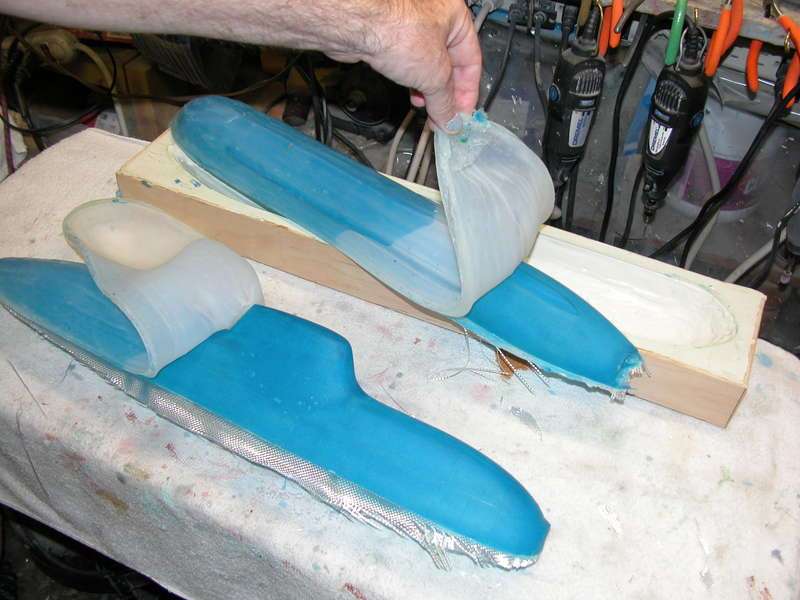

Part rubber part hardcase GRP tooling

Collapse

X

-

Familiar with that method, however it doesn't seem to be suitable for joining the parts together in the tool, which is a method I favour.Leave a comment:

-

If I had to do it ...and I don't know if it would work-yet...I'd build the tool (and I assume mold) from rubber to as stated to allow for undercut and/or detail. Then I'd produce a splittable hardcase support mold of and for that rubber liner...I'd build in alignment tabs and rails to both hold and position the inner liner and outer shell-two separate entities more like a hybrid mold..I think also with the rubber-no need for parting agent or air pressure or wild gymnastics to separate the finished product from the mold.Last edited by Bob Gato; 03-17-2019, 12:49 PM.Leave a comment:

-

Part rubber part hardcase GRP tooling

I remember reading about tools where part of the tooling was rubber, to resolve fine detail and/or relieve an undercut, and the rest a hardcase. I was looking at using this method for a couple of hulls I want to mould, part of reasoning is to reduce the amount of tool parts I'd need to effect a release, and the other is that I would like a tool where I can join the halves together in the tool if possible.

It seems most builders use a complete rubber tool or complete hardcase tool, which made me wonder if there as a few issues with the combined method?Tags: None

Leave a comment: