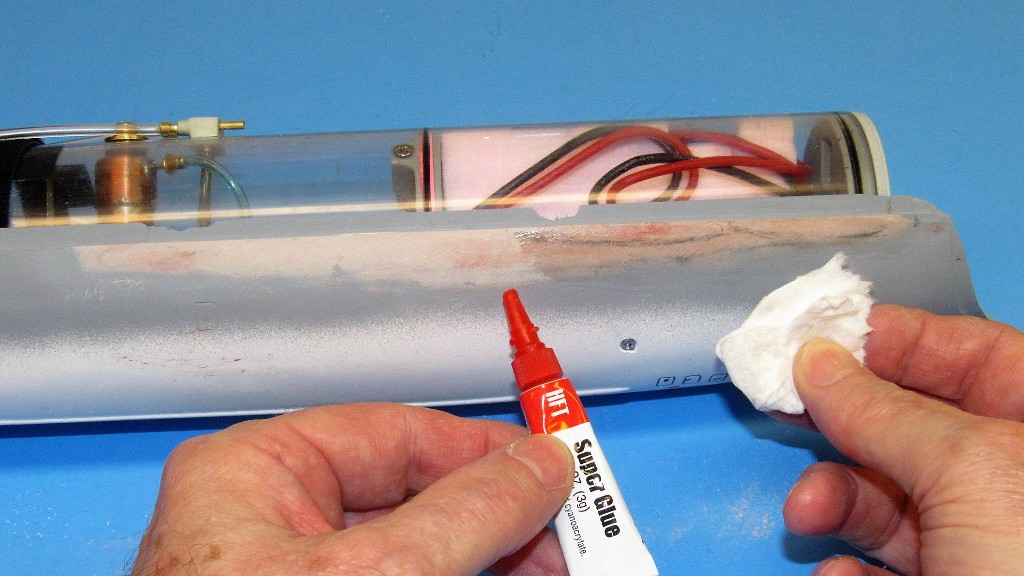

I have seen your advice regarding application of thin CA over filler, with a quick wipe down following. Is that to strengthen the Nitro-Stan, or just a sealer? Does that also apply to other fillers? I pretty much exclusively use Evercoat F27. This is a very fine grain, extremely hard filler that sands well and is pretty smooth when finished off. Bondo looks like a rock beach in comparison!

Thanks,

Bill

I have seen your advice regarding application of thin CA over filler, with a quick wipe down following. Is that to strengthen the Nitro-Stan, or just a sealer? Does that also apply to other fillers? I pretty much exclusively use Evercoat F27. This is a very fine grain, extremely hard filler that sands well and is pretty smooth when finished off. Bondo looks like a rock beach in comparison!

Thanks,

Bill

Comment